Abstract

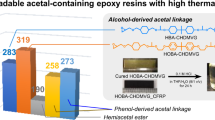

Novel addition-type phenylethynyl-containing imide oligomers (degree of polymerization: n=1–10) derived from 1,2,4,5-benzenetetracarboxylic dianhydride or pyromellitic dianhydride (PMDA), 2-phenyl-(4,4′-diaminodiphenyl ether) (p-ODA) and 4-phenylethynylphthalic anhydride (PEPA) were prepared and evaluated as a matrix resin for high heat-resistant carbon fiber-reinforced composites. The uncured imide oligomers showed good solubility (>30 wt%) in N-methyl-2-pyrrolidone and very low melt viscosities. These imide oligomers were successfully converted to crosslinked structures after curing at 370 °C. The glass transition temperature (Tg) and the elongation at break (ɛb) of the cured imide resin were found to be excellent (almost 340 °C and >15%, respectively). The carbon fiber prepreg was prepared from the imide oligomer solution and used to fabricate void-free laminates with high Tg. The thermal and mechanical properties of the laminates were determined at ambient temperature.

Similar content being viewed by others

Introduction

Aromatic polyimides (PIs), such as Kapton (DuPont, Wilmington, DE, USA) and Apical (Kaneka Corporation, Osaka, Japan), derived from 1,2,4,5-benzenetetracarboxylic dianhydride (PMDA) and 4,4′-oxydianiline (4,4′-ODA), and Upilex-R (Ube Industries, Tokyo, Japan), derived from 3,3′,4′,4′-biphenyltetracarboxylic dianhydride (symmetric-BPDA (s-BPDA)) and 4,4′-ODA, are well known to have high dimensional stability, low thermal expansion, and outstanding thermal and mechanical properties, as well as environmental stability.1, 2, 3 These properties are attributed not only to their rigid structures (planar and symmetric pyromellitimide or biphenylimide) but also to the formation of high-ordered structures due to chain-to-chain interactions. Accordingly, these aromatic PIs did not exhibit high molecular mobility at temperatures higher than their glass transition temperature (Tg), indicating that the processing conditions for molding were extremely severe. Significant effort has been devoted to the development of aromatic imide oligomers with good processability and high Tg by disrupting chain-to-chain interactions.

One well-known, high-performance, thermosetting PI is PMR-15, developed by NASA in the early 1970s for aerospace applications. High-temperature composites from low-molecular-weight resins that are end capped with reactive groups, such as PMR-15, are generally fabricated by autoclave processing. The PMR-15 cured resin exhibited a cured Tg of >300 °C, but the resin lacked toughness because of its high crosslink density.4 Consequently, the PMR-15 composites exhibited low impact resistance or compressive strength after impact and displayed microcracking upon thermal cycling.

The second-generation development of high-temperature matrix resins at NASA focused on phenylethynyl-containing imide oligomers. The resins were designed for use in high-temperature structural composites with applications in advanced aerospace vehicles, such as the once-proposed high-speed civil transport. The materials for this vehicle were required to have stable mechanical properties for 60 000 h at 177 °C. PETI-5 was the material selected for the matrix resin of high-speed civil transport vehicles and was prepared from the reaction of s-BPDA and two aromatic diamines, with 4-phenylethynylphthalic anhydride (PEPA) as the reactive end cap at a calculated molecular weight of 5000 g mol−1.5, 6, 7, 8 The cured PI film exhibited a moderate Tg of 270 °C and more than 30% elongation at break (ɛb). The moldings and composite laminates exhibited high toughness, indicating that upon thermal curing, the chain extension of the imide oligomers is significant and occurs by the thermal reaction of PEPA.9, 10 The phenylethynyl end cap offered important benefits, such as a large processing window and good thermo-oxidative stability. The PETI-5 imide exhibited excellent processability during the fabrication of neat resin molding, bonded panels and composites by autoclave processing under pressures of 1.4 MPa or less for approximately 1 h at 350–370 °C. PETI-5 was extensively evaluated and selected as a candidate for use as the adhesive and composite matrix for high-speed civil transport vehicles.11, 12, 13

Yokota et al.14, 15, 16, 17 recently found that a PI based on 2,3,3′,4′-biphenyltetracarboxylic dianhydride (asymmetric-BPDA or a-BPDA) and 4,4′-ODA exhibited a Tg higher than that of a similar s-BPDA-based PI, and the a-BPDA-based PI also showed a large drop in the storage modulus, E′, at temperatures higher than the Tg.

