Abstract

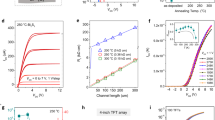

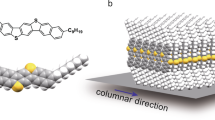

The use of solution processes—as opposed to conventional vacuum processes and vapour-phase deposition—for the fabrication of electronic devices has received considerable attention for a wide range of applications1,2,3,4,5,6,7, with a view to reducing processing costs. In particular, the ability to print semiconductor devices using liquid-phase materials could prove essential for some envisaged applications, such as large-area flexible displays. Recent research in this area has largely been focused on organic semiconductors8,9,10,11, some of which have mobilities comparable to that of amorphous silicon11 (a-Si); but issues of reliability remain. Solution processing of metal chalcogenide semiconductors to fabricate stable and high-performance transistors has also been reported12,13. This class of materials is being explored as a possible substitute for silicon, given the complex and expensive manufacturing processes required to fabricate devices from the latter. However, if high-quality silicon films could be prepared by a solution process, this situation might change drastically. Here we demonstrate the solution processing of silicon thin-film transistors (TFTs) using a silane-based liquid precursor. Using this precursor, we have prepared polycrystalline silicon (poly-Si) films by both spin-coating and ink-jet printing, from which we fabricate TFTs with mobilities of 108 cm2 V-1 s-1 and 6.5 cm2 V-1 s-1, respectively. Although the processing conditions have yet to be optimized, these mobilities are already greater than those that have been achieved in solution-processed organic TFTs, and they exceed those of a-Si TFTs (≤ 1 cm2 V-1 s-1).

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Shimoda, T. et al. Multicolor pixel patterning of light-emitting polymers by ink-jet printing. In 1999 SID International Symposium Digest of Technical Papers 376–379 (Society for Information Display, San Jose, 1999).

Miyashita, S. et al. Full color displays fabricated by ink-jet printing. In Proc. 21st International Display Research Conference in Conjunction with 8th International Display Workshop (Asia Display / IDW '01) 1399–1402 (2001)

Peumans, P., Uchida, S. & Forrest, S. R. Efficient bulk heterojunction photovoltaic cells using small-molecular-weight organic thin films. Nature 425, 158–162 (2003)

Okamura, S., Takeuchi, R. & Shiozaki, T. Fabrication of ferroelectric Pb(Zr,Ti)3 thin films with various Zr/Ti ratios by ink-jet printing. Jpn. J. Appl. Phys. 41, 6714–6717 (2002)

Tahar, R. B. H., Ban, T., Ohya, Y. & Takahashi, Y. Optical, structural, and electrical properties of indium oxide thin films prepared by the sol-gel method. J. Appl. Phys. 82, 865–870 (1997)

Yudasaka, I., Tanaka, H., Miyasaka, M., Inoue, S. & Shimoda, T. Poly-Si thin-film transistors using polysilazane-based spin-on glass for all dielectric layers. In 2004 SID International Symposium Digest of Technical Papers 964–967 (Society for Information Display, San Jose, 2004).

Furusawa, M. et al. Inkjet-printed bus and address electrodes for plasma display. In 2002 SID International Symposium Digest of Technical Papers 753–755 (Society for Information Display, San Jose, 2002)

Sirringhaus, H. et al. High-resolution inkjet printing of all-polymer transistor circuits. Science 290, 2123–2126 (2000)

Kawase, T., Sirringhaus, H., Friend, R. H. & Shimoda, T. All-polymer thin film transistors fabricated by high-resolution ink-jet printing. In 2000 International Electron Device Meeting (IEDM) Tech. Digest 623–626 (2000)

Gelinck, G. H. et al. Flexible active-matrix displays and shift registers based on solution-processed organic transistors. Nature Mater. 3, 106–110 (2004)

Afzali, A., Dimitrakopoulos, C. D. & Breen, T. L. High-performance, solution-processed organic thin film transistors from a novel pentacene precursor. J. Am. Chem. Soc. 124, 8812–8813 (2002)

Ridley, B. A., Nivi, B. & Jacobson, J. M. All-inorganic field effect transistors fabricated by printing. Science 286, 746–749 (1999)

Mitzi, D. B., Kosbar, L. L., Murray, C. E., Copel, M. & Afzali, A. High-mobility ultrathin semiconducting films prepared by spin coating. Nature 428, 299–303 (2004)

Aoki, T. et al. Method of manufacturing device, device, and electronic apparatus. US Patent Application 0029364 (2004).

