Abstract

In a conventional flat plate solar cell under direct sunlight, light is received from the solar disk, but is re-emitted isotropically. This isotropic emission corresponds to a significant entropy increase in the solar cell, with a corresponding drop in efficiency. Here, using a detailed balance model, we show that limiting the emission angle of a high-quality GaAs solar cell is a feasible route to achieving power conversion efficiencies above 38% with a single junction. The highest efficiencies are predicted for a thin, light trapping cell with an ideal back reflector, though the scheme is robust to a non-ideal back reflector. Comparison with a conventional planar cell geometry illustrates that limiting emission angle in a light trapping geometry not only allows for much thinner cells, but also for significantly higher overall efficiencies with an excellent rear reflector. Finally, we present ray-tracing and detailed balance analysis of two angular coupler designs, show that significant efficiency improvements are possible with these couplers, and demonstrate initial fabrication of one coupler design.

Similar content being viewed by others

Introduction

Under direct sunlight, conventional solar cells emit light isotropically, while receiving light only from the angles spanned by the solar disk. This increase in the angular distribution of light increases the photon entropy, and the inherent entropy increase reduces the solar cell efficiency. Thus, efficiency may be increased by reducing the angular spread of emitted light from the solar power conversion system.1,2,3,4 As shown in Figure 1a, concentrating solar systems partially exploit this angular photon entropy term by redirecting the solar cell light emission into a narrow angular range, giving efficiency increases at low concentration ratios due to increased current densities and resulting increases in voltage. However, concentrators do not realize all the potential gains from reducing the angular spread of emitted light because as the sunlight concentration and current density rise increased series resistance and heating degrade the efficiency.5,6,7

Photon entropy in concentrator and angularly restricted systems. (a) A concentrator system takes the light emitted from all angles in a solar cell and reflects it to within a narrow range of angles. As concentration ratio increases, the emission angle from the concentrator is reduced, so to fully reduce the angle of emission, maximum concentration is required. This corresponds to maximal theoretical efficiency in a concentrator system, due to the increase in short circuit current density, qVoc≈kTln(Jsc/Jo), where Jsc is the short ciruit current density and Jo is the dark current density. (b) We propose a design for a thin coupler which limits the emission angle without concentrating thereby avoiding deleterious heating and series resistance effects. The efficiency gains are via photon recycling, as illustrated by the arrows, representing radiatively emitted photons. This photon recycling gain corresponds to a dark current reduction in the expression above, as in high-quality GaAs the dark current is dominated by radiative emission from the cell. Key to achieving the highest possible efficiencies with this design are the thin cell and the highly reflective, light trapping back reflector shown in the schematic.

Here we consider a non-concentrating system with limited emission angle in a thin, light trapping GaAs solar cell with high radiative efficiency, as shown in Figure 1b. While this approach also addresses angular photon entropy, the specific mechanism of the efficiency increase is due to photon recycling, as photons that would otherwise be radiatively emitted from the cell are reflected back into the cell and reabsorbed.4 Using a detailed balance model that accounts for realistic semiconductor absorption, emission and recombination, as well as the limited number of optical modes in thin film cells, we demonstrate that efficiencies exceeding 38% are potentially achievable with limited emission angle and an ideal back reflector. Furthermore, we find that the scheme is robust to a non-ideal back reflector.

Figure 1 contrasts the scheme considered here with a traditional concentrator cell. As with a concentrator cell, only the direct portion of the solar radiation can be utilized, and solar tracking is required. By limiting the solar cell emission angle, as shown in Figure 1b, photons emitted by radiative recombination are less likely to escape from a solar cell, reducing dark current and increasing efficiency. This photon recycling effect is inherent in Shockley and Queisser’s original detailed balance analysis, but the limited emission angle case was not considered explicitly.1 While it has been calculated that limiting emission angle could yield efficiencies exceeding 40%, more recent work analyzing this effect in a planar GaAs cell concluded that no advantage would exist for a realistic material owing to non-radiative recombination.3,4 In contrast, we find that utilizing a light-trapping, rather than planar, cell geometry mitigates losses from non-radiative recombination and allows for significant benefits.