These observations are attributed to the decrease in the intermolecular interactions of the PIs that are derived from a-BPDA, which have asymmetric and nonplanar structures. On the basis of the thermal and rheological behavior of a-BPDA-based PIs, Yokota et al.18, 19 designed an a-BPDA-based phenylethynyl-terminated oligomer (TriA-PI) with excellent processability, high temperature resistance and more than 20% ɛb after curing at 370 °C for 1 h.

Because TriA-PI is insufficiently soluble in the imide form, the prepregs were manufactured by impregnating the carbon fibers with a TriA-PI amide acid oligomer solution at high concentrations. However, the evolution of water caused by the imidization of the amide acid oligomers during molding has a tendency to create voids in the composites. The preparation of void-less, high heat-resistant composites can be achieved using prepregs prepared by impregnating the fibers with a high concentration solution of imide oligomers if imide oligomers can be synthesized with both high solubility and good processability.

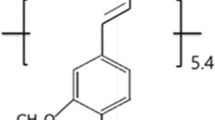

We describe in this paper the design and preparation of a phenylethynyl-terminated imide oligomer derived from pyromellitic dianhydride (PMDA) and an asymmetric diamine, 2-phenyl-4,4′-diaminodiphenyl ether (p-ODA). PMDA has symmetric and planar structures, and p-ODA is an extremely simple diamine with asymmetric and nonplanar structures. The effects of the asymmetry and the resulting nonplanar structure on the solubility and processability of addition-type aromatic imide oligomers were investigated.

On the basis of the thermal and rheological behavior of the PI(PMDA/p-ODA) film, we found by using dynamic mechanical analysis (DMA) measurements that the asymmetric and nonplanar structures of p-ODA were able to prevent the intramolecular–intermolecular interactions of the PMDA-based PI chains. Moreover, the PEPA-terminated aromatic imide oligomers were found to have high solubility in N-methyl-2-pyrrolidone (NMP) (>33 wt%) and good processability. In addition, upon thermal curing at 370 °C for 1 h, the crosslinked polymers exhibited excellent thermal (Tg >340 °C) and mechanical properties (elongation at break, ɛb>10%).

Materials and methods

Materials

The following chemicals were purchased from the indicated sources and used without further purification: PMDA (Tokyo Kasei, Tokyo, Japan; melting point 286 °C), NMP (Kanto Kagaku, Tokyo, Japan) and PEPA (Manac, Tokyo, Japan; melting point 152–153 °C). 4,4′-ODA (melting point 189–190 °C) and p-ODA (melting point 115–116 °C) were kindly supplied by Seika (Wakayama, Japan).

Measurements

Differential scanning calorimetry (DSC) was performed using a TA instruments DSC-2010 thermal analyzer at a heating rate of 20 °C min−1, with the Tg taken at the inflection point of the differential heat flow (ΔH) versus temperature curve in a nitrogen atmosphere. The samples were measured in a sealed aluminum pan. DMA were performed on thin film specimens (23.7 mm long, 5.0 mm wide and 0.05–0.15 mm thick) using a rheometric solids analyzer (RSA II instrument) at a heating rate of 10 °C min−1 and load frequency of 1 Hz in air. Dynamic thermogravimetric analyses were conducted using a TA instruments SDT-2960 thermal analyzer at a heating rate of 5 °C min−1. Melt viscosity measurements were performed on a AR-2000 dynamic rheometer (TA Instruments, New Castle, DE, USA) at a heating rate of 5 °C min−1. Specimen disks (25.4 mm diameter and 1.0−1.5 mm thick) were prepared by compression molding of the imide oligomer powder at room temperature.

