Abstract

Polymer electrolyte membrane fuel cells (PEMFCs) running on hydrogen are attractive alternative power supplies for a range of applications1,2,3, with in situ release of the required hydrogen from a stable liquid offering one way of ensuring its safe storage and transportation4,5 before use. The use of methanol is particularly interesting in this regard, because it is inexpensive and can reform itself with water to release hydrogen with a high gravimetric density of 18.8 per cent by weight. But traditional reforming of methanol steam operates at relatively high temperatures (200–350 degrees Celsius)6,7,8, so the focus for vehicle and portable PEMFC applications9 has been on aqueous-phase reforming of methanol (APRM). This method requires less energy, and the simpler and more compact device design allows direct integration into PEMFC stacks10,11. There remains, however, the need for an efficient APRM catalyst. Here we report that platinum (Pt) atomically dispersed on α-molybdenum carbide (α-MoC) enables low-temperature (150–190 degrees Celsius), base-free hydrogen production through APRM, with an average turnover frequency reaching 18,046 moles of hydrogen per mole of platinum per hour. We attribute this exceptional hydrogen production—which far exceeds that of previously reported low-temperature APRM catalysts—to the outstanding ability of α-MoC to induce water dissociation, and to the fact that platinum and α-MoC act in synergy to activate methanol and then to reform it.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Steele, B. C. & Heinzel, A. Materials for fuel-cell technologies. Nature 414, 345–352 (2001)

Schlapbach, L. & Zuttel, A. Hydrogen-storage materials for mobile applications. Nature 414, 353–358 (2001)

Amphlett, J. C. et al. Hydrogen-production by steam reforming of methanol for polymer electrolyte fuel-cells. Int. J. Hydrogen Energy 19, 131–137 (1994)

David, W. I. et al. Hydrogen production from ammonia using sodium amide. J. Am. Chem. Soc. 136, 13082–13085 (2014)

Yu, K. M. K. et al. Non-syngas direct steam reforming of methanol to hydrogen and carbon dioxide at low temperature. Nat. Commun. 3, 1230 (2012)

Lee, J. K., Ko, J. B. & Kim, D. H. Methanol steam reforming over Cu/ZnO/Al2O3 catalyst: kinetics and effectiveness factor. Appl. Catal. A Gen. 278, 25–35 (2004)

Sá, S., Silva, H., Brandão, L., Sousa, J. M. & Mendes, A. Catalysts for methanol steam reforming—a review. Appl. Catal. B 99, 43–57 (2010)

Setthapun, W., Bej, S. K. & Thompson, L. T. Carbide and nitride supported methanol steam reforming catalysts: parallel synthesis and high throughput screening. Top. Catal. 49, 73–80 (2008)

Davda, R. R., Shabaker, J. W., Huber, G. W., Cortright, R. D. & Dumesic, J. A. A review of catalytic issues and process conditions for renewable hydrogen and alkanes by aqueous-phase reforming of oxygenated hydrocarbons over supported metal catalysts. Appl. Catal. B 56, 171–186 (2005)

Song, C. Fuel processing for low-temperature and high-temperature fuel cells: challenges and opportunities for sustainable development in the 21st century. Catal. Today 77, 17–49 (2002)

Deng, Z.-Y., Ferreira, J. M. F. & Sakka, Y. Hydrogen-generation materials for portable applications. J. Am. Ceram. Soc. 91, 3825–3834 (2008)

Cortright, R. D., Davda, R. R. & Dumesic, J. A. Hydrogen from catalytic reforming of biomass-derived hydrocarbons in liquid water. Nature 418, 964–967 (2002)

Shabaker, J. W., Davda, R. R., Huber, G. W., Cortright, R. D. & Dumesic, J. A. Aqueous-phase reforming of methanol and ethylene glycol over alumina-supported platinum catalysts. J. Catal. 215, 344–352 (2003)

Nielsen, M. et al. Low-temperature aqueous-phase methanol dehydrogenation to hydrogen and carbon dioxide. Nature 495, 85–89 (2013)

Gunanathan, C. & Milstein, D. Bond activation and catalysis by ruthenium pincer complexes. Chem. Rev. 114, 12024–12087 (2014)

Denard, C. A. et al. Cooperative tandem catalysis by an organometallic complex and a metalloenzyme. Angew. Chem. Int. Ed. 126, 475–479 (2014)

