Abstract

In recent years, there has been a significant increase in the studies on effective energy-conversion devices, including photovoltaics and fuel cells, which aim to alleviate the enormous energy demand, as well as the environmental pollution issues associated with current power consumption. Among these devices, dye-sensitized solar cells (DSCs) have received significant attention owing to their simple fabrication procedure, cost-effectiveness and high-power-conversion efficiency. The counter electrode (CE) of the DSCs is an important component and generally uses platinum as its benchmark material, the high cost and scarcity of which have limited the broad application of the DSCs. Thus, substantial effort has been devoted to seek active CE materials with low cost, high electrocatalytic activity and excellent stability. Nevertheless, this is generally achieved via a ‘trial-and-error’ method owing to the lack of information on the mechanism of the electrocatalytic reaction on the CE’s surface. This report summarizes the recent advances in the mechanistic study of the interfacial electrocatalytic reaction on CE materials, as well as the establishment of a rational screening protocol for efficient CE materials. Furthermore, several outstanding CE materials developed via this protocol have been reviewed. The demonstrated combined approach can be extended to the studies of other essential electrocatalytic reactions.

Similar content being viewed by others

Introduction

The global demand for energy has significantly increased, and this trend is predicted to continue in the future. Solar energy, which is one of the most abundant and least-utilized clean energy sources, demonstrates great potential to satisfy the future global energy consumption. A photovoltaic (PV) system or solar cell, which directly converts sunlight into electricity, has attracted significant attention in the academic and industrial fields. Although the current PV market is dominated by silicon-based solar cells, several studies have been performed to develop new-generation solar cells with a higher efficiency and a lower price. Among them, dye-sensitized solar cells (DSCs) exhibit a promising future owing to their ease of fabrication, low-cost and high sunlight-harvesting efficiency.1, 2, 3, 4 In typical single p–n junction PV devices, semiconducting materials are used to generate, separate and transport charge carriers (electrons and holes) to transmit electricity under solar illumination. However, in the DSCs, photoelectrons are generated by separate photosensitive dyes and transported using semiconducting materials. The unique charge separation and injection processes lead to a relatively low-recombination rate compared with that of traditional solar cells. In addition, the DSCs can be fabricated using inexpensive and earth-abundant materials into different shapes, colors and transparencies with a high efficiency under both high or low light intensity.5 Significant progress has been achieved in improving the power-conversion efficiency (PCE) and operation stability.6 Recently, the DSCs have achieved a PCE of 12.3% in laboratory experiments,7 which indicates a great potential as new-generation PV devices for renewable energy sources in the future.

Generally, a DSC has a sandwich structure consisting of a dye-sensitized mesoporous nanocrystalline semiconductor photoanode, an electrolyte containing a redox couple and a counter electrode (CE). A schematic diagram of a typical DSC construction along with its major electron pathways is illustrated in Figure 1. An electrocatalyst-coated CE used for redox couple regeneration after electron injection is one of the most crucial components in the DSCs.8, 9, 10, 11, 12, 13, 14, 15 Platinum (Pt) has been used as a benchmark CE material because of its excellent catalytic activity and high conductivity. Nevertheless, its drawbacks, such as high cost and scarcity, strongly hinder the broad application of Pt in the DSCs. Thus, to overcome this challenge, several inexpensive Pt-free catalytic alternatives with outstanding electrocatalytic activity and electrical conductivity, for example, inorganic semiconductor,16, 17, 18, 19 carbon,20, 21 conductive polymers22, 23 and hybrid materials,24, 25 have been developed. However, most CE materials have been discovered using the ‘trial-and-error’ methodology owing to the lack of information on the electrocatalytic reaction at the solution/CE material interface. In early 2013, a breakthrough has been made in this field: a general screening strategy for high-efficient CE materials has been successfully established based on the first-principles calculations,26 and numerous new CE materials have been thus developed via this protocol. In this report, we first summarize the recent advances in the mechanistic study via theoretical calculations for a triiodide reduction reaction (widely used redox couple in DSCs) on a CE surface. Then, to confirm the as-developed screening strategy based on the mechanistic study, we highlight various high-performance Pt-free CE materials, such as metals, metal oxides, metal sulfides, metal nitrides and metal carbides. Finally, conclusions and perspectives are provided to illustrate the opportunities, as well as challenges in this field.

Working principles and key components of DSCs

Generally, the working principle of the DSCs involves several elementary processes (Figure 1). Under solar illumination, the adsorbed dye molecule is promoted to the excited state (process 1), photogenerated electrons are injected into the conduction band of the photoanode materials (semiconductors) and the molecule is transitioned into its oxidized state (process 2). The injected electrons will then be collected by the photoanode substrate (process 3), transferred from the outer circuit and used to reduce the oxidized redox mediator on the CE’s surface (process 4). The entire electron transfer cycle will be finished when the oxidized dye molecule is reduced to its ground state by the redox mediator in the electrolyte (process 5). Recombination processes, including the injected electron recombined with the oxidized dye molecule and/or the oxidized redox mediator (processes 6 and 7), may also occur during this cycle.

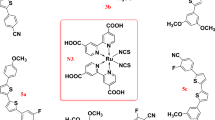

Since the development of the initial DSC by Grätzel et al. in 1991, various optimized DSC components have been developed to achieve a high PCE and improved operation stability. Thus far, thousands of dyes (sensitizers) have been investigated to achieve an efficient light absorption.27, 28 The most widely applied sensitizers are Ru(II)−polypyridyl complexes, such as dye N3 and N719.29 Furthermore, substantial effort has been devoted to the development of new semiconductors for the photoanodes of the DSCs, such as SnO2,30 ZnO31 and Nb2O5.32 Furthermore, mesoporous TiO2 is still the preferred choice in the DSCs owing to its large band gap and high-conduction band energy.3 Moreover, the electrolyte is another critical part of the DSCs. A prompt and non-interrupted electron supply is the basic requirement needed to regenerate the dye sensitizer for a redox couple in the electrolyte. Generally, the electrolytes used in the DSCs can be divided into three categories: liquid electrolytes,33 quasi-solid electrolytes34 and solid-state hole conductors.35 Among them, liquid electrolyte is generally used, and several different redox couples have been reported, such as the Co-complex (Co(II)/Co(III)),36 disulfide/thiolate (T−/T2),37 ferrocene/ferrocenium (Fc/Fc+),38 Cu(I)/Cu(II)39 and Ni(III)/Ni(IV).40 Thus far, the iodide/triiodide ( ) redox couple in an organic solvent (normally CH3CN) is the most preferred and commonly used redox couple because of its high solubility and ionic mobility. The rapid kinetics of electron donation (for dye regeneration by I−) and the extremely slow recombination (between electrons in the photoanode and

) redox couple in an organic solvent (normally CH3CN) is the most preferred and commonly used redox couple because of its high solubility and ionic mobility. The rapid kinetics of electron donation (for dye regeneration by I−) and the extremely slow recombination (between electrons in the photoanode and  in the electrolyte) leads to a high PCE of the DSC compared with that of the other redox couples investigated. Moreover, the

in the electrolyte) leads to a high PCE of the DSC compared with that of the other redox couples investigated. Moreover, the  redox couple exhibits an outstanding stability during the long run of the DSCs.41 After I− regenerates the dye sensitizer (by donating one electron) and evolves into

redox couple exhibits an outstanding stability during the long run of the DSCs.41 After I− regenerates the dye sensitizer (by donating one electron) and evolves into  , it is important to rapidly reduce

, it is important to rapidly reduce  to I−. The region where the triiodide reduction reaction occurs is the solid–liquid interface between the electrolyte and the CE of the DSC. The CE here has a dual role: providing a prompt electron transport from the outer circuit and ensuring a rapid

to I−. The region where the triiodide reduction reaction occurs is the solid–liquid interface between the electrolyte and the CE of the DSC. The CE here has a dual role: providing a prompt electron transport from the outer circuit and ensuring a rapid  to I− conversion process. Therefore, a good conductivity and high electrocatalytic activity toward the triiodide reduction reaction are the basic requirements for the CE materials. Herein, the report only concentrates on the development of efficient CE materials for the triiodide reduction reaction. Reviews on DSCs with other redox couples are available elsewhere.5, 42, 43

to I− conversion process. Therefore, a good conductivity and high electrocatalytic activity toward the triiodide reduction reaction are the basic requirements for the CE materials. Herein, the report only concentrates on the development of efficient CE materials for the triiodide reduction reaction. Reviews on DSCs with other redox couples are available elsewhere.5, 42, 43

Basic theory of rational screening strategy for CE materials

To date, a large number of efficient CE materials have been developed for the triiodide reduction reaction; however, most of them are based on a ‘trial-and-error’ approach. Thus, an effective combinational screening approach is highly necessary to reduce the research and development cost and cycle. The computational approach is regarded as an efficient, high-throughput alternative.44 As one of the most effective and accurate computational methods, the density functional theory (DFT) has been widely applied to analyze the catalytic mechanism in several different heterogeneous catalytic processes, such as oxygen reduction reaction45, 46 and hydrogen evolution reaction.47 Recently, a DFT modeling method has been introduced to the DSCs field.48, 49, 50 Specifically, it can be applied to explore the fundamental processes in the electrocatalysis reaction and understand the characteristics of fabricated CEs in the DSCs systems, which is beneficial in discovering the weak points in the designing stage and assisting in discovering molecularly designed CE materials with more optimized solutions. Using the first-principles calculations, our research group has explored the key parameter affecting the electrocatalytic efficiency and developed a general and efficient screening framework for the electrocatalytic activity of potential CE materials.