In a light trapping geometry, light is randomized inside the solar cell to increase the optical path length. By limiting the solar cell emission angle in this geometry, the optical escape cone is reduced for enhanced light trapping.8,9 Previously, efficiency benefits under angular restriction were considered with silicon in a light-trapping geometry.2 However, photon recycling benefits are minimal due to low radiative efficiency in silicon and were not included in the model. Here we consider a light-trapping GaAs cell where photon recycling is much more prominent owing to high radiative efficiency in GaAs. Thus, while previous work considered either light trapping or photon recycling, the thin, light-trapping GaAs solar cells considered here maximize both of these effects and we find a new regime of higher efficiencies that were not previously considered achievable for a single-junction solar cell under one sun illumination.2,4,10 We also illustrate that this approach is robust to a non-ideal back reflector and that a light trapping, as opposed to planar, geometry allows for thinner cells with higher overall efficiencies.

Materials and methods

We implement a detailed balance model, which accounts for photon recycling and is fairly realistic in GaAs, as experimental GaAs cells have recently come within a few percentage points of the detailed balance efficiency limit with high radiative efficiency.11,12 As in previous work, we initially assume that all recombination is radiative so at open circuit the only route for carrier loss from the cell is via a radiatively emitted photon.1,4,8 As the sun shines on the cell, the carrier concentration and chemical potential inside the cell increase, increasing the rate of radiatively emitted photon loss until steady state is reached. At steady state, the carriers created from the solar photons absorbed by the cell must equal the carriers lost via radiatively emitted photons leaving the cell:

where a(E) is the fraction of photons at energy E, absorbed by the solar cell, Ωc is the solid angle the cell emits into, S(E) is the solar spectrum, and qVoc equals the chemical potential of the cell.4 The left side is the flux of solar photons absorbed by the cell, and the right side is the flux of radiatively emitted photons leaving the cell as given by Planck’s law with increased emission owing to the chemical potential, or voltage, of the cell. To find the net current at conditions other than open circuit, Voc is replaced by an input voltage, and the radiatively emitted flux from the cell is subtracted from the solar flux. Tracing out the current–voltage relationship in this way, we find the maximum power point and the cell efficiency.

With tighter angular restriction, the absorptivity increases in a light trapping cell geometry.2,9 While previous analyses calculated the absorption with angle restriction in the ray optics limit, the thinner cells considered here have a modal structure that must be accounted for. To accurately model thin cells, we follow the approach taken by Stuart and Hall, with modification to account for angle restriction.13 The fundamental assumption is that all optical modes are equally occupied by some scattering mechanism, such as a textured surface. We calculate the modal structure for a GaAs cell clad with thick layers of silicon nitride, neglecting absorption. The modal occupancy is then found as a function of the light intensity entering the cell from the free space optical modes which are reduced by a factor of sin2(θ), where θ is the angle of emission, to account for angle restriction. The resulting absorption expression, given in the supplemental information, reproduces the ray optics result for limited emission angle, and the original absorption expression when the angle is unrestricted.

The detailed balance model was implemented in Matlab using the optical constants of GaAs and the AM 1.5 direct solar spectrum; it neglects shunt and series resistance effects. Throughout this paper, we assume that there are perfect antireflection coatings at all interfaces, owing to the advanced state of this technology.14

