Abstract

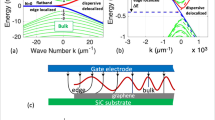

Epitaxy—the growth of a crystalline material on a substrate—is crucial for the semiconductor industry, but is often limited by the need for lattice matching between the two material systems. This strict requirement is relaxed for van der Waals epitaxy1,2,3,4,5,6,7,8,9,10, in which epitaxy on layered or two-dimensional (2D) materials is mediated by weak van der Waals interactions, and which also allows facile layer release from 2D surfaces3,8. It has been thought that 2D materials are the only seed layers for van der Waals epitaxy3,4,5,6,7,8,9,10. However, the substrates below 2D materials may still interact with the layers grown during epitaxy (epilayers), as in the case of the so-called wetting transparency documented for graphene11,12,13. Here we show that the weak van der Waals potential of graphene cannot completely screen the stronger potential field of many substrates, which enables epitaxial growth to occur despite its presence. We use density functional theory calculations to establish that adatoms will experience remote epitaxial registry with a substrate through a substrate–epilayer gap of up to nine ångströms; this gap can accommodate a monolayer of graphene. We confirm the predictions with homoepitaxial growth of GaAs(001) on GaAs(001) substrates through monolayer graphene, and show that the approach is also applicable to InP and GaP. The grown single-crystalline films are rapidly released from the graphene-coated substrate and perform as well as conventionally prepared films when incorporated in light-emitting devices. This technique enables any type of semiconductor film to be copied from underlying substrates through 2D materials, and then the resultant epilayer to be rapidly released and transferred to a substrate of interest. This process is particularly attractive in the context of non-silicon electronics and photonics, where the ability to re-use the graphene-coated substrates8 allows savings on the high cost of non-silicon substrates.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Koma, A., Sunouchi, K. & Miyajima, T. Fabrication and characterization of heterostructures with subnanometer thickness. Microelectron. Eng. 2, 129–136 (1984)

Ueno, K., Saiki, K., Shimada, T. & Koma, A. Epitaxial-growth of transition-metal dichalcogenides on cleaved faces of mica. J. Vac. Sci. Technol. A 8, 68–72 (1990)

Chung, K., Lee, C. H. & Yi, G. C. Transferable GaN layers grown on ZnO-coated graphene layers for optoelectronic devices. Science 330, 655–657 (2010)

Shi, Y. et al. van der Waals epitaxy of MoS2 layers using graphene as growth templates. Nano Lett. 12, 2784–2791 (2012)

Gehring, P., Gao, B. F., Burghard, M. & Kern, K. Growth of high-mobility Bi2Te2Se nanoplatelets on hBN sheets by van der Waals epitaxy. Nano Lett. 12, 5137–5142 (2012)

Gupta, P. et al. MOVPE growth of semipolar III-nitride semiconductors on CVD graphene. J. Cryst. Growth 372, 105–108 (2013)

Zhang, Y. et al. Direct observation of the transition from indirect to direct bandgap in atomically thin epitaxial MoSe2 . Nat. Nanotechnol. 9, 111–115 (2013)

Kim, J. et al. Principle of direct van der Waals epitaxy of single-crystalline films on epitaxial graphene. Nat. Commun. 5, 4836 (2014)

Lin, Y. C. et al. Direct synthesis of van der Waals solids. ACS Nano 8, 3715–3723 (2014)

Alaskar, Y. et al. Theoretical and experimental study of highly textured GaAs on silicon using a graphene buffer layer. J. Cryst. Growth 425, 268–273 (2015)

Shih, C. J., Strano, M. S. & Blankschtein, D. Wetting translucency of graphene. Nat. Mater. 12, 866–869 (2013)

Rafiee, J. et al. Wetting transparency of graphene. Nat. Mater. 11, 217–222 (2012)

Raj, R., Maroo, S. C. & Wang, E. N. Wettability of graphene. Nano Lett. 13, 1509–1515 (2013)

Giannozzi, P. et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 21, 395502 (2009)

Biegelsen, D. K., Bringans, R. D., Northrup, J. E. & Swartz, L. E. Surface reconstructions of GaAs(100) observed by scanning tunneling microscopy. Phys. Rev. B 41, 5701–5706 (1990)

