Abstract

A crown ether–ammonium salt-type rotaxane monomer was synthesized in a high yield using dibenzo-24-crown-8-ether and sec-ammonium salt having a hydroxy terminal by means of an end-capping reaction with an ethynyl benzoic acid. Its N-acetylated derivative was also synthesized in a quantitative yield using excess acetic anhydride and triethylamine. Novel side chain-type polyrotaxanes, that is, ammonium-type and neutral polyphenylacetylenes tethering rotaxane moieties in side chains with high molecular weights, were obtained in high yields by polymerizations with an Rh catalyst. The structures of the polymers were characterized by infrared, ultraviolet-visible (UV-vis) spectra and size exclusion chromatography. N-acetylation of the rotaxane moieties of the ammonium salt-type polymer resulted in the formation of a reddish-colored neutral polymer showing red-shifted UV-vis absorptions around 500 nm based on the conjugated main chain, according to the structural change of rotaxane side chains, that is, the change of the distance of the wheel component to the polyacetylene main chain. The solubility of the polymers was evaluated.

Similar content being viewed by others

Introduction

Among the various types of polyrotaxanes (side chain-type polyrotaxane),1, 2, 3, 4 the side chain type is an intriguing class of polyrotaxanes, which can be characterized by the regular and controllable arrangement of rotaxane functions along the main chain polymer. Side chain-type polyrotaxanes are classified into two types: wheel pendant and axle pendant types. The latter type of polyrotaxanes is often synthesized by the radical polymerization of vinylic monomers, often using cyclodextrines and crown ethers as wheel components. Ritter and co-workers5 first reported side chain-type polyrotaxanes possessing β-cyclodextrin wheels (first synthesis of side chain-type polyrotaxane), whereas crown ether-containing polyrotaxanes were synthesized by a few groups (cyclodextrine type; except for crown ether type).6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21 However, some issues remain to be addressed in the construction of functionalized side chain-type polyrotaxanes, such as high polymerization degree, controlled rotaxane content, regular arrangement of rotaxane moietes and so on. These matters depend mainly on the low polymerizability of the rotaxane-containing monomer due to the wheel component working as a sterically hindered group toward the growing end; competitive occurrence of the dethreading of the wheel component during polymerization when a pseudorotaxane monomer is used; and a nonstereoregular main chain polymer being formed by the polymerization of vinylic monomer.9 Polymerization of a vinylic rotaxane monomer but not pseudorotaxane monomer has been reported only by Osakada et al.11 To overcome such issues, we have noticed and studied the synthesis of ethynyl-functionalized rotaxane monomer for high polymerization and its derivation to polyacetylene, because the high polymerization of bulky acetylenes is readily achieved with appropriate catalysts,22, 23, 24, 25, 26, 27, 28, 29 and polyacetylenes usually have a stable main chain conformation. In this paper, we wish to disclose the synthesis of phenylacetylene monomers tethering rotaxane moieties and their polymerization to novel side chain-type polyrotaxanes.

Experimental procedure

Measurements

Melting points were measured on a melting point apparatus SMP3 (Bibby Scientific, Stone, UK) instrument. 1H and 13C nuclear magnetic resonance (NMR) spectra were recorded on a JEOL AL-400 NMR spectrometer (JEOL, Tokyo, Japan) operating at 400 and 100 MHz, respectively, in CDCl3 with tetramethylsilane as an internal standard. Infrared (IR) spectra were measured by a JASCO FT/IR-460 plus spectrometer (JASCO, Tokyo, Japan). Ultraviolet-visible (UV-vis) spectra were obtained with a JASCO V-550 spectrometer. Molecular weight and its distribution were measured by size exclusion chromatography (SEC), which was performed on a JASCO HSS-1500 system equipped with consecutive TOHSO TSK gel G2000HXL (Tohso, Tokyo, Japan) and a GMHXL eluted with chloroform at a flow rate of 0.85 ml min−1 calibrated using polystyrene standards. Preparative high-performance liquid chromatography was carried out using a JAI HPLC LC-918 (Japan Analytical Industry Co. Ltd, Tokyo, Japan) (columns: JASCO Megapack-Gel 201C, Megapack-Gel 201 CP and JAI JAIGEL-1H; eluent: chloroform; flow rate: 3.5 ml min−1). Mass spectra were recorded on a JEOL JMS-700 with NBA as the matrix. Elemental analysis was carried out using LECO CHNS-932 (LECO, Tokyo, Japan).

