Abstract

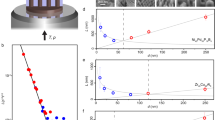

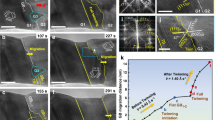

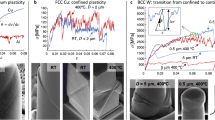

Deformation twinning1,2,3,4,5,6 in crystals is a highly coherent inelastic shearing process that controls the mechanical behaviour of many materials, but its origin and spatio-temporal features are shrouded in mystery. Using micro-compression and in situ nano-compression experiments, here we find that the stress required for deformation twinning increases drastically with decreasing sample size of a titanium alloy single crystal7,8, until the sample size is reduced to one micrometre, below which the deformation twinning is entirely replaced by less correlated, ordinary dislocation plasticity. Accompanying the transition in deformation mechanism, the maximum flow stress of the submicrometre-sized pillars was observed to saturate at a value close to titanium’s ideal strength9,10. We develop a ‘stimulated slip’ model to explain the strong size dependence of deformation twinning. The sample size in transition is relatively large and easily accessible in experiments, making our understanding of size dependence11,12,13,14,15,16,17 relevant for applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Chen, M. W. et al. Deformation twinning in nanocrystalline aluminum. Science 300, 1275–1277 (2003)

Christian, J. W. & Mahajan, S. Deformation twinning. Prog. Mater. Sci. 39, 1–157 (1995)

Ogata, S., Li, J. & Yip, S. Energy landscape of deformation twinning in bcc and fcc metals. Phys. Rev. B 71, 224102 (2005)

Wu, X. L. & Zhu, Y. T. Inverse grain-size effect on twinning in nanocrystalline Ni. Phys. Rev. Lett. 101, 025503 (2008)

Warner, D. H., Curtin, W. A. & Qu, S. Rate dependence of crack-tip processes predicts twinning trends in f.c.c. metals. Nature Mater. 6, 876–881 (2007)

Niewczas, M. in Dislocations in Solids Vol. 13 (eds Nabarro, F. R. N. & Hirth, J. P.) 263–364 (Elsevier, 2007)

Song, S. G. & Gray, G. T. Structural interpretation of the nucleation and growth of deformation twins in Zr and Ti. Acta Metall. Mater. 43, 2325–2350 (1995)

Williams, J. C., Baggerly, R. G. & Paton, N. E. Deformation behavior of HCP Ti-Al alloy single crystals. Metall. Mater. Trans. A 33, 837–850 (2002)

Ogata, S., Li, J., Hirosaki, N., Shibutani, Y. & Yip, S. Ideal shear strain of metals and ceramics. Phys. Rev. B 70, 104104 (2004)

Suresh, S. & Li, J. Deformation of the ultra-strong. Nature 456, 716–717 (2008)

Lu, L., Chen, X., Huang, X. & Lu, K. Revealing the maximum strength in nanotwinned copper. Science 323, 607–610 (2009)

Argon, A. S. & Yip, S. The strongest size. Phil. Mag. Lett. 86, 713–720 (2006)

Schiotz, J. & Jacobsen, K. W. A maximum in the strength of nanocrystalline copper. Science 301, 1357–1359 (2003)

Shan, Z. W. et al. Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305, 654–657 (2004)

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004)

Shan, Z. W., Mishra, R. K., Asif, S. A. S., Warren, O. L. & Minor, A. M. Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nature Mater. 7, 115–119 (2008)

Greer, J. R., Oliver, W. C. & Nix, W. D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821–1830 (2005)

Meyers, M. A., Vohringer, O. & Lubarda, V. A. The onset of twinning in metals: a constitutive description. Acta Mater. 49, 4025–4039 (2001)

Stanford, N., Carlson, U. & Barnett, M. R. Deformation twinning and the Hall-Petch relation in commercial purity Ti. Metall. Mater. Trans. A 39, 934–944 (2008)