Electrocatalytic activity origin of CE electrocatalysts

The overall triiodide reduction reaction occurring on the CE can be described as follows:

This reaction can be divided into three detailed steps:

where ‘*’ represents the free site on the electrode surface; and ‘sol’ indicates the solution (generally CH3CN). The solution reaction, reaction step (2), has been verified to be typically fast and in equilibrium.51 Therefore, the overall catalytic activity can be determined by the iodine reduction reaction (IRR) as follows:

which occurs at the liquid–solid interface, that is, the dissociative adsorption of one iodine molecule onto the CE’s surface to form two surface iodine atoms (reaction step (3)), and the removal of one electron from each adsorbed iodine atom to produce solvated iodides (reaction step (4)).

To identify the key parameter affecting the entire IRR process, a two-step model, which has been reported previously by Wang et al.,52, 53 was applied to illustrate the heterogeneous catalytic reactions, that is, the adsorption of the reactants to form intermediates and the desorption of the intermediates to form products. The energy profile involved in these two steps is provided in Figure 2a. Two important parameters, that is, the I2 dissociation barrier ( ) and the I* desorption barrier (

) and the I* desorption barrier ( ), were used to determine the thermodynamics of the IRR process.26

), were used to determine the thermodynamics of the IRR process.26

(a) Schematic energy profile of a two-step model considering the dissociative adsorption of reactants and associative desorption of products on a catalyst surface. (b) Schematic diagram of the variation in activity (black volcano curve) as a function of the adsorption energy of the I atom. The adsorption (red) and desorption (blue) are rate-determining processes. Adapted from Hou et al.26 Copyright © 2013 Rights Managed by Nature Publishing Group.

According to the Bronsted–Evans–Polanyi relation of dissociative adsorption,53 one can obtain the expression as follows:

where  is the adsorption energies of the I atom on the surface of the electrodes. Because the CH3CN solvent molecule has a relatively strong adsorption energy on the electrode’s surface, a competitive adsorption effect exists between the I atoms and the CH3CN molecules when the I atoms are introduced onto the electrode’s surface. Therefore,

is the adsorption energies of the I atom on the surface of the electrodes. Because the CH3CN solvent molecule has a relatively strong adsorption energy on the electrode’s surface, a competitive adsorption effect exists between the I atoms and the CH3CN molecules when the I atoms are introduced onto the electrode’s surface. Therefore,  can be defined as follows:

can be defined as follows:

where E(interface), E(I2) and E(I/interface) represent the energies of the liquid/electrode interface, I2 in the gas phase and the liquid/electrode interface with the adsorbed I atoms, respectively.

When considering the desorption process, the desorption barrier generally becomes higher as its binding strength with the electrocatalyst surface increases. A linear relationship between  and

and  was revealed, which can be given as follows:

was revealed, which can be given as follows:

In equations (6) and (8), α1, α2, β1 and β2 are constants. Clearly, both the I2 dissociation barrier and the I* desorption barrier are related to the adsorption energy of I:  has a negative linear correlation with

has a negative linear correlation with  whereas

whereas  increases linearly as

increases linearly as  increases. These two linear relationships demonstrate that the

increases. These two linear relationships demonstrate that the  on the CE material’s surfaces has a crucial role in determining the overall catalytic activity of the IRR. In other words, the

on the CE material’s surfaces has a crucial role in determining the overall catalytic activity of the IRR. In other words, the  can serve as a good descriptor for the IRR activity. When

can serve as a good descriptor for the IRR activity. When  is too large, the removal of I to form I− will be difficult, and the overall activity of desorption is limited. If

is too large, the removal of I to form I− will be difficult, and the overall activity of desorption is limited. If  is weak, the I2 dissociation step will be hindered.

is weak, the I2 dissociation step will be hindered.

Using a microkinetic analysis, further quantitative discussions were performed by estimating the turnover frequency (TOF) of the two-step IRR under steady-state conditions. Within the microkinetic framework, the reaction rate of steps (3) and (4) can be written as follows:

where θ and  are the coverage of the surface-free site and the I atom, respectively;

are the coverage of the surface-free site and the I atom, respectively;  is the concentration of the I2 molecule in the solution; Z1 and Z2 are the reaction reversibility of steps (3) and (4), respectively; and k1 and k2 are the rate constants of reactions (3) and (4), respectively, which can be determined using the transition-state theory as follows:

is the concentration of the I2 molecule in the solution; Z1 and Z2 are the reaction reversibility of steps (3) and (4), respectively; and k1 and k2 are the rate constants of reactions (3) and (4), respectively, which can be determined using the transition-state theory as follows:

where KB and h are constants; and T is the reaction temperature.

At steady state (TOF=2r1=r2), by applying the condition  , we can solve the reaction TOF numerically.

, we can solve the reaction TOF numerically.

Analytically, considering the relationships of (6) and (8), it is evident that the TOF of the entire reaction can primarily be determined using  .

.

If adsorption is the rate-determining step (Z2=1,  ), we can obtain the expression as follows:

), we can obtain the expression as follows:

If desorption is the rate-determining step (Z1=1, Z2=Ztot), we can obtain the expression as follows:

where Keq1 and Keq2 are the reaction equilibrium constants of steps (3) and (4), respectively.

In actuality, the TOF would be determined using TOF=min {TOF1, TOF2} (Figure 2b), which indicates that  is a key parameter used to determine the complete catalytic activity.

is a key parameter used to determine the complete catalytic activity.

Establishment of screening framework for CE materials

The identification of the decisive parameter of the electrocatalytic activity, that is,  , is followed by the determination of a suitable energy range of

, is followed by the determination of a suitable energy range of  for the IRR. For a multistep reaction system, the Gibbs free-energy should be negative to ensure that the overall reaction proceeds in the forward direction. With respect to the IRR, the total Gibbs free-energy change ΔG0 provides the thermodynamic driving force as follows:

for the IRR. For a multistep reaction system, the Gibbs free-energy should be negative to ensure that the overall reaction proceeds in the forward direction. With respect to the IRR, the total Gibbs free-energy change ΔG0 provides the thermodynamic driving force as follows:

It is difficult to directly calculate the energy of the charged periodic system accurately. However, because we know that the Gibbs free-energy change of the standard hydrogen electrode (SHE) reaction is zero, that is,

Then, we can obtain the reaction when combining reactions (4) and (15) as follows:

where eU represents the electron free-energy shift in the CE at the voltage U relative to the SHE. Clearly, the Gibbs free-energy change ΔG1 of reaction (16) is the same as the ΔG0 of the IRR. Thus, based on Hess’s Law, we can design a thermodynamic cycle to calculate ΔG1 indirectly as follows:

Clearly, for the above cycle,  . We used the Gaussian 03 software (Gaussian, Wallingford, CT, USA) to calculate ΔG2. The salvation energies of I− in the CH3CN solvent

. We used the Gaussian 03 software (Gaussian, Wallingford, CT, USA) to calculate ΔG2. The salvation energies of I− in the CH3CN solvent  and H+ in the water

and H+ in the water  use experimental values, that is, −2.86 and −11.53 eV, respectively.54, 55 The chemical potential difference of the I2 molecule between the gas phase and the CH3CN solvent

use experimental values, that is, −2.86 and −11.53 eV, respectively.54, 55 The chemical potential difference of the I2 molecule between the gas phase and the CH3CN solvent  can be calculated according to the ideal solution model by considering the phase equilibrium at the gas/liquid interface during the dissolution of I2 as follows:

can be calculated according to the ideal solution model by considering the phase equilibrium at the gas/liquid interface during the dissolution of I2 as follows:

where  is the saturated vapor pressure of the I2 molecule, which can be calculated based on the Antonie equation (obtained from the NIST WebBook).

is the saturated vapor pressure of the I2 molecule, which can be calculated based on the Antonie equation (obtained from the NIST WebBook).

