Abstract

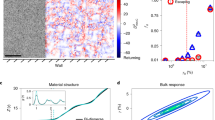

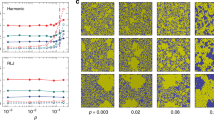

Soft particle glasses form a broad family of materials made of deformable particles, as diverse as microgels1, emulsion droplets2, star polymers3, block copolymer micelles and proteins4, which are jammed at volume fractions where they are in contact and interact via soft elastic repulsions. Despite a great variety of particle elasticity, soft glasses have many generic features in common. They behave like weak elastic solids at rest but flow very much like liquids above the yield stress. This unique feature is exploited to process high-performance coatings, solid inks, ceramic pastes, textured food and personal care products. Much of the understanding of these materials at volume fractions relevant in applications is empirical, and a theory connecting macroscopic flow behaviour to microstructure and particle properties remains a formidable challenge. Here we propose a micromechanical three-dimensional model that quantitatively predicts the nonlinear rheology of soft particle glasses. The shear stress and the normal stress differences depend on both the dynamic pair distribution function and the solvent-mediated EHD interactions among the deformed particles. The predictions, which have no adjustable parameters, are successfully validated with experiments on concentrated emulsions and polyelectrolyte microgel pastes, highlighting the universality of the flow properties of soft glasses. These results provide a framework for designing new soft additives with a desired rheological response.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Mattsson, J. et al. Soft colloids make strong glasses. Nature 462, 83–86 (2009).

Mason, T. G., Bibette, J. & Weitz, D. A. Elasticity of compressed emulsions. Phys. Rev. Lett. 75, 2051–2054 (1995).

Mayer, C. et al. Asymmetric caging in soft colloidal mixtures. Nature Mater. 7, 780–784 (2008).

Zhoua, E. H. et al. Universal behavior of the osmotically compressed cell and its analogy to the colloidal glass transition. Proc. Natl Acad. Sci. USA 106, 10632–10637 (2009).

Meeker, S. P., Bonnecaze, R. T. & Cloitre, M. Slip and flow in soft particle pastes. Phys. Rev. Lett. 92, 198302 (2004).

Liu, K. K., Williams, D. R. & Briscoe, B. J. The large deformation of a single micro-elastomeric sphere. J. Phys. D. 31, 294–303 (1998).

Seth, J., Cloitre, M. & Bonnecaze, R. T. Elastic properties of soft particle pastes. J. Rheol. 50, 353–376 (2006).

Zhang, Z. et al. Thermal vestige of the zero-temperature jamming transition. Nature 459, 230–233 (2009).

Seth, J. R. On the Rheology of Dense Pastes of Soft Particle PhD thesis, Univ. Texas (2008).

Tighe, B. P., Wodhuis, E., Remmers, J. J. C., van Saarloos, W. & van Hecke, M. Model for the scaling of stresses and fluctuations in flows near jamming. Phys. Rev. Lett. 105, 088303 (2010).

Nordstrom, K. N. et al. Microfluidic rheology of soft colloids above and below jamming. Phys. Rev. Lett. 105, 175701 (2010).

Princen, H. M. & Kiss, A. D. Rheology of foams and highly concentrated emulsions: IV. An experimental study of the shear viscosity and yield stress of concentrated emulsions. J. Colloid Interface Sci. 128, 176–187 (1989).

Cloitre, M., Borrega, R., Monti, F. & Leibler, L. Glassy dynamics and flow properties of soft colloidal pastes. Phys. Rev. Lett. 90, 068303 (2003).

Larson, R. G. The elastic stress in film fluids. J. Rheol. 41, 365–372 (1997).

Denkov, N. D., Tcholakova, S., Golemanov, K., Ananthapadmanabhan, K. P. & Lips, A. Viscous friction in foams and concentrated emulsions under steady shear. Phys. Rev. Lett. 100, 138301 (2008).

Hanley, H. J. M., Rainwater, J. C. & Hess, S. Shear-induced dependence of the liquid pair correlation function. Phys. Rev. A 36, 1795–1802 (1987).

Morris, J. F. & Katyal, B. Microstructure from simulated Brownian suspension flows at large shear rate. Phys. Fluids 14, 1920–1937 (2002).

Schosseler, F., Ilmain, F. & Candau, S. J. Structure and properties of partially neutralized poly (acry1ic acid) gels. Macromolecules 24, 225–234 (1991).

Sollich, P., Lequeux, F., Hébraud, P. & Cates, M. E. Rheology of soft glassy materials. Phys. Rev. Lett. 78, 2020–2023 (1997).

Fuchs, M. & Cates, M. E. Theory of nonlinear rheology and yielding of dense colloidal suspensions. Phys. Rev. Lett. 89, 248304 (2002).

Brady, J. H. & Morris, J. F. Microstructure of strongly sheared suspensions and its impact on rheology and diffusion. J. Fluid Mech. 348, 103–139 (1997).

Crassous, J. J. et al. Shear stresses of colloidal dispersions at the glass transition in equilibrium and in flow. J. Chem. Phys. 128, 204902 (2008).

Erwin, B., Vlassopoulos, D., Gauthier, M. & Cloitre, M. Dynamics and rheology of colloidal star polymers. Soft Matter 6, 2825–2833 (2010).

Plimpton, S. J. Fast parallel algorithms for short-range molecular dynamics. Comput. Phys. 117, 1–19 (1995).

Rapaport, D. C. The Art of Molecular Dynamics Simulation (Cambridge Univ. Press, 2004).

Larson, R. G. The Structure and Rheology of Complex Fluids (Oxford Univ. Press, 1999).

Borrega, R., Cloitre, M., Betremieux, I., Ernst, B. & Leibler, L. Concentration dependence of the low-shear viscosity of polyelectrolyte micro-networks: From hard spheres to soft microgels. Europhys. Lett. 47, 729–735 (1999).

Rubinstein, M., Colby, R. H. & Dobrynin, A. V. Elastic modulus and equilibrium swelling of polyelectrolyte gels. Macromolecules 29, 398–406 (1996).

Acknowledgements

We are grateful to D. Vlassopoulos for a critical reading of the manuscript. This work was supported by the NoE European Network Sofcomp, the CNRS (PICS 4176), the Petroleum Research Fund (ACS PRF #41236-AC9), and the National Science Foundation (CBET 0854420).

Author information

Authors and Affiliations

Contributions

J.R.S, L.M. and R.T.B. conceived the model, developed the simulations and analysed the results. C.L. and M.C. conceived and conducted the experiments and analysed the results. M.C. and R.T.B. interpreted and synthesized the results and wrote the paper. J.R.S., L.M. and C.L. provided editorial comments on the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1036 kb)

Rights and permissions

About this article

Cite this article

Seth, J., Mohan, L., Locatelli-Champagne, C. et al. A micromechanical model to predict the flow of soft particle glasses. Nature Mater 10, 838–843 (2011). https://doi.org/10.1038/nmat3119

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3119

This article is cited by

-

A unified state diagram for the yielding transition of soft colloids

Nature Physics (2023)

-

Progress and challenges in suspension rheology

Rheologica Acta (2023)

-

Relationships between structure, memory and flow in sheared disordered materials

Nature Physics (2022)

-

Pathways and challenges towards a complete characterization of microgels

Nature Communications (2020)

-

Linear and nonlinear rheology of oil in liquid crystal emulsions

Rheologica Acta (2020)