PI films

PMDA/p-ODA and PMDA/4,4′-ODA PIs were prepared using a conventional two-step procedure from poly(amic acid)s with the corresponding diamine and dianhydride, as described in an earlier report.20

PMDA/p-ODA/PEPA imide oligomers

Phenylethynyl-containing imide oligomers were prepared from the reaction of PMDA and PEPA with the appropriate quantity of p-ODA.21 Initially, the aromatic diamine(s) were dissolved in NMP at room temperature under nitrogen, and the appropriate quantities of PMDA were added and stirred into one portion. After the complete dissolution of PMDA, PEPA was added with extra NMP to adjust the concentration of total solids to 33 wt% (w/w). The solution was allowed to stir for 2 h at room temperature. The imide oligomers were prepared directly from the amide acid solutions by imidization at 195 °C for 5 h in an oil bath. The p-ODA-based imide oligomers (n=1–4) remained soluble during the imidization process. By contrast, the 4,4′-ODA-based imide oligomer (n=4) precipitated during the imidization process. The imide oligomers were isolated by adding the reaction mixtures to water and washing with methanol. The yellow powders were dried at ∼240 °C for 4 h under vacuum to a constant weight, with yields >95%.

Preparation of cured resins

The obtained imide oligomers were molded using a MP-WNL MINI TEST PRESS machine (Toyo Seiki Seisaku-Sho, Tokyo, Japan). A 6 cm × 6 cm × 0.05 mm PI film frame was put onto a 20 cm × 20 cm stainless-steel plate with UPILEX-S separator films. The imide oligomers were initially heated at 310 °C for 10 min and subsequently heated to 370 °C and held for 1 h at a pressure of 1.4 MPa. Brown-colored, film-like specimens of 6 cm × 6 cm × 0.05 mm were obtained.

Processing of PI/carbon fiber composites

An NMP solution of imide oligomers (35 wt%) was impregnated into a 30 cm2 of plain woven carbon fiber (Toho Tenax IM600-6K, desized by washing with acetone and then drying). The imide oligomer solution prepreg was dried at 100 °C for 10 min. The average areal weight of the prepregs was almost 380 g m−2. The average solid, volatile and carbon fiber contents were 35, 17 and 48 wt%, respectively. The plain fabric composites (12 Ply) were cured in a vacuum hot press machine (Kitagawa Seiki, Hiroshima, Japan, KVHCII-Press). The solvent (NMP) was initially removed at 260 °C for 2 h without applying any pressure. The temperature was subsequently increased to 370 °C and held for 1 h at a pressure of 1.4 MPa. DMA was performed on a rectangular specimen (17.5 mm span length, 5.0 mm width and 2.1 mm thick), using a TA Instruments DMA Q-800 in the single cantilever beam test mode at a heating rate of 10 °C min−1 with a 1 Hz cycling rate and strain of 0.1% in air. The laminates were ultrasonically scanned (C-scanned, Pulse echo), cut into specimens and tested for mechanical properties. The panel was examined for microcracks and voids using a microscope at up to × 400 magnification. The short beam shear strength, based on a three-point bending test, was determined for the specimens (approximately 80 mm long, 60 mm width and 20 mm thick). Five specimens were tested at room temperature.

Results and discussion

Thermal and rheological properties of PMDA/p-ODA PIs

Recently, Yokota et al. found that the thermoplastic PI a-BPDA/4,4′-ODA exhibited a high Tg of 319 °C and a remarkably large drop in the E′ above the Tg (Figure 1). The difference in the temperature dependence of the DMA curves between PI(a-BPDA/4,4′-ODA) and PI(s-BPDA/4,4′-ODA) was attributed to the geometric structures of the PI chains. The a-BPDA-based PIs not only have an amorphous morphology but also have a higher Tg because of the restriction of free rotation as a result of internal steric hindrance.

Dynamic mechanical analysis (DMA) curve of PI(s-BPDA/4,4′-ODA) (black line) and PI(a-BPBA/4,4′-ODA) (red line). PI(a-BPDA/4,4′-ODA) showed both a higher glass transition temperature (Tg) and a remarkably large drop above the Tg. Asymmetric-BPDA, 2,3,3′,4′-biphenyltetracarboxylic dianhydride; 4,4′-ODA, 4,4′-oxydianiline; PI, polyimide; 3,3′,4′,4′-biphenyltetracarboxylic dianhydride, symmetric-BPDA.