Qiao, B. T. et al. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 3, 634–641 (2011)

Zhai, Y. et al. Alkali-stabilized Pt-OHx species catalyze low-temperature water-gas shift reactions. Science 329, 1633–1636 (2010)

Zhao, D. & Xu, B. Q. Enhancement of Pt utilization in electrocatalysts using gold nanoparticles. Angew. Chem. Int. Ed. 45, 4955–4959 (2006)

Fu, Q., Saltsburg, H. & Flytzani-Stephanopoulos, M. Active nonmetallic Au and Pt species on ceria-based water-gas shift catalysts. Science 301, 935–938 (2003)

Yang, M. et al. Catalytically active Au-O(OH)x-species stabilized by alkali ions on zeolites and mesoporous oxides. Science 346, 1498–1501 (2014)

Li, J. et al. Direct conversion of cellulose using carbon monoxide and water on a Pt–Mo2C/C catalyst. Energy Environ. Sci. 7, 393–398 (2014)

Lebarbier, V. M. et al. Sorption-enhanced synthetic natural gas (SNG) production from syngas: a novel process combining CO methanation, water-gas shift, and CO2 capture. Appl. Catal. B 144, 223–232 (2014)

Fu, Q. et al. Interface-confined ferrous centers for catalytic oxidation. Science 328, 1141–1144 (2010)

US Department of Energy. Compare Fuel Cell Vehicleshttp://www.fueleconomy.gov/feg/fcv_sbs.shtml (accessed 19 January 2017)

Schweitzer, N. M. et al. High activity carbide supported catalysts for water gas shift. J. Am. Chem. Soc. 133, 2378–2381 (2011)

Wei, H. et al. FeOx-supported platinum single-atom and pseudo-single-atom catalysts for chemoselective hydrogenation of functionalized nitroarenes. Nat. Commun. 5, 5634 (2014)

Moulder, J. F ., Chastain, J & King, R. C. Handbook of X-ray Photoelectron Spectroscopy: A Reference Book of Standard Spectra For Identification and Interpretation of XPS Data (Perkin–Elmer, 1992)

Lee, J. S., Volpe, L., Ribeiro, F. H. & Boudart, M. Molybdenum carbide catalysts: II. Topotactic synthesis of unsupported powders. J. Catal. 112, 44–53 (1988)

Ma, Y. et al. Low-temperature steam reforming of methanol to produce hydrogen over various metal-doped molybdenum carbide catalysts. Int. J. Hydrogen Energy 39, 258–266 (2014)

Toby, B. H. EXPGUI, a graphical user interface for GSAS. J. Appl. Cryst. 34, 210–213 (2001)

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005)

Krivanek, O. L. et al. in Low Voltage Electron Microscopy: Principles and Applications (eds Bell, D. & Erdman N. ) 119–161 (Wiley–Blackwell, 2013)

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996)

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996)

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994)

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999)

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996)

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000)

Acknowledgements

We received financial support from the 973 Project (grants 2011CB201402 and 2013CB933100) and the Natural Science Foundation of China (grants 91645115, 21473003, 91645115, 21222306, 21373037, 21577013 and 91545121). The electron-microscopy work was supported in part by the Chinese Academy of Sciences (CAS) Pioneer Hundred Talents Program; by the US Department of Energy (DOE), Office of Science, Basic Energy Science, Materials Sciences and Engineering Division (to W.Z.); and through a user project at Oak Ridge National Laboratory’s Center for Nanophase Materials Sciences (CNMS), which is a DOE Office of Science User Facility. The XAS experiments were conducted in the Shanghai Synchrotron Radiation Facility (SSRF) and Beijing Synchrotron Radiation Facility (BSRF). This research used Beamline 17-BM of the Advanced Photon Source (APS), a US DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under contract no. DE-AC02-06CH11357 (to W.X.). We also acknowledge National Thousand Young Talents Program of China the CAS Hundred Talents Program and the Shanxi Hundred Talent Program.

Author information

Authors and Affiliations

Contributions

D.M. designed the study. L.L. performed most of the reactions. W.Z. and S.Z. performed the electron-microscopy characterization and proposed the structural model for the active sites. C.S. and X.Z. synthesized part of the molybdenum carbides. R.G., Y.-W.L. and X.-D.W. finished the DFT calculations. S.Y., W.X. and Z.J. carried out the X-ray structure characterization and analysis. L.L., D.M., X.-D.W., S.Y., C.S. and W.Z. wrote the paper. The other authors provided reagents, performed some of the experiments and revised the paper.