For good CE electrocatalysts, to ensure that the reaction occurs spontaneously, it is required that the chemical potentials conform to the sequence as follows:

By combining equations (14) and (18), we can obtain the theoretical deduction as follows:

where  is the entropy correction term of I2 in a gas phase at T=298 K (relative to gaseous I2 at 0 K). Here, μe is the chemical potential of the electron, and

is the entropy correction term of I2 in a gas phase at T=298 K (relative to gaseous I2 at 0 K). Here, μe is the chemical potential of the electron, and  can be defined as follows:

can be defined as follows:

where  is the coverages of the absorbed I*; and θ* is the free site * on the CE’s surface; and

is the coverages of the absorbed I*; and θ* is the free site * on the CE’s surface; and  is the standard chemical potential of the I* species, which can be readily obtained from the

is the standard chemical potential of the I* species, which can be readily obtained from the  using DFT calculations with the necessary thermal correction. For simplicity, the minor contribution of the I2 and I− concentrations in the solution (~0.02 eV, estimated under experimental conditions) into the free energy was neglected. The coverage-dependent term

using DFT calculations with the necessary thermal correction. For simplicity, the minor contribution of the I2 and I− concentrations in the solution (~0.02 eV, estimated under experimental conditions) into the free energy was neglected. The coverage-dependent term  , which was previously proposed by Cheng56, could occur within a small range for the best catalyst (~0.06–0.12 eV at 298 K) and was defined as ε.56

, which was previously proposed by Cheng56, could occur within a small range for the best catalyst (~0.06–0.12 eV at 298 K) and was defined as ε.56

In other words, for a good electrocatalyst,  should satisfy equation (21).

should satisfy equation (21).

Here the suitable range of  for a good CE electrocatalyst can be depicted as follows:

for a good CE electrocatalyst can be depicted as follows:

where  is the chemical potential difference of the I2 molecule between the gas phase and the CH3CN solvent at 298 K.

is the chemical potential difference of the I2 molecule between the gas phase and the CH3CN solvent at 298 K.

Thus, there are upper and lower limits for  from equation (22):

from equation (22):  is required to be high enough such that the I2 dissociate adsorption is exothermic, and it needs to be low enough for the subsequent desorption to proceed exothermically (Figure 3a). Because the IRR is an electrode reaction, the electrode voltage effect needs to be considered (equation (16)). As illustrated in Figure 3b, the lower the electrode voltage (U), the larger the absolute value of ΔG0. For the most common DSCs, which use TiO2 as the anode material, when the electrode voltage

is required to be high enough such that the I2 dissociate adsorption is exothermic, and it needs to be low enough for the subsequent desorption to proceed exothermically (Figure 3a). Because the IRR is an electrode reaction, the electrode voltage effect needs to be considered (equation (16)). As illustrated in Figure 3b, the lower the electrode voltage (U), the larger the absolute value of ΔG0. For the most common DSCs, which use TiO2 as the anode material, when the electrode voltage  (relative to SHE),57 ΔG0 reaches its maximum, which provides the maximal upper boundary for

(relative to SHE),57 ΔG0 reaches its maximum, which provides the maximal upper boundary for  according to equation (14). Therefore, under this condition, we estimated the variation range of

according to equation (14). Therefore, under this condition, we estimated the variation range of  to be between 0.33 and 1.20 eV for good CE electrocatalysts. It is worth noting that the first-principles simulations can handle system sizes of only ~100 atoms owing to the computational expense. Other factors that may also affect the performance of the CE electrocatalysts, such as nanoscale structures, electrical conductivity and macro/meso-scale morphologies, cannot be systematically considered using the DFT method. Therefore, the

to be between 0.33 and 1.20 eV for good CE electrocatalysts. It is worth noting that the first-principles simulations can handle system sizes of only ~100 atoms owing to the computational expense. Other factors that may also affect the performance of the CE electrocatalysts, such as nanoscale structures, electrical conductivity and macro/meso-scale morphologies, cannot be systematically considered using the DFT method. Therefore, the  can be used only as a qualitative predictor.

can be used only as a qualitative predictor.

(a) Demonstration of the estimated range for suitable electrodes in terms of the adsorption energy of the I atom. Adapted from Hou et al.26 (b) Energy level scheme of the DSCs. Potentials are referred to the standard hydrogen electrode (SHE). Adapted from Zhang et al.58 Copyright © 2013 Rights Managed by Nature Publishing Group.

Application of screening framework for efficient CE materials and their experimental performances

Once the optimal range of  has been determined, it can be utilized as a guideline to estimate the electrocatalytic activity and, more importantly, search for new CE materials without the need to experimentally prepare the solar cells. It should be noted that the

has been determined, it can be utilized as a guideline to estimate the electrocatalytic activity and, more importantly, search for new CE materials without the need to experimentally prepare the solar cells. It should be noted that the  value of one substance may vary as it depends on the exposed surface structures. Crystalline materials are first investigated because they are composed of atoms with highly ordered microscopic arrangements; therefore, they are easier to prepare, model and are more stable in the long term.

value of one substance may vary as it depends on the exposed surface structures. Crystalline materials are first investigated because they are composed of atoms with highly ordered microscopic arrangements; therefore, they are easier to prepare, model and are more stable in the long term.

Essentially, the DFT is used to create a stabilized crystal surface model of the CE candidates and calculate the  values of the relevant surfaces. Using the established CE material screening strategy, a range of different materials, including metals, metal oxides, metal carbides, metal nitrides and metal sulfides, have been examined by our group, as summarized in Figure 4. A few materials have been previously experimentally proven to be good CE electrocatalysts, (blue triangles in Figure 4), such as CoS, FeS, MoC, MoN, WC and WO3, which possess favorable

values of the relevant surfaces. Using the established CE material screening strategy, a range of different materials, including metals, metal oxides, metal carbides, metal nitrides and metal sulfides, have been examined by our group, as summarized in Figure 4. A few materials have been previously experimentally proven to be good CE electrocatalysts, (blue triangles in Figure 4), such as CoS, FeS, MoC, MoN, WC and WO3, which possess favorable  values. The theory–experiment match confirms the feasibility of this strategy. On the other hand, the

values. The theory–experiment match confirms the feasibility of this strategy. On the other hand, the  values of the metal oxides, including TiO2, MnO2, SnO2, CeO2, ZrO2, La2O3, Al2O3, Ga2O3, Cr2O3 and Ta2O5, are out of the optimal range (black squares in Figure 4), which indicates inferior catalytic activities. Using this screening strategy, we successfully predicted the pioneer facet of Pt(111) of the triiodide reduction reaction.58 Several excellent Pt-free CE materials (red pentagon in Figure 4), including α-Fe2O3,26 RuO2,59 N-doped In2O3 (N-In2O3),60 S-doped Co3O4 (S-Co3O4)61 and NiS,62 also have an

values of the metal oxides, including TiO2, MnO2, SnO2, CeO2, ZrO2, La2O3, Al2O3, Ga2O3, Cr2O3 and Ta2O5, are out of the optimal range (black squares in Figure 4), which indicates inferior catalytic activities. Using this screening strategy, we successfully predicted the pioneer facet of Pt(111) of the triiodide reduction reaction.58 Several excellent Pt-free CE materials (red pentagon in Figure 4), including α-Fe2O3,26 RuO2,59 N-doped In2O3 (N-In2O3),60 S-doped Co3O4 (S-Co3O4)61 and NiS,62 also have an  value within the optimal range. The calculated results are subsequently proven by experimental measurement of the CE materials, as discussed below.

value within the optimal range. The calculated results are subsequently proven by experimental measurement of the CE materials, as discussed below.

Metals

As a noble metal, Pt has been recognized as the best classic material that can be used for various heterogeneous catalytic reactions, such as the triiodide reduction reaction,58 oxygen reduction reaction,63 hydrogen evolution reaction64 and so on. Platinum is known to be a unique catalytic material because of its exceptional stability in corrosive electrolytes, good electrical and thermal conductivity and excellent electrocatalytic activity.65 Specifically, Pt has been the benchmark CE material used in the DSCs owing to its unparalleled catalytic performance in the  redox mediator system. In addition, the diverse catalytic activities of the Pt nanocrystals are known to be highly dependent on the exposed facets of the Pt surface.66 To investigate the facet-dependent catalytic behavior of the different faceted Pt nanocrystal, we calculated the

redox mediator system. In addition, the diverse catalytic activities of the Pt nanocrystals are known to be highly dependent on the exposed facets of the Pt surface.66 To investigate the facet-dependent catalytic behavior of the different faceted Pt nanocrystal, we calculated the  values for three different facets ({100}, {111} and {411}), and the facet with the best catalytic activity for the IRR was discovered.58 Upon adsorption at the interfaces of these Pt surfaces and the CH3CN solution, the I2 molecule was found to dissociate into two I* atoms without an apparent

values for three different facets ({100}, {111} and {411}), and the facet with the best catalytic activity for the IRR was discovered.58 Upon adsorption at the interfaces of these Pt surfaces and the CH3CN solution, the I2 molecule was found to dissociate into two I* atoms without an apparent  , which suggests that the dissociation of I2 is quite fast and can be considered to be in equilibrium. Therefore, the IRR process is determined by the desorption step. As indicated in Figure 5a–c, the elongated distance between the Pt and the I atom was observed for the Pt(100) and Pt(411) surfaces (4.48 and 4.49 Å, respectively) to be greater than that of the Pt(111) counterpart (4.20 Å). The charge-density-difference between the I and Pt atoms in their transition states are displayed in Figure 5a–c (inset) to depict the bond properties. On the investigated Pt surfaces, the electrons that were depleted at the surface of the Pt atom and the adsorbed CH3CN molecules were found to accumulate at the adsorbed I atoms. The reaction energy profile of the IRR on these three Pt surfaces is illustrated in Figure 5d and e. To remove the effects of the electrode voltage on the electron potential, the electrode voltage was set as U=0 V vs SHE, which provides the largest thermodynamic driving force (Figure 5d). The corresponding

