Abstract

Ordinarily, the strength and plasticity properties of a metal are defined by dislocations—line defects in the crystal lattice whose motion results in material slippage along lattice planes1. Dislocation dynamics models are usually used as mesoscale proxies for true atomistic dynamics, which are computationally expensive to perform routinely2. However, atomistic simulations accurately capture every possible mechanism of material response, resolving every “jiggle and wiggle”3 of atomic motion, whereas dislocation dynamics models do not. Here we present fully dynamic atomistic simulations of bulk single-crystal plasticity in the body-centred-cubic metal tantalum. Our goal is to quantify the conditions under which the limits of dislocation-mediated plasticity are reached and to understand what happens to the metal beyond any such limit. In our simulations, the metal is compressed at ultrahigh strain rates along its [001] crystal axis under conditions of constant pressure, temperature and strain rate. To address the complexity of crystal plasticity processes on the length scales (85–340 nm) and timescales (1 ns–1μs) that we examine, we use recently developed methods of in situ computational microscopy4,5 to recast the enormous amount of transient trajectory data generated in our simulations into a form that can be analysed by a human. Our simulations predict that, on reaching certain limiting conditions of strain, dislocations alone can no longer relieve mechanical loads; instead, another mechanism, known as deformation twinning (the sudden re-orientation of the crystal lattice6), takes over as the dominant mode of dynamic response. Below this limit, the metal assumes a strain-path-independent steady state of plastic flow in which the flow stress and the dislocation density remain constant as long as the conditions of straining thereafter remain unchanged. In this distinct state, tantalum flows like a viscous fluid while retaining its crystal lattice and remaining a strong and stiff metal.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bulatov, V. V. & Cai, W. Computer Simulations of Dislocations 196–240 (Oxford Univ. Press, 2006)

Ghoniem, N. M. et al. Parametric dislocation dynamics: a thermodynamics-based approach to investigations of mesoscopic plastic deformation. Phys. Rev. B. 61, 913–927 (2000)

Feynman, R. Lectures on Physics Vol. 1, 3–6 (1963)

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO — the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010)

Stukowski, A. & Albe, K. Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 18, 085001 (2010)

Christian, J. W. & Mahajan, S. Deformation twinning. Prog. Mater. Sci. 39, 1–157 (1995)

Hoge, K. G. & Mukherjee, A. K. The temperature and strain rate dependence of the flow stress of tantalum. J. Mater. Sci. 12, 1666–1672 (1977)

Tramontina, D. et al. Molecular dynamics simulations of shock-induced plasticity in tantalum. High Energy Density Phys. 10, 9–15 (2014)

Mitchell, T. E. & Spitzig, W. A. Three-stage hardening in tantalum single crystals. Acta Metall. 13, 1169–1179 (1965)

Frank, F. C. & Read, W. T. Jr. Multiplication processes for slow moving dislocations. Phys. Rev. 79, 722–723 (1950)

Meyers, M. A. et al. The onset of twinning in metals: a constitutive description. Acta Mater. 49, 4025–4039 (2001)

Shields, J. A. et al. Deformation of high purity tantalum single crystals at 4.2 K. Mater. Sci. Eng. 20, 71–81 (1975)

Cotterill, R. M. J. Does dislocation density have a natural limit? Phys. Lett. A 60, 61–62 (1977)

Florando, J. N. et al. Effect of strain rate and dislocation density on the twinning behavior in tantalum. AIP Adv. 6, 045120 (2016)

Sleeswyk, A. W. 1/2〈111〉 screw dislocations and nucleation of {112}〈111〉 twins in the b.c.c. lattice. Phil. Mag. 8, 1467–1486 (1963)

Marian, J., Cai, W. & Bulatov, V. V. Dynamic transitions from smooth to rough to twinning in dislocation motion. Nat. Mater. 3, 158–163 (2004)

Martyushev, L. M. & Seleznev, V. D. Maximum entropy production principle in physics, chemistry and biology. Phys. Rep. 426, 1–45 (2006)

Hsiung, L. L. Shock-induced phase transformation in tantalum. J. Phys. Condens. Matter 22, 385702 (2010)

Nemat-Nasser, S. et al. Microstructure of high-strain, high-strain-rate deformed tantalum. Acta Mater. 46, 1307–1325 (1998)