Shimoda, T. et al. Method for forming silicon film. US Patent 6541354 (2003).

Kipping, F. S. Organic derivatives of silicon. Complex silicohydrocarbons [SiPh2]n . J. Chem. Soc. 125, 2291–2297 (1924)

John, P., Oder, I. M. & Wood, J. The electrical conductivity of polysilane, (SiH2)x . J. Chem. Soc. Chem. Commun. 1496–1497 (1983)

Suzuki, M., Kotani, J., Gyobu, S., Kaneko, T. & Saegusa, T. Synthesis of sequence-ordered polysilane by anionic ring-opening polymerization of phenylnonamethycyclopentasilane. Macromolecules 27, 2360–2363 (1994)

Cypryk, M., Gupta, Y. & Matyjaszewski, K. Anionic ring-opening polymerization of 1,2,3,4-tetramethyl-1,2,3,4-tetraphenylcyclotetrasilane. J. Am. Chem. Soc. 113, 1046–1047 (1991)

Hengge, E. & Bauer, G. Cyclopentasilan, das erste unsubstituierte cyclische Siliciumhydrid. Angew. Chem. 85, 304–305 (1973)

Hengge, E. & Bauer, G. Darstellung und Eigenschaften von Cyclopentasilan. Monatsh. Chem. 106, 503–512 (1975)

Raabe, G. & Michl, J. Multiple bonding to silicon. Chem. Rev. 85, 419–509 (1985)

Sameshima, T., Usui, S. & Sekiya, M. XeCl excimer laser annealing used in the fabrication of poly-Si TFTs. IEEE Electron Device Lett. 7, 276–278 (1986)

Kitahara, K., Yamazaki, R., Kurosawa, T., Nakajima, K. & Moritani, A. Analysis of stress in laser-crystallized polysilicon thin films by Raman scattering spectroscopy. Jpn. J. Appl. Phys. 41, 5055–5059 (2002)

Chatgilialoglu, C. et al. Autoxidation of poly(hydrosilane)s. Organometallics 17, 2169–2176 (1998)

Morii, K. et al. Characterization of light-emitting polymer devices prepared by ink-jet printing. In Proc. 10th Int. Workshop on Inorganic and Organic Electroluminescence 357–360 (2000)

Morii, K., Masuda, T., Ishida, M., Hotta, S. & Shimoda, T. The direct patterning of crystalline organic-semiconductor films on a substrate by ink-jet printing. In Proc. Int. Conference on Synthetic Metals 126–127 (2004)

Acknowledgements

We thank the members of Seiko Epson Corporation's pilot line and ink-jet industrial application project, for fabricating TFTs and ink-jet experiments in this research. This work is partially supported by a grant from the New Energy and Industrial Technology Development Organization (NEDO).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

Reprints and permissions information is available at npg.nature.com/reprintsandpermissions. The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Shimoda, T., Matsuki, Y., Furusawa, M. et al. Solution-processed silicon films and transistors. Nature 440, 783–786 (2006). https://doi.org/10.1038/nature04613

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/nature04613

This article is cited by

-

Electrodeposition of silicon films from organic solvents on nanoporous copper substrates

Journal of Applied Electrochemistry (2024)

-

Surface engineering of zinc phthalocyanine organic thin-film transistors results in part-per-billion sensitivity towards cannabinoid vapor

Communications Chemistry (2022)

-

Steering and in situ monitoring of drying phenomena during film fabrication

Journal of Coatings Technology and Research (2019)

-

Solution-based polycrystalline silicon transistors produced on a paper substrate

npj Flexible Electronics (2017)

-

Effects of laser parameters on optoelectronic properties of polycrystalline silicon films prepared by two-step annealing process

The International Journal of Advanced Manufacturing Technology (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.