Abstract

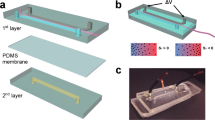

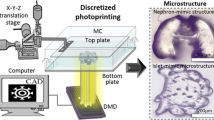

Heterotypic functional materials with compositional and topographical properties that vary spatiotemporally on the micro- or nanoscale are common in nature. However, fabricating such complex materials in the laboratory remains challenging. Here we describe a method to continuously create microfibres with tunable morphological, structural and chemical features using a microfluidic system consisting of a digital, programmable flow control that mimics the silk-spinning process of spiders. With this method we fabricated hydrogel microfibres coded with varying chemical composition and topography along the fibre, including gas micro-bubbles as well as nanoporous spindle-knots and joints that enabled directional water collection. We also explored the potential use of the coded microfibres for tissue engineering applications by creating multifunctional microfibres with a spatially controlled co-culture of encapsulated cells.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Daher, R. J., Chahine, N. O., Greenberg, A. S., Sgaglione, N. A. & Grande, D. A. New methods to diagnose and treat cartilage degeneration. Nature Rev. Rheumatol. 5, 599–607 (2009).

Silva, G. A. et al. Selective differentiation of neural progenitor cells by high-epitope density nanofibers. Science 303, 1352–1355 (2004).

Moutos, F. T., Freed, L. E. & Guilak, F. A biomimetic three-dimensional woven composite scaffold for functional tissue engineering of cartilage. Nature Mater. 6, 162–167 (2007).

Shi, J. J., Votruba, A. R., Farokhzad, O. C. & Langer, R. Nanotechnology in drug delivery and tissue engineering: From discovery to applications. Nano Lett. 10, 3223–3230 (2010).

Greiner, A. & Wendorff, J. H. Electrospinning: A fascinating method for the preparation of ultrathin fibres. Angew. Chem. Int. Ed. 46, 5670–5703 (2007).

Sill, T. J. & von Recum, H. A. Electro spinning: Applications in drug delivery and tissue engineering. Biomaterials 29, 1989–2006 (2008).

Hu, M. et al. Hydrodynamic spinning of hydrogel fibers. Biomaterials 31, 863–869 (2010).

Rammensee, S., Slotta, U., Scheibel, T. & Bausch, A. R. Assembly mechanism of recombinant spider silk proteins. Proc. Natl Acad. Sci. USA 105, 6590–6595 (2008).

Pregibon, D. C., Toner, M. & Doyle, P. S. Multifunctional encoded particles for high-throughput biomolecule analysis. Science 315, 1393–1396 (2007).

Xu, Q. B. et al. Preparation of monodisperse biodegradable polymer microparticles using a microfluidic flow-focusing device for controlled drug delivery. Small 5, 1575–1581 (2009).

Breslauer, D. N., Muller, S. J. & Lee, L. P. Generation of monodisperse silk microspheres prepared with microfluidics. Biomacromolecules 11, 643–647 (2010).

Chung, S. E., Park, W., Shin, S., Lee, S. A. & Kwon, S. Guided and fluidic self-assembly of microstructures using railed microfluidic channels. Nature Mater. 7, 581–587 (2008).

Mandal, S., Bhaskar, S. & Lahann, J. Micropatterned fiber scaffolds for spatially controlled cell adhesion. Macromol. Rapid Commun. 30, 1638–1644 (2009).

Bhaskar, S., Hitt, J., Chang, S. W. L. & Lahann, J. Multicompartmental microcylinders. Angew. Chem. Int. Ed. 48, 4589–4593 (2009).

Jeong, W. et al. Hydrodynamic microfabrication via ‘on the fly’ photopolymerization of microscale fibers and tubes. Lab Chip 4, 576–580 (2004).

Breslauer, D. N., Lee, L. P. & Muller, S. J. Simulation of flow in the silk gland. Biomacromolecules 10, 49–57 (2009).

Kang, E., Shin, S. J., Lee, K. H. & Lee, S. H. Novel PDMS cylindrical channels that generate coaxial flow, and application to fabrication of microfibers and particles. Lab Chip 10, 1856–1861 (2010).

