Abstract

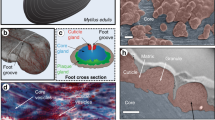

Hierarchical composite materials design in biological exoskeletons achieves penetration resistance through a variety of energy-dissipating mechanisms while simultaneously balancing the need for damage localization to avoid compromising the mechanical integrity of the entire structure and to maintain multi-hit capability. Here, we show that the shell of the bivalve Placuna placenta (~99 wt% calcite), which possesses the unique optical property of ~80% total transmission of visible light, simultaneously achieves penetration resistance and deformation localization via increasing energy dissipation density (0.290 ± 0.072 nJ μm−3) by approximately an order of magnitude relative to single-crystal geological calcite (0.034 ± 0.013 nJ μm−3). P. placenta, which is composed of a layered assembly of elongated diamond-shaped calcite crystals, undergoes pervasive nanoscale deformation twinning (width ~50 nm) surrounding the penetration zone, which catalyses a series of additional inelastic energy dissipating mechanisms such as interfacial and intracrystalline nanocracking, viscoplastic stretching of interfacial organic material, and nanograin formation and reorientation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kamat, S., Su, X., Ballarini, R. & Heuer, A. H. Structural basis for the fracture toughness of the shell of the conch Strombus gigas. Nature 405, 1036–1040 (2000).

Kamat, S., Kessler, H., Ballarini, R., Nassirou, M. & Heuer, A. H. Fracture mechanisms of the Strombus gigas conch shell: II-micromechanics analyses of multiple cracking and large-scale crack bridging. Acta Mater. 52, 2395–2406 (2004).

Aizenberg, J. et al. Skeleton of Euplectella sp: Structural hierarchy from the nanoscale to the macroscale. Science 309, 275–278 (2005).

Weaver, J. C. et al. The stomatopod dactyl club: A formidable damage-tolerant biological hammer. Science 336, 1275–1280 (2012).

Ortiz, C. & Boyce, M. C. Biological structural materials. Science 319, 1053–1054 ( 2008).

Dunlop, J. W. C. & Fratzl, P. Biological composites. Annu. Re. Mater. Res. 40, 10.1–10.24 (2010).

Yang, W. et al. Nature flexible dermal armor. Adv. Mater. 25, 31–48 (2013).

Gao, H., Ji, B., Jäger, I. L., Arzt, E. & Fratzl, P. Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc. Natl Acad. Sci. USA 100, 5597–5600 (2003).

Huang, Z. et al. Uncovering high-strain rate protection mechanism in nacre. Sci. Rep. 1, 148 (2011).

Bruet, B. J. F., Song, J., Boyce, M. C. & Ortiz, C. Materials design principles of ancient fish armour. Nature Mater. 7, 748–756 (2008).

Barthelat, F., Tang, H., Zavattieri, P. D., Li, C-M. & Espinosa, H. D. On the mechanics of mother-of-pearl: A key feature in the material hierarchical structure. J. Mech. Phys. Solids 55, 306–337 (2007).

Tai, K., Dao, M., Suresh, S., Palazoglu, A. & Ortiz, C. Nanoscale heterogeneity promotes energy dissipation in bone. Nature Mater. 6, 454–462 (2007).

Sands, J. M., Patel, P. J., Dehmer, P. G., Hsieh, A. J. & Boyce, M. C. Transparent armour materials. Military Tech. 12, 82–91 (2008).

Li, L. & Ortiz, C. Biological design for simultaneous optical transparency and mechanical robustness in the shell of Placuna placenta. Adv. Mater. 25, 2344–2350 (2013).

Checa, A. G., Esteban-Delgado, F. J. & Rodríguez-Navarro, A. B. Crystallographic structure of the foliated calcite of bivalves. J. Struct. Biol. 157, 393–402 (2007).

Arciszewski, T. & Cornell, J. in Intelligent Computing in Engineering and Architecture (ed Smith, I.) 32–53 (Springer, (2006).

Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

Song, J., Ortiz, C. & Boyce, M. C. Threat-protection mechanics of an armored fish. J. Mech. Behav. Biomed. Mater. 4, 699–712 (2011).

Kunitake, M. E., Mangano, L. M., Peloquin, J. M., Baker, S. P. & Estroff, L. A. Evaluation of strengthening mechanisms in calcite single crystals from mollusk shells. Acta Biomater. 9, 5353–5359 (2013).

Bruet, B. J. F. et al. Nanoscale morphology and indentation of individual nacre tablets from the gastropod mollusc Trochus niloticus. J. Mater. Res. 7, 2400–2419 (2005).