Including Auger recombination in the detailed balance equation gives:

where C is the Auger coefficient of 7×10−30 cm6 s−1, and ni is the intrinsic carrier concentration in GaAs.10,15,16 This expression is applicable under high injection, where the carrier concentration is dominated by light generation and is proportional to (for a discussion of general, rather that Auger, non-radiative recombination with a constant internal fluorescence yield, see the supplemental information). High quality material with a Shockley–Read–Hall lifetime greater than 14.3 μs and surface recombination velocity less than 1.75 cm s−1 for a 500-nm-thick cell is required for Auger recombination to be dominant at open circuit. Finally, for a non-ideal back reflector, we must consider parasitic absorption of both incoming and radiatively emitted photons. In the Stuart and Hall formalism, we account for parasitic absorption in the radiating modes of the cell to find the expressions given in the supplemental. We note that the expression for parasitic absorption of emitted light is applicable in both the planar and light trapping cases, as radiative emission randomizes the light in a planar cell. Absorption in the semiconductor for the planar case was calculated by considering the path of light inside the cell and the losses at the reflector, as shown in the supplemental.

The ray tracing of coupler designs was performed using a Matlab code. Each ray is defined by an in-plane and out-of-plane angle relative to the plane of the coupler top, as well as the ray’s starting location on the top of the cone structure. For each in-plane and out-of-plane angle, we average rays starting at different points on the cone top, and then average over the in-plane angles. To incorporate the coupler results into the detailed balance model, the factors of sin2(θ) in the previous equations are replaced by angular transmission averages from ray-tracing. The cone or cup-like structures we ray trace have the side curvature of a compound parabolic concentrator, or compound parabolic concentrator (CPC).17 However, in the double-array dielectric case, the curvature of each portion of the side, as defined by the CPC shape acceptance angle, is modified so that the top of the cone-type object has a hexagonal cross-section, allowing for an array of close-packed structures with circular openings at the bottom.

The fabricated coupling structures were written into IP-L resist using the Nanoscribe Photonic Professional two-photon lithography system.18 To prepare the sample for writing, optical coupling fluid was placed on one side of a glass slide, and IP-L placed on the other. After writing, development in 2-propanol for 20 min, which removes all unwritten IP-L and the optical coupling fluid, was followed by drying of the glass slide. The structures written in resist remained on the glass slide and were then coated with a 20-nm layer of sputtered chromium to aid conductivity for imaging. A focused gallium ion beam (9.7 pA, 30 kV) was used to mill circular apertures through the base of the parabolas into the substrate. The scanning electron microscopic image shown was taken at 25° and 5.05 kV of accelerating voltage.

Results and discussion

Figure 2a gives detailed balance efficiencies calculated for various GaAs cell thicknesses with a light trapping cell geometry and no non-radiative recombination. With narrow angle restriction, cell performance is independent of cell thickness, as increased light trapping allows all the light to be absorbed within even a 50-nm-thick cell, or one-sixtieth of the material in a non-angle restricted cell. Thus, beyond about 3° of angle restriction, photon recycling gives all further improvement. Concentration factors which correspond to a given angular restriction are marked, suggesting that very high single-junction efficiencies are possible using existing two-axis solar tracking technology.19,20

Effect of angle restriction in a light trapping GaAs cell. Detailed balance efficiencies as a function of maximum emission angle for various thickness light trapping GaAs solar cells with thick silicon nitride cladding. In panel a, all recombination is assumed to be radiative with an ideal back reflector. In panel b, Auger recombination is accounted for assuming an ideal back reflector. In panel c, the back reflector is assumed to have 98% angle-averaged reflectivity, as is typical in silver, and Auger recombination is also included. The dotted lines indicate concentration factors that have the same degree of angular restriction to illustrate the tracking difficulty.

While the results in Figure 2a are encouraging, they assume all recombination is radiative, which is unrealistic in a real material. Since GaAs can be fabricated with very high purity and excellent surface passivation via III–V capping layers, we consider only Auger recombination as it is the sole intrinsic, unavoidable source of non-radiative recombination.15,21,22,23,24 With increased voltage from photon recycling, Auger recombination increases relative to radiative emission. Thus, as Figure 2b illustrates, the effect of Auger recombination is the greatest for narrow emission angles, and there is little benefit for emission angles below 1°. Thinner cells show the best performance for small emission angle, because the Auger term is minimized while enhanced light trapping allows for full absorption. Furthermore, the results suggest that efficiencies above 38% are achievable with a 50-nm-thick cell.