, which suggests that the dissociation of I2 is quite fast and can be considered to be in equilibrium. Therefore, the IRR process is determined by the desorption step. As indicated in Figure 5a–c, the elongated distance between the Pt and the I atom was observed for the Pt(100) and Pt(411) surfaces (4.48 and 4.49 Å, respectively) to be greater than that of the Pt(111) counterpart (4.20 Å). The charge-density-difference between the I and Pt atoms in their transition states are displayed in Figure 5a–c (inset) to depict the bond properties. On the investigated Pt surfaces, the electrons that were depleted at the surface of the Pt atom and the adsorbed CH3CN molecules were found to accumulate at the adsorbed I atoms. The reaction energy profile of the IRR on these three Pt surfaces is illustrated in Figure 5d and e. To remove the effects of the electrode voltage on the electron potential, the electrode voltage was set as U=0 V vs SHE, which provides the largest thermodynamic driving force (Figure 5d). The corresponding  values for the Pt(111), Pt(100), and Pt(411) surfaces were calculated to be 0.39, 0.63 and 0.74 eV, respectively. This result indicates that the desorption of the I atoms from the Pt(100) or Pt(411) surfaces becomes more difficult than that of the Pt(111) surface. Furthermore, under the equilibrium voltage (0.54 V), the free-energy change of the IRR reaches zero (Figure 5e). On the basis of the DFT calculation, Pt(111) possesses a favorable

values for the Pt(111), Pt(100), and Pt(411) surfaces were calculated to be 0.39, 0.63 and 0.74 eV, respectively. This result indicates that the desorption of the I atoms from the Pt(100) or Pt(411) surfaces becomes more difficult than that of the Pt(111) surface. Furthermore, under the equilibrium voltage (0.54 V), the free-energy change of the IRR reaches zero (Figure 5e). On the basis of the DFT calculation, Pt(111) possesses a favorable  of 0.52 eV. However, on Pt(411) and Pt(100), the

of 0.52 eV. However, on Pt(411) and Pt(100), the  values are beyond the optimal range, that is, 1.38 and 1.56 eV, respectively, which indicates less electrocatalytic activity.

values are beyond the optimal range, that is, 1.38 and 1.56 eV, respectively, which indicates less electrocatalytic activity.

Transition-state (TS) structures at (a) CH3CN/Pt(111), (b) CH3CN/Pt(100) and (c) CH3CN/Pt(411) interfaces; inserts: corresponding charge-density-difference map of TS, and a light-blue color represents electron accumulation and yellow represents electron depletion. (d) Standard Gibbs free-energy profiles of the IRR on Pt(111), Pt(100), Pt(411). (e) Gibbs free-energy profiles of the IRR on Pt(111), Pt(100), Pt(411), under the  equilibrium voltage of 0.54 V. (f) Linear relationship between the I* desorption barrier

equilibrium voltage of 0.54 V. (f) Linear relationship between the I* desorption barrier  and the adsorption energy

and the adsorption energy  . Adapted from Zhang et al.58 Copyright © 2013 Rights Managed by Nature Publishing Group.

. Adapted from Zhang et al.58 Copyright © 2013 Rights Managed by Nature Publishing Group.

To experimentally validate the theoretical prediction, Pt nanocubes and truncated nano-octahedrons with exposed {100} and {111} facets were synthesized by a soft chemical method using CO derived from W(CO)6 as a reducing agent under an argon atmosphere, whereas Pt nanooctapods with exposed {411} facet was prepared using a solvothermal method at 160 °C, as indicated in Figure 6.67, 68 These individual Pt nanocrystals were used as the CE materials in the DSCs, and Pt(111) was found to be the prominent facet for the triiodide reduction reaction, which is consistent with the theoretical prediction. The maximum PCE was found to be 6.91%, with a high current density (Jsc=16.29 mA cm−2) and a large open circuit voltage (Voc) of 757 mV. The DSCs with the Pt(100) and Pt(411) faceted Pt CE exhibited relatively lower PV performances than that of the Pt(111) faceted Pt CE, and the overall PCE order was Pt(111)>Pt(411)>Pt(100), which is consistent with the theoretical prediction.58 In addition to the facets, the structural morphology was also reported to significantly influence the catalytic behavior by exposing the excessive catalytic sites for effective electrocatalysis.69, 70, 71, 72, 73 In addition to Pt, a few other metals, such as W, Mo and Ni, have also been tested as a CE material in the DSCs; however, the PCEs were significantly lower than that of the Pt CE.15, 74

Morphologies and crystal structure of (a, d) Pt(111), (b, e) Pt(100) and (c, f) Pt(411) faceted Pt nanocrystals. Adapted from Zhang et al.58 Copyright © 2013 Rights Managed by Nature Publishing Group.

Metal oxides

Semiconducting transition metal oxides that possess a reasonable band gap for photoexcitation are thought to be potential candidates as photoanode materials instead of CE materials in DSCs.75, 76, 77 Among all of the semiconducting metal oxides, α-Fe2O3 is one of the most abundant and low-cost materials on earth. On the basis of the theoretical calculations, the  values of the two typical surfaces of α-Fe2O3 (that is, Fe2O3(012) and Fe2O3(104)) were estimated to be 0.51 and 0.42 eV, respectively, indicating that it may be catalytically active.26 To further investigate the activity of α-Fe2O3, the reaction pathway of the IRR at the interface between CH3CN/Fe2O3(012) and CH3CN/Fe2O3(104) was calculated using the DFT.26 The I2 molecules can dissociate directly on top of the five-coordinated surface Fe3+ ions. Compared with the initial Fe–I bond length (2.72 Å) in the adsorption configuration, the transition state of the I* desorption exhibited a significantly elongated Fe–I bond length (4.12 Å) (Figure 7a–c). No particular high point was found in the overall standard free-energy profiles (Figure 7d) for both the Fe2O3(012) and Fe2O3(104) surfaces, implying a good kinetic performance for the IRR compared with the Pt(111). To verify the expected catalytic activity of α-Fe2O3, a simple hydrothermal method was used to prepare cube-like α-Fe2O3 nanoparticles that have generally exposed {012} and {104} facets and used as a CE in the DSCs to evaluate the PV parameters. The experimental results (Figure 8) indicate that the α-Fe2O3-based DSC can record a Jsc of 15.92 mA cm−2, a Voc of 784 mV, a fill factor of 0.56 and a PCE of 6.92%, which is comparable with that of the Pt-based DSC (Figure 8b and c). Furthermore, from the electrochemical impedance spectroscopic data, α-Fe2O3 has a lower interfacial charge transfer resistance (Rct) value (2.3 Ω) than that of Pt (3.4 Ω), which further confirmed the excellent catalytic activity for the triiodide reduction reaction. Another transition metal oxide, RuO2, possesses superior electrocatalytic activity in different heterogeneous catalysis, such as oxidation reactions, reduction/hydrogenation reactions, oxygen evolution reactions78 and ammonia synthesis.79 Regarding the IRR, the DFT calculation was used to estimate the

values of the two typical surfaces of α-Fe2O3 (that is, Fe2O3(012) and Fe2O3(104)) were estimated to be 0.51 and 0.42 eV, respectively, indicating that it may be catalytically active.26 To further investigate the activity of α-Fe2O3, the reaction pathway of the IRR at the interface between CH3CN/Fe2O3(012) and CH3CN/Fe2O3(104) was calculated using the DFT.26 The I2 molecules can dissociate directly on top of the five-coordinated surface Fe3+ ions. Compared with the initial Fe–I bond length (2.72 Å) in the adsorption configuration, the transition state of the I* desorption exhibited a significantly elongated Fe–I bond length (4.12 Å) (Figure 7a–c). No particular high point was found in the overall standard free-energy profiles (Figure 7d) for both the Fe2O3(012) and Fe2O3(104) surfaces, implying a good kinetic performance for the IRR compared with the Pt(111). To verify the expected catalytic activity of α-Fe2O3, a simple hydrothermal method was used to prepare cube-like α-Fe2O3 nanoparticles that have generally exposed {012} and {104} facets and used as a CE in the DSCs to evaluate the PV parameters. The experimental results (Figure 8) indicate that the α-Fe2O3-based DSC can record a Jsc of 15.92 mA cm−2, a Voc of 784 mV, a fill factor of 0.56 and a PCE of 6.92%, which is comparable with that of the Pt-based DSC (Figure 8b and c). Furthermore, from the electrochemical impedance spectroscopic data, α-Fe2O3 has a lower interfacial charge transfer resistance (Rct) value (2.3 Ω) than that of Pt (3.4 Ω), which further confirmed the excellent catalytic activity for the triiodide reduction reaction. Another transition metal oxide, RuO2, possesses superior electrocatalytic activity in different heterogeneous catalysis, such as oxidation reactions, reduction/hydrogenation reactions, oxygen evolution reactions78 and ammonia synthesis.79 Regarding the IRR, the DFT calculation was used to estimate the  value at the CH3CN/RuO2 interface. The RuO2(110) surface contained exposed rows of five-coordinated Ru cations (Ru5c), which constituted typical catalytically active sites. Upon adsorption on the Ru5c row, the I2 readily dissociated into two I* without any apparent dissociation barrier. The