Figure 2 shows the temperature dependence of the E′ curves of PI(PMDA/p-ODA) and the PI(PMDA/4,4′-ODA) films observed by the DMA measurement in air. The Tg was determined from the E′ as the tangent taken at the curve before and after the drop-off in the modulus. The PI(PMDA/4,4′-ODA) film did not show an obvious Tg based on the high-ordered molecular interaction of the polymer chains with a symmetric and rigid structure.22, 23 In contrast, PI(PMDA/p-ODA) clearly showed not only a high Tg at 325 °C but also a remarkably large drop of E′ from 109 to 107 Pa (the rubbery plateau region) above the Tg. The observed high Tg and the remarkably large drop in E′ are attributed to the pendant phenyl group of p-ODA, which restricted rotation. Moreover, the intra/intermolecular interactions of the PI(PMDA/p-ODA) chains were also prevented by the steric hindrance of the pendant phenyl group substituted onto the PI(PMDA/4,4′-ODA) chain. In Figure 2, the increasing behavior of E′ observed at temperatures above 420 °C is attributed to the thermo-oxidative crosslinking of cured resin caused by the DMA measurement in air. The wide-angle X-ray diffraction patterns of PI(PMDA/p-ODA) showed only a broadened peak without a dependency on the annealing temperature, indicating that PI(PMDA/p-ODA) did not form a high-ordered structure.20

Dynamic mechanical analysis (DMA) curve of PI(PMDA/4,4′-ODA) (black line) and PI(PMDA/p-ODA) (red line). E′ of PI(PMDA/p-ODA) showed a remarkably large drop above the glass transition temperature (Tg). 4,4′-ODA, 4,4′-oxydianiline; PI, polyimide; PMDA, 1,2,4,5-benzenetetracarboxylic dianhydride or pyromellitic dianhydride; p-ODA, 2-phenyl-(4,4′-diaminodiphenyl ether).

The thermal and mechanical properties of the aromatic PI(PMDA/p-ODA) film, determined by DSC and tensile measurements, are summarized in Table 1. The PI(PMDA/p-ODA) showed a high Tg up to 330 °C in a nitrogen atmosphere and high Td5 values were recorded as 549 °C on the thermal gravimetry analysis curve. Moreover, the PI(PMDA/p-ODA) was also found to be very tough on the basis of the high elongation of the thin film tensile specimens.

Solubility, processability and thermal properties of imide oligomers

The PMDA-based imide oligomers derived from 4,4′-ODA and p-ODA were obtained from the imidization of the solution of the corresponding amide acid oligomers (Figure 3). The PMDA/4,4′-ODA/PEPA imide oligomer (n=4) was insoluble in NMP and could not be compression molded because of the lack of melt flow. In contrast, the PMDA/p-ODA/PEPA imide oligomers (n=1–4) were completely soluble in the NMP solution at high concentrations, even at room temperature (>30 wt%).

Table 2 summarizes the solubility and thermal and mechanical properties of the PMDA/p-ODA/PEPA imide oligomer and cured resin (n=1–10). The minimum melt viscosity of the imide oligomers also increased with the degree of polymerization (Supplementary Figure S1). However, all of these materials exhibited their respective minimum melt viscosities at temperatures at which the phenylethynyl groups react. Thus, all of these imide oligomers are not stable at the temperatures of their minimum melt viscosities.8 These results indicate that the PMDA/p-ODA/PEPA imide oligomer has significantly better processability for molding fiber-reinforced, heat-resistant composites compared with conventional PMDA-based PIs. The low melt viscosities of the imide oligomer (n=1–4) are thought to be due to the formation of randomized repeating units of three types, shown in Figure 4: (a) head-to-tail , (b) head-to-head and (c) tail-to-tail.

The three possible types of repeated units in a (PMDA/p-ODA) polymer chain. Three possible types ((a) head-to-tail, (b) head-to-head and (c) tail-to-tail) of repeat units exist because of the asymmetric structure of p-ODA. PMDA, 1,2,4,5-benzenetetracarboxylic dianhydride or pyromellitic dianhydride; p-ODA, 2-phenyl-(4,4′-diaminodiphenyl ether).

