Abstract

Dye-sensitized solar cells have attracted intense research attention owing to their ease of fabrication, cost-effectiveness and high efficiency in converting solar energy. Noble platinum is generally used as catalytic counter electrode for redox mediators in electrolyte solution. Unfortunately, platinum is expensive and non-sustainable for long-term applications. Therefore, researchers are facing with the challenge of developing low-cost and earth-abundant alternatives. So far, rational screening of non-platinum counter electrodes has been hamstrung by the lack of understanding about the electrocatalytic process of redox mediators on various counter electrodes. Here, using first-principle quantum chemical calculations, we studied the electrocatalytic process of redox mediators and predicted electrocatalytic activity of potential semiconductor counter electrodes. On the basis of theoretical predictions, we successfully used rust (α-Fe2O3) as a new counter electrode catalyst, which demonstrates promising electrocatalytic activity towards triiodide reduction at a rate comparable to platinum.

Similar content being viewed by others

Introduction

As one of the most abundant and yet least collected sources of renewable energy, solar energy has attracted considerable interest in scientific research and industrial applications. Dye-sensitized solar cells (DSCs) have stood out among various photovoltaic devices because of their low cost, relative high energy-conversion efficiency and simple production procedure1,2,3,4,5. In this rapidly developing field, finding active counter electrode (CE) material for triiodide reduction reaction (iodine reduction reaction) is of great importance for the promotion of DSCs. It has been confirmed that platinum (Pt) is a superior CE material with excellent catalytic activity, high electrical conductivity and stability. Unfortunately, the disadvantages such as the high cost and low abundance greatly restrict the large-scale application of Pt in DSCs6,7,8,9. Thus, several Pt-free alternative materials have been explored as CEs in DSCs, such as carbon materials8,10, conductive organic polymers6,11 and inorganic semiconductor materials including metal sulfides12,13, metal nitrides14,15, metal carbides16,17, metal oxides18 and copper zinc tin sulfide19 and so on. Recently, Wu et al.20 synthesized three classes (carbides, nitrides and oxides) of nanoscaled early-transition metal catalysts and applied them in DSC systems as CE catalysts to replace the expensive Pt. However, the rational screening for Pt-free alternative CE materials has not been explored, and the catalytic mechanism of electrocatalysis for triiodide reduction on the electrode surface has also not been fully understood so far.

Herein, for the first time, we develope a general and efficient screening strategy for electrocatalytic activity of the potential non-Pt CE materials using first-principle calculations. Based on theoretical predictions, we explore a range of low-cost semiconducting materials, and successfully confirm that rust (α-Fe2O3) nanocrystals mainly bounded by (012) and (104) surfaces demonstrate high electrocatalytic activity. The overall energy-conversion efficiency is comparable to that of Pt CE, and more importantly, the origin of the superiority of α-Fe2O3 as the CE is investigated by kinetic analysis. Compared with Pt or some other CE materials, α-Fe2O3 is composed of the most abundant elements in the Earth’s crust and has no toxicity. Thus, ferric oxide has superiority over other existing electrode materials in terms of the low cost, high abundance and superior efficiency. The findings in this work may pave the way for further development of more practical non-Pt CEs, which can help to accelerate the large-scale applications of DSCs in the future.

Results

Activity origin of Pt electrode and speculation

To start a rational screening for the electrocatalytic activity of CE materials, it is essential to elucidate the origin of the excellent performance of Pt electrode for triiodide reduction, aiming at identifying the key parameter affecting the catalytic efficiency. Triiodide reduction reaction occurring on the CE can be written as: I3−(sol) +2e−→3I−(sol), and the general consensus of the reaction mechanism can be described as follows:

I3−(sol)↔I2(sol)+I−(sol) (I)

I2(sol)+2*→2I* (II)