value at the CH3CN/RuO2 interface. The RuO2(110) surface contained exposed rows of five-coordinated Ru cations (Ru5c), which constituted typical catalytically active sites. Upon adsorption on the Ru5c row, the I2 readily dissociated into two I* without any apparent dissociation barrier. The  was calculated to be 0.59 eV, which was similar to that of the Pt(111) surface (0.52 eV) and within the optimal range.59 Therefore, RuO2 is expected to be a catalytically active CE electrocatalyst for the triiodide reduction reaction. In the past, Papageorgiou et al.80, reported the promising Rct of RuO2 and our recent theoretical study also support the previous findings.59 Interestingly, the RuO2 nanocrystals were found to afford almost same level of catalytic performance (7.22%) compared with Pt (7.17%). The extraordinary catalytic behavior of RuO2 might be owing to the favorable adsorption–desorption energy and good electrical conductivity within the nanocrystals.59

was calculated to be 0.59 eV, which was similar to that of the Pt(111) surface (0.52 eV) and within the optimal range.59 Therefore, RuO2 is expected to be a catalytically active CE electrocatalyst for the triiodide reduction reaction. In the past, Papageorgiou et al.80, reported the promising Rct of RuO2 and our recent theoretical study also support the previous findings.59 Interestingly, the RuO2 nanocrystals were found to afford almost same level of catalytic performance (7.22%) compared with Pt (7.17%). The extraordinary catalytic behavior of RuO2 might be owing to the favorable adsorption–desorption energy and good electrical conductivity within the nanocrystals.59

(a–c) α-Fe2O3 surface structure in the presence of the CH3CN solvent, I adsorption structure and transition-state structure. (d) Energy profiles of the CE reaction on Pt(111), Fe2O3(104) and Fe2O3(012), which were calculated at U=0.61 V vs SHE. Adapted from Hou et al.26 Copyright © 2013 Rights Managed by Nature Publishing Group.

(a) Surface morphology, cross-sectional view and TEM images of the α-Fe2O3 nanoparticle film. (b) Nyquist plots for the symmetrical cells of the α-Fe2O3 and Pt electrodes. (c) J-V characteristic curves for α-Fe2O3 and the Pt-based DSCs. Adapted from Hou et al.26 Copyright © 2013 Rights Managed by Nature Publishing Group.

As another useful metal oxide, WO3 has been firstly utilized as CE material in DSCs and the overall PCE was reported to be 4.67%.81 Our theoretical prediction suggested that WO3 could be an efficient electrocatalyst for triiodide reduction reaction as its  (0.54 eV) is very close to that of standard Pt. The inferior PCE of commercial WO3-based DSC was found in our group, however, after hydrogen treatment (H-WO3), the overall PCE markedly improved and reached 5.43%. The origin of the catalytic activity of the H-WO3 may result from the oxygen vacancy created by the hydrogen treatment, which eased the facile adsorption of the

(0.54 eV) is very close to that of standard Pt. The inferior PCE of commercial WO3-based DSC was found in our group, however, after hydrogen treatment (H-WO3), the overall PCE markedly improved and reached 5.43%. The origin of the catalytic activity of the H-WO3 may result from the oxygen vacancy created by the hydrogen treatment, which eased the facile adsorption of the  species on the vacant sites and thereby enhanced the electrocatalytic performance.82 Meanwhile, other tungsten oxides, such as WO2 and W18O49, also showed exceptional catalytic ability toward the triiodide reduction, leading to PCEs of 7.25 and 7.94%, respectively, which were extremely close to that of the standard Pt.81, 83 The authors believe that the underlying reason for the exceptional catalytic activity of W18O49 is the oxygen vacancies of W18O49, which can offer abundant active sites for the triiodide reduction reaction. Furthermore, the charge transport can be facilitated with the one-dimensional nanofiber structure. Moreover, our rational screening strategy anticipated a few other metal oxides, such as TiO2, MnO2, SnO2, CeO2, MoO3, Al2O3, Ga2O3, La2O3, Cr2O3, Ta2O5 and ZrO2, which may possess limited activity toward the triiodide reduction reaction because of their low-adsorption energy. A few of these oxides, such as TiO2, Cr2O3 and ZrO2, were tested as CE electrocatalysts in the DSCs, and their PCEs values were found to be 0.76, 1.07 and 2.60%, respectively, as reported by Wu et al.18 (Figure 9), which further validated the screening framework. Yun et al.84 investigated the HfO2 as a catalytic CE material in the DSCs, and their result indicated that its catalytic performance (7.75%) was superior to that of standard Pt (7.20%) when HfO2 was supported by mesoporous-graphitic-carbon. A recent study also suggested that spinel types of ternary oxides, such as CoCr2O4, can also be used as the CE material in the DSCs, and the overall PCE was reported to be 8.40%, which is close to that of the Pt-based DSCs (8.68%).85

species on the vacant sites and thereby enhanced the electrocatalytic performance.82 Meanwhile, other tungsten oxides, such as WO2 and W18O49, also showed exceptional catalytic ability toward the triiodide reduction, leading to PCEs of 7.25 and 7.94%, respectively, which were extremely close to that of the standard Pt.81, 83 The authors believe that the underlying reason for the exceptional catalytic activity of W18O49 is the oxygen vacancies of W18O49, which can offer abundant active sites for the triiodide reduction reaction. Furthermore, the charge transport can be facilitated with the one-dimensional nanofiber structure. Moreover, our rational screening strategy anticipated a few other metal oxides, such as TiO2, MnO2, SnO2, CeO2, MoO3, Al2O3, Ga2O3, La2O3, Cr2O3, Ta2O5 and ZrO2, which may possess limited activity toward the triiodide reduction reaction because of their low-adsorption energy. A few of these oxides, such as TiO2, Cr2O3 and ZrO2, were tested as CE electrocatalysts in the DSCs, and their PCEs values were found to be 0.76, 1.07 and 2.60%, respectively, as reported by Wu et al.18 (Figure 9), which further validated the screening framework. Yun et al.84 investigated the HfO2 as a catalytic CE material in the DSCs, and their result indicated that its catalytic performance (7.75%) was superior to that of standard Pt (7.20%) when HfO2 was supported by mesoporous-graphitic-carbon. A recent study also suggested that spinel types of ternary oxides, such as CoCr2O4, can also be used as the CE material in the DSCs, and the overall PCE was reported to be 8.40%, which is close to that of the Pt-based DSCs (8.68%).85

Photovoltaic performances and distribution of the relative PCE of late transition metal carbides, nitrides and oxides as CE catalysts in the  electrolyte system. Adapted from Wu et al.18 Copyright © 2012 American Chemical Society.

electrolyte system. Adapted from Wu et al.18 Copyright © 2012 American Chemical Society.

Metal sulfides

Transition metal sulfides are one of the most promising classes of CE electrocatalysts used to replace Pt owing to their outstanding electrocatalytic activity, thermal and chemical stability, abundant feedstock and low cost.9 On the basis of theoretical calculations, the  value for the most abundant facets of the CoS was estimated to be 0.59 eV, which lies within the range of 0.33–1.20 eV. Among all of the cobalt sulfides, CoS has been proven to be an efficient CE material in the DSCs. The first study was performed by Wang et al.16, who electrochemically deposited CoS nanoparticles on a flexible ITO/PEN substrate and applied it as a CE in the DSCs with a promising PCE of 6.5%. Later, this CoS material was further explored by several scientists, and the surface morphology and the electrical conductivity of the CoS films were found to be critically important for electrocatalysis in the triiodide reduction reaction, as reported by Lin et al.86 A controlled potentiodynamic deposition of CoS can produce a highly porous CoS film with an extremely low Rct value (~1.03 Ω cm2) and be used as an electrocatalyst (6.33%) that is superior to Pt (6.06%). Kung et al.87 prepared one-dimensional CoS acicular nanorod arrays (ANRAs) by converting Co3O4 ANRAs into CoS ANRAs without damaging the structural integrity using a simple chemical-bath process at a relatively low temperature of 90 °C for 24 h (Figure 10a and b). The CoS ANRAs CE displayed a larger catholic current density than that of Pt (Figure 10c), with an exceptional catalytic stability toward the triiodide reduction reaction after 200 cycles of consecutive runs (Figure 10d) and the PCE was reported to be as high as 7.67%, which is close to the standard Pt-based DSCs (7.70%). Another study was performed by Hsu et al.88, who synthesized the CoS nanoparticles with controlled particle sizes ranging from 50 to 320 nm using a surfactant-assisted preparation of a metal organic framework along with subsequent oxidation and sulfidation processes. Then, different composites of CoS with graphene,89 multi-wall carbon nanotubes (MWCNT)90 and PEDOT:PSS91 were identified as potential CE candidates, especially CoS nanocomposite with MWCNT outperformed the Pt-based DSC (6.39%), and the PCE was as high as 8.05%.90

