Abstract

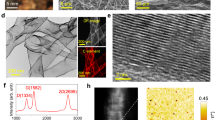

Lightweight materials that are both highly compressible and resilient under large cyclic strains can be used in a variety of applications1,2,3,4,5,6,7,8. Carbon nanotubes offer a combination of elasticity, mechanical resilience and low density9, and these properties have been exploited in nanotube-based foams10,11,12,13,14 and aerogels15,16. However, all nanotube-based foams and aerogels developed so far undergo structural collapse15 or significant plastic deformation with a reduction in compressive strength10,11,13,14 when they are subjected to cyclic strain. Here, we show that an inelastic aerogel made of single-walled carbon nanotubes can be transformed into a superelastic material by coating it with between one and five layers of graphene nanoplates. The graphene-coated aerogel exhibits no change in mechanical properties after more than 1 × 106 compressive cycles, and its original shape can be recovered quickly after compression release. Moreover, the coating does not affect the structural integrity of the nanotubes or the compressibility and porosity of the nanotube network. The coating also increases Young's modulus and energy storage modulus by a factor of ∼6, and the loss modulus by a factor of ∼3. We attribute the superelasticity and complete fatigue resistance to the graphene coating strengthening the existing crosslinking points or ‘nodes’ in the aerogel.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Nesterenko, V. F. Dynamics of Heterogeneous Materials (Springer, 2001).

Hilyard, N. C. & Cunningham, A. Low Density Cellular Plastics: Physical Basis of Behavior (Chapman and Hall, 1994).

Gibson, L. J. & Ashby, M. F. Cellular Solids: Structure and Properties (Pergamon, 1997).

Kong, X. & Qiao, Y. Improvement of recoverability of a nanoporous energy absorption system by using chemical admixture. Appl. Phys. Lett. 86, 151919 (2005).

Gibson, L. J. Mechanical behavior of metallic foams. Annu. Rev. Mater. Sci. 30, 191–227 (2000).

Fernández, J. A. et al. Performance of mesoporous carbons derived from poly(vinyl alcohol) in electrochemical capacitors. J. Power Sources 175, 675–679 (2008).

Zhu, Y. et al. Carbon-based supercapacitors produced by activation of graphene. Science 332, 1537–1541 (2011).

He, X. & Antonelli, D. Recent advances in synthesis and applications of transition metal containing mesoporous molecular sieves. Angew. Chem. Int. Ed. 41, 214–229 (2002).

Dresselhaus, M. S., Dresselhaus, G. & Avouris, P. Carbon Nanotubes: Synthesis, Structure, Properties, and Applications (Springer, 2001).

Cao, A., Dickrell, P. L., Sawyer, W. G., Ghasemi-Nejhad, M. N. & Ajayan, P. M. Super-compressible foamlike carbon nanotube films. Science 310, 1307–1310 (2005).

Suhr, J. et al. Fatigue resistance of aligned carbon nanotube arrays under cyclic compression. Nature Nanotech. 2, 417–421 (2007).

Aliev, A. E. et al. Giant-stroke, superelastic carbon nanotube aerogel muscles. Science 323, 1575–1578 (2009).

Gui, X. et al. Carbon nanotube sponges. Adv. Mater. 22, 617–621 (2010).

Xu, M., Futaba, D. N., Yamada, T., Yumura, M. & Hata, K. Carbon nanotubes with temperature-invariant viscoelasticity from –196 °C to 1000 °C. Science 330, 1364–1368 (2010).

Bryning, M. B. et al. Carbon nanotube aerogels. Adv. Mater. 19, 661–664 (2007).

Kim, K. H., Vural, M. & Islam, M. F. Single wall carbon nanotube aerogel-based elastic conductors. Adv. Mater. 23, 2865–2869 (2011).

Hough, L. A., Islam, M. F., Janmey, P. A. & Yodh, A. G. Viscoelasticty of single wall carbon nanotube suspensions. Phys. Rev. Lett. 93, 168102 (2004).

Hough, L. A., Islam, M. F., Hammouda, B., Yodh, A. G. & Heiney, P. A. Structure of semidilute single-wall carbon nanotube suspensions and gels. Nano Lett. 6, 313–317 (2006).

Islam, M. F., Rojas, E., Bergey, D. M., Johnson, A. T. & Yodh, A. G. High weight fraction surfactant solubilization of single-wall carbon nanotubes in water. Nano Lett. 3, 269–273 (2003).

Frank, O. et al. Raman 2D-band splitting in graphene: theory and experiment. ACS Nano 5, 2231–2239 (2011).

Dresselhaus, M. S., Jorio, A., Hofmann, M., Dresselhaus, G. & Saito, R. Perspectives on carbon nanotubes and graphene Raman spectroscopy. Nano Lett. 10, 751–758 (2010).

Fitzer, E., Frohs, W. & Heine, M. Optimization of stabilization and carbonization treatment of pan fibres and structural characterization of the resulting carbon fibres. Carbon 24, 387–395 (1986).

Faugeras, C. et al. Few-layer graphene on SiC, pyrolitic graphite, and graphene: a Raman scattering study. Appl. Phys. Lett. 92, 011914 (2008).

Robinson, J. A. et al. Correlating Raman spectral signatures with carrier mobility in epitaxial graphene: a guide to achieving high mobility on the wafer scale. Nano Lett. 9, 2873–2876 (2009).

Dato, A. & Frenklach, M. Substrate-free microwave synthesis of graphene: experimental conditions and hydrocarbon precursors. New J. Phys. 12, 125013 (2010).

Klug, H. & Alexander, L. E. X-Ray Diffraction Procedures (Wiley, 1974).

Dienwiebel, M. et al. Superlubricity of graphite. Phys. Rev. Lett. 92, 126101 (2004).

Acknowledgements

The authors thank T. Kowalewski and M. Zhong for providing polyacrylonitrile polymer, and W. Goldberg, K. N. Dahl, M. Widom, M. Deserno, A. Roy and V. Varshney for valuable discussions. This work was supported by the National Science Foundation (grant nos DMR-0645596, CBET-0933510 and DMR-0619424), the Sloan Foundation, the American Chemical Society Petroleum Research Fund and the Korea Institute of Energy Research.

Author information

Authors and Affiliations

Contributions

M.F.I. conceived the project. K.H.K., Y.O. and M.F.I. designed the experiments. K.H.K. and Y.O. synthesized the aerogels and performed the experiments. K.H.K., Y.O. and M.F.I. analysed the data. K.H.K., Y.O. and M.F.I. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 394 kb)

Supplementary movie

Supplementary movie (WMV 2736 kb)

Rights and permissions

About this article

Cite this article

Kim, K., Oh, Y. & Islam, M. Graphene coating makes carbon nanotube aerogels superelastic and resistant to fatigue. Nature Nanotech 7, 562–566 (2012). https://doi.org/10.1038/nnano.2012.118

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2012.118

This article is cited by

-

Advanced nanofabrication for elastic inorganic aerogels

Nano Research (2024)

-

Highly cross-linked carbon tube aerogels with enhanced elasticity and fatigue resistance

Nature Communications (2023)

-

Failure-analysis of carbon nanotubes and their extreme applications

Nano Research (2023)

-

Robust and superelastic spider web-like polyimide fiber-based conductive composite aerogel for extreme temperature-tolerant linear pressure sensor

Science China Materials (2023)

-

Highly compressible and environmentally adaptive conductors with high-tortuosity interconnected cellular architecture

Nature Synthesis (2022)