Abstract

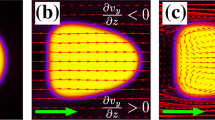

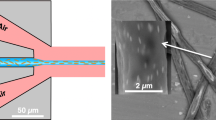

From drug delivery1,2 to chemical and biological catalysis3 and cosmetics4, the need for efficient fabrication pathways for particles over a wide range of sizes, from a variety of materials, and in many different structures has been well established5. Here we harness the inherent scalability of fibre production6 and an in-fibre Plateau–Rayleigh capillary instability7 for the fabrication of uniformly sized, structured spherical particles spanning an exceptionally wide range of sizes: from 2 mm down to 20 nm. Thermal processing of a multimaterial fibre8 controllably induces the instability9, resulting in a well-ordered, oriented emulsion10 in three dimensions. The fibre core and cladding correspond to the dispersed and continuous phases, respectively, and are both frozen in situ on cooling, after which the particles are released when needed. By arranging a variety of structures and materials in a macroscopic scaled-up model of the fibre, we produce composite, structured, spherical particles, such as core–shell particles, two-compartment ‘Janus’ particles11, and multi-sectioned ‘beach ball’ particles. Moreover, producing fibres with a high density of cores allows for an unprecedented level of parallelization. In principle, 108 50-nm cores may be embedded in metres-long, 1-mm-diameter fibre, which can be induced to break up simultaneously throughout its length, into uniformly sized, structured spheres.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Timko, B. P. et al. Advances in drug delivery. Annu. Rev. Mater. Res. 41, 1–20 (2011)

Wang, J., Byrne, J. D., Napier, M. E. & DeSimone, J. M. More effective nanomedicines through particle design. Small 7, 1919–1931 (2011)

Bell, A. T. The impact of nanoscience on heterogeneous catalysis. Science 299, 1688–1691 (2003)

Souto, E. B. & Müller, R. H. Cosmetic features and applications of lipid nanoparticles. Int. J. Cosmet. Sci. 30, 157–165 (2008)

Rotello, V. Nanoparticles: Building Blocks for Nanotechnology (Springer, 2003)

Li, T., ed. Optical Fiber Communications Vol. 1, Fiber Fabrication (Academic, 1985)

Eggers, J. & Villermaux, E. Physics of liquid jets. Rep. Prog. Phys. 71, 036601 (2008)

Abouraddy, A. F. et al. Towards multimaterial multifunctional fibres that see, hear, sense and communicate. Nature Mater. 6, 336–347 (2007)

Shabahang, S., Kaufman, J. J., Deng, D. S. & Abouraddy, A. F. Observation of the Plateau-Rayleigh capillary instability in multi-material optical fibers. Appl. Phys. Lett. 99, 161909 (2011)

Sjöblom, J. Encyclopedic Handbook of Emulsion Technology (Marcel Dekker, 2001)

Walther, A. & Müller, A. H. E. Janus particles. Soft Matter 4, 663–668 (2008)

Cao, G. Nanostructures and Nanomaterials: Synthesis, Properties and Applications (Imperial College Press, 2004)

Vollath, D. Nanomaterials: An Introduction to Synthesis, Properties and Application (Wiley-VCH, 2008)

Merkel, T. J. et al. Scalable shape-specific, top-down fabrication methods for the synthesis of engineered colloidal microparticles. Langmuir 26, 13086–13096 (2010)

Utada, A. S. et al. Monodisperse double emulsions generated from a microcapillary device. Science 308, 537–541 (2005)

Dendukuri, D. & Doyle, P. S. The synthesis and assembly of polymeric microparticles using microfluidics. Adv. Mater. 21, 4071–4086 (2009)

Dendukuri, D., Pregibon, D. C., Collins, J., Hatton, T. A. & Doyle, P. S. Continuous-flow lithography for high-throughput microparticle synthesis. Nature Mater. 5, 365–369 (2006)

Hernandez, C. J. & Mason, T. G. Colloidal alphabet soup: Monodisperse dispersions of shape-designed LithoParticles. J. Phys. Chem. C 111, 4477–4480 (2007)

Rolland, J. P. et al. Direct fabrication and harvesting of monodisperse, shape specific nano-biomaterials. J. Am. Chem. Soc. 127, 10096–10100 (2005)

Kaufman, J. J. et al. Thermal drawing of high-density macroscopic arrays of well-ordered sub-5-nm-diameter nanowires. Nano Lett. 11, 4768–4773 (2011)

Nie, Z. H. et al. Emulsification in a microfluidic flow-focusing device: Effect of the viscosities of the liquids. Microfluidics and Nanofluidics 5, 585–594 (2008)