Lu, C. H. et al. Phase transformation in tantalum under extreme laser deformation. Sci. Rep. 5, 15064 (2015)

Reed, B. W. et al. A unified approach for extracting strength information from non-simple compression waves. Part II. Experiment and comparison with simulation. J. Appl. Phys. 110, 113506 (2011)

Johnston, W. G. & Gilman, J. J. Dislocation velocities, dislocation densities and plastic flow in lithium fluoride crystals. J. Appl. Phys. 30, 129–144 (1959)

Mecking, H. & Kocks, U. F. Kinetics of flow and strain hardening. Acta Metall. 29, 1865–1875 (1981)

Seeger, A. Evidence of enhanced self-organization in the work-hardening stage V of fcc metals. Philos. Mag. Lett. 81, 129–136 (2001)

Banerjee, J. K. Barreling of solid cylinders under axial compression. J. Eng. Mater. Technol. 107, 138–144 (1985)

Roylance, D. Stress–Strain Curves https://ocw.mit.edu/courses/materials-science-and-engineering/3-11-mechanics-of-materials-fall-1999/modules/MIT3_11F99_ss.pdf (MIT OpenCourseWare, 2001)

Khan, A. S. & Huang, S. Continuum Theory of Plasticity 37–40 (Wiley-Interscience, 1995)

Carpay, F. M. A. et al. Constrained deformation of molybdenum single crystals. Acta Metall. 23, 1473–1478 (1975)

Saada, G. On hardening due to the recombination of dislocations. Acta Metall. 8, 841–847 (1960)

Bulatov, V. V. et al. Dislocation multi-junctions and strain hardening. Nature 440, 1174–1178 (2006)

Louchet, F. & Viguier, B. Ordinary dislocations in γ-TiAl: cusp unzipping, jog dragging and stress anomaly. Philos. Mag. A 80, 765–779 (2000)

Christian, J. W. & Masters, B. C. Low-temperature deformation of body-centered cubic metals. Proc. R. Soc. Lond. A 281, 223–239 (1964)

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

Li, Y. H. et al. Embedded-atom-method tantalum potential developed by force-matching method. Phys. Rev. B 67, 125101 (2003)

Boxall, A. IBM’s Sequoia tops the world’s fastest supercomputer list. Digital Trendshttp://www.digitaltrends.com/computing/ibms-sequoia-tops-the-worlds-fastest-supercomputer-list/ (2012)

Nguyen, L. D. & Warner, D. H. Improbability of void growth in aluminum via dislocation nucleation under typical laboratory conditions. Phys. Rev. Lett. 108, 035501 (2012)

Mauro, J. C. & Smedskjaer, M. M. Unified physics of stretched exponential relaxation and Weibull fracture statistics. Physica A 391, 6121–6127 (2012)

Hähner, P. et al. Fractal dislocation patterning during plastic deformation. Phys. Rev. Lett. 81, 2470–2473 (1998)

Acknowledgements

This work was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under contract W-7405-Eng-48. This work was supported by the NNSA ASC programme. Computing support for this work came from the Lawrence Livermore National Laboratory (LLNL) Institutional Computing Grand Challenge programme and Jülich Supercomputing Centre at Forschungszentrum Jülich, Germany.

Author information

Authors and Affiliations

Contributions

L.A.Z.-R. ran most of the molecular dynamics simulations and analysed the results, A.S. ran molecular dynamics simulations and developed methods for computational microscopy and visualization, T.O. optimized run-time efficiency and data management of molecular dynamics simulations, and V.V.B. developed the concept, planned the research, generated starting configurations for molecular dynamics simulations, analysed the results and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information Nature thanks M. Zaiser and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

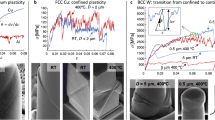

Extended Data Figure 1 Plastic yield response depends on the initial density of dislocation sources.

Stress as a function of true strain and specimen size computed in three MD simulations of compression at rate ×25 from three different initial configurations of dislocation sources.

Extended Data Figure 2 Detecting twinning during straining simulations.

Stress (dashed curve) and the volume fraction of twins (solid curve) as a function of true strain under compression at rate ×5 and temperature 25 K. The twin fraction was computed using the GSA.