Vollrath, F. Biology of spider silk. Int. J. Biol. Macromol. 24, 81–88 (1999).

Vollrath, F. & Knight, D. P. Liquid crystalline spinning of spider silk. Nature 410, 541–548 (2001).

Shin, S. et al. “On the fly” continuous generation of alginate fibers using a microfluidic device. Langmuir 23, 9104–9108 (2007).

Kang, E., Lee, D. H., Kim, C. B., Yoo, S. J. & Lee, S. H. A hemispherical microfluidic channel for the trapping and passive dissipation of microbubbles. J. Micromech. Microeng. 20, 045009 (2010).

Hwang, C. M., Khademhosseini, A., Park, Y., Sun, K. & Lee, S. H. Microfluidic chip-based fabrication of PLGA microfiber scaffolds for tissue engineering. Langmuir 24, 6845–6851 (2008).

Jung, J. H., Choi, C. H., Chung, S., Chung, Y. M. & Lee, C. S. Microfluidic synthesis of a cell adhesive Janus polyurethane microfiber. Lab Chip 9, 2596–2602 (2009).

Zheng, Y. M. et al. Directional water collection on wetted spider silk. Nature 463, 640–643 (2010).

Blackledge, T. A. & Hayashi, C. Y. Silken toolkits: Biomechanics of silk fibers spun by the orb web spider Argiope argentata (Fabricius 1775). J. Exp. Biol. 209, 2452–2461 (2006).

Renneberg, R., Sonomoto, K., Katoh, S. & Tanaka, A. Oxygen diffusivity of synthetic gels derived from prepolymers. Appl. Microbiol. Biot. 28, 1–7 (1988).

Acknowledgements

This study was supported by a grant from the NRL (National Research Laboratory) programme, the Korea Science and Engineering Foundation (KOSEF), Republic of Korea (No. 20110020455), basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (No. R11-2008-044-02002-0) and the Korea Research and Engineering Foundation (KOSEF) funded by the Korea government (KRF; No. KRF-2008-220-D00133).

Author information

Authors and Affiliations

Contributions

E.K. designed and carried out the experiments and prepared most of the data; G.S.J. carried out an analytical study of the valve system and assisted with the experiments; Y.Y.C. carried out the cell-based evaluation; K.H.L. optimized the material and developed the flow analysis; A.K. consulted on the manuscript and contributed in writing the paper; S-H.L. proposed the idea, managed the research process and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1270 kb)

Supplementary Information

Supplementary Movie (MOV 449 kb)

Supplementary Information

Supplementary Movie (MOV 531 kb)

Supplementary Information

Supplementary Movie (MOV 297 kb)

Supplementary Information

Supplementary Movie (MOV 456 kb)

Supplementary Information

Supplementary Movie (MOV 647 kb)

Supplementary Information

Supplementary Movie (MOV 703 kb)

Supplementary Information

Supplementary Movie (MOV 194 kb)

Supplementary Information

Supplementary Movie (MOV 690 kb)

Supplementary Information

Supplementary Movie (MOV 1139 kb)

Supplementary Information

Supplementary Movie (MOV 2389 kb)

Rights and permissions

About this article

Cite this article

Kang, E., Jeong, G., Choi, Y. et al. Digitally tunable physicochemical coding of material composition and topography in continuous microfibres. Nature Mater 10, 877–883 (2011). https://doi.org/10.1038/nmat3108

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3108

This article is cited by

-

Aqueous spinning of robust, self-healable, and crack-resistant hydrogel microfibers enabled by hydrogen bond nanoconfinement

Nature Communications (2023)

-

A ‘print–pause–print’ protocol for 3D printing microfluidics using multimaterial stereolithography

Nature Protocols (2023)

-

Bioinspired artificial spider silk photocatalyst for the high-efficiency capture and inactivation of bacteria aerosols

Nature Communications (2023)

-

Numerical analysis on the effects of microfluidic-based bioprinting parameters on the microfiber geometrical outcomes

Scientific Reports (2022)

-

On-demand formation of heterogeneous gel fibers using two-dimensional micronozzle array

Microfluidics and Nanofluidics (2022)