While a nearly ideal back reflector may be achieved utilizing a dielectric stack reflector in air (see supplemental information), a metallic back reflector is more likely to be cost effective.25 However, an imperfect back reflector will reduce the absorbed solar flux and photon recycling via parasitic absorption of solar and radiatively emitted photons. In Figure 2c, we have calculated efficiencies for a 98% reflective rear surface, as is typical for smooth reflective silver coatings.26 While the benefits of limiting emission angle persist, the maximum achievable efficiency is reduced. In contrast to the ideal reflector case, thicker cells now give better performance. This indicates that, despite the high back surface reflectivity, the reduced reflector losses with increased thickness outweigh the increased Auger recombination. While these results demonstrate the feasibility of the scheme, they also indicate the benefits of a highly reflective back surface, particularly for thin cells.

Figure 3 gives analogous results for a planar, rather than light-trapping, cell geometry. As we expect, thinner cells have lower efficiencies in a planar geometry owing to poor absorption of incident light. Thus, with an ideal back reflector, the light-trapping geometry gives a significant overall efficiency gain, because very thin cells can give full light absorption while minimizing Auger recombination, as Equation (2) indicates. Note that any bulk non-radiative recombination process, such as Shockley–Read–Hall recombination, will scale with thickness as Auger recombination does, allowing for a similar advantage. However, with a non-ideal back reflector, performance is very similar between thick, fully absorbing, planar and light-trapping devices. Thus, when back reflector losses dominate bulk non-radiative processes, the light-trapping geometry allows for much thinner cells but has little effect on maximizing overall efficiency.

Effect of angle restriction in a planar GaAs cell. Detailed balance efficiencies as a function of maximum emission angle planar GaAs solar cells of various thicknesses. In panel a, all recombination is assumed to be radiative with an ideal back reflector. In panel b, Auger recombination is accounted for assuming an ideal back reflector. In panel c, the back reflector is assumed to have 98% angle-averaged reflectivity, as is typical in silver, and Auger recombination is also included. The dotted lines indicate the concentration factors that have the same degree of angular restriction to illustrate the tracking difficulty.

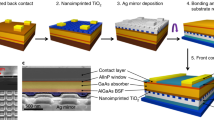

Throughout the previous analysis, we have assumed a device which facilitates light in-coupling within the specified angle without loss, while excluding all other light spanning wavelengths from the blue edge of the solar spectrum to the band edge of GaAs at 870 nm. While there has been some discussion in the literature about possible strategies for designing such a coupler, we are not aware of designs whose performance has been optically analyzed.2,27 Other than the design of an emission angle limiting coupler, our scheme relies largely on existing technologies, such as tracking and high-quality GaAs cells. Thus, to complete the feasibility argument, two possible coupler designs are presented and their performance is analyzed, with experimental work showing the early fabrication of one design.

Figure 4a and 4b illustrates a coupler that utilizes total internal reflection within dielectric cone-type structures based on a modified CPC shape. A double close-packed array of cones, separated by a perfect, broadband reflector with small holes at the cone bottoms completes the coupler design. While total internal reflection serves for the relatively collimated incoming light, it will not serve for the isotropically emitted light from the solar cell, thus necessitating the broadband reflector. Unlike a single array of these cone type structures, the double array gives uniform, near normal illumination of the cell, minimizing reflection losses and improving device performance. A similar end to end double CPC structure was used in the COBE satellite measurement of the cosmic microwave background.28 This coupler is naturally broadband, because it functions on ray optics principles.