I*+e−→I−(sol) (III)

where * represents the free site on the electrode surface and sol indicates the acetonitrile solution. The solution reaction, I3−(sol)↔I2(sol)+I−(sol), has been verified to be usually fast and considered to be in equilibrium21. The subsequent iodine reduction reaction (IRR: steps (II) and (III)) occurring at the liquid–solid interface, that is, the I2 dissociation into two surface I atoms (I*) upon adsorption on the electrode surface and the removal of I* through one-electron transfer to produce solvated I−(sol), would determine the overall electrocatalytic activity. Herein, we first investigated these two elementary reactions at the interface of Pt(111) and CH3CN, CH3CN/Pt(111) (see Supplementary Note 1 for calculation model). To simulate the interface solution environment, several acetonitrile layers were introduced in the surface slab with a density of 0.79 gcm−3, while the effect of electrode voltage on the material properties was taken into account by tuning the work function of Pt electrode22 (see Supplementary Figs S1 and S2). Upon adsorption at the CH3CN/Pt(111) interface, iodine molecule can readily dissociate into two I* atoms, which sit preferably on the top of Pt atoms at a distance of d(Pt-I)=2.62 Å, giving rise to an adsorption energy of 0.52 eV at the CH3CN/Pt(111) interface (see Supplementary Note 2). For the one-electron reduction of I* into solvated I−(sol), the transition state with an elongated d(Pt-I)=4.20 Å was located, yielding a barrier as low as 0.39 eV under Ueq=0.61 V versus SHE23, in favour of the kinetic feasibility. The standard Gibbs free-energy change of the half reaction (I2(sol)+2e−→2I−(sol)) was also calculated, being exothermic by 0.40 eV (see Supplementary Note 3). Therefore, IRR can be expected to proceed readily at CH3CN/Pt(111) interface.

After obtaining the basic kinetic and thermodynamic data, we used the microkinetics to estimate the turnover frequency of the two-step reaction I2(sol)+2e−→2I−(sol) under the steady-state condition, the results of which show that IRR is determined by two important parameters, that is, I2 dissociation barrier (Eadis) and I* desorption barrier (Eades). Moreover, it is found that Eadis and Eades are related to the adsorption energy of I (EadI): Eadis is linear with EadI with a negative slope (Eadis=α1EadI +β1, α1<0, a typical Bronsted–Evans–Polanyi relationship), whereas Eades increases linearly as EadI goes up (Eades=α2EadI+β2, α2>0) on Pt(111) under different electrode voltages (see Supplementary Fig. S2). It is therefore clear that the binding strength of I on the Pt(111) has a crucial role in determining the catalytic activity in the reaction of I2(sol)+2e−→2I−(sol) (see kinetic analysis details in Supplementary Note 4 and Supplementary Fig. S3). These two linear relationships provide a kinetic base for placing the I adsorption energy as a fundamental property of rational screening, being in agreement with the rate-controlling rule obtained previously24,25. In other words, the adsorption energy of I atom on catalyst surfaces may be a good descriptor for the catalytic activity: Quantitatively, if the adsorption energy of I is too large, the desorption of I* into I−(sol) would be hard to proceed thermodynamically, limited by the large total Gibbs free-energy change of reaction (I*+e−→I−(sol)), and thus the overall activity is restricted; when I adsorption is weak, I2 molecular dissociation is hindered.

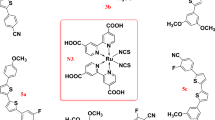

By virtue of density functional theory (DFT) calculations, we examined the adsorption of I atom on more than 20 candidate materials including metal oxides, carbide, nitride and sulphide, as summarized in Fig. 1a (see details in Supplementary Fig. S4 and Supplementary Table S1). It can be seen that the materials reported in the literature, such as WO3, CoS, NiS, FeS and TiN, possess adsorption energies around that of Pt12,13,14,18. On the other hand, of the unreported compounds, Cr2O3 and Ta2O5 may be expected to be less active owing to too strong M–I binding (M=Cr3+, Ta5+), whereas the compounds such as TiO2, MnO2, SnO2, CeO2, ZrO2, La2O3, Al2O3 and Ga2O3 may be anticipated to possess limited activity because of their low binding ability towards I (being endothermic for I2 dissociation). Ta2O5, TiO2 and CeO2 were selected to test experimentally and these predications are confirmed (see Supplementary Fig. S5 and Supplementary Table S2). Interestingly, Fe2O3(012) exhibits an almost identical adsorption energy of I with Pt (111) at the acetonitrile/electrode interface, indicating that it may be catalytically active.