Thermal and mechanical properties of the cured resins

In Table 2, the thermal and mechanical properties of the cured resin (PMDA/p-ODA/PEPA) were obtained from 100 to 150 mm homogeneous brown films. The Tg values of each cured resin, measured by DMA, were found to be very high. The E′ of the cured resin also exhibited a large drop at temperatures above Tg, as the pendant phenyl group of p-ODA in the polymer chain disrupts intermolecular interactions. The pattern of increase of E′ was observed at temperatures up to 420 °C because of the thermo-oxidative crosslinking caused by performing the measurements in air. All of the cured resins exhibited high Td5 values (>525 °C). Surprisingly, the ɛb values of the cured polymers were very high (>9.5%), indicating that the reaction mechanism of the PEPA was mainly chain extension rather than cyclization or crosslinking, as reported by Meyer et al.,9, 10 Nakamura et al.24

Incorporation of the BAFL diamine monomer into the PMDA/p-ODA/PEPA imide oligomers

After preparing a highly concentrated NMP solution of the PMDA/p-ODA/PEPA imide oligomer (33 wt%, n=4–10) at 150 °C, the solution formed a gel after storage for several days at room temperature. When the gel was heated to 150 °C for 1 h, it gradually changed to a solution without any precipitation of solids. This behavior is possibly due to the intermolecular interactions of the tail-to-tail units (Figure 4c) in the oligomer chains in the NMP solution, resulting in some molecular order that leads to the formation of a reversible gel.

In general, the preparation of the prepreg from solution requires an approximately 30 wt% solid solution to obtain sufficient resin content in a single dip process. The above gelation behavior is undesirable; therefore, it was proposed to investigate the use of a second diamine that would provide more steric hindrance and prevent gelation from occurring. The addition of a bulky substituent on the polymer side chain is well known to improve solubility; therefore, we selected 9,9-bis(4-aminophenyl)fluorene (BAFL), which contains a bulky fluorenyl side group, as a diamine monomer to copolymerize with the PMDA/p-ODA imide oligomer.

Table 3 shows the solubility and thermal and mechanical properties of the PI imide oligomer containing 10 mol% of BAFL. An addition of a small amount of BAFL allowed the imide oligomer solution to remain stable for over a few months with no sacrifice in the melt viscosity or the Tg of the cured resin. Only a decrease in the ɛb of the cured resin was observed, indicating that the molecular mobility and flexibility derived from the ether linkage of the p-ODA in the polymer chains was decreased concomitantly with the increase in the rigid units of PMDA-BAFL-PMDA. Increasing the amount of BAFL in the oligomers produces improved solubility, a higher Tg and increasing melt viscosity (Supplementary Table S1).

On the basis of these results, the PI PMDA/p-ODA(90);BAFL(10) imide oligomer was found to have high solubility (>33 wt%), storage stability in an NMP solution and low melt viscosity (<1500 Pa·s). Upon thermal curing, the imide oligomer exhibited both a high Tg (>350 °C) and good mechanical properties (ɛb>13%).

Carbon fiber-reinforced PI composites

The prepreg of the phenylethynyl-terminated PMDA/p-ODA(90);BAFL(10) imide oligomers was prepared by impregnating a carbon fiber plain woven cloth with the NMP solution of the imide oligomer.25, 26, 27 A PI/carbon fiber composite was fabricated from the prepreg in two steps. First, the laid-up prepregs (12 ply) were heated at 260 °C for 2 h on a hot plate under vacuum to remove the solvent. The laminate was subsequently cured at 370 °C for 1 h under 1.4 MPa of pressure. The resultant composite was of good quality as determined by an ultrasonic inspection (Figure 5). No void or cracks were observed in the composites by optical microscopy or a c-scan. The fibers in the composite appeared to be well wet-out by the resin.

The Tg of PI/carbon fiber composite was 356 °C, the same as that of the neat cured resin (Table 3). The short beam shear strength of the composite was found to be high (63 MPa), presumably due to the excellent quality of the laminate. In the fabrication of the 12 ply laminates, no problems were encountered with the removal of volatiles. It is unknown whether the removal of the volatiles will be more difficult with thicker laminates.

The detailed thermal and mechanical property measurements of the composites prepared from the phenylethynyl-terminated (PMDA/p-ODA; BAFL) imide oligomers are now in progress. We believe that this PMDA/p-ODA-type imide resin possesses a variety of excellent properties that will greatly enhance the possibilities for developing new heat resistance composite materials.

Conclusions

A novel phenylethynyl-terminated, addition-type imide oligomer (n=1–4) with a Kapton-type backbone structure was found to have high solubility and good processability. The imide oligomers were successfully converted to a cured resin with a Tg >345 °C and excellent preliminary mechanical properties. Preliminary studies were conducted for processing and determining the thermal and mechanical properties of the carbon fiber-reinforced PMDA/p-ODA(90);BAFL(10) composite. The IM600 plain woven composite exhibited excellent processability, high Tg and good mechanical properties at high temperatures.

