Abstract

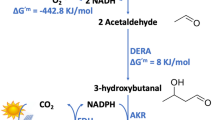

Global energy and environmental problems have stimulated increased efforts towards synthesizing biofuels from renewable resources1,2,3. Compared to the traditional biofuel, ethanol, higher alcohols offer advantages as gasoline substitutes because of their higher energy density and lower hygroscopicity. In addition, branched-chain alcohols have higher octane numbers compared with their straight-chain counterparts. However, these alcohols cannot be synthesized economically using native organisms. Here we present a metabolic engineering approach using Escherichia coli to produce higher alcohols including isobutanol, 1-butanol, 2-methyl-1-butanol, 3-methyl-1-butanol and 2-phenylethanol from glucose, a renewable carbon source. This strategy uses the host’s highly active amino acid biosynthetic pathway and diverts its 2-keto acid intermediates for alcohol synthesis. In particular, we have achieved high-yield, high-specificity production of isobutanol from glucose. The strategy enables the exploration of biofuels beyond those naturally accumulated to high quantities in microbial fermentation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lin, Y. L. & Blaschek, H. P. Butanol production by a butanol-tolerant strain of Clostridium acetobutylicum in extruded corn broth. Appl. Environ. Microbiol. 45, 966–973 (1983)

Nair, R. V., Bennett, G. N. & Papoutsakis, E. T. Molecular characterization of an aldehyde/alcohol dehydrogenase gene from Clostridium acetobutylicum ATCC 824. J Bacteriol. 176, 871–885 (1994)

Ingram, L. O. et al. Enteric bacterial catalysts for fuel ethanol production. Biotechnol. Prog. 15, 855–866 (1999)

Sentheshanuganathan, S. The mechanism of the formation of higher alcohols from amino acids by Saccharomyces cerevisiae . Biochem. J. 74, 568–576 (1960)

Dickinson, J. R. et al. A 13C nuclear magnetic resonance investigation of the metabolism of leucine to isoamyl alcohol in Saccharomyces cerevisiae . J. Biol. Chem. 272, 26871–26878 (1997)

Dickinson, J. R., Harrison, S. J. & Hewlins, M. J. An investigation of the metabolism of valine to isobutyl alcohol in Saccharomyces cerevisiae . J. Biol. Chem. 273, 25751–25756 (1998)

Dickinson, J. R., Harrison, S. J., Dickinson, J. A. & Hewlins, M. J. An investigation of the metabolism of isoleucine to active Amyl alcohol in Saccharomyces cerevisiae . J. Biol. Chem. 275, 10937–10942 (2000)

Dickinson, J. R. et al. The catabolism of amino acids to long chain and complex alcohols in Saccharomyces cerevisiae . J. Biol. Chem. 278, 8028–8034 (2003)

Farmer, W. R. & Liao, J. C. Improving lycopene production in Escherichia coli by engineering metabolic control. Nature Biotechnol. 18, 533–537 (2000)

Khosla, C. & Keasling, J. D. Metabolic engineering for drug discovery and development. Nature Rev. Drug Discov. 2, 1019–1025 (2003)

Barbirato, F., Grivet, J. P., Soucaille, P. & Bories, A. 3-Hydroxypropionaldehyde, an inhibitory metabolite of glycerol fermentation to 1,3-propanediol by enterobacterial species. Appl. Environ. Microbiol. 62, 1448–1451 (1996)

Zhu, M. M., Lawman, P. D. & Cameron, D. C. Improving 1,3-propanediol production from glycerol in a metabolically engineered Escherichia coli by reducing accumulation of sn-glycerol-3-phosphate. Biotechnol. Prog. 18, 694–699 (2002)

Pitera, D. J., Paddon, C. J., Newman, J. D. & Keasling, J. D. Balancing a heterologous mevalonate pathway for improved isoprenoid production in Escherichia coli . Metab. Eng. 9, 193–207 (2007)

Sentheshanmuganathan, S. & Elsden, S. R. The mechanism of the formation of tyrosol by Saccharomyces cerevisiae . Biochem. J. 69, 210–218 (1958)

Konig, S. Subunit structure, function and organisation of pyruvate decarboxylases from various organisms. Biochim. Biophys. Acta 1385, 271–286 (1998)

Hohmann, S. Characterization of PDC6, a third structural gene for pyruvate decarboxylase in Saccharomyces cerevisiae . J. Bacteriol. 173, 7963–7969 (1991)