Corresponding authors

Ethics declarations

Competing interests

D.M., L.L. and S.Y. declare a financial interest: patents related to this research have been filed by Peking University. The University’s policy is to share financial rewards from the exploitation of patents with the inventors.

Additional information

Reviewer Information Nature thanks D. Vlachos and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Figure 1 Structural characterization of Pt/MoC-based catalysts.

a, Rietveld structure refinement results obtained from XRD analysis of different Pt/MoC-based catalysts, including α-MoC lattice constants and molar percentages of fcc α-MoC. b, Molybdenum K-edge (20,000 eV) X-ray absorption near-edge structure (XANES) spectra of different Pt/MoC-based catalysts and of molybdenum foil and molybdenum oxides; the results suggest that no molybdenum oxide is present in the catalysts. c–g, Platinum L3-edge EXAFS fitting results for: c, 2%Pt/α-MoC; d, 2%Pt/MoC-2; e, 2%Pt/MoC-3; f, 2%Pt/β-Mo2C; and g, 2% Pt/Al2O3 catalysts in R space, where R represents the distance between scattering neighbour atoms and the absorbing atom, without correcting for scattering phase shift. The circles show the original data, and the red curve is the fitting curve; the areas enclosed by dotted green lines represent the fitting region. h, Corresponding platinum L3-edge XANES spectra for the catalysts, platinum foil and platinum oxides. The platinum L3 ‘white line’ (the first maximum of the XANES curve after the absorption edge; dotted line) of Pt/α-MoC catalysts moves to a higher energy than in metallic platinum foil, suggesting that platinum in the catalyst exhibits a positive charge.

Extended Data Figure 2 Electron microscopy characterization.

a, Low-magnification STEM Z-contrast image of 2% Pt/α-MoC. b, Corresponding fast Fourier transform (FFT) pattern of the image, showing that the α-MoC substrate has a fcc structure and is imaged along the  zone axis. The red dashed lines illustrate the {111} planes. The polycrystalline substrate is highly textured. c, Electron energy-loss spectrum (EELS) acquired from a 16 × 16 nm2 region of the α-MoC substrate, showing the presence of a very small amount of oxygen and the strong molybdenum and carbon signals. d, STEM bright-field image of 0.2%Pt/α-MoC catalyst. e, Corresponding FFT pattern. The α-MoC support has a porous appearance, with highly textured nanocrystals of 2–6 nm in size. This textured structure shows a strong tendency to align along the {111} direction (as shown in the FFT pattern)—that is, the nanocrystals have strong tendency to expose the {111} surfaces.

zone axis. The red dashed lines illustrate the {111} planes. The polycrystalline substrate is highly textured. c, Electron energy-loss spectrum (EELS) acquired from a 16 × 16 nm2 region of the α-MoC substrate, showing the presence of a very small amount of oxygen and the strong molybdenum and carbon signals. d, STEM bright-field image of 0.2%Pt/α-MoC catalyst. e, Corresponding FFT pattern. The α-MoC support has a porous appearance, with highly textured nanocrystals of 2–6 nm in size. This textured structure shows a strong tendency to align along the {111} direction (as shown in the FFT pattern)—that is, the nanocrystals have strong tendency to expose the {111} surfaces.

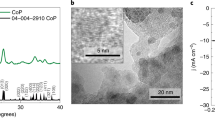

Extended Data Figure 3 XRD characterization and reaction kinetics.