Materials

All solvents were distilled before use according to the general purification procedure. Commercially available reagents were used without further purification, unless otherwise noted. Column chromatography was performed using Wakogel C-400HG (Wako Pure Chemical Industries Ltd., Osaka, Japan). Axle precursor 1 was prepared according to literature.30

Preparation of 3

Methyl 3-bromo-5-iodobenzoate

To a solution of 3-bromo-5-iodobenzoic acid (20.0 g, 61.2 mmol) in MeOH (200 ml) was added H2SO4 (18 M, 0.5 ml). After refluxing for 12 h, half of the MeOH was removed under reduced pressure. The resulting mixture was poured into water, neutralized with K2CO3 and extracted twice with ether (50 ml). The combined organic layer was washed with water, dried over anhydrous MgSO4 and evaporated. The residual mixture was subjected to purification with silica gel column chromatography (hexane:AcOEt=4:1). The titled compound 3 was obtained as a colorless solid in 94% yield (19.5 g, 57.2 mmol).

m.p. 62.0–63.0 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 8.29 (s, 1H), 8.13 (s, 1H), 8.04 (s, 1H), 3.93 (s, 3H) p.p.m.; 13C NMR (100 MHz, CDCl3) δ 164.4, 143.8, 137.2, 133.2, 132.0, 123.0, 94.0, 52.7 p.p.m.; IR (KBr) 3070, 2956, 2857, 1732 cm−1; HRMS (FAB): exact mass calcd for C8H7BrO2[M+H]+, 340.8674. Found 340.8673.

Methyl 3-bromo-5-(triisopropylsilyl)ethynylbenzoate

To a solution of methyl 3-bromo-5-iodobenzoate (5.00 g, 14.7 mmol) in Et3N (50.0 ml) were added PdCl2(PPh3)2 (200 mg, 284 μmol), CuI (62.3 mg, 331 μmol) and (triisopropylsilyl)acetylene (3.33 ml, 14.9 mmol) in this order, and the mixture was heated to 70 °C for 4 h. After cooling the mixture to room temperature, the inorganic precipitate was removed by filtration with Celite. The collected filtrate was washed with water, dried over anhydrous MgSO4 and evaporated. The obtained crude material was subjected to purification by silica gel column chromatography (hexane). The titled compound was obtained as a colorless oil (5.73 g, 14.5 mmol) in 99% yield. 1H NMR (400 MHz, CDCl3, 298 K) δ 8.10 (s, 1H), 8.03 (s, 1H), 7.71 (s, 1H), 3.93 (s, 3H), 1.11 (s, 21H) p.p.m.; 13C NMR (100 MHz, CDCl3, 298 K) δ 165.2, 138.7, 132.3, 131.9, 131.6, 125.7, 122.1, 104.2, 93.8, 52.6, 18.6, 11.2 p.p.m.; IR (neat) 3077, 2945, 2866, 2160, 1726 cm–1. HRMS (FAB): exact mass calcd for C19H28BrO2Si [M+H]+, 395.1042. Found 395.1050.

3-Bromo-5-(triisopropylsilyl)ethynylbenzoic acid 3

To a solution of methyl 3-bromo-5-(triisopropylsilyl)ethynyl benzoate (5.73 g, 14.5 mmol) in tetrahydrofuran (THF) (110 ml) was added a solution of KOH (2.51 g, 44.7 mmol) in H2O (5.0 ml) and the mixture was stirred for 40 h at ambient temperature. A half amount of THF was removed under reduced pressure, and 3 M HCl (30 ml) was added to the residue. The mixture was extracted with ether (50 ml × 3) and the combined organic layer was washed with brine. After drying over anhydrous MgSO4, the solvent was removed under reduced pressure. The residual mixture was subjected to purification by silica gel column chromatography (CHCl3:MeOH=100:3) to give the titled compound as a colorless solid (5.53, 14.4 mmol) in 99% yield.

m.p. 152–154 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 8.17 (s, 1H), 8.10 (s, 1H), 7.83 (s, 1H), 1.13 (s, 21H) p.p.m.; IR (KBr) 3422, 2944, 2866, 2150, 1700 cm−1; HRMS (FAB): exact mass calcd for C18H26BrO2Si [M+H]+, 381.0885. Found 381.0887.