(a) Calculated adsorption energy of I atom in the gas phase or in the CH3CN solvent using DFT method. Red triangles indicate the reported active materials; blank squares represent the unreported materials, which were predicted to be less catalytically active. For materials on which the adsorption of iodine atom is endothermic, solvent effects were not considered any more. (b) Demonstration of range estimation model for the suitable electrodes in terms of the adsorption energy of I atom. TΔSI2 is the entropy correction term of I2 in gas phase, ΔμI2 is chemical potential difference of I2 molecule in between gas phase and CH3CN solvent at 298 K and ΔG0 is the Gibbs free-energy change of half reaction I2(sol)+2e−→2I−(sol).

Establishment and application of the screening framework

Having obtained the results above, we are in the position to establish a quantitative or semi-quantitative framework to estimate the suitable range of EadI for active CE materials. Kinetically, it is advantageous if the Gibbs free-energy of a sequential multistep reaction occurred on the solid catalyst surface decreases step by step, ensuring the overall reaction to proceed in the forward direction26. With respect to IRR, it demands the chemical potentials following  , in which μe is the chemical potential of electron and μΙ* is defined as26

, in which μe is the chemical potential of electron and μΙ* is defined as26

where θI* and θ* are the coverages of adsorbed I* and free site * on the catalyst surface, respectively;  is the standard chemical potential of species I* and can be readily obtained from the adsorption energy of I from DFT with the necessary thermal correction. Cheng and Hu26 proposed that the coverage-dependent term RTlnθI*/θ* would lie in a small range on the best catalyst (about 0.06–0.12 eV at 298 K) and was defined as ε. Following the same approach, we can obtain the theoretical boundaries for the adsorption energy of I atom on good electrode surface (see Supplementary Note 5):

is the standard chemical potential of species I* and can be readily obtained from the adsorption energy of I from DFT with the necessary thermal correction. Cheng and Hu26 proposed that the coverage-dependent term RTlnθI*/θ* would lie in a small range on the best catalyst (about 0.06–0.12 eV at 298 K) and was defined as ε. Following the same approach, we can obtain the theoretical boundaries for the adsorption energy of I atom on good electrode surface (see Supplementary Note 5):

in which  is the entropy correction term of I2 in gas phase at T=298 K (relative to gaseous I2 at 0 K),

is the entropy correction term of I2 in gas phase at T=298 K (relative to gaseous I2 at 0 K),  is chemical potential difference of I2 molecule in between gas phase and CH3CN solvent at 298 K and ΔG0 (

is chemical potential difference of I2 molecule in between gas phase and CH3CN solvent at 298 K and ΔG0 ( ) is the Gibbs free-energy change of half reaction I2(sol)+2e−→2I−(sol). It should be noted that for clarity, we neglected the minor contribution of I2 and I− concentration in the solution (~0.02 eV, estimated from experimental condition) to the free energy. Equation (2) sets two boundaries for I adsorption: The lower boundary requires that the binding strength between the electrode and I atom should be so strong that I2 dissociative adsorption is exothermic in Gibbs free-energy, whereas the upper boundary ensures the subsequent desorption to proceed also exothermically, as shown in Fig. 1b. It is worth pointing out that the free-energy change ΔG0 varies with the electrode voltage U that determines the electronic chemical potential μe (μe=eU versus SHE). When