a, XRD profiles of fresh and spent 0.2%Pt/α-MoC catalysts after 1 and 11 reaction cycles. The similar diffraction patterns suggest that this catalyst is stable under APRM conditions. There is no sign of bulk phase oxidation or phase transformation. The diffraction peaks of the α-MoC substrate appear at higher 2θ angles than the theoretical predicted values, indicating that the lattice constant of this substrate is slightly smaller than that of stoichiometric α-MoC. We ascribe the shift in the diffraction peaks to a deficiency in carbon as compared with the stoichiometric value. b, XRD profiles of Pt/α-MoC catalysts with different Pt loadings (0.7 wt%, 2.2 wt%, 3.1 wt%, 5.1 wt% or 7.4 wt%, numbered 1, 2, 3, 5 and 7, respectively, in the figure). XRD profiles were collected on a Rigaku X-ray diffractometer operated at 40 kV and 100 mA, using Cu Kα radiation. We observed no peaks associated with Pt nanoparticles for catalysts with Pt loading lower than 0.7%. However, when the Pt loading increases from 2.2 wt% to 7 wt%, a small peak associated with fcc Pt diffraction appears and increases gradually, indicating the presence and growth of Pt nanoparticles. c, Variation in catalytic activity (hydrogen evolution rate) versus Pt loading on Pt/α-MoC catalysts (190 °C; n(CH3OH):n(H2O) = 1:3). The activity of catalysts with less than 3.1% Pt loading was determined in three parallel reactions. The activity values are the numerical averages; the error bars represent the standard deviation of the three tests. d, Arrhenius plot of the methanol-reforming reaction for 2%Pt/α-MoC. The estimated apparent activation energy (Ea) is 82.9 kJ mol−1, similar to the reaction barrier energy calculated from DFT.

Extended Data Figure 4 XANES characterization of Pt/α-MoC.

a, Platinum L3-edge and b, molybdenum K-edge XANES results from fresh and used 0.2%Pt/α-MoC. These XANES spectra suggest that charge transfer from platinum to molybdenum is unchanged after the reaction, and that there is no sign of bulk phase oxidation in α-MoC. c, Pt L3-edge XANES spectra of Pt/α-MoC catalysts with different Pt loadings. Platinum foil and platinum oxide were used as standards. The position of the ‘white line’ (dashed line) shows gradual positive movement (from 0.5 eV to 0.6 eV) with decreasing Pt loading.

Extended Data Figure 5 Pt L3-edge EXAFS fitting results for Pt/α-MoC catalysts with different Pt loadings.

a–d, Fitting details for Pt L3-edge EXAFS spectra obtained for the 0.2%Pt/α-MoC catalyst (a, b) and the 2%Pt/α-MoC catalyst (c, d) as examples (‘k’ and ‘q’ refer to the EXAFS annotation for the wavenumber of the photoelectron) e–h, Pt L3-edge EXAFS fitting results for e, 0.7%, f, 3.1%, g, 5.1%, and h, 7.4% Pt/α-MoC catalysts in R space (k weight = 3).

Extended Data Figure 6 XPS characterization of 2%Pt/α-MoC and 0.2%Pt/α-MoC.

a, XPS spectra of the platinum 4f regions (the binding energy of pure platinum foil is 71.2 eV) and b, the molybdenum 3d regions of 2%Pt/α-MoC before and after exposure to methanol/water vapour at 190 °C for 1 hour. Ptδ+ denotes a partial positive charge on Pt. c, XPS spectra of the platinum 4f and d, molybdenum 3d regions of 0.2%Pt/α-MoC before and after exposure to methanol/water vapour at 190 °C for 1 hour. After the reaction, we detected no oxidation of platinum in either catalyst (as compared with the fresh catalysts); however, we did observe oxidation of a small amount of molybdenum, as shown by the generation of weak components in the high-energy region. These findings show that: first, platinum is not oxidized during the reaction; and second, perhaps only the MoC domain that is far from the Pt1 species is oxidized by the dissociated water, while oxygen-containing groups on the MoC domain adjacent to Pt1 will be converted to CO2 and H2 through the ongoing reaction cycles.

Extended Data Figure 7 Calculation models and electronic properties.

a, Top views of molybdenum-terminated α-MoC(111) (representing the α-MoC surface without loaded Pt), Pt(111) (representing pure Pt) and Pt1/α-MoC structures obtained from DFT models. Blue, Pt atoms; cyan, Mo atoms; grey, C atoms. b, Charge-density differences for Pt atoms, Pt–Mo bonds and Mo atoms from Pt1/α-MoC(111), in top and side views. Blue and red represent charge depletion and charge accumulation, respectively. Electron densities over the Pt and Mo sites in the catalyst are reduced greatly compared with the density over metallic Pt, while the Pt–Mo bonds form electron-rich regions. The units for the colour scale bar are a.u.−3. c, Crystal orbital overlap population (COOP) analysis of the Mo–C and Mo–Mo bonds in α-MoC(111), the Pt–Pt bond in Pt(111), and the Mo–C, Mo–Mo and Mo–Pt bonds in Pt1/α-MoC(111). In a COOP analysis, all energies are measured with respect to the Fermi level; a bonding contribution is represented by a positive COOP and an anti-bonding contribution by a negative COOP. For example, it can be found that charge transfer from Pt to the Pt–Mo interface in the Pt1/α-MoC(111) model effectively arouses the anti-oxidation ability of α-MoC (as seen by looking at the Mo–C bonds: anti-bonding characters (a negative sign around the Fermi level) in MoC(111) become bonding characters (a positive sign) in Pt1/MoC(111), indicating a stronger Mo–C bond, which is related to anti-oxidation ability).

