Abstract

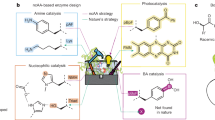

Three-dimensional (3D) printing has the potential to transform science and technology by creating bespoke, low-cost appliances that previously required dedicated facilities to make. An attractive, but unexplored, application is to use a 3D printer to initiate chemical reactions by printing the reagents directly into a 3D reactionware matrix, and so put reactionware design, construction and operation under digital control. Here, using a low-cost 3D printer and open-source design software we produced reactionware for organic and inorganic synthesis, which included printed-in catalysts and other architectures with printed-in components for electrochemical and spectroscopic analysis. This enabled reactions to be monitored in situ so that different reactionware architectures could be screened for their efficacy for a given process, with a digital feedback mechanism for device optimization. Furthermore, solely by modifying reactionware architecture, reaction outcomes can be altered. Taken together, this approach constitutes a relatively cheap, automated and reconfigurable chemical discovery platform that makes techniques from chemical engineering accessible to typical synthetic laboratories.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Marks, P., Campbell, M., Aron, J. & Lipson, H. 3D printing: second industrial revolution is under way (special report). New Sci. 2823, 17–20 (2011).

Geissler, M. & Xia, Y. Patterning: principles and some new developments. Adv. Mater. 16, 1249–1269 (2004).

Nakamura, M., Iwanaga, S., Henmi, C., Arai, K. & Nishiyama, Y. Biomatrices and biomaterials for future developments of bioprinting and biofabrication. Biofabrication 2, 014110 (2010).

Lee, K-W., Wang, S., Dadsetan, M., Yaszemski, M. J. & Lu, L. Enhanced cell ingrowth and proliferation through three-dimensional nanocomposite scaffolds with controlled pore structures. Biomacromolecules 11, 682–689 (2010).

Hanson Shepherd, J. N. et al. 3D microperiodic hydrogel scaffolds for robust neuronal cultures. Adv. Funct. Mater. 21, 47–54 (2011).

Cohen, D. L., Malone, E., Lipson, H. & Bonassar, L. J. Direct freeform fabrication of seeded hydrogels in arbitrary geometries. Tissue Eng. 12, 1325–1335 (2006).

Stampfl, J. & Liska, R. New materials for rapid prototyping applications. Macromol. Chem. Phys. 206, 1253–1256 (2005).

Ahn, B. Y. et al. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323, 1590–1593 (2009).

Therriault, D., White, S. R. & Lewis, J. A. Chaotic mixing in three-dimensional microvascular networks fabricated by direct-write assembly. Nature Mater. 2, 265–271 (2003).

Ilievski, F., Mazzeo, A. D., Shepherd, R. F., Chen, X. & Whitesides, G. M. Soft robotics for chemists. Angew. Chem. Int. Ed. 50, 1890–1895 (2011).

Hasegawa, T., Nakashima, K., Omatsu, F. & Ikuta, K. Multi-directional micro-switching valve chip with rotary mechanism. Sensor. Actuat. A Phys. 143, 390–398 (2007).

Vilbrandt, T., Pasko, A. & Vilbrandt, C. Fabricating nature. Technoetic Arts 7, 165–174 (2009).

Pearce, J. M. et al. 3-D printing of open source appropriate technologies for self-directed sustainable development. J. Sustain. Develop. 3, 17–29 (2010).

Yager, P. et al. Microfluidic diagnostic technologies for global public health. Nature 442, 412–418 (2006).

Cook, T. R. et al. Solar energy supply and storage for the legacy and nonlegacy worlds. Chem. Rev. 110, 6474–6502 (2010).

Gratson, G. M., Xu, M. & Lewis, J. A. Microperiodic structures: direct writing of three-dimensional webs. Nature 428, 386 (2004).

Lewis, J. A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 16, 2193–2204 (2006).

Moore, J. L., McCuiston A., Mittendorf, I., Ottway, R. & Johnson, R. D. Behavior of capillary valves in centrifugal microfluidic devices prepared by three-dimensional printing. Microfluid. Nanofluid. 10, 877–888 (2011).

Fab@Home. The open-source personal fabricator project, http://www.fabathome.org (accessed 21/02/2012).

Malone, E. & Lipson, H. Fab@Home: the personal desktop fabricator kit. Rapid Prototyping J. 13, 245–255 (2007).

Parenty, A. D. C., Smith, L. V., Pickering, A. L., Long, D-L. & Cronin, L. General one-pot, three-step methodology leading to an extended class of N-heterocyclic cations: spontaneous nucleophilic addition, cyclization, and hydride loss. J. Org. Chem. 69, 5934–5946 (2004).