) is the Gibbs free-energy change of half reaction I2(sol)+2e−→2I−(sol). It should be noted that for clarity, we neglected the minor contribution of I2 and I− concentration in the solution (~0.02 eV, estimated from experimental condition) to the free energy. Equation (2) sets two boundaries for I adsorption: The lower boundary requires that the binding strength between the electrode and I atom should be so strong that I2 dissociative adsorption is exothermic in Gibbs free-energy, whereas the upper boundary ensures the subsequent desorption to proceed also exothermically, as shown in Fig. 1b. It is worth pointing out that the free-energy change ΔG0 varies with the electrode voltage U that determines the electronic chemical potential μe (μe=eU versus SHE). When  (−0.06 V versus SHE), ΔG0 reaches approximately maximum and thus provides the maximal upper boundary for EadI according to equation (2). Therefore, to be inclusive, we estimated the variation range of EadI under the condition U=−0.06 V versus SHE, which gives rise to the range from around 0.33 to 1.20 eV for good catalysts. Using this range to re-evaluate the above CE materials, we can see the usefulness of the adsorption range for catalyst screening, as shown in Fig. 1. Some CE materials such as CoS, MoC, MoN, FeS, NiS, WC and WO3 are known experimentally to be good catalysts (Fig. 1a, red triangles) and possess a EadI within the range, supporting the feasibility of this strategy. As an example, according to the theoretical calculations, the EadI of CoS (0.59 eV) is closed to that of Pt (0.52 eV). Grätzel and co-workers deposited electrochemically CoS nanoparticles on PEN/ITO film to obtain a high-performance Pt-free CE12. The energy-conversion efficiency reached the same level of the Pt-CE DSCs, which matches well with the theoretical screening strategy shown in this work. For the materials, the activities of which remain to be tested, including TiO2, MnO2, SnO2, CeO2, ZrO2, La2O3, Al2O3, Ga2O3, Cr2O3 and Ta2O5, EadI are out of the optimal range (Fig. 1a, black squares), indicating that their activity may be low. On two typical surfaces of α-Fe2O3, Fe2O3(012) and Fe2O3(104), EadI are 0.51 and 0.42 eV, respectively, and they are within this estimated range for suitable CE materials.

(−0.06 V versus SHE), ΔG0 reaches approximately maximum and thus provides the maximal upper boundary for EadI according to equation (2). Therefore, to be inclusive, we estimated the variation range of EadI under the condition U=−0.06 V versus SHE, which gives rise to the range from around 0.33 to 1.20 eV for good catalysts. Using this range to re-evaluate the above CE materials, we can see the usefulness of the adsorption range for catalyst screening, as shown in Fig. 1. Some CE materials such as CoS, MoC, MoN, FeS, NiS, WC and WO3 are known experimentally to be good catalysts (Fig. 1a, red triangles) and possess a EadI within the range, supporting the feasibility of this strategy. As an example, according to the theoretical calculations, the EadI of CoS (0.59 eV) is closed to that of Pt (0.52 eV). Grätzel and co-workers deposited electrochemically CoS nanoparticles on PEN/ITO film to obtain a high-performance Pt-free CE12. The energy-conversion efficiency reached the same level of the Pt-CE DSCs, which matches well with the theoretical screening strategy shown in this work. For the materials, the activities of which remain to be tested, including TiO2, MnO2, SnO2, CeO2, ZrO2, La2O3, Al2O3, Ga2O3, Cr2O3 and Ta2O5, EadI are out of the optimal range (Fig. 1a, black squares), indicating that their activity may be low. On two typical surfaces of α-Fe2O3, Fe2O3(012) and Fe2O3(104), EadI are 0.51 and 0.42 eV, respectively, and they are within this estimated range for suitable CE materials.