Coupler designs and performance. (a) Dielectric coupler schematic. The double array of cone-like structures is separated by a broadband ideal reflector. The solar cell has a light trapping, randomizing back reflector. (b) Representative rays illustrate the function of the dielectric coupler. For the center CPC split rays that would be strike the reflector are not shown. (c) Reflectivity curves for three couplers, all 1 mm in height. The solid curves are for 870-nm light, and the dotted for 300-nm light. The curves are labeled with the maximum angle of emission that defines the CPC-shaped sides. The observed angles are about double the design angle because the light is refracted as it enters the dielectric. (d) Detailed balance current–voltage curves are shown for light trapping cells with the couplers shown in part b, as well as cells without angle restriction. Auger recombination is considered with an ideal back reflector. The legend gives the efficiencies; the design angles from part b and the cell thickness are given in parentheses. (e) Schematic of metal array coupler on a solar cell with a randomizing back reflector and scanning electron microscopy of structure fabricated in metal-coated resist via two-photon lithography. The SEM image was taken at 5.05 kV accelerating voltage at a 25° angle. (f) Representative rays illustrate the function of the metallic coupler. (g) Expected reflectivity from ideal fabricated structure, as determined by ray tracing, for a 98% reflective surface independent of wavelength. Gaps between structures are neglected. (h) Detailed balance current–voltage curves for light randomizing cells with metal array coupler, and without angle restriction. Auger recombination is considered with an ideal back reflector. CPC, compound parabolic concentrator; SEM, scanning electron microscopy.

A thinner coupler allows for easier integration with existing systems and lower materials cost. Since this coupler is based on ray optics, it can be built on any scale much larger than the wavelength. To minimize the coupler height, we set the scale so that the reflector openings are in the ray optic limit (4 μm diameter). As the maximum CPC acceptance angle decreases, narrowing the allowed angles, the optimal height of the cone structure increases.17 Thus, to more strictly limit the emission angle, we must either tolerate a thicker coupler structure or truncate from the optimal CPC height.

In Figure 4c, we compare three designs limited to 1 mm in height. For the design marked 3.7°, with the least angular restriction, there is no truncation, while for design with maximal restriction, marked 2°, the shape is truncated to approximately 30% of its optimal height. Owing to the large size of the coupler relative to the wavelengths of interest, we analyze the coupler performance using ray tracing with silicon nitride dielectric structures. We see excellent angular cutoff, and a broadband response, as illustrated by the curves for 300 and 870 nm. For the more truncated designs, the angular cut-off is less abrupt but begins at smaller angles.

The ray tracing results can then be incorporated into the detailed balance calculation. Figure 4d shows current–voltage curves for the three different coupler designs on a 250-nm-thick cell with Auger recombination and an ideal back reflector, as well as results for cells with no angularly restricting coupler. We see that the most significantly truncated design performs the best, with a four absolute percent efficiency increase over a thicker cell with no coupler, and a seven absolute percent increase over a no-coupler cell of the same thickness. While there is an approximately 100-mV increase in open circuit voltage, the short circuit current only increases by about 3 mA cm−2, so there should be no significant heating or series resistance effects, as in concentrator systems. Thus, this coupler design could be used to experimentally demonstrate significantly improved performance due to limited emission angle.

In Figure 4e–h, we analyze a similar coupler that is easier to fabricate, and show an initial fabrication of the shape via two-photon lithography. This coupler has a single, rather than double, array and uses metal coated cups rather than total internal reflection in a dielectric. To limit degradation in device performance, the illuminating holes at the bottoms of the cups should be spaced by a distance equal to or less than the carrier diffusion length, so the coupler CPC’s must have a relatively small diameter while remaining ray optical. Assuming 98% metal reflectivity and neglecting the gaps between cups, ray tracing results coupled to the detailed balance model suggest a significant performance increase despite the short circuit current losses in the metal.