Extended Data Figure 3 Continuous cooling during straining permits detection of a twinning transition.

Volume fraction of twins (solid curve) and flow stress (dashed curve) as a function of temperature, computed in a simulation at fixed rate ×5 in which temperature was reduced at a constant rate from 300 K to 10 K. A twinning transition is identified by the temperature at which the twin fraction begins to rise rapidly from zero. Preceding this simulation, the crystal was pre-strained at the same rate ×5 and a fixed temperature T = 300 K, where it attained a steady flow stress of 3.2 GPa.

Extended Data Figure 4 Relaxation of dislocation density after unloading of two crystals pre-strained at rate ×75.

The blue line represents isothermal relaxation after isothermal straining at T = 300 K. The red line depicts additional relaxation after two opposite surfaces of the simulated crystal were exposed to vacuum. The black line is adiabatic relaxation after adiabatic straining. Both isothermal and adiabatic relaxation simulations start at 2.5 ns in the end of isothermal and adiabatic pre-straining simulations (not shown).

Extended Data Figure 5 Kneading the metal.

Stress as a function of true (von Mises) strain, computed under compression at constant true rate ×25 along the three principal axes of the crystal. After compressing the crystal to one-quarter of its initial length along the z axis, the strain axis is changed from z to y, from y to x, and then from x back to z. Letters above the stress–strain curves label the axes for each compression cycle.

Extended Data Figure 6 Evolution of dislocation network topology under compressive strain at rate ×1.

Following rapid dislocation multiplication at yield, regular binary junctions appear first (red line) closely followed by ternary multi-junctions (black line). After reaching stationary flow at a strain of about 0.4, dislocation density and network composition (topology) remain stationary within statistical noise.

Extended Data Figure 7 Network evolution along a stepwise increase in the strain rates.

The number of binary junctions along a stepwise strain trajectory is shown as red circles and the solid red line, and the number of ternary junctions is shown as green squares and the solid green line. The dashed blue line shows the stepwise strain trajectory with strain rates marked at each rate step. The thin solid lines show the numbers of binary (red) and ternary (green) junctions along continuations of the interrupted straining steps. The inset shows the ratio of the number of ternary junctions to the number of binary junctions attained in the saturated flow state as a function of strain rate. Error bars are the standard deviation from the mean values.

Extended Data Figure 8 Evolution of dislocation characters under compression at rate ×25.

a, Histograms of dislocation character angle distributions computed for configurations A (black bar near zero), B (red bars) and C (open bars), which are marked along the strain trajectory in b. For reference, the dashed line depicts a hypothetical uniform distribution of character angles with the same integral length of dislocations as in configuration C. The histogram counts are over the bins along the log[cos(θ)] axis. b, Ratio of the total length of near-screw dislocations to the total length of near-edge dislocations as a function of strain.

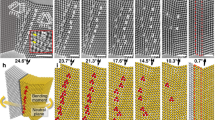

Extended Data Figure 9 Differential slip trace analysis reveals how dislocations move and interact.

a, The blue lines show positions and shapes of the dislocation lines in the initial configuration and the green lines show dislocations in the final configuration attained a few picoseconds later. The grey ‘slip traces’ consist of atoms whose local von Mises shear strain accumulated between the initial and the final dislocation positions exceeds the 0.15 threshold. Only a relatively small fraction of dislocations had swept substantial areas, whereas positions of most other dislocations in the two configurations coincide, suggesting little or no motion over the time interval. b, A magnified fragment of the same differential plot showing grey areas swept by several dislocations in more detail. The smooth step seen on the slip trace in the foreground reveals a ‘jog’ (a turn of a dislocation line inside a crystal) on the moving dislocation. c, Cross-slip of a screw dislocation from its initial position (blue) to its final position (green). The shape of the cylindrical traced area reveals the detailed trajectory of the screw dislocation between its initial and final positions. d, Annihilation of two dislocations, as evidenced by a slip trace area bounded on its two sides by two blue lines: one straight screw dislocation above and one curved dislocation below. That annihilation has taken place is deduced from the absence of green lines, which would otherwise show final positions of the two dislocations.