We believe that these excellent properties of the PMDA/p-ODA-based addition-type aromatic PIs suggest promising possibilities for the application to highly heat-resistant composites prepared by imide solution prepreg techniques.

References

Polyimides: Fundamental and Applications, (Marcel Dekker, New York, 1996).

Polyamic Acids and Polyimides: Synthesis, Transformations and Structure, (CRC Press, Boca Raton, 1993).

Polyimides: Trends in Materials and Applications, (Society of Plastic Engineers, Mid-Hudson Section, New York, 1996).

Serafini, T. T., Delvigs, P. & Lightsey, G. R. Thermally stable polyimides from solutions of monomeric reactants. J. Appl. Polym. Sci. 16, 905–915 (1972).

Cano, R. J. & Jensen, B. J. Effect of molecular weight on processing and adhesive properties of the phenylethynyl-terminated polyimide LARC™-PETI-5. J. Adhes. 60, 113–123 (1997).

Hergenrother, P. M. & Smith, J. G. Chemistry and properties of imide oligomers end-capped with phenylethynylphthalic anhydrides. Polymer (Guildf) 35, 4857–4864 (1994).

Hergenrother, P. M., Connell, J. W. & Smith, J. G. Phenylethynyl containing imide oligomers. Polymer (Guildf) 41, 5073–5081 (2000).

Smith, J. G., Connell, J. W. & Hergenrother, P. M. The effect of phenylethynyl terminated imide oligomer molecular weight in the properties of composites. J. Comp. Matls. 34, 614–628 (2000).

Meyer, G. W., Tan, B. & McGrath, J. E. Solvent-resistant polyetherimide network systems via phenylethynylphthalic anhydride endcapping. High Perform. Polym. 6, 423–435 (1994).

Holland, T. V., Glass, T. E. & McGrath, J. E. Investigation of The thermal curing chemistry of the phenylethynyl group using a model aryl ether imide. Polymer (Guildf) 41, 4965–4990 (2000).

Jensen, B. J., Bryant, R. G., Smith, J. G. & Hergenrother, P. M. Adhesive properties of cured phenylethynyl-terminated imide oligomers. J. Adhes. 54, 57 (1995).

Hou, T., Jensen, B. J. & Hergenrother, P. M. Processing and properties of IM7/PETI composites. J. Comp. Matls. 30, 109–122 (1996).

Rommel, M., Konopka, L. & Hergenrother, P. M. Process development and mechanical properties of IM7/LaRC PETI-5 composites. Intl. SAMPE Tech. Conf. Ser. 28, 1–13 (1996).

Hasegawa, M., Sensui, N., Shindo, Y. & Yokota, R. Structure and properties of asymmetric biphenyl type polyimides. homo- and copolymers and blends. Macromolecules 32, 387–396 (1999).

Chen, C., Yokota, R., Hasegawa, M., Kochi, M., Hori,e, K. & Hergenrother, P. M. Isomeric biphenyl polyimides. (I) Chemical structure–property relationships. High Perform. Polym. 17, 317–333 (2005).

Kochi, M., Chen, C., Yokota, R., Hasegawa, M. & Hergenrother, P. M. Isomeric biphenyl polyimides. (II) Glass transitions and secondary relaxation process. High Perform. Polym. 17, 335–347 (2005).

Zhou, H., Chen, C., Kanbara, R., Sakaki, T. & Yokota, R. Synthesis and properties of copolyimides derived from isometric biphenyltetracarboxylic dianhydrides (a-BPDA and i-BPDA) and oxydiphthalic dianhydride (ODPA) with 4,4′-oxydianiline (4,4′-ODA).. High Perform. Polym. 17, 213–224 (2005).

Yokota, R., Yamamoto, S., Yano, S., Sawaguchi, T., Hasegawa, M., Yamaguchi, H., Ozawa, H. & Sato, R. Molecular design of resistant polyimides having excellent processability and glass transition temperature. High Perform. Polym. 13, S61–S72 (2001).

Ogasawara, T., Ishikawa, T., Yokota, R., Ozawa, H., Taguchi, M., Sato, R., Shigenari, Y. & Miyagawa, K. Processing and properties of carbon fiber reinforced Triple-A polyimide (Tri-A PI) matrix composites. Adv. Compos. Mater. 11, 277 (2003).

