Abstract

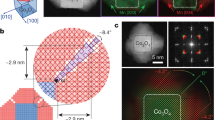

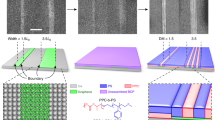

Grain boundaries play a vital role in determining materials behaviour1,2,3, and the nature of these intercrystalline interfaces is dictated by chemical composition4, processing history5, and geometry2,6 (misorientation and inclination). The interrelation among these variables and material properties may be systematically studied in bicrystals7. Conventional bicrystal fabrication offers control over these variables, but its ability to mimic grain boundaries in polycrystalline materials is ambiguous8,9,10,11,12. Here we describe a novel solid-state process for rapidly generating intercrystalline interfaces with controlled geometry and chemistry, applicable to a broad range of materials. A fine-grained polycrystalline layer, contacted by two appropriately misoriented single-crystal seeds, is consumed by an epitaxial solid-state transformation until the directed growth fronts impinge. The seed misorientations establish the geometry of the resulting intercrystalline boundaries, and the composition of the sacrificial polycrystalline layer establishes the chemistry of the boundaries and their adjacent grains. Results from a challenging model system, titanium-doped sapphire, illustrate the viability of the directed assembly technique for preparing high-quality bicrystals in both twist and tilt configurations.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

McLean, D. Grain Boundaries in Metals (Clarendon, Oxford, 1957).

Chaudhari, P. & Matthews, J.W. in Proc. Int. Conf. Structure and Properties of Grain Boundaries and Interfaces (North-Holland, Amsterdam, 1972).

Flewitt, P.E.J. & Wild, R.K. Grain Boundaries: Their Microstructure and Chemistry (Wiley, Chichester, 2001).

Joshi, A. & Stein, D.F. Impurity segregation to grain boundaries. (Auger spectroscopy). J. Test. Eval. (USA) 1, 202–208 (1973).

American Society for Metals. Materials Science Division. Seminar Committee & Metallurgical Society of AIME. in 1979 ASM Materials Science Seminar (American Society for Metals, Metals Park, Ohio, 1980).

Bollmann, W. Crystal Defects and Crystalline Interfaces (Springer, Berlin, 1970).

Chalmers, B. The influence of the difference of orientation of two crystals on the mechanical effect of their boundary. Proc. R. Soc. Lond. A 162, 120–127 (1937).

Morris, P.A. & Coble, R.L. Grain boundary structures in high-purity Al2O3 bicrystals grown from the melt. Mater. Res. Soc. Symp. Proc. 60, 281–289 (1986).

Parker, H.S. & Harding, C.A. Vapor growth of Al2O3 bicrystals. J. Am. Ceram. Soc. (USA) 53, 583–585 (1970).

Davis, M.P. Pressure sintered alumina bicrystals. J. Am. Ceram. Soc. (USA) 47, 463–464 (1964).

Hoche, T. & Ruhle, M. Effect of calcium doping on the atomistic structure of the (1104) twin boundary in alumina. J. Am. Ceram. Soc. (USA) 79, 1961–1966 (1996).

Ikuhara, Y. et al. Dislocation structures of low-angle and near-Σ3 grain boundaries in alumina bicrystals. J. Am. Ceram. Soc. (USA) 86, 595–602 (2003).

Wolf, H. et al. in Metastable, Mechanically Alloyed and Nanocrystalline Materials: ISMANAM-99: Proc. Int. Symp. Metastable, Mechanically Alloyed and Nanocrystalline Materials (eds Eckert, J., Schlèorb, H. & Schultz, L.) 847–852 (Trans Tech Publications, Ütikon-Zürich, 2000).

Kodiyalam, S. et al. Grain boundaries in gallium arsenide nanocrystals under pressure: a parallel molecular-dynamics study. Phys. Rev. Lett. (USA) 86, 55–58 (2001).

Randle, V. The Measurement of Grain Boundary Geometry (Institute of Physics, Bristol, 1993).

Sutton, A.P. & Vitek, V. On the structure of tilt grain boundaries in cubic metals. I. Symmetrical tilt boundaries. Phil. Trans. R. Soc. Lond. A, 309, 1–36 (1983).

Kinoshita, M. Boundary migration of single crystal in polycrystalline alumina. Yogyo-Kyokai-Shi 82, 295–296 (1974).

Matsuzawa, S. & Mase, S. Method for producing singel crystal of ferrite. US Patent 4,339,301 (1982).