The activity comparison between α-Fe2O3 and Pt electrode

To further estimate the activity of Fe2O3, a detailed DFT calculation on the whole reaction pathway of IRR, involving the reaction barriers of I2 dissociation and I* removal into I−(sol), was carried out at the interface of CH3CN/Fe2O3(012) and CH3CN/Fe2O3(104), respectively. The CH3CN/Fe2O3(012) interface model is illustrated in Fig. 2d. On both interfaces, it is found that I2 molecules can dissociate directly and the formed I atoms sit on the top of five-coordinated surface Fe3+ ions (Fig. 2e), whereas the desorption barrier of I* from the surface to CH3CN solvent was calculated to be as low as 0.18 and 0.08 eV on (012) and (104) surfaces, respectively. The transition state of I* desorption at CH3CN/Fe2O3(012) interface is shown in Fig. 2f, with a much elongated Fe–I bond length (4.12 Å) as compared with the initial Fe–I bond length (2.72 Å) in the adsorption configuration. The binding properties of Fe–I bond in the transition state were also investigated by virtue of charge density difference and Bader charge analysis (see Supplementary Fig. S6), indicating the ionic bond characteristic between Fe3+ and ion-like I (with 0.69 e from Bader charge). Kinetically, as shown in Fig. 2g, the overall standard free-energy profiles on both Fe2O3(012) and (104) surfaces have no particularly high point. Therefore, it can be expected that Fe2O3(012) and Fe2O3(104) would exhibit kinetically good performance for the I3− reduction reaction. In addition, the energy level at the conduction band edge of Fe2O3(012) was calculated to be higher relative to the position of I3−/I− equilibrium potential, indicating the ability of Fe2O3 in electron transfer to I3− (see Supplementary Fig. S7). To obtain a comparison further, we calculated the reaction profile of I2+2e−→2I− at CH3CN/Pt(111) interface, and the corresponding interface model, adsorption configuration of I* and transition state of I* desorption are illustrated in Fig. 2a–c. Comparing the whole reaction energy profile of Fe2O3 with that on Pt electrode (Fig. 2g), the two Fe2O3 surfaces have lower apparent barriers, suggesting that a higher catalytic activity for iodine reduction on α-Fe2O3 CEs could be expected.

(a–c) Pt(111) surface structure in the presence of CH3CN solvent, I adsorption structure and the transition-state structure. (d–f) For the α-Fe2O3(012) surface, similar with a–c. (g) Energy profiles of the whole CE reaction on Pt(111), Fe2O3(104) and Fe2O3(012), respectively, which were calculated at U=0.61 V vs SHE.

Characterizations of α-Fe2O3 and as-prepared CEs

To verify these theoretical predictions, pure-phase Fe2O3 was synthesized via a simple modified hydrothermal method using Iron (III) nitrate nonahydrate Fe(NO3)3·9 H2O and sodium-hydroxide aqueous solution as the precursor and the reaction controlling agent, respectively27. All diffraction peaks of the typical X-ray diffraction pattern (see Supplementary Fig. S8) match well with the crystal structure of the α-Fe2O3 phase (space group: R-3c, JCPDS No. 84-0310). Representative electron microscopy images of α-Fe2O3 nanoparticles and electrode films (cross-section) were shown in Fig. 3a. Square-like paticles were formed and these α-Fe2O3 nanocrystals were mostly exposed by (012) and (104) facets. The enlarged transmission electron microscopy image shows the (012) and (104) planes with a lattice spacing of 2.68 Å and interfacial angle of 85° (ref. 28). To confirm the catalytic activity of the α-Fe2O3, subsequently, the as-prepared α-Fe2O3 powder was used as CE materials to fabricate DSCs.

(a) The scanning electron microscopy images of α-Fe2O3 nanoparticles and electrode films (cross-section) and the transmission electron microscopy images of α-Fe2O3 nanoparticles. Scale bar, 5 nm. (b) Photocurrent–voltage (J–V) curves of DSCs with different CEs: α-Fe2O3 (blue line) and Pt (red line), which were measured in the dark and under illumination of air mass 1.5 G full sunlight (100 mW cm−2). (c) Nyquist plots for the symmetric cells with two identical CEs of α-Fe2O3 (blue) or Pt (red). The cells were measured with the frequency range from 100 MHz to 1 MHz, and the amplitude of the alternating current was set to 10 mV. The corresponding circuit is shown in the inset.

Photovoltaic data

Figure 3b demonstrates the photocurrent–voltage (J–V) curves for the DSCs and Nyquist plots of electrochemical impedance spectroscopy (EIS) for the dummy cells, respectively. The photovoltaic parameters are displayed in Table 1. As shown in Fig. 3b, the short-circuit photocurrent density (Jsc), open-circuit voltage (Voc) and fill factor of DSCs based on α-Fe2O3 CE are 15.92 mA cm−2, 784 mV and 0.56, respectively, yielding an overall energy-conversion efficiency (Eff.) of 6.96%, which is remarkably comparable to that of DSCs with Pt CE (7.32%). The results demonstrate that α-Fe2O3 possessed an excellent catalytic activity to reduce oxidized triiodide to iodide. The observed low Jsc with α-Fe2O3 CE may be attributed to high resistance for electron transport owing to a thick film used (see Supplementary Fig. S9). Interestingly, a higher open-circuit voltage (Voc) with 25 mV of improvement was observed after replacing the Pt CE with α-Fe2O3 CE. The photovoltaic results indicate that the α-Fe2O3 shows a Pt-like catalytic behaviour.