He, L. H. & Swain, M. V. Energy absorption characterization of human enamel using nanoindentation. J. Biomed. Mater. Res. A 81, 484–492 (2007).

Turner, F. J., Griggs, D. T. & Heard, H. Experimental deformation of calcite crystals. Bull. Geo. Soc. Amer. 65, 883–934 (1954).

Barber, D. J. & Wenk, H. R. Deformation twinning in calcite, dolomite, and other rhombohedral carbonates. Phys. Chem. Minerals 5, 141–165 (1979).

Chen, M. et al. Deformation twinning in nanocrystalline aluminum. Science 300, 1275–1277 (2003).

Li, X., Xu, Z-H. & Wang, R. In-situ observation of nanograin rotation and deformation in nacre. Nano Lett. 6, 2301–2304 (2006).

Oyen, M. L. & Cook, R. F. A practical guide for analysis of nanoindentation data. J. Mech. Behav. Biomed. Mater. 2, 396–407 (2009).

Yu, Q. et al. Strong crystal size effect on deformation twinning. Nature 463, 335–338 (2010).

Zhu, Y. T., Liao, X. Z. & Wu, X. L. Deformation twinning in nanocrystalline materials. Prog. in Mater. Sci. 57, 1–62 (2012).

Zlufarska, I., Nakano, A. & Vashishta, P. A crossover in the mechanical response of nanocrystalline ceramics. Science 309, 911–914 (2005).

Li, Y. S., Tao, N. R. & Lu, K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 56, 230–241 (2008).

Lu, K., Lu, L. & Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 324, 349–352 (2009).

Smith, B. L. et al. Molecular mechanistic origin of the toughness of natural adhesives, fibres and composites. Nature 399, 761–763 (1999).

Goetz, A. J. et al. Interdigitating biocalcite dendrites form a 3-D jigsaw structure in brachiopod shells. Acta Biomater. 7, 2237–2243 (2011).

O’Neill, P. L. Polycrystalline echinoderm calcite and its fracture mechanics. Science 213, 646–648 (1981).

Wang, R. Z., Addadi, L. & Weiner, S. Design strategies of sea urchin teeth: Structure, composition and micromechanical relations to function. Phil. Trans. R. Soc. Lond. B 352, 469–480 (1997).

Suzuki, M., Kim, H., Mukai, H., Nagasawa, H. & Kogure, T. Quantitative XRD analysis of {110} twin density in biotic aragonites. J. Struct. Biol. 180, 458–468 (2012).

Younis, S., Kauffmann, Y., Pokroy, B. & Zolotoyabko, E. Atomic structure and ultrastructure of the Murex troscheli shell. J. Struct. Biol. 180, 539–545 (2012).

Acknowledgements

We gratefully acknowledge the support of the National Science Foundation through the MIT Center for Materials Science and Engineering (DMR-0819762), the US Army Research Office through the MIT Institute for Soldier Nanotechnologies (Contract W911NF-07-D-0004), the National Security Science and Engineering Faculty Fellowship Program (N00244-09-1-0064), and the Office of Assistant Secretary of Defense for Research and Engineering. The authors would like to thank J. Li, Y. Zhu, M. Dao and A. Schwartzman for fruitful general discussions of the manuscript. The authors would like to thank J. C. Weaver for his assistance in scanning electron microscopy imaging. The authors would also like to thank L. Han, A. Schwartzman, S. Chen, Y. Zhang and M. J. Connors for their technical assistance.

Author information

Authors and Affiliations

Contributions

L.L. and C.O. designed the research, analysed the data and wrote the manuscript. L.L. conducted the experiments

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 932 kb)

Rights and permissions

About this article

Cite this article

Li, L., Ortiz, C. Pervasive nanoscale deformation twinning as a catalyst for efficient energy dissipation in a bioceramic armour. Nature Mater 13, 501–507 (2014). https://doi.org/10.1038/nmat3920

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3920

This article is cited by

-

Transcriptome analysis of the bivalve Placuna placenta mantle reveals potential biomineralization-related genes

Scientific Reports (2022)

-

Graphene oxide bulk material reinforced by heterophase platelets with multiscale interface crosslinking

Nature Materials (2022)

-

High strength and damage-tolerance in echinoderm stereom as a natural bicontinuous ceramic cellular solid

Nature Communications (2022)

-

PU14, a Novel Matrix Protein, Participates in Pearl Oyster, Pinctada Fucata, Shell Formation

Marine Biotechnology (2021)

-

A natural impact-resistant bicontinuous composite nanoparticle coating

Nature Materials (2020)