Tomotika, S. On the instability of a cylindrical thread of a viscous liquid surrounded by another viscous fluid. Proc. R. Soc. Lond. A 150, 322–337 (1935)

Deng, D. S. et al. In-fiber nanoscale semiconductor filament arrays. Nano Lett. 8, 4265–4269 (2008)

Nisisako, T. & Torii, T. Microfluidic large-scale integration on a chip for mass production of monodisperse droplets and particles. Lab Chip 8, 287–293 (2008)

Liang, X., Deng, D. S., Nave, J.-C. & Johnson, S. G. Linear stability analysis of capillary instabilities for concentric cylindrical shells. J. Fluid Mech. 683, 235–262 (2011)

Deng, D. S., Nave, J.-C., Liang, X., Johnson, S. G. & Fink, Y. Exploration of in-fiber nanostructures from capillary instability. Opt. Express 19, 16273–16290 (2011)

Smith, K. A., Solis, F. J. & Chopp, D. L. A projection method for motion of triple junctions by levels sets. Interfaces Free Bound. 4, 263–276 (2002)

Dussan, V. E. B. On the spreading of liquids on solid surfaces: static and dynamic contact lines. Annu. Rev. Fluid Mech. 11, 371–400 (1979)

de Gennes, P. G. Wetting: statics and dynamics. Rev. Mod. Phys. 57, 827–863 (1985)

Israelachvili, J. N. Intermolecular and Surface Forces (Academic, 1992)

Ballato, J. et al. Advancements in semiconductor core optical fiber. Opt. Fiber Technol. 16, 399–408 (2010)

Orf, N. D. et al. Fiber draw synthesis. Proc. Natl Acad. Sci. USA 108, 4743–4747 (2011)

Acknowledgements

Work at UCF was supported by the US National Science Foundation (award number ECCS-1002295), a Ralph E. Powe Junior Faculty Enhancement Award from the Oak Ridge Associated Universities (ORAU), in part by the US Air Force Office of Scientific Research (AFOSR) under contract FA-9550-12-1-0148, and by CREOL, The College of Optics & Photonics. Work at MIT was supported in part by the Materials Research Science and Engineering Program of the US NSF under award number DMR-0819762, and also in part by the US Army Research Office through the Institute for Soldier Nanotechnologies under contract number W911NF-07-D-0004. We thank Sasha Stolyarov, J. Manuel Perez, Sudipta Seal and Kirk Scammon for assistance. We especially thank M. J. Soileau, B. E. A. Saleh, D. N. Christodoulides and M. Z. Bazant for encouragement and support.

Author information

Authors and Affiliations

Contributions

J.J.K., Y.F. and A.F.A. developed and directed the project. S.S. first observed the PRI phenomenon, developed the fibre tapering process and the particle extraction approach, and demonstrated the scale invariance of the PRI and particle extraction strategies. G.T. prepared and characterized all the glasses, carried out the preform extrusions, and produced the ‘beach ball’ fibre. J.J.K. produced the other preforms and fibres, performed PRI breakup and particle extraction experiments, and carried out the SEM, EDX, FIB and optical imaging and characterization. E.-H.B. aided in choice and characterization of materials and in preparation of the polymers. D.S.D., X.L. and S.G.J. carried out the theoretical calculations and performed the simulations. J.J.K., D.S.D., Y.F. and A.F.A. wrote the paper. All authors contributed to the interpretation of the results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

This file contains Supplementary Text and Data, Supplementary Table 1, Supplementary Figures 1-10, legend for Supplementary Movie 1 and additional references. (PDF 1065 kb)

Supplementary Movie 1

This file contains a movie showing computed core-shell particle breakup dynamics (see Supplementary Information file for full legend). (MP4 1760 kb)

Rights and permissions

About this article

Cite this article

Kaufman, J., Tao, G., Shabahang, S. et al. Structured spheres generated by an in-fibre fluid instability. Nature 487, 463–467 (2012). https://doi.org/10.1038/nature11215

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature11215

This article is cited by

-

Design, fabrication and assembly considerations for electronic systems made of fibre devices

Nature Reviews Materials (2023)

-

Multimaterial fiber as a physical simulator of a capillary instability

Nature Communications (2023)

-

Analytical instability theory of a liquid jet under a thermal field

Acta Mechanica Sinica (2023)

-

Industrial scale production of fibre batteries by a solution-extrusion method

Nature Nanotechnology (2022)

-

Bubble casting soft robotics

Nature (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.