Miyauchi, M., Kazama, K., Sawaguchi, T. & Yokota, R. Dynamic tensile properties of a novel Kapton-type asymmetric polyimide derived from 2-phenyl-4,4′-diaminodiphenyl ether. Polym. J. 43, 866–868 (2011).

Ishida, Y., Ogasawara, T. & Yokota, R. Development of highly soluble addition-type imide oligomers for matrix of carbon fiber composite (I): imide oligomers based on asymmetric biphenyltetracarboxylic dianhydride and 9,9-bis(4-aminophenyl)fluorene. High Perform. Polym. 18, 727–737 (2006).

Coburn, J. C. & Pottiger, M. T. in Advances in Polyimide Science and Technology. Feger C., Khojasteh M. M., Htoo M. S. (eds) 360 (Technomic, NewYork, 1993).

Isoda, S., Shimada, H., Kochi, M. & Kambe, H. Molecular aggregation of solid aromatic polymers. I. Small-angle x-ray scattering from aromatic polyimide film. J. Polym. Sci. Polym. Phys. Ed. 19, 1293–1312 (1981).

Nakamura, K., Ando, S. & Takeichi, T. Thermal analysis and solid-state 13C NMR study of crosslink in polyimides containing acetylene groups in the main chain. Polymer (Guildf) 42, 4045–4054 (2001).

Miyauchi, M., Ishida, Y., Ogasawara, T. & Yokota, R. Synthesis and Properties of Novel Asymmetric Addition-type Imide Oligomers with High Solubility. Recent Advances in Polyimides. Takeichi T., Kawauchi T., Akahori K. (eds) 139–141 (Meibunsha, Aichi, 2009).

Miyauchi, M., Ishida, Y., Ogasawara, T. & Yokota, R. Synthesis and properties of novel asymmetric addition-type imide resins based on Kapton®-type structure, in Proc. of 14TH European Conference on Composite Materials 2010, ID:754 (Budapest, Hungary).

Miyauchi, M., Ishida, Y., Ogasawara, T. & Yokota, R. Novel phenylethyneyl-terminated asymmetric KAPTON®-type polyimides consisting of 2-phenyl-4,4′-diaminodiphenyl ether for heat resistant composites. in Proc. of Society for the Advancement of Material and Process Engineering (Long beach, CA, 2011).

Acknowledgements

The authors would like to acknowledge Dr Akihiro Tamaki and Dr Motonori Takeda of Seika for supplying the monomer, Professor Masakatsu Kochi of the Shizuoka Institute of Science and Technology, Assistant Professor Atsushi Morikawa of Ibaraki University and Dr John Connell of the NASA Langley Research Center for helpful technical discussions. This report is part of a series of studies entitled ‘Development of Novel Asymmetric Polyimides for Fiber-Reinforced Composite Materials with High Heat Resistance’ for which M Miyauchi received an Award for Encouragement of Research in Polymer Science from The Society of Polymer Science, Japan (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Miyauchi, M., Ishida, Y., Ogasawara, T. et al. Highly soluble phenylethynyl-terminated imide oligomers based on KAPTON-type backbone structures for carbon fiber-reinforced composites with high heat resistance. Polym J 45, 594–600 (2013). https://doi.org/10.1038/pj.2012.160

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.160

Keywords

This article is cited by

-

Development of High-Performance Composites with Molecular Weight Controlled Polyimide Oligomers End-Capped with Phenylethynyl Groups

Fibers and Polymers (2020)

-

Highly soluble phenylethynyl terminated oligoimides derived from 5(6)-amino-1-(4-aminophenyl)-1,3,3-trimethylindane, 4,4′-oxydianiline and mixed thioetherdiphthalic anhydride isomers

Journal of Polymer Research (2018)

-

High thermal stable polyimide resins derived from phenylethynyl-endcapped fluorenyl oligoimides with low melt viscosities

Chinese Journal of Polymer Science (2016)

-

Synthesis and characterization of phenylethynyl-terminated polyimide oligomers derived from 2,3,3′,4′-diphenyl ether tetracarboxylic acid dianhydride and 3,4′-oxydianiline

Chinese Journal of Polymer Science (2016)