value for the most abundant facets of the CoS was estimated to be 0.59 eV, which lies within the range of 0.33–1.20 eV. Among all of the cobalt sulfides, CoS has been proven to be an efficient CE material in the DSCs. The first study was performed by Wang et al.16, who electrochemically deposited CoS nanoparticles on a flexible ITO/PEN substrate and applied it as a CE in the DSCs with a promising PCE of 6.5%. Later, this CoS material was further explored by several scientists, and the surface morphology and the electrical conductivity of the CoS films were found to be critically important for electrocatalysis in the triiodide reduction reaction, as reported by Lin et al.86 A controlled potentiodynamic deposition of CoS can produce a highly porous CoS film with an extremely low Rct value (~1.03 Ω cm2) and be used as an electrocatalyst (6.33%) that is superior to Pt (6.06%). Kung et al.87 prepared one-dimensional CoS acicular nanorod arrays (ANRAs) by converting Co3O4 ANRAs into CoS ANRAs without damaging the structural integrity using a simple chemical-bath process at a relatively low temperature of 90 °C for 24 h (Figure 10a and b). The CoS ANRAs CE displayed a larger catholic current density than that of Pt (Figure 10c), with an exceptional catalytic stability toward the triiodide reduction reaction after 200 cycles of consecutive runs (Figure 10d) and the PCE was reported to be as high as 7.67%, which is close to the standard Pt-based DSCs (7.70%). Another study was performed by Hsu et al.88, who synthesized the CoS nanoparticles with controlled particle sizes ranging from 50 to 320 nm using a surfactant-assisted preparation of a metal organic framework along with subsequent oxidation and sulfidation processes. Then, different composites of CoS with graphene,89 multi-wall carbon nanotubes (MWCNT)90 and PEDOT:PSS91 were identified as potential CE candidates, especially CoS nanocomposite with MWCNT outperformed the Pt-based DSC (6.39%), and the PCE was as high as 8.05%.90

(a) SEM images for surface morphology. (b) Cross-section of the CoS acicular nanorod arrays (ANRAs) prepared at a 24 h reaction time. The inset of a depicts a large-scale SEM image of the corresponding ANRAs. (c) Cyclic voltammetry (CV) curves. (d) Stability test of the ANRAs in the  electrolyte. Adapted from Kung et al.87 Copyright © 2012 American Chemical Society.

electrolyte. Adapted from Kung et al.87 Copyright © 2012 American Chemical Society.

Similarly, NiS has been of particular interest owing to its salient electrocatalytic activity, earth abundance and cost effectiveness.62 In our study, we determined that a {0001}-faceted single-crystal NiS nanosheet film, as shown in Figure 11a and b, can be used as a superior CE for the triiodide reduction reaction owing to its exceptional crystal structure and sulfur vacancy-induced catalysis.62 The presence of the sulfur vacancy was found to be responsible for the rapid dissociation of I2 into two I* atoms, which has a stretched bond length of 3.664 Å compared with the free I2 molecular bond length of 2.681 Å (Figure 11c and d), indicating sufficient activation power of the NiS(0001) surface toward the I2 molecule. Along with the unique adsorption sites, the descriptor ( ) value was calculated to be 0.62 eV, which is within the optimal range of efficiently good electrocatalysts and close to that of the Pt(111) surface. An outstanding PCE of 8.62% was achieved with the DSCs equipped with {0001} faceted NiS CE, which is 17.1% higher than that of the PCE obtained from the Pt-based DSCs (7.36%). In addition, an interesting ‘two-in-one’ CE-based on a single crystalline NiS grown on bare glass using a simple one-pot hydrothermal approach was realized by Zhao et al.92 In their report, they tested oriented NiS nanorod arrays that could be used to replace transparent conductive oxide and Pt. The device made of Pt and transparent conductive oxide-free CE displayed a PCE of 7.41%, which was close to the PCE obtained from the DSC prepared with the transparent conductive oxide-supported Pt CE (7.55%). Xiao et al.93 investigated an NiS composite with MWCNTs as the CE material in the DSCs. Initially, the MWCNTs were electrophoretically deposited on a Ti foil, and a nano-corallines NiS was deposited over it using a potentiostatic method; this hybrid system was able to produce an enhanced PCE of up to 7.90%, which was higher than that of the PCE obtained from the DSC prepared with the Pt/Ti CE (6.36%). Furthermore, the NiS/graphene composite CE-based DSCs indicated a larger PCE value (5.25%) than that of the Pt-based one (5.00%).89

) value was calculated to be 0.62 eV, which is within the optimal range of efficiently good electrocatalysts and close to that of the Pt(111) surface. An outstanding PCE of 8.62% was achieved with the DSCs equipped with {0001} faceted NiS CE, which is 17.1% higher than that of the PCE obtained from the Pt-based DSCs (7.36%). In addition, an interesting ‘two-in-one’ CE-based on a single crystalline NiS grown on bare glass using a simple one-pot hydrothermal approach was realized by Zhao et al.92 In their report, they tested oriented NiS nanorod arrays that could be used to replace transparent conductive oxide and Pt. The device made of Pt and transparent conductive oxide-free CE displayed a PCE of 7.41%, which was close to the PCE obtained from the DSC prepared with the transparent conductive oxide-supported Pt CE (7.55%). Xiao et al.93 investigated an NiS composite with MWCNTs as the CE material in the DSCs. Initially, the MWCNTs were electrophoretically deposited on a Ti foil, and a nano-corallines NiS was deposited over it using a potentiostatic method; this hybrid system was able to produce an enhanced PCE of up to 7.90%, which was higher than that of the PCE obtained from the DSC prepared with the Pt/Ti CE (6.36%). Furthermore, the NiS/graphene composite CE-based DSCs indicated a larger PCE value (5.25%) than that of the Pt-based one (5.00%).89

(a) Cross-sectional SEM image. (b) SAED pattern of hydrothermally synthesized {0001}-faceted NiS nanosheet film. The inset of b depicts the TEM image of the NiS nanosheet film. (c) Direct dissociation of the I2 molecule upon adsorption at the S-vacancy dimer in the direction of (0001) at the NiS(0001) surface. (d) Adsorption configuration of the I atom sitting at the S-vacancy position. Light-blue, yellow and brown represent the Ni, S and I atoms, respectively. Adapted from Li et al.62 Copyright © 2014 Royal Society of Chemistry.

Another metal sulfide, FeS, was predicted to be potentially active for the triiodide reduction reaction because of its calculated  value of 0.64 eV, which is similar to that of Pt (0.52 eV). Unfortunately, this material has not been widely studied in the past because of its pyrophoric and non-stoichiometric nature. Hu et al.94 synthesized an FeS nanosheet film on an iron foil using a simple hydrothermal treatment in the presence of sulfur powder. The resulting film was fitted as a CE in tandem-type DSCs using

value of 0.64 eV, which is similar to that of Pt (0.52 eV). Unfortunately, this material has not been widely studied in the past because of its pyrophoric and non-stoichiometric nature. Hu et al.94 synthesized an FeS nanosheet film on an iron foil using a simple hydrothermal treatment in the presence of sulfur powder. The resulting film was fitted as a CE in tandem-type DSCs using  as a redox couple, and a PCE of 1.32% was obtained.

as a redox couple, and a PCE of 1.32% was obtained.

MoS2 with a layer structure has attracted considerable attention as a CE material because of its analogous structure to that of graphene and potential electrocatalytic activity.95 However, no theoretical calculation of MoS2 as a CE material has been available thus far. The application of MoS2 and WS2 as efficient electrocatalysts in the DSCs was first published by Wu et al.96 in 2011, and the obtained PCEs were 7.59 and 7.73%, respectively, which is comparable with the Pt CE. In our study, we directly grew a semi-transparent ultrathin MoS2 nanostructured film on an FTO substrate using a hydrazine-assisted hydrothermal method and used it as a CE in the DSCs.97 The obtained MoS2 film as a CE for the DSC can afford a PCE up to 7.41%, which was slightly better than that of the Pt-based DSC (7.13%). Further studies on both of the sulfides were performed, and an outstanding PCE (outperforming Pt) was achieved with the introduction of carbon.24 Thus far, different sulfides of metals, such as cobalt,98 nickel99 bismuth,100 tin,101 antimony,102 iron,103 tungsten104 and titanium105 have been studied as CE electrocatalysts in the DSCs. In addition to binary sulfides, a few tertiary or quaternary sulfides, including CuInS2,106 NiCo2S4,107 CoMoS4, NiMoS4108 and Cu2ZnSnS4,109, 110 were extensively studied as CE materials in the DSCs.