Imaeda, M. & Matsuzawa, S. Growth of yttrium iron garnet single crystal by solid-solid reaction. 1st Japan Int. SAMPE Symp. 419–424 (1989).

Hirao, K., Nagaoka, T., Brito, M.E. & Kanzaki, S. Microstructure control of silicon-nitride by seeding with rodlike beta-silicon nitride particles. J. Am. Ceram. Soc. (USA) 77, 1857–1862 (1994).

Seabaugh, M.M., Kerscht, I.H. & Messing, G.L. Texture development by templated grain growth in liquid phase sintered α-alumina. J. Am. Ceram. Soc. (USA) 80, 1181–1188 (1997).

Scott, W.D. Fabrication of bicrystals of aluminum oxide. Trans. Brit. Ceram. Soc. 66, 315–318 (1967).

Kim, D.-Y., Wiederhorn, S.M., Hockey, B.J., Handwerker, C.A. & Blendell, J.E. Stability and surface energies of wetted grain boundaries in aluminum oxide. J. Am. Ceram. Soc. (USA) 77, 444–453 (1994).

Mar, H.Y.B. & Scott, W.D. Fracture induced in Al2O3 bicrystals by anisotropic thermal expansion. J. Am. Ceram. Soc. (USA) 53, 555–558 (1970).

Bagley, R.D., Cutler, I.B. & Johnson, D.L. Effect of TiO2 on initial sintering of Al2O3 . J. Am. Ceram. Soc. (USA) 53, 136–141 (1970).

Brook, R.J. Effect of TiO2 on the initial sintering of Al2O3 . J. Am. Ceram. Soc. (USA) 55, 114–115 (1972).

Phillips, D.S., Mitchell, T.E. & Heuer, A.H. Precipitation in star sapphire. III. Chemical effects accompanying precipitation. Phil. Mag. A, Phys. Condens. Matter Defects Mech. Prop. (UK) 42, 417–432 (1980).

Morgan, P.E.D. & Koutsoutis, M.S. Phase studies concerning sintering in aluminas doped with Ti4+. J. Am. Ceram. Soc. (USA) 68, C156–158 (1985).

Ikegami, T., Kotani, K. & Eguchi, K. Some roles of MgO and TiO2 in densification of a sinterable alumina. J. Am. Ceram. Soc. (USA) 70, 885–890 (1987).

Powers, J.D. & Glaeser, A.M. High-temperature healing of cracklike flaws in titanium ion-implanted sapphire. J. Am. Ceram. Soc. (USA) 76, 2225–2234 (1993).

Horn, D.S. & Messing, G.L. Anisotropic grain growth in TiO2-doped alumina. Mater. Sci. Eng. A 195A, 169–178 (1995).

Kebbede, A., Messing, G.L. & Carim, A.H. Grain boundaries in titania-doped α-alumina with anisotropic microstructure. J. Am. Ceram. Soc. (USA) 80, 2814–2820 (1997).

Powers, J.D. Titanium Effects on Microstructure Development in Alumina. Thesis, Univ. California, Berkeley, 1997.

Jones, T.P., Coble, R.L. & Mogab, C.J. Defect diffusion in single crystal aluminum oxide. J. Am. Ceram. Soc. (USA) 52, 331–334 (1969).

Schober, T. & Balluffi, R.W. Dislocations in symmetric high angle (001) tilt boundaries in gold. Phys. Status Solidi 44, 115–126 (1971).

Ravishankar, N. & Carter, C.B. Glass/crystal interfaces in liquid-phase sintered materials. Interf. Sci. 8, 295–304 (2000).

Marks, R.A. Fabrication of Controlled-Misorientation Alumina Grain Boundaries and Implications of the Triple-Junction Equilibrium Conditions. Thesis, Univ. California, Berkeley, 2003.

Acknowledgements

This work was supported by the Laboratory Directed Research and Development Program of Lawrence Berkeley National Laboratory under the Department of Energy Contract No. DE-AC03-76SF00098. Access to National Center for Electron Microscopy is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Marks, R., Taylor, S., Mammana, E. et al. Directed assembly of controlled-misorientation bicrystals. Nature Mater 3, 682–686 (2004). https://doi.org/10.1038/nmat1214

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1214

This article is cited by

-

Twisted oxide lateral homostructures with conjunction tunability

Nature Communications (2022)

-

Polymorphism of dislocation core structures at the atomic scale

Nature Communications (2014)