Extended Data Figure 10 Effect of simulation volume size on the strain response.

a, Stress–strain response under straining at rate ×1 (1.11 × 107 s−1). The thick red line is the stress–strain response simulated in a volume eight times greater (about 268 million atoms) than the one used in most other simulations. The thin grey lines correspond to eight independent simulations at the same rate, but performed in the standard-sized volume with about 33 million atoms. The thick black line was obtained by averaging over these eight simulations. b, The corresponding density–strain curves, with line colours and types matching the stress–strain curves on the left.

Supplementary information

Dislocation multiplication from the initial sources results in the development of a dense dislocation network.

Crystal containing dislocations sources (loops) is subjected to uniaxial compression along the [001] axis at a constant true straining rate of 2.78.108 1/s (x25). The simulation volume contains about 268 million atoms of tantalum. The video sequence progresses through extension of the initial hexagon-shaped loops, to dislocation collisions resulting in the formation of dislocation junctions, to an increasingly dense dislocation network. Dislocation positions, shapes and Burgers vectors were extracted using the DXA algorithm5. All atoms and defects other than dislocations, such as vacancies, interstitials and clusters, are removed for clarity. The green lines represent ½<111> dislocations and the pink lines depict <100> junction dislocations. (MP4 27123 kb)

Crystal microstructure evolution under straining at rate x50.

In this MD simulation a crystal containing dislocations sources (loops) was subjected to uniaxial compression along the [001] axis at a constant true straining rate of 5.56.108 1/s (x50). The simulation volume contains about 33 million atoms of tantalum. This video sequence progresses through extension of the initial loops, to nucleation of embryonic twins on screw dislocations, to rapid propagation and growth of twinning particles. The meaning of colours is as defined in the caption to Fig. 1: the outer surfaces bounding the twins are coloured light grey whereas the insides of twin particles are coloured red, yellow, magenta or cyan depending to each twin's rotational variant. (MP4 19343 kb)

“Metal kneading” at rate x25.

This MD simulation was performed on a brick-shaped tantalum crystal with the ratio of initial box dimensions 1:2:4. After full compression along Z axis to ¼ of its initial dimension the brick’s shape becomes 2:4:1 (due to Poisson’s expansion in two lateral dimensions, the brick’s volume remains very nearly constant under compression) another MD simulation starts in which the brick is compressed along its now longest Y-axis. After the second compression cycle is completed, the brick is compressed along its now longest X-axis. After three compression cycles the brick recovers its initial shape 1:2:4 and one more Z-axis compression cycle is performed (see related stress-strain plots in Extended Data Figure 5). (MP4 26846 kb)

Dislocation motion in more detail

This simulation was performed at rate 1.11.107 1/s (x1) from a configuration attained past yield under pre-straining at rate 5.55.107 1/s (x5). Reduction in dislocation density can be observed over the first few frames immediately following the sudden drop in the straining rate from x5 to x1 at time t=0. Subsequently the network attains a dynamic steady state in which dislocation multiplication is balanced by dislocation annihilation. Taken at more frequent time intervals, this sequence reveals various events in the life of dislocations in greater detail than in the other videos. One can observe that dislocation motion is not steady but proceeds in a stop-and-go manner which is also revealed in Extended Data Fig. 9a. (MP4 26951 kb)

Rights and permissions

About this article

Cite this article

Zepeda-Ruiz, L., Stukowski, A., Oppelstrup, T. et al. Probing the limits of metal plasticity with molecular dynamics simulations. Nature 550, 492–495 (2017). https://doi.org/10.1038/nature23472

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature23472

This article is cited by

-

Atomic-scale observation of nucleation- and growth-controlled deformation twinning in body-centered cubic nanocrystals

Nature Communications (2024)

-

Molecular Dynamics Simulation of 40Cr/Q345 Hot Compression Process

Journal of Materials Engineering and Performance (2024)

-

Atomistic modeling of idealized equal channel angular pressing process

Journal of Materials Science (2024)

-

Machine learning of atomic dynamics and statistical surface identities in gold nanoparticles

Communications Chemistry (2023)

-

Molecular dynamics study of the mechanical and tribological properties of graphene oxide-reinforced polyamide 66/nitrile butadiene rubber composites

Applied Physics A (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.