Protected rotaxane 4

Hydroxy-terminated sec-ammonium PF6 salt-type 130 (269 mg, 671 μmol) was mixed with dibenzo-24-crown-8-ether (435 mg, 949 μmol) in chloroform (1.1 ml). To the resulting homogeneous pseudorotaxane mixture was added 3-bromo-5-(triisopropylsilyl)ethynylbenzoic acid 3 (255 mg, 669 μmol), N, N′-dicyclohexylcarbodiimide (270 mg, 1.34 mmol) and tributylphosphane (16.7 μl, 66.9 μmol). After stirring for 24 h, the mixture was diluted with dichloromethane and the precipitate formed was removed by filtration. The filtrate was washed with 5% NaHCO3 and brine, dried with anhydrous MgSO4 and evaporated. The crude mixture was subjected to purification by silica gel column chromatography using chloroform as the eluent and successive preparative SEC using chloroform as the eluent. Pure [2]rotaxane 4 was obtained as a colorless powder in 54% yield (432 mg, 361 μmol).

m.p. 72–74 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 8.09 (s, 1H), 8.04 (s, 1H), 7.79 (s, 1H), 7.59 (br, 2H), 7.36 (d, J=7.8 Hz, 2H), 7.24 (d, J=7.8 Hz, 2H), 6.89–6.86 (m, 5H), 6.84 (s, 2H), 6.79–6.77 (m, 4H), 5.27 (s, 2H), 4.67–4.64 (m, 2H), 4.49–4.45 (m, 2H), 4.10–4.09 (m, 8H), 3.79–3.77 (m, 8H), 3.48 (s, 8H), 2.16 (s, 6H), 1.12 (s, 21H) p.p.m.; IR (KBr) 2942 (νC–H, as), 2866 (νC–H, s), 2156 (νC≡C), 1727 (νC=O), 1253 (νC–O–CO, as), 1123 (νC–O–CO, s), 842 (νP–F, as), 557 (νP–F, s) cm–1.

Ammonium salt-type rotaxane monomer 5

To a solution of 4 (1.50 g, 1.24 mmol) in THF (6.30 ml) was added 1 M teterabutylammonium fluoride in THF (1.45 ml, 1.45 mmol) and the mixture was stirred for 12 h at ambient temperature. The mixture was diluted with dichloromethane, washed with 10% Na2CO3 and 10% NH4PF6 and the organic layer was dried over MgSO4. Evaporation of the resulting mixture was followed by purification by the preparative SEC using chloroform as the eluent. [2]Rotaxane 5 was obtained as a colorless powder in 77% yield (1.01 g, 1.24 mmol).

m.p. 129–131 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 8.14–8.13 (m, 1H), 8.06 (m, 1H), 7.80–7.79 (m, 1H), 7.59 (br, 2H), 7.36 (d, J=8.1 Hz, 2H), 7.24 (d, J=8.0 Hz, 2H), 6.89–6.84 (m, 7H), 6.80–6.77 (m, 4H), 5.25 (s, 2H), 4.68–4.65 (m, 2H), 4.49–4.46 (m, 2H), 4.10–4.09 (m, 8H), 3.79 (m, 8H), 3.49 (s, 8H), 3.21 (s, 1H), 2.16 (s, 6H) p.p.m.; IR (KBr) 3273 (νC–H), 2920 (νC–H, as), 2876 (νC–H, s), 2112 (νC≡C), 1726 (νC=O), 1255 (νC–O–CO, as), 1124 (νC–O–CO, s), 842 (νP–F, as), 557 (νP–F, s) cm−1; Anal. Calcd for C50H57O10NBrPF6: C, 56.82; H, 5.44; N, 1.33. Found: C, 57.37; H, 5.65; N, 1.45; HRMS (FAB): exact mass calcd for C50H57O10NBrPF6 [M–PF6]+, 910.3166. Found 910.3190.

N-Acetylated rotaxane monomer 6

To a solution of 5 (294 mg, 279 μmol) and Et3N (200 μl, 1.44 mmol) in dimethyl formamide (2.22 ml) was added Ac2O (83.6 μl, 836 μmol), and the mixture was stirred at 40 °C for 12 h. After the reaction was quenched by the addition of 1 M HCl aqueous, the homogeneous mixture was extracted three times using dichloromethane. The combined organic layer was washed with 5% Na2CO3 aqueous and satuarted NH4Cl aqueous, dried over anhydrous MgSO4 and evaporated. The crude mixture was separated by the preparative SEC using chloroform as the eluent to afford N-acetylated rotaxane 6 as a colorless powder in 84% yield (224 mg, 235 μmol).