Vuralhan, Z., Morais, M. A., Tai, S. L., Piper, M. D. & Pronk, J. T. Identification and characterization of phenylpyruvate decarboxylase genes in Saccharomyces cerevisiae . Appl. Environ. Microbiol. 69, 4534–4541 (2003)

de la Plaza, M., Fernandez de Palencia, P., Pelaez, C. & Requena, T. Biochemical and molecular characterization of α-ketoisovalerate decarboxylase, an enzyme involved in the formation of aldehydes from amino acids by Lactococcus lactis . FEMS Microbiol. Lett. 238, 367–374 (2004)

Russell, D. W., Smith, M., Williamson, V. M. & Young, E. T. Nucleotide sequence of the yeast alcohol dehydrogenase II gene. J. Biol. Chem. 258, 2674–2682 (1983)

Lutz, R. & Bujard, H. Independent and tight regulation of transcriptional units in Escherichia coli via the LacR/O, the TetR/O and AraC/I1–I2 regulatory elements. Nucleic Acids Res. 25, 1203–1210 (1997)

Gollop, N., Damri, B., Chipman, D. M. & Barak, Z. Physiological implications of the substrate specificities of acetohydroxy acid synthases from varied organisms. J. Bacteriol. 172, 3444–3449 (1990)

Woods, D. R. The genetic engineering of microbial solvent production. Trends Biotechnol. 13, 259–264 (1995)

Bogosian, G. et al. Biosynthesis and incorporation into protein of norleucine by Escherichia coli . J. Biol. Chem. 264, 531–539 (1989)

Calhoun, D. H., Rimerman, R. A. & Hatfield, G. W. Threonine deaminase from Escherichia coli. I. Purification and properties. J. Biol. Chem. 248, 3511–3516 (1973)

Charon, N. W., Johnson, R. C. & Peterson, D. Amino acid biosynthesis in the spirochete Leptospira: evidence for a novel pathway of isoleucine biosynthesis. J. Bacteriol. 117, 203–211 (1974)

Howell, D. M., Xu, H. & White, R. H. (R)-citramalate synthase in methanogenic archaea. . J. Bacteriol. 181, 331–333 (1999)

Xu, H. et al. Isoleucine biosynthesis in Leptospira interrogans serotype lai strain 56601 proceeds via a threonine-independent pathway. J. Bacteriol. 186, 5400–5409 (2004)

Flint, D. H., Emptage, M. H., Finnegan, M. G., Fu, W. & Johnson, M. K. The role and properties of the iron-sulfur cluster in Escherichia coli dihydroxy-acid dehydratase. J. Biol. Chem. 268, 14732–14742 (1993)

Miwa, K. et al. Construction of L-threonine overproducing strains of Escherichia coli K-12 using recombinant DNA techniques. Agric. Biol. Chem. 47, 2329–2334 (1983)

Alper, H., Moxley, J., Nevoigt, E., Fink, G. R. & Stephanopoulos, G. Engineering yeast transcription machinery for improved ethanol tolerance and production. Science 314, 1565–1568 (2006)

Acknowledgements

This work was partially supported by UCLA-DOE Institute for Genomics and Proteomics. We are grateful to H. Bujard for plasmids, and members of the Liao laboratory for discussion and comments on the manuscript.

Author Contributions S.A. and J.C.L. designed experiments; S.A. and T.H. performed the experiments; S.A. and J.C.L. analysed the data; and S.A. and J.C.L. wrote the paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The University of California has filed a provisional patent application based on this work, and has licensed the technology to Gevo, a biofuel company. J.C.L. serves on the Scientific Advisory Board of Gevo. No financial support was received from Gevo to support this work.

Supplementary information

Supplementary Information

The file contains Supplementary Figures 1-4 with Legends and Supplementary Tables 1-4. (PDF 361 kb)

Rights and permissions

About this article

Cite this article

Atsumi, S., Hanai, T. & Liao, J. Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels. Nature 451, 86–89 (2008). https://doi.org/10.1038/nature06450

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nature06450

This article is cited by

-

Elucidation of unusual biosynthesis and DnaN-targeting mode of action of potent anti-tuberculosis antibiotics Mycoplanecins

Nature Communications (2024)

-

Microbial host engineering for sustainable isobutanol production from renewable resources

Applied Microbiology and Biotechnology (2024)

-

Growth-coupled anaerobic production of isobutanol from glucose in minimal medium with Escherichia coli

Biotechnology for Biofuels and Bioproducts (2023)

-

Biosynthesis pathways of expanding carbon chains for producing advanced biofuels

Biotechnology for Biofuels and Bioproducts (2023)

-

Synthesis of isobutanol using acetate as sole carbon source in Escherichia coli

Microbial Cell Factories (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.