Temmen, M., Ochedowski, O., Schleberger, M., Reichling, M. & Bollmann, T. R. J. Hydration layers trapped between graphene and a hydrophilic substrate. New J. Phys. 16, 053039 (2014)

Chhikara, M., Pavlica, E., Matkovic, A., Gajic, R. & Bratina, G. Effect of water layer at the SiO2/graphene interface on pentacene morphology. Langmuir 30, 11681–11688 (2014)

Cheng, Z. et al. Toward intrinsic graphene surfaces: a systematic study on thermal annealing and wet-chemical treatment of SiO2-supported graphene devices. Nano Lett. 11, 767–771 (2011)

Lin, Y. C. et al. Graphene annealing: how clean can it be? Nano Lett. 12, 414–419 (2012)

Kumar, K., Kim, Y. S. & Yang, E. H. The influence of thermal annealing to remove polymeric residue on the electronic doping and morphological characteristics of graphene. Carbon 65, 35–45 (2013)

Kim, J. et al. Layer-resolved graphene transfer via engineered strain layers. Science 342, 833–836 (2013)

Kiraly, B. et al. Electronic and mechanical properties of graphene-germanium interfaces grown by chemical vapor deposition. Nano Lett. 15, 7414–7420 (2015)

Cho, J. et al. Atomic-scale investigation of graphene grown on Cu foil and the effects of thermal annealing. ACS Nano 5, 3607–3613 (2011)

Bedell, S. W. et al. Kerf-less removal of Si, Ge, and III-V layers by controlled spalling to enable low-cost PV technologies. IEEE J. Photovolt. 2, 141–147 (2012)

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996)

Kneedler, E. M. et al. Influence of substrate surface reconstruction on the growth and magnetic properties of Fe on GaAs(001). Phys. Rev. B 56, 8163–8168 (1997)

Moosbühler, R., Bensch, F., Dumm, M. & Bayreuther, G. Epitaxial Fe films on GaAs(001): does the substrate surface reconstruction affect the uniaxial magnetic anisotropy? J. Appl. Phys. 91, 8757–8759 (2002)

Acknowledgements

This work was partly supported by the One to One Joint Research Project of the MI/MIT Cooperative Program. We thank the LG Electronics R&D Center for partial support of the GaAs 2DLT programme. We also thank the LAM Research Foundation, Analog Devices, Inc. and the MIT Lincoln Laboratory for general support; and Y. S. Lee of IBM, D. Sadana of IBM, A. Yoon of LAM Research, R. J. Molnar of MIT Lincoln Laboratory, C. V. Thompson of MIT, and J. Lee of LG Electronics for discussions. J. Kim thanks M. Baldo, D. Ha, and K. Jung of MIT for their assistance with electroluminescence measurements. S.S.C. thanks the National Science Foundation for a graduate research fellowship (grant no. 1122374). Y. S. and J. Kong thank support for Y.S. from NSF (DMR/ECCS – 1509197). J. H and J.M.J thank support for J.M.J from NSF (MRSEC DMR-1420451).

Author information

Authors and Affiliations

Contributions

J. Kim conceived the 2DLT process, designed experiments, and directed the team. Y.K., S.S.C., K.L., C.C., Y.S., C.H., W.K., S.C., K.Q. and I.A. performed the epitaxial growths/transfer experiments and characterization. K.L. fabricated and measured LED devices. J.M.J. and J.H. performed TEM analysis. B.O.A. contributed to the computational model and DFT simulation. All authors contributed to the discussion and analysis of the results regarding the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Figure 1 Natural slab separation with n graphene layers present between GaAs slabs.

To determine the maximum number of graphene layers that can be inserted within this critical gap, we calculate the natural separation induced by graphene interlayers using the structure shown on the left. The results show that the graphene–As distance d3 is 3.14 Å, the graphene–graphene distance d2 is 3.15 Å and the graphene–Ga distance d1 is 1.9 Å. A detailed description of calculated distances is in the table at the bottom for both Ga–As and As–As terminated cases.