m.p. 73–74 °C; 1H NMR (400 MHz, CDCl3, 298 K) δ 8.72 (m, 1H), 8.61 and 8.60 (two m, 1H), 7.96 (d, J=8.1 Hz, 1H), 7.87 (d, J=8.3 Hz, 1H), 7.64 and 7.63 (two m, 1H), 6.96 (d, J=8.1 Hz, 1H), 6.91 (d, J=7.1 Hz, 1H), 6.90–6.88 (m, 1H), 6.83–6.80 (m, 5H), 6.75–6.71 (m, 5H), 5.88 and 5.83 (two s, 2H), 4.50 and 4.25 (two s, 2H), 4.40 and 4.24 (two s, 2H), 4.11–4.00 (m, 8H), 3.74–3.64 (m, 8H), 3.28–3.19 (m, 4H), 3.08–3.02 (m, 4H), 2.86 and 2.82 (two s, 1H), 2.30 and 2.28 (two s, 6H), 2.15 and 2.14 (two s, 3H) p.p.m.; IR (KBr) 3245 (νC–H), 2917 (νC–H, as), 2875 (νC–H, s), 2125 (νC≡C), 1719 (νC=O, ester), 1650 (νC=O, amide), 1252 (νC–O–CO, as), 1127 (νC–O–CO, s) cm–1; Anal. Calcd for C52H58O11NBr: C, 65.54; H, 6.13; N, 1.47. Found: C, 65.59; H, 6.16; N, 1.62; HRMS (FAB): exact mass calcd for C52H58O11NBr [M+H]+, 951.3193. Found 952.3264.

Polymerization

A typical procedure for the polymerization reaction of 5. Polymerization of 5 was carried out according to Masuda's report.31 Monomer 5 (26.4 mg, 25.0 μmol) was placed in a flask, which was then evacuated on a vacuum line and flushed with argon. After the evacuation-flush procedure was repeated three times, a three-way stopcock was attached to the flask and dry CHCl3 (98 μl) was introduced by means of a syringe. To the flask was added a solution of [RhCl(nbd)]2/Et3N/CHCl3 (15 μM, 1.5 M, 8.3 μl) and the resulting mixture was stirred at room temperature for 3 h. The mixture was poured into MeOH to precipitate a polymeric material, which was collected by filtration and dried under reduced pressure.

Polymer 7

Polymer 7 is a brownish yellow solid (21.1 mg, 80%). IR (KBr) 3433, 2922, 1725, 1505, 1456, 1252, 1211, 1125, 1056, 841, 558 cm–1; 1H NMR spectrum of 7 was too broad to be analyzed.

Polymer 8

Polymer 8 is a reddish solid (40 mg, 78%). IR (KBr) 3433, 2919, 2876, 1718, 1646, 1506, 1450, 1251, 1212, 1125, 1053, 738 cm–1; 1H NMR spectrum of 8 was too broad to be analyzed. Mn and Mw/Mn were over the measurable molecular weight range of SEC (more than 2000 × 103).

N-Acetylation of 7

To a solution of 7 (20.0 mg, 141 μmol) in dry dimethyl formamide (1 ml) was added Et3N (1.0 ml, 7.2 mmol) and acetic anhydride (1.0 ml, 11 mmol). The mixture was stirred for 24 h at 40 °C and directly precipitated into diethyl ether. After stirring the mixture for 1 h, the precipitate formed was collected by filtration and washed with MeOH. After drying under reduced pressure, N-acetylated polyrotaxane 7Ac was obtained as a reddish solid (17.8 mg, 0.135 mmol) in 96% yield.

IR (KBr) ν 3062, 2950, 2866, 2153, 1725, 1648, 1624, 1592, 1505, 1459, 1361, 1249, 1214, 1125, 1070, 986, 804, 741, 679 cm–1; Mn 465 × 103, Mw/Mn 5.9.