El-Danaf, E., Kalidindi, S. R. & Doherty, R. D. Influence of grain size and stacking-fault energy on deformation twinning in fcc metals. Metall. Mater. Trans. A 30, 1223–1233 (1999)

Paton, N. E. & Backofen, W. A. Plastic deformation of titanium at elevated temperatures. Metall. Trans. 1, 2839–2847 (1970)

Akhtar, A. Basal slip and twinning in alpha-titanium single-crystals. Metall. Trans. A 6, 1105–1113 (1975)

Yoo, M. H. Twinning and mechanical behavior of titanium aluminides and other intermetallics. Intermetallics 6, 597–602 (1998)

Xiao, L. Twinning behavior in the Ti-5 at.% Al single crystals during cyclic loading along. Mater. Sci. Eng. A 394, 168–175 (2005)

Svelto, O. Principles of Lasers (Springer, 1998)

Cottrell, A. H. & Bilby, B. A. A mechanism for the growth of deformation twins in crystals. Phil. Mag. 42, 573–581 (1951)

Niewczas, M. & Saada, G. Twinning nucleation in Cu-8 at.% Al single crystals. Phil. Mag. A 82, 167–191 (2002)

Song, S. G. & Gray, G. T. Double dislocation pole model for deformation twinning in fcc lattices. Phil. Mag. A 71, 661–670 (1995)

El-Azab, A. The statistical mechanics of strain-hardened metals. Science 320, 1729–1730 (2008)

Zhu, T., Li, J., Samanta, A., Leach, A. & Gall, K. Temperature and strain-rate dependence of surface dislocation nucleation. Phys. Rev. Lett. 100, 025502 (2008)

Acknowledgements

We thank Q. Liu for help with EBSD experiments. This work was supported by grants from the NSFC (50671077, 50720145101, 50831004 and 50925104), the 973 Program of China (2004CB619303, 2007CB613804 and 2010CB613003) and the 111 Project of China (B06025). J.L. was supported by ONR grant N00014-05-1-0504, NSF grant CMMI-0728069, MRSEC grant DMR-0520020 and AFOSR grant FA9550-08-1-0325. X.H. was supported by the Danish National Research Foundation. The in situ TEM work was performed at the National Center for Electron Microscopy, Lawrence Berkeley Laboratory, which is supported by the US Department of Energy under contract DE-AC02-05CH11231.

Author Contributions Q.Y. and Z.-W.S. carried out the experiments, J.L. constructed the model, X.H. interpreted the EBSD results, L.X. supervised the sample selection, J.S. designed the project, J.L. and E.M. wrote the paper. All authors contributed to the discussions.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

This file contains Supplementary Figure S1- S5 with Legends, Supplementary Methods, Supplementary Table S1, Supplementary Data and Supplementary References. (PDF 732 kb)

Supplementary Movie 1

This movie shows the in situ compression of the 250 nm Ti-5at% Al single crystal pillar in TEM. (MOV 7748 kb)

Rights and permissions

About this article

Cite this article

Yu, Q., Shan, ZW., Li, J. et al. Strong crystal size effect on deformation twinning. Nature 463, 335–338 (2010). https://doi.org/10.1038/nature08692

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nature08692

This article is cited by

-

Atomic-scale observation of nucleation- and growth-controlled deformation twinning in body-centered cubic nanocrystals

Nature Communications (2024)

-

Size-dependent thermoelastic damping analysis in functionally graded bi-layered microbeam resonators considering the nonlocal dual-phase-lag heat conduction model

Archive of Applied Mechanics (2024)

-

Trifunctional nanoprecipitates ductilize and toughen a strong laminated metastable titanium alloy

Nature Communications (2023)

-

Harnessing dislocation motion using an electric field

Nature Materials (2023)

-

Effect of Pyramidal Plane II Twinning in Tensile Deformation on Tensile–Compression Yield Asymmetry in Three Orthogonal Directions of Mg Alloy

Journal of Materials Engineering and Performance (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.