Metal nitrides

Transition metal nitrides are another class of alternative materials that have been tested as CEs in DSCs owing to their low cost, high catalytic activity and good thermal stability.111 According to our theoretical prediction, TiN could be catalytically promising for the triiodide reduction reaction because its  value was calculated to be 0.65 eV, which is within the range of 0.33–1.20.26 In 2009, Jiang et al.112 prepared TiN nanotube arrays by the anodization of Ti foil followed by nitridation in an ammonia atmosphere at 800 °C for 1 h and investigated the prepared film as a CE in the DSCs. In the electrochemical impedance spectroscopic measurement, the TiN electrode exhibited an ohmic internal resistance of 5.68 Ω smaller than that of the Pt-FTO electrode (21.88 Ω). The simulated Rct value for the TiN nanotube arrays electrode was 1.51 Ω, which was nearly one-fifth of the value obtained for the Pt-FTO electrode. However, a larger Warburg diffusion impedance was observed because of the higher capacitance developed at the porous electrode/electrolyte interface. To overcome this higher diffusion resistance, the layer thicknesses of the TiN nanotube arrays were suggested to be kept as small as possible for any practical application. The DSC prepared using the TiN nanotube arrays CE had a PCE of 7.73%, which was relatively higher than that of the Pt-FTO-based DSC (7.45%). Chen et al.113 prepared TiN nanoplates supported with carbon fibers. In their report, they first grew TiO2 nanoplates onto a carbon fibers, and a high-temperature ammonification process was used to convert TiO2 into porous TiN nanoplates, as indicated in Figure 12. The prepared TiN nanoplates supported with carbon fibers acted as the CE material in the DSCs and exhibited a superior PCE (7.20%) to that of the Pt (6.23%; Figure 12e). Later, TiN composites were investigated as the CE material in the DSCs, and in certain cases, superior performances were achieved because of the synergistic effect of the individual components.114, 115 According to our theoretical calculation, Fe2N and MoN could also be used as an active electrocatalyst for the triiodide reduction reaction because their

value was calculated to be 0.65 eV, which is within the range of 0.33–1.20.26 In 2009, Jiang et al.112 prepared TiN nanotube arrays by the anodization of Ti foil followed by nitridation in an ammonia atmosphere at 800 °C for 1 h and investigated the prepared film as a CE in the DSCs. In the electrochemical impedance spectroscopic measurement, the TiN electrode exhibited an ohmic internal resistance of 5.68 Ω smaller than that of the Pt-FTO electrode (21.88 Ω). The simulated Rct value for the TiN nanotube arrays electrode was 1.51 Ω, which was nearly one-fifth of the value obtained for the Pt-FTO electrode. However, a larger Warburg diffusion impedance was observed because of the higher capacitance developed at the porous electrode/electrolyte interface. To overcome this higher diffusion resistance, the layer thicknesses of the TiN nanotube arrays were suggested to be kept as small as possible for any practical application. The DSC prepared using the TiN nanotube arrays CE had a PCE of 7.73%, which was relatively higher than that of the Pt-FTO-based DSC (7.45%). Chen et al.113 prepared TiN nanoplates supported with carbon fibers. In their report, they first grew TiO2 nanoplates onto a carbon fibers, and a high-temperature ammonification process was used to convert TiO2 into porous TiN nanoplates, as indicated in Figure 12. The prepared TiN nanoplates supported with carbon fibers acted as the CE material in the DSCs and exhibited a superior PCE (7.20%) to that of the Pt (6.23%; Figure 12e). Later, TiN composites were investigated as the CE material in the DSCs, and in certain cases, superior performances were achieved because of the synergistic effect of the individual components.114, 115 According to our theoretical calculation, Fe2N and MoN could also be used as an active electrocatalyst for the triiodide reduction reaction because their  values (0.77 and 0.90 eV) are within the optimal range. Li et al.19 evaluated a few typical transition metal nitrides, such as MoN, Fe2N and WN, which were derived from the nitridation of MoO2, Fe2O3 and WO3, respectively. On the basis of electrochemical impedance spectroscopic, the MoN and WN electrode achieved Rct values of 0.92 and 0.94 Ω cm2, respectively, which were remarkably smaller than that of the Pt electrode (2.28 Ω cm2), thus exhibiting potential as CE materials. On the other hand, the Fe2N electrode displayed a relatively larger Rct value of 5.45 Ω cm2 and the largest mass-transfer diffusion resistance among all of the electrocatalysts investigated in their study. Eventually, MoN exhibited the highest PCE after Pt, and the PCE order was reported to be Pt>MoN>WN>Fe2N. In addition, further improvements on the electrocatalytic performance were conducted by controlling the diffusion kinetics in porous MoN nanorods, and a few composites have also been studied.116

values (0.77 and 0.90 eV) are within the optimal range. Li et al.19 evaluated a few typical transition metal nitrides, such as MoN, Fe2N and WN, which were derived from the nitridation of MoO2, Fe2O3 and WO3, respectively. On the basis of electrochemical impedance spectroscopic, the MoN and WN electrode achieved Rct values of 0.92 and 0.94 Ω cm2, respectively, which were remarkably smaller than that of the Pt electrode (2.28 Ω cm2), thus exhibiting potential as CE materials. On the other hand, the Fe2N electrode displayed a relatively larger Rct value of 5.45 Ω cm2 and the largest mass-transfer diffusion resistance among all of the electrocatalysts investigated in their study. Eventually, MoN exhibited the highest PCE after Pt, and the PCE order was reported to be Pt>MoN>WN>Fe2N. In addition, further improvements on the electrocatalytic performance were conducted by controlling the diffusion kinetics in porous MoN nanorods, and a few composites have also been studied.116

(a, c) TEM images, (b) SAED, (d) HRTEM images for the TiN nameplates. (e) J-V characteristic curves of the DSCs prepared using TiN-CF, Pt wire and bare CF as the CE. Adapted from Chen et al.113 Copyright © 2014 Royal Society of Chemistry.

Metal carbides

Transition metal carbides (TMCs) have been studied extensively because of their interesting physicochemical and catalytic properties that are similar to certain noble metals, including Ru, Rh, Pd, Os, Ir and Pt.117, 118 Interestingly, our theoretical calculation results indicated that the  values of MoC and WC (estimated to be 0.91 and 1.02 eV, respectively) fall within the optimal range of efficient electrocatalysts (0.33–1.20 eV), demonstrating their potential as good electrocatalysts for the triiodide reduction reaction. Jang et al.119 initially used WC as a electrocatalyst in the triiodide reduction reaction, and a promising result was obtained. The polymer-derived (WC-PD) and microwave-assisted (WC-MW) products they prepared were tested as CEs in the DSCs, and the PCEs were reported to be 6.61 and 7.01%, respectively, which were slightly lower than that of the conventional Pt-based DSC (8.23%). Recently, a WC and carbon-composite nanofiber was prepared by electro-spinning followed by a one-step carburization method, and it was demonstrated to be a powerful electrocatalyst in the

values of MoC and WC (estimated to be 0.91 and 1.02 eV, respectively) fall within the optimal range of efficient electrocatalysts (0.33–1.20 eV), demonstrating their potential as good electrocatalysts for the triiodide reduction reaction. Jang et al.119 initially used WC as a electrocatalyst in the triiodide reduction reaction, and a promising result was obtained. The polymer-derived (WC-PD) and microwave-assisted (WC-MW) products they prepared were tested as CEs in the DSCs, and the PCEs were reported to be 6.61 and 7.01%, respectively, which were slightly lower than that of the conventional Pt-based DSC (8.23%). Recently, a WC and carbon-composite nanofiber was prepared by electro-spinning followed by a one-step carburization method, and it was demonstrated to be a powerful electrocatalyst in the  electrolyte system, resulting in the highest PCE of 7.77%.120 A further attempt was made by Wu et al.,17 who fabricated the composites of MoC and WC embedded in the ordered nanomesoporous carbon materials (MoC-OMC, WC-OMC). The prepared composites were reported to possess an extremely large surface area of 611 and 598 m2 g−1 respectively, which was beneficial as a larger contact area for the triiodide reduction reaction during catalysis and resulted in superb electrocatalytic activity. The MoC-OMC and WC-OMC were found to produce PCEs of 8.34 and 8.18%, respectively, which is higher than that of the Pt-based DSCs (7.89%; Figure 13). Then, titanium carbide121 and silicon carbide122 were also identified to be efficient CE materials for the triiodide reduction reaction.

electrolyte system, resulting in the highest PCE of 7.77%.120 A further attempt was made by Wu et al.,17 who fabricated the composites of MoC and WC embedded in the ordered nanomesoporous carbon materials (MoC-OMC, WC-OMC). The prepared composites were reported to possess an extremely large surface area of 611 and 598 m2 g−1 respectively, which was beneficial as a larger contact area for the triiodide reduction reaction during catalysis and resulted in superb electrocatalytic activity. The MoC-OMC and WC-OMC were found to produce PCEs of 8.34 and 8.18%, respectively, which is higher than that of the Pt-based DSCs (7.89%; Figure 13). Then, titanium carbide121 and silicon carbide122 were also identified to be efficient CE materials for the triiodide reduction reaction.