Results and discussion

Monomer synthesis

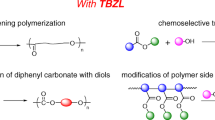

Two new rotaxane monomers possessing ethynylphenyl groups on the axle termini were designed and synthesized according to our previously reported ester end-capping method (Scheme 1).32 3-Bromo-5-(triisopropylsilylethynyl)benzoic acid 3 was prepared from 3-bromo-5-iodobenzoic acid by means of Sonogashira coupling, according to literature.33 Pseudorotaxane 2 was prepared in situ from DB24C8 and hydroxy-terminated sec-ammonium salt 1 in chloroform. To a solution of 2 were added 3, N,N′-dicyclohexylcarbodiimide and a catalytic amount of tributylphosphane,30, 34 and the mixture was stirred for 1 h at room temperature. Purification by preparative high-performance liquid chromatography resulted in ethynyl-protected rotaxane 4 in 54% yield. Successive deprotection of the triisopropylsilyl group with tetrabutylammonium fluoride afforded sec-ammonium salt-type rotaxane monomer 5 in 77% yield. Neutral rotaxane monomer 6 was obtained in 84% yield by N-acetylation of 5 with excess acetic anhydride and triethylamine.35, 36, 37

The structures of these monomers were determined by 1H, 13C NMR and IR spectral analyses along with mass spectra. 1H NMR spectra of 5 and 6 clearly supported their structures as assigned in Figure 1. N-Benzylic proton signals (h and i) on the axle component clearly appeared as two characteristic multiplets30 around 4.6 p.p.m., suggesting the presence of hydrogen bonding with the ether oxygen of DB24C8 as proof of the formation of the rotaxane structure of 5. Other signals such as those of crown ether oxyethylene protons, O-benzylic protons and the acetylenic proton were also well consistent with the proposed structures. Although all signals were split due to the presence of syn-anti isomers of the amide group, the spectrum confirmed the rotaxane structure of amide-type rotaxane monomer 6. Splitting of the crown ether oxyethylene proton signals were characteristic of this type of rotaxane, as assigned in Figure 1.30, 35, 36, 37 O-Benzylic proton signal, which is sensitive to the position of the crown ether wheel on the axle, moved to 5.9 p.p.m., indicating the localization of the wheel around the ester group. This result suggests that the wheel component gets considerably close to the acetylene moiety in comparison with that of 5.

Polymerization

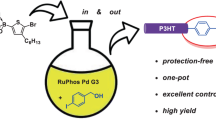

[RhCl(nbd)]2, a typical catalyst for synthesis of polyphenylacetylenes, was used by coupling with triethylamine as a cocatalyst for the polymerization of rotaxane monomers 5 and 6 (Scheme 2).

Polymerization was conducted under the typical conditions31, 38, 39 reported so far: [5 or 6] 250 mM, {[RhCl(nbd)]2} 1.25 mM (0.5 mol%) and [Et3N] 12.5 mM (5 mol%); at room temperature for 3 h. The polymerization of 5 and 6 proceeded smoothly to result in the corresponding polyacetylenes 7 and 8 as brownish yellow solids in 92% yield and red solids in 78% yield, respectively. Although both 1H NMR spectra of these polymers were too broad for their structures to be analyzed, the IR and UV spectra afforded firm evidence for their structures (Figures 2 and 4). Namely, two absorptions of the ethynyl group around 2100 and 3300 cm–1 in the IR spectra completely disappeared after polymerizations, whereas the characteristic absorptions of the counterion around 850 and 560 cm–1, corresponding to the P-F stretching vibration, remained unchanged before and after the polymerization of 5–7 (Figures 2a and b). As these spectra were well coincident each other in the fingerprint region and no decomposition product was confirmed through purification, the obtained polymer must retain the rotaxane structure after polymerization under basic conditions, as described in previous reports.30, 34 Otherwise, the amide carbonyl absorption around 1700 cm–1 of 6 (N-Ac) was not lost in 8 (Figures 2c and d). Most reliable evidence was found in the UV-vis spectra of 7 and 8, which showed clear absorption peaks at the 450–500 nm region characteristic of the absorptions based on conjugated polyphenylacetylene main chains (Figure 4). Although the SEC molecular weight of 7 could not be evaluated owing to its polyion structure and low solubility to the SEC solvent, the SEC profile of 8 showed Mn over the measurable molecular weight range of the SEC (more than 2000 × 103). The unusually high molecular weight of 8 might be attributed to a certain special structure formed during polymerization, although the structure and its reason are unclear at present.