Conclusions

Developing a detailed balance model for a thin, light trapping GaAs solar cell with limited emission angle, we have found efficiencies above 38% may be achievable with a single junction solar cell. We identify a regime of efficiencies significantly higher than those previously predicted for realistic cells with limited emission angle by maximizing both light trapping and photon recycling effects. A light trapping geometry, high-quality material, an excellent back reflector and a very thin cell are critical to reaching the highest single junction efficiencies. Furthermore, this design is tolerant to the use of a non-ideal, metallic back reflector and conversion efficiencies above 35% are possible. These results suggest that limiting emission angle with a light trapping GaAs cell could provide a new route to achieving high efficiencies without a tandem or third generation cell. Furthermore, this scheme relies almost entirely on existing technology, with the exception of a low-loss, broadband, angularly specific concentrator. We therefore analyzed two possible coupler designs, found that these couplers could produce significant performance increases, and demonstrated initial fabrication of one design. Thus, we have identified a new regime of very high efficiencies achievable by limiting emission angle, laid out the critical factors necessary to realizing these efficiencies, and considered designs for the angularly restrictive coupler required.

References

Shockley W, Queisser HJ . Detailed balance limit of efficiency of p-n junction solar cells. J Appl Phys 1961; 32: 510–519.

Campbell P, Green MA . The limiting efficiency of silicon solar cells under concentrated sunlight. IEEE Trans Electron Dev 1986; ED–33: 234–239.

Araújo GL, Martí A . Absolute limiting efficiencies for photovoltaic energy conversion. Solar Energy Mater Solar Cells 1994; 33: 213–240.

Martí A, Balenzategui JL, Reyna RF . Photon recycling and Shockely’s diode equation. J Appl Phys 1997; 82: 4067–4075.

Green MA . Solar cells: operating principles, technology, and system applications. New Jersey: Prentice-Hall, 1982.

Algora C, Ortiz E, Rey-Stolle I, Díaz V, Peña R et al. A GaAs solar cell with an efficiency of 26.2% at 1000 suns and 25.0% at 2000 suns. IEEE Trans Electron Dev 2001; 48: 840–844.

Swanson RM . The promise of concentrators. Prog Photovolt Res Appl 2000; 8: 93–111.

Tiedje T, Yablonovitch E, Cody GD, Brooks BG . Limiting efficiency of silicon solar cells. IEEE Trans Electron Dev 1984; ED–31: 711–716.

Yablonovitch E . Statistical ray optics. J Opt Soc Am 1982; 72: 899–907.

Araújo GL, Martí A . Limiting efficiencies of GaAs solar cells. IEEE Trans Electron Dev 1990; 37: 1402–1405.

Kayes BM, Nie H, Twist R, Spruytte SG, Reinhardt F et al. 27.6% conversion efficiency, a new record for single-junction solar cells under 1 sun illumination. Proceedings of the 37th IEEE Photovoltaic Specialists Conference, 2011

Green MA . Radiative efficiency of state-of-the-art photovoltaic cells. Prog Photovolt Res Appl 2012; 20: 472–476.

Stuart HR, Hall DB . Thermodynamic limit to light trapping in thin planar structures. J Opt Soc Am A 1997; 14: 3001–3008.

Zhao J, Green MA . Optimized antireflection coatings for high-efficiency silicon solar cells. IEEE Trans Electron Dev 1991; 38: 1925–1934.

Strauss U, Ruhle WW, Kohler K . Auger recombination in intrinsic GaAs. Appl Phys Lett 1993; 62: 55–57.

Miller O, Yablonovitch E, Kurtz SR . Intense internal and external luminescence as solar cells approach the Shockley-Queisser limit. IEEE J Photovoltaics 2012; 2: 303–311.

Welford WT, Winston R . High collection nonimaging optics. San Diego: Academic Press, 1989.

Atwater JH, Spinelli P, Kosten E, Parsons J, van Lare C et al. Microphotonic parabolic light directors fabricated by two-photon lithography. Appl Phys Lett 2011; 99: 151113.