Richmond, C. J., Eadie, R. M., Parenty, A. D. C. & Cronin, L. Fine tuning reactivity: synthesis and isolation of 1,2,3,12b-tetrahydroimidazo[1,2-f] phenanthridines. J. Org. Chem. 74, 8196–8202 (2009).

Rhino3D, NURBS modeling for Windows, http://www.rhino3d.com (McNeel, Barcelona).

Kataria, A. & Rosen, D. W. Building around inserts: methods for fabricating complex devices in stereolithography. Rapid Prototyping J. 7, 253–261 (2001).

Kortz, U., Savelieff, M. G., Bassil, B. S. & Dickman, M. H. A large, novel polyoxotungstate: [As(III)6W65O217(H2O)7]26–. Angew. Chem. Int. Ed. 40, 3384–3386 (2001).

Tanaka, N., Unoura, K. & Itabashi, E. Voltammetric and spectroelectrochemical studies of dodecamolybdophosphoric acid in aqueous and water–dioxane solutions at a gold-minigrid optically transparent thin-layer electrode. Inorg. Chem. 21, 1662–1666 (1982).

Mandal, P. K. & McMurray, J. S. Pd–C induced catalytic transfer of hydrogen with triethylsilane. J. Org. Chem. 72, 6599–6601 (2007).

Boyle, M. M. et al. Mechanised materials. Chem. Sci. 2, 204–210 (2011).

Maldonado, A. G. & Rothenberg, G. Predictive modeling in homogeneous catalysis: a tutorial. Chem. Soc. Rev. 39, 1891–1902 (2010).

Browne, K. P., Walker, D. A., Bishop, K. J. M. & Grzybowski, B. A. Self-division of macroscopic droplets: partitioning of nanosized cargo into nanoscale micelles. Angew. Chem. Int. Ed. 49, 6756–6759 (2010).

Cooper, G. J. T. et al. Modular redox active inorganic chemical cells: iCHELLs. Angew. Chem. Int. Ed. 50, 10373–10376 (2011).

Murphy, R. F. An active role for machine learning in drug development. Nature Chem. Biol. 7, 327–330 (2011).

Acknowledgements

This work was supported by the Engineering and Physical Sciences Research Council UK via Creativity@HOME. L.C. thanks the Royal Society/Wolfson Foundation for a Merit Award. We thank R.M. Eadie (University of Glasgow) for samples of 2-bromoethylphenanthridinium bromide and E. Malone and K. Kondo (NextFab Studio, Philadelphia) for assistance with building the fabricator.

Author information

Authors and Affiliations

Contributions

L.C. conceived the idea and the organized the fabricator assembly, M.D.S., P.J.K., T.V., G.J.T.C. and R.W.B. designed the reactionware, M.D.S. and P.J.K. printed the devices, M.D.S., P.J.K., J.Y. and C.J.R. performed the experiments, L.C., M.D.S, P.J.K., J.Y. and C.J.R. analysed the results and M.D.S. and L.C. co-wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 901 kb)

Supplementary Movie 1

Supplementary Movie 1 (MOV 15090 kb)

Supplementary Movie 2

Supplementary Movie 2 (MOV 9654 kb)

Supplementary information

Crystallographic data for compound 1 (CIF 37 kb)

Supplementary information

Crystallographic data for compound 2 (CIF 27 kb)

Supplementary information

Crystallographic data for compound 3 (CIF 15 kb)

Rights and permissions

About this article

Cite this article

Symes, M., Kitson, P., Yan, J. et al. Integrated 3D-printed reactionware for chemical synthesis and analysis. Nature Chem 4, 349–354 (2012). https://doi.org/10.1038/nchem.1313

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nchem.1313

This article is cited by

-

Ultrahigh-printing-speed photoresists for additive manufacturing

Nature Nanotechnology (2024)

-

Analysis of plant cuticles and their interactions with agrochemical surfactants using a 3D printed diffusion chamber

Plant Methods (2023)

-

Exploring metallic and plastic 3D printed photochemical reactors for customizing chemical synthesis

Scientific Reports (2022)

-

Complementary catalysis and analysis within solid state additively manufactured metal micro flow reactors

Scientific Reports (2022)

-

Additive Manufacturing of Functional Microarchitected Reactors for Energy, Environmental, and Biological Applications

International Journal of Precision Engineering and Manufacturing-Green Technology (2021)