Meanwhile, an alternative synthesis of 8 was examined by direct derivation from 7, that is, by polymer reaction using an excess amount of acetic anhydride and triethylamine in dimethyl formamide at 40 °C (Scheme 2).30, 34 Polymer 7Ac obtained in 96% yield after 24 h reaction was a red-colored solid, similar to 8. The SEC molecular weight of 7Ac reached Mn 465 × 103 (Mw/Mn 5.9), being sufficiently high as a polyhenylacetylene. This value also proves the high polymerizability of 5, as well as the high molecular weight of 7. 7Ac displayed the characteristic absorptions in IR and UV-vis spectra that are similar to those of 8, indicating sufficient progress of the N-acetylation process (Figures 3 and 4). The N-acetylation degree of 7Ac was also estimated from its IR spectrum (Figure 3). The disappearance of the strong absorptions of PF6 at 850 and 560 cm–1 supported the almost complete occurrence of the N-acetylation process. Indeed, new absorption at 1700 cm–1 appeared in the spectrum of 7Ac, of which the fingerprint region was well consistent with that of 8. Furthermore, as shown in the UV-vis spectrum of 7Ac, although the solvent was slightly different from that of 7, the absorption peak was red shifted from 449 to 499 nm by the N-acetylation process (Figure 4). This UV-vis result suggests that polymer 7Ac has an effective length of the conjugated main chain that is longer than that of 7. Although the unusually high SEC molecular weight value of 8, which is much higher than that of 7Ac, still cannot be explained, it is clear that the structures of 7Ac and 8 are not same. The difference between 8 and 7Ac lies in the synthetic process, which may cause a serious difference in the polymer structure. In fact, the UV-vis absorption maximum due to the conjugated main chain of 8 (507 nm) is longer than that of 7Ac (499 nm), as shown in Figure 4. The result seems to support the essentially high molecular weight of 8.

The extension of the conjugated main chain length by the N-acetylation of 7 to 7Ac might reveal that the change of the side-chain structure helps to extend the main-chain conjugation so as to avoid the steric repulsion between the side chains that is increased by N-acetylation, because it is reported that the crown ether wheel moves from the ammonium moiety to the ester moiety by the N-acetylation of such types of rotaxanes.30 Considering the increasing bulkiness by the movement of the crown ether wheel in the conversion of 7 to 7Ac, the polymerizability of 6 can be estimated to be somewhat low as a result of the increased steric hindrance around the acetylene group, but it was very high if SEC data are reliable (Table 1).

The solubility of 7 and 7Ac to organic solvents was investigated (Table 2). Polyammonium salt 7 was soluble in aprotic polar solvents such as dimethylsulfoxide, acetonitrile and acetone. On the contrary, neutral amide-type polymer 7Ac showed good solubility to chloroform, THF and toluene, and was much less polar than dimethylsulfoxide. This solubility change is clearly attributable to the nonionic character of 7Ac, whereas the significant red shift of the absorption λmax and apparent color change obviously support the main-chain structural and configurational change caused by the positional change of the wheel component on the side-chain axle by the N-acetylation process.

Conclusion

In this study, the synthesis and polymerization of the novel crown ether–ammonium salt-type rotaxane monomer and its N-acetylated counterpart with polymerizable acetylenic functions have been demonstrated. Novel side chain-type polyrotaxanes, that is, ammonium salt-type and neutral polyphenylacetylenes tethering rotaxane structures in side chains with high molecular weights were obtained in high yields. The N-acetylation of the rotaxane moieties of the ammonium salt-type polymer (7) resulted in the formation of a reddish-colored polymer (7Ac) showing red-shifted UV-vis absorptions around 500 nm based on the conjugated main chain, according to the structural change of rotaxane side chains, that is., the change of the distance of the wheel component to the polyacetylene main chain. This type of chromisms is under active investigation in our laboratory.

References

Raymo, F. M. & Stoddart, J. F. Interlocked macromolecules. Chem. Rev. 99, 1643–1663 (1999).

Huang, F. & Gibson, H. W. Polypseudorotaxanes and polyrotaxanes. Prog. Polym. Sci. 30, 982–1018 (2005).

Tomatsu, I., Hashizume, A. & Harada, A. Cyclodextrin-based side-chain polyrotaxane with unidirectional inclusion in aqueous media. Angew. Chem., Int. Ed. 45, 4605–4608 (2006).

Pang, Y. & Ritter, H. Novel side-chain polyrotaxane with cyclodextrin: syntheses and study of water-soluble copolymers bearing hydrophobically associative components. Macromol. Chem. Phys. 207, 201–208 (2006).

Born, M. & Ritter, H. Comb-like rotaxane polymers containing non-covalently bound cyclodextrins in the side chains. Macromol. Chem., Rapid Commun. 12, 471–476 (1991).

Gong, C. & Gibson, H. W. Self-threading-based approach for branched and/or cross-linked Poly(methacrylate rotaxane)s. J. Am. Chem. Soc. 119, 5862–5866 (1997).