Gordon JM, Katz EA, Feuermann D, Huleihil M . Toward ultrahigh-flux photovoltaic concentration. Appl Phys Lett 2004; 84: 3642–3644.

Luque-Heredia I, Cervantes R, Quéméré G . A sun tracking error monitor for photovoltaic concentrator. Conference Record of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, pp 706–709 .

Schnitzer I, Yablonovitch E, Caneau C, Gmitter TJ . Ultrahigh spontaneous emission quantum efficiency, 99.7% internally and 72% eternally, from AlGaAs/GaAs/AlGaAs double heterostructures. Appl Phys Lett 1992; 62: 131–133.

Nelson RJ, Sobers RG . Minority-carrier lifetimes and internal quantum efficiency of surface-free GaAs. J Appl Phys 1978; 49: 6103–6108.

Olson JM, Ahrenkiel RK, Dunlavy DJ, Keyes B, Kibbler AE . Ultralow recombination velocity at Ga0.5In0.5P/GaAs heterointerfaces. Appl Phys Lett 1989; 55: 1208–1210.

Ahrenkiel RK, Dunlavy DJ, Keyes B, Vernon SM, Dixon TM et al. Ultralong minority-carrier lifetime epitaxial GaAs by photon recycling. Appl Phys Lett 1989; 55: 1088–1090.

Deopura M, Ullal CK, Temelkuran B, Fink Y . Dielectric omnidirectional visible reflector. Opt Lett 2001; 26: 1197–1199.

Kuhn H, Wilson BA . Reflectivity of thin silver films and their use in interferometry. Proc Phys Soc B 1950; 63: 745–755.

Luque A . The confinement of light in solar cells. Solar Energy Mater Solar Cells 1991; 23: 152–163.

Mather JC, Fixsen DJ, Shafer RA, Mosier C, Wilkinson DT . Calibrator design for the COBE far infrared absolute spectrophotometer (FIRAS). Astrophys J 1999; 512: 511–520.

Acknowledgements

Thanks to D Callahan, M Sheldon and J van de Groep for insightful discussions and advice on the manuscript. The authors also found advice from O Miller on handling non-radiative recombination, R Briggs on mode structure calculations, J Zipkin on numerical methods and C Eisler on internal fluorescence yield derivations extremely helpful. The authors are grateful for technical assistance from G Vollenbroek. The Caltech researchers are supported by the ‘Light-Material Interactions in Energy Conversion’ Energy Frontier Research Center funded by the US Department of Energy, Office of Science, Office of Basic Energy Sciences under grant DE-SC0001293 (EK and HA). EK also acknowledges the support of the Resnick Sustainability Institute. Researchers of the Center for Nanophotonics at AMOLF are supported by the research program of FOM which is financially supported by NWO and by the European Research Council.

Author information

Authors and Affiliations

Corresponding author

Additional information

Note: Supplementary information for this article can be found on Light: Science & Applications' website.

Supplementary information

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Kosten, E., Atwater, J., Parsons, J. et al. Highly efficient GaAs solar cells by limiting light emission angle. Light Sci Appl 2, e45 (2013). https://doi.org/10.1038/lsa.2013.1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/lsa.2013.1

Keywords

This article is cited by

-

Recent Progress of Surface Plasmon–Enhanced Light Trapping in GaAs Thin-Film Solar Cells

Plasmonics (2023)

-

A Comprehensive Review of Tandem Solar Cells Integrated on Silicon Substrate: III/V vs Perovskite

Silicon (2023)

-

Three-dimensional acetylenic modified graphene for high-performance optoelectronics and topological materials

npj Computational Materials (2021)

-

Efficiency limits of concentrating spectral-splitting hybrid photovoltaic-thermal (PV-T) solar collectors and systems

Light: Science & Applications (2021)

-

Development of photovoltaic solar cells based on heterostructure of layered materials: challenges and opportunities

Emergent Materials (2021)