Extended Data Figure 8 Adsorption energies in surface models and some detailed reaction paths.

a, Adsorption energies (Eads, measured in eV) of CH3OH, H2O, CO, CO2, H and H2 in different surface models. b, c, Reaction pathways for the APRM-driven formation of formic acid (HCOOH) via OH oxidation on b, Pt(111) and c, Pt1/α-MoC(111). The energy profile for the HCOOH conversion route of methanol reforming over the two models incorporates the zero-point energy and entropy correction at 463 K. The results suggest that the HCOOH route is not kinetically favoured as compared with the CHO dissociation route. d, Intermediate structures and corresponding energies for elementary steps of the reaction CO + 2OH → CO2 + H2O. TS, transition state; FS, final state.

Extended Data Figure 9 Energy profiles for methanol dissociation and the water–gas shift reaction on α-MoC(111) and Pt(111).

a, Methanol dissociation into CO and H atoms on α-MoC(111). b, Water–gas shift reaction on α-MoC(111). c, Methanol dissociation on Pt(111). d, Water–gas shift reactions on Pt(111).

Extended Data Figure 10 Studies of temperature desorption and surface reactions.

a, Temperature-programmed surface reaction (TPSR) of methanol and water over 2%Pt/α-MoC. The very-low-temperature H2 generation with CO2 at 115 °C is due to the methanol reforming with water. The signals around 214 °C are attributed to the reaction of methanol and water adsorbed at bare α-MoC sites. b, TPSR of methanol and water over α-MoC. At low temperatures (166 °C), no C-containing species is generated, indicating that α-MoC cannot dissociate the C–H bond of methanol at this temperature, let alone catalyse the successive reforming or decomposition processes. In other words, Pt1 is indispensable for low-temperature C–H clearage. Only at temperatures greater than 220 °C could α-MoC catalyse the methanol-reforming reaction. c, Temperature-programmed desorption (TPD) of methanol over 2%Pt/α-MoC. The signals at 145 °C are attributed to the intermolecular reforming of methanol, and the signals at 206 °C signals come from the decomposition of methanol into CO, CO2 and H2. d, TPSR of methanol and water over 2%Pt/Al2O3. Without α-MoC, Pt particles mainly catalyse methanol decomposition to CO and H2, as the signals at 183 °C show. Owing to the lack of surface hydroxyl from water dissociation at this temperature, CO2 does not form, and can be detected only at higher temperatures. The results show that the α-MoC support in the 2%Pt/α-MoC catalyst serves as the centre of water dissociation and suppresses the side reaction of methanol decomposition at low temperatures. The combination of Pt1 and α-MoC renders this catalyst capable of water dissociation, C–H bond activation and reformation, and thus a good choice for low-temperature hydrogen production.

PowerPoint slides

Rights and permissions

About this article

Cite this article

Lin, L., Zhou, W., Gao, R. et al. Low-temperature hydrogen production from water and methanol using Pt/α-MoC catalysts. Nature 544, 80–83 (2017). https://doi.org/10.1038/nature21672

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature21672

This article is cited by

-

Investigating the role of undercoordinated Pt sites at the surface of layered PtTe2 for methanol decomposition

Nature Communications (2024)

-

Promoting Effect of Zn on Pd/MoC Catalyst for the Hydrogen Production From Methanol Steam Reforming

Catalysis Letters (2024)

-

Graphene-anchored sodium single atoms: A highly active and stable catalyst for transesterification reaction

Nano Research (2024)

-

The reformation of catalyst: From a trial-and-error synthesis to rational design

Nano Research (2024)

-

Direct synthesis of extra-heavy olefins from carbon monoxide and water

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.