Takata, T., Kawasaki, H., Kihara, N. & Furusho, Y. Radically polymerizable pseudorotaxane monomers: versatile building units for side chain polyrotaxane synthesis. Chem. Lett. 28, 111–112 (1999).

Yamaguchi, N. & Gibson, H. W. Non-covalent chemical modification of crown ether side-chain polymethacrylates with a secondary ammonium salt: a family of new polypseudorotaxanes. Macromol. Phys. Chem. 201, 815–824 (2000).

Takata, T., Kawasaki, H., Kihara, N. & Furusho, Y. Synthesis of side-chain polyrotaxane by radical polymerizations of pseudorotaxane monomers consisting of crown ether wheel and acrylate axle bearing bulky end-cap and ammonium group. Macromolecules 34, 5449–5456 (2001).

Gibson, H. W., Bryant, W. S. & Lee, S.- H. Polyrotaxanes by free-radical polymerization of acrylate and methacrylate monomers in the presence of a crown ether. J. Polym. Sci., Part A: Polym. Chem. 39, 1978–1993 (2001).

Suzaki, Y., Murata, S. & Osakada, K. Ferrocene-containing side chain polyrotaxanes obtained by radical copolymerization of styrenes with acrylamide with a [2]rotaxane structure. Chem. Lett. 38, 356–357 (2009).

Born, M. & Ritter, H. Side-chain polyrotaxanes with a tandem structure based on cyclodextrins and a polymethacrylate main chain. Angew. Chem., Int. Ed. 34, 309–311 (1995).

Born, M. & Ritter, H. Topologically unique side-chain polyrotaxanes based on triacetyl-β-cyclodextrin and a poly(ether sulfone) main chain. Macromol. Rapid Commun. 17, 197–202 (1996).

Born, M. & Ritter, H. Pseudo-polymer analogous reactions: Methylation of alcohol groups of non-covalently anchored 2,6-dimethyl-β-cyclodextrin components located in branched side chains of a poly(tandem-rotaxane). Adv. Mater. 8, 149–151 (1996).

Yamaguchi, I., Osakada, K. & Yamamoto, T. Introduction of a long Alkyl side chain to Poly(benzimidazole)s. N-alkylation of the imidazole ring and synthesis of novel side chain polyrotaxanes. Macromolecules 30, 4288–4294 (1997).

Noll, O. & Ritter, H. New side-chain poly(methacryl-rotaxanes) bearing cyclodextrins as non-covalently anchored ring components. Chemoenzymatic synthesis and degradation. Macromol. Rapid Commun. 18, 53–58 (1997).

Noll, O. & Ritter, H. Synthesis of new side-chain polyrotaxanes via free radical polymerization of a water-soluble semi-rotaxane monomer consisting of 2,6-dimethyl-β-cyclodextrin and 3-O-(11-acryloylaminoundecanoyl)cholic acid. Macromol. Chem. Phys. 199, 791–794 (1998).

Yamaguchi, I., Osakada, K. & Yamamoto, T. A novel crown ether stopping group for side chain polyrotaxane. preparation of side chain polybenzimidazole rotaxane containing alkyl side chain ended by crown ether-ONa group. Macromolecules 33, 2315–2319 (2000).

Pang, Y. & Ritter, H. Novel side-chain polyrotaxane with cyclodextrin: syntheses and study of water-soluble copolymers bearing hydrophobically associative components. Macromol. Chem. Phys. 207, 201–208 (2006).

Kwan, P. H., MacLachlan, M. J. & Swager, T. M. Rotaxanated conjugated sensory polymers. J. Am. Chem. Soc. 126, 8638–8639 (2004).

Bria, M., Bigot, J., Cooke, G., Lyskawa, J., Rabani, G., Rotello, V. M. & Woisel, P. Synthesis of a polypseudorotaxane, polyrotaxane, and polycatenane using ‘click’ chemistry. Tetrahedron 65, 400–407 (2009).

Tang, B. Z., Poon, W. H., Leung, S. M., Leung, W. H. & Peng, H. Synthesis of stereoregular Poly(phenylacetylene)s by organorhodium complexes in aqueous media. Macromolecules 30, 2209 (1997).

Kishimoto, Y., Eckerle, P., Miyatake, T., Kainosho, M., Ono, A., Ikariya, T. & Noyori, R. Well-controlled polymerization of phenylacetylenes with organorhodium(I) complexes: mechanism and structure of the polyenes. J. Am. Chem. Soc. 121, 12035–12044 (1999).