TEM images of (a) MoC and (b) WC embedded in the ordered nanomesoporous carbon (OMC). The insets in a and b depict the magnified areas. (c) J-V characteristic curves of the DSCs prepared using WC-OMC, MoC-OMC and Pt CEs. Adapted from Wu et al.17 Copyright © 2011 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Doped metal oxides

The doping treatment on a variety of metal oxides has been proven to be an effective way to improve the electrocatalytic activity for several applications.123, 124 In the study on DSCs, conductive oxides are primarily used as a conducting support for electrocatalytically active materials (for example, Pt) to facilitate a faster electron transfer throughout the external circuit. Unfortunately, a few conductive oxides, such as indium oxide (In2O3), stannic oxide (SnO2) and zinc oxide (ZnO), were tested to be catalytically inactive toward the triiodide reduction reaction because of their low-adsorption energy and limited number of active sites.26 To enable these materials to be active for the triiodide reduction reaction, N atoms were purposely incorporated into the In2O3 nanocrystals. As depicted in Figure 14, the inserted N atoms formed a local NO2δ−, in which two O atoms deviated from the original lattice site in In2O3. The doped N atom preferred to be located at the subsurface and bind with the surface of the In atoms at a distance of 2.30 Å. The surface-binding energy of the N-In2O3 toward I or I2 varied with a change in the coordination environment. Using the DFT calculation, the  for CH3CN/N-In2O3 (0.94 eV) was significantly enhanced compared with that of the pure In2O3 (0.16 eV).60 Clearly, the

for CH3CN/N-In2O3 (0.94 eV) was significantly enhanced compared with that of the pure In2O3 (0.16 eV).60 Clearly, the  value of In2O3 after N doping is well within the optimal range for a good electrocatalyst, indicating an increased catalytic activity. This theoretically affirmative result encouraged the use of N-In2O3 as a CE material in DSCs.60 Compared with the undoped In2O3 counterpart, N-In2O3 exhibited remarkable electrocatalytic activity, resulting in a PCE as high as 7.78%, which is higher than that of the DSCs equipped with the Pt CE (Figure 14).

value of In2O3 after N doping is well within the optimal range for a good electrocatalyst, indicating an increased catalytic activity. This theoretically affirmative result encouraged the use of N-In2O3 as a CE material in DSCs.60 Compared with the undoped In2O3 counterpart, N-In2O3 exhibited remarkable electrocatalytic activity, resulting in a PCE as high as 7.78%, which is higher than that of the DSCs equipped with the Pt CE (Figure 14).

(a) Most stable structure of the interstitial N-doped In2O3 (N-In2O3); (b) top view and (c) side view of the optimized-surface structure of N-In2O3. Red, brown, blue and purple balls represent O, In, N and I, respectively. (d, e) High-resolution XPS of N 1 s, O 1 s. (f) TEM and (g) HRTEM images of N-In2O3 nanocrystals. (h) Electrochemical impedance spectroscopic spectra of the symmetrical cells prepared using the Pt, N-In2O3 and In2O3 electrocatalysts. (i) J-V curves of the DSCs. Adapted from Zhang et al.60 Copyright © 2013 Rights Managed by Nature Publishing Group.

In a recent study, we used a facile in situ vapor-phase hydrothermal surface-doping approach on Co3O4 nanosheets to achieve an unprecedentedly high surface S content (>47%) and realized a triiodide reduction reaction ability in the DSCs (Figure 15).61 The theoretical calculation on the S-doped {111} faceted Co3O4 nanosheets suggested a favorable  of 0.57 eV, which is close to the value obtained for Pt (0.52 eV) and expected to be a potential electrocatalyst for the triiodide reduction reaction. The S-Co3O4 displayed a competing PCE (7.79%) compared with the Pt-based DSC (7.81%). It is believed that the surface O substituted with S led to a Co–S bond formation that may promote active sites for the triiodide reduction reaction. In another example, a nitrogen-doped TiO2/graphene (N-TA/G) nanohybrid prepared at 700 °C under a continuous flow of ammonia gas was also reported to be a potential CE electrocatalyst for the DSC, exhibiting a PCE of 5.04%, which was slightly lower than that of the Pt-based DSC (6.40%).125

of 0.57 eV, which is close to the value obtained for Pt (0.52 eV) and expected to be a potential electrocatalyst for the triiodide reduction reaction. The S-Co3O4 displayed a competing PCE (7.79%) compared with the Pt-based DSC (7.81%). It is believed that the surface O substituted with S led to a Co–S bond formation that may promote active sites for the triiodide reduction reaction. In another example, a nitrogen-doped TiO2/graphene (N-TA/G) nanohybrid prepared at 700 °C under a continuous flow of ammonia gas was also reported to be a potential CE electrocatalyst for the DSC, exhibiting a PCE of 5.04%, which was slightly lower than that of the Pt-based DSC (6.40%).125

(a) TEM and (b) HRTEM images of the S-doped Co3O4 nanosheets. (c) Atomic arrangement of the clean and I adsorbed {111} faceted surface. Atoms in blue, red, yellow and purple represent Co, O, S and I, respectively. Adapted from Tan et al.61 Copyright © 2015 Royal Society of Chemistry.

Thus far, we have discussed the development of a generic and efficient screening strategy for the electrocatalytic activity of Pt-free materials for the triiodide reduction reaction with respect to the benchmark Pt electrocatalyst. On the basis of the first-principles calculations, the theoretical screening primarily focused on a few semiconducting materials, including oxides, sulfides, nitrides and carbides, and several of them were predicted to be potentially good candidates as CE materials in DSCs. It is worth mentioning that a few of these inorganic materials have already been proven to possess excellent electrocatalytic activity for the triiodide reduction reaction, and a few of them still deserve to be investigated further. To the best of our knowledge, no specific theoretical investigation is available for certain classes of materials, including phosphides,126 selenides,127 tellurides,128 carbon,129, 130, 131, 132, 133, 134 polymer135 and hybrids,136 which are experimentally proven to be active for the triiodide reduction reaction. The authors believe that a comprehensive theoretical model should be developed to categorize a wide variety of materials in a more efficient way.

Conclusions and perspectives

As a complex photoelectrochemical device, DSCs are a promising alternative to traditional semiconductor-based solar cells. In this rapidly developing field, finding an active CE material for redox mediators, such as  , is of great importance for the promotion of the DSCs. Using theoretical calculations, a general principle has been developed for screening Pt-free alternative CE materials for a triiodide reduction reaction in the DSCs, and more importantly, a series of new Pt-free CE materials, such as metals, metal oxides, metal sulfides, metal nitrides and metal carbides, have been successfully prepared, all of which demonstrate an excellent PV performance. With this theoretical screening principle, more low-cost and high-efficiency CE materials are expected to be designed and fabricated through adjusting the local geometrical and electronic structures of certain functional materials. Furthermore, these recent developments in the DSCs’ field will pave the way for a large-scale production of the

, is of great importance for the promotion of the DSCs. Using theoretical calculations, a general principle has been developed for screening Pt-free alternative CE materials for a triiodide reduction reaction in the DSCs, and more importantly, a series of new Pt-free CE materials, such as metals, metal oxides, metal sulfides, metal nitrides and metal carbides, have been successfully prepared, all of which demonstrate an excellent PV performance. With this theoretical screening principle, more low-cost and high-efficiency CE materials are expected to be designed and fabricated through adjusting the local geometrical and electronic structures of certain functional materials. Furthermore, these recent developments in the DSCs’ field will pave the way for a large-scale production of the  shuttle redox mediator-based DSCs as a commercial product for solar energy conversion. Furthermore, the theoretical framework in this report can be applied to other redox couples, such as Co-complex (Co(II)/Co(III)), disulfide/thiolate (T−/T2), ferrocene/ferrocenium (Fc/Fc+), Cu(I)/Cu(II) and Ni(III)/Ni(IV) in the DSCs. Interestingly, the screening principle highlighted in this report may offer a promising approach to advance the insight into the inherent electrocatalysis for dye-sensitized photoelectrochemical cells for the hydrogen evolution or synthesis, lithium−iodine (Li−I2) cell for energy storage and two-step photoexcitation for overall water splitting.

shuttle redox mediator-based DSCs as a commercial product for solar energy conversion. Furthermore, the theoretical framework in this report can be applied to other redox couples, such as Co-complex (Co(II)/Co(III)), disulfide/thiolate (T−/T2), ferrocene/ferrocenium (Fc/Fc+), Cu(I)/Cu(II) and Ni(III)/Ni(IV) in the DSCs. Interestingly, the screening principle highlighted in this report may offer a promising approach to advance the insight into the inherent electrocatalysis for dye-sensitized photoelectrochemical cells for the hydrogen evolution or synthesis, lithium−iodine (Li−I2) cell for energy storage and two-step photoexcitation for overall water splitting.

References

O’regan, B. & Grätzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991).

Grätzel, M. Photoelectrochemical cells. Nature 414, 338–344 (2001).