Extended Data Figure 2 SEM images of front grown surface and released surface of GaAs films grown on monolayer, bilayer and tetralayer graphene stacks transferred onto GaAs(001) substrates.

a, The front surface of the GaAs epilayer grown on monolayer graphene–GaAs substrate is generally smooth but also contains impinging marks which need to be addressed by further optimization of nucleation and growth. Inset, 1 μm × 1 μm non-contact AFM scan; the epitaxial layer appears to be growing via step flow growth. The r.m.s. roughness of the AFM scan is 0.3 nm. b, c, Three-dimensional growth was observed for films grown on thicker graphene–substrates owing to limited registry from the substrates. Scale bars, 4 μm. Top and bottom panels of a–c indicate front and released surfaces, respectively.

Extended Data Figure 3 HRXRD ω–2θ scans of ‘exfoliated’ GaAs epilayers.

a, Diagram of exfoliated stacks of GaAs released from a graphene–GaAs(001) substrate. b, ω–2θ scan of GaAs exfoliated from monolayer graphene transferred on a GaAs(001) substrate showing (001) single-crystallinity as indicated by XRD peaks of the (002) and (004) lattice labelled in red. c, ω–2θ scan of GaAs exfoliated from bilayer graphene transferred on GaAs(100) substrate showing polycrystallinity with dominant (111) orientation, as indicated by the XRD peak of the (111) lattice labelled in red, and d, ω–2θ scan of GaAs exfoliated from tetralayer graphene transferred on a GaAs(001) substrate showing polycrystallinity with dominant (111) orientation, also indicated by XRD peak of the (111) lattice labelled in red. The ω–2θ scans also picked up XRD peaks from the Ni stressor film and the Ti adhesion layer that was used to exfoliate the GaAs films (Methods). The presence of these films are shown by the XRD peak of the (111) Ni lattice and the (101) lattice of anatase TiO2 from the Ti layer.

Extended Data Figure 4 GaAs(111) films grown on a monolayer graphene–GaAs(111)B substrate.

Schematic illustration at left shows exfoliation process of a thin-film GaAs(111) epilayer. The EBSD map demonstrates the versatility of the method used to copy the substrate orientation through graphene by remote homoepitaxy. On the right is the inverse pole figure colour triangle for crystallographic orientations. a, EBSD map of the released surface of a GaAs(111) layer substrate. b, SEM image of the front surface, as grown. c, SEM image of the released surface.

Extended Data Figure 5 Steady-state room temperature photoluminescence spectra.

Shown are steady-state photoluminescence spectra of GaAs substrate and exfoliated GaAs epilayer grown by remote epitaxy.

Extended Data Figure 6 LED light emission before and after transfer.

a, Diagram of the graphene-based layer transfer of LEDs. b, I–V curves of LEDs before and after transfer. c, Light emission of LEDs before and after transfer.

Extended Data Figure 7 Plan-view SEM of exfoliated surface of GaAs.

a, Smooth parts indicate release from graphene, and rough parts indicate spalling directly from GaAs substrate surface through graphene defects. If mechanical defects such as holes and cracks in graphene exist, they permit direct exposure of the GaAs(001) surface to adatoms, resulting in the direct binding of adatoms to the substrate. Location of b is shown boxed. b, Direct epitaxy of GaAs epilayers on GaAs substrates causes jagged topology (spalling marks) upon exfoliation due to the occurrence of spalling. However, such marks are observed in limited areas.

Rights and permissions

About this article

Cite this article

Kim, Y., Cruz, S., Lee, K. et al. Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 544, 340–343 (2017). https://doi.org/10.1038/nature22053

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature22053

This article is cited by

-

Formation techniques for upper active channel in monolithic 3D integration: an overview

Nano Convergence (2024)

-

A 2D ferroelectric vortex pattern in twisted BaTiO3 freestanding layers

Nature (2024)

-

Remote heteroepitaxy of transition metal dichalcogenides through monolayer hexagonal boron nitride

Nano Research (2024)

-

Applications of remote epitaxy and van der Waals epitaxy

Nano Convergence (2023)

-

Lattice modulation strategies for 2D material assisted epitaxial growth

Nano Convergence (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.