Miyake, M., Misumi, Y. & Masuda, T. Living polymerization of phenylacetylene by isolated rhodium complexes, Rh[C(C6H5) C(C6H5)2](nbd)(4-XC6H4)3P (X=F, Cl). Macromolecules 33, 6636–6639 (2000).

Takata, T., Ishiwari, F., Sato, T., Seto, R. & Koyama, Y. Synthesis, structure, and properties of polyacetylenes possessing chiral spirobifluorene moieties in the side chain. Polym. J. 40, 846–853 (2008).

Nishimura, T., Maeda, K., Ohsawa, S. & Yashima, E. Helical arrays of pendant fullerenes on optically active Poly(phenylacetylene)s. Chem. Eur. J. 11, 1181–1190 (2005).

Kwak, G. & Masuda, T. Poly(phenylacetylene) with bulky chiral germyl groups: synthesis and effects of measuring solvents and temperature on chiroptical properties. Polymer 43, 665–669 (2002).

Kwak, G. & Masuda, T. Synthesis, chiroptical properties, and high gas permeability of Poly(phenylacetylene) with bulky chiral silyl groups. Macromolecules 33, 6633–6635 (2000).

Nanjo, K., Karim, S. M. A., Nomura, R., Wada, T., Sasabe, H. & Masuda, T. Synthesis and properties of poly(1-naphthylacetylene) and poly(9-anthrylacetylene). J. Polym. Sci., Part A: Polym. Chem. 37, 277–282 (1999).

Kihara, N., Tachibana, Y. & Takata, T. Unusually lowered acidity of ammonium group surrounded by crown ether in a rotaxane system and its acylative neutralization. Chem. Lett. 29, 506–507 (2000).

Morino, K., Maeda, K., Okamoto, Y., Yashima, E. & Sato, T. Temperature dependence of helical structures of Poly(phenylacetylene) derivatives bearing an optically active substituent. Chem. Eur. J. 8, 5112–5120 (2002).

Makita, Y., Kihara, N. & Takata, T. Tributylphosphane-catalyzed condensation of alcohol and carboxylic acid with DCC directed toward rotaxane synthesis. Chem. Lett. 36, 102–103 (2007).

Tobe, Y., Utsumi, N., Kawabata, K., Nagano, A., Adachi, K., Araki, S., Sonoda, M., Hirose, K. & Naemura, K. m-Diethynylbenzene macrocycles: syntheses and self-association behavior in solution. J. Am. Chem. Soc. 124, 5350–5364 (2002).

Tachibana, Y., Kawasaki, H., Kihara, N. & Takata, T. Sequential O- and N-acylation protocol for high-yield preparation and modification of rotaxanes: synthesis, functionalization, structure, and intercomponent interaction of rotaxanes. J. Org. Chem. 71, 5093–5104 (2006).

Ashton, P. R., Chrystal, E. J. T., Glink, P. T., Menzer, S., Schiavo, C., Spencer, N., Stoddart, J. F., Tasker, P. A., White, A. J. P. & Williams, D. J. Pseudorotaxanes formed between secondary dialkylammonium salts and crown ethers. Chem. Eur. J. 2, 709–727 (1996).

Loeb, S. J. & Wisner, J. A. [3]Rotaxanes employing multiple 1,2-bis(pyridinium) ethane binding sites and dibenzo-24-crown-8 ethers. Chem. Commun. 10, 845–846 (2000).

Cantrill, S. J., Pease, A. R. & Stoddart, J. F. A molecular meccano kit. J. Chem. Soc., Dalton Trans. 3715–3734 (2000).

Yashima, E., Maeda, K. & Nishimura, T. Detection and amplification of chirality by helical polymers. Chem. Eur. J. 10, 42–51 (2004).

Sanda, F., Nishiura, S., Shiotsuki, M. & Masuda, T. Synthesis and secondary structure of cis-stereoregular Poly(N-propargylcarbamates) having various side chains. Macromolecules 38, 3075–3078 (2005).

Acknowledgements

This study was financially supported by the Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology of Japan (nos. 18064008 and 19655013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakazono, K., Fukasawa, K., Sato, T. et al. Synthesis of acetylene-functionalized [2]rotaxane monomers directed toward side chain-type polyrotaxanes. Polym J 42, 208–215 (2010). https://doi.org/10.1038/pj.2009.331

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2009.331