Electrochemical impedance spectroscopy

To further investigate the electrochemical characteristics of α-Fe2O3 electrodes, the EIS measurements were carried out with symmetric cells fabricated with two identical electrodes (CE//electrolyte//CE) at 20 °C. The Nyquist plots (Fig. 3c) illustrated impedance characteristics, in which two semicircles can be observed in the high-frequency (left) and low-frequency (right) regions. The high-frequency intercept on the real axis (Z′ axis) represents the series resistance (Rs). The semicircle in the high-frequency regions arise from the charge-transfer resistance (Rct)29. In contrast to Pt, the larger Rs and smaller Rct of the α-Fe2O3 can be observed. The Rs is mainly composed of the bulk resistance of α-Fe2O3, resistance of fluorine-doped SnO2 (FTO) glass substrate, contact resistance and so on. The significant difference of Rs between α-Fe2O3 (15.8 Ω) and Pt (10.5 Ω) is obvious. The bulk resistance, conductivity of α-Fe2O3 and adhesive between α-Fe2O3 and FTO substrate should be responsible for its higher Rs. With respect to photovoltaic performance and EIS fitting data, it can be deduced that Rct of CEs is a major factor in the performance of DSCs, suggesting catalytic activity for triiodide reduction30. In Table 1, the Rct of α-Fe2O3 is 2.3 Ω and this value is much smaller than the Rct of Pt (3.4 Ω), which may be one important cause that the energy-conversion efficiency of DSCs using α-Fe2O3 CE is comparable to that of Pt CE. Thus, the high catalytic activity of α-Fe2O3 is validated and a faster reduction rate of triiodide on the α-Fe2O3 CE was obtained. The equivalent circuit used to fit the experimental EIS data is shown in the inset of Fig. 3c. In the modelling circuit used to mimic the EIS set up, the left semicircle consisting of Rct, Cdl and Zw represents the CE12,31. Similar circuits have been used to model carbonaceous systems earlier32. Cdl stands for the double-layer capacitance at the electrode/electrolyte interface because of the accumulation of ions at the electrode surface. The Cdl indicates a surface property of the materials16. In the case of these two CE materials, the Cdl of α-Fe2O3 is 5.8 μF, indicating a similar surface area as compared with Pt (6.3 μF). Zw stands for Warburg impedance, which arises from mass transport limitations due to diffusion of the triiodide/iodide couple in the electrolytes14.

Electrochemical behaviours

It is well known that cyclic voltammetry (see Supplementary Fig. S10) and Tafel-polarization measurement are powerful electrochemical characterization methods. Fig. 4a demonstrates the Tafel-polarization curves of the symmetrical cells. They show the current density (J) as a function of voltage (U) at 20 °C for the oxidation/reduction of triiodide to iodide. The slope of a tangent to the α-Fe2O3 curve is higher than that of Pt, indicating that α-Fe2O3 shows a larger exchange current density (J0), which is also in good agreement with the EIS values in terms of the following equation (3)12,33.

(a) Current–voltage characteristics of the symmetrical (CE//IL//CE) cells fabricated with two identical α-Fe2O3 and Pt electrodes at 20 °C. (b) Charge-transfer resistance–temperature (left ordinate) and exchange current density–temperature data (right ordinate) in the Arrhenius coordinates with different CEs: α-Fe2O3 (blue line) and Pt (red line).

where R is the gas constant, T is the temperature, F is the Faraday’s constant and n is the number of electrons involved in the electrochemical reduction of triiodide at the electrode.

These results confirm that the catalytic activity of α-Fe2O3 is sufficient to catalyse the reduction of triiodide to iodide21. To further investigate the catalytic activity of the electrode materials, we scrutinized the variation tendency of the charge-transfer resistance and exchange current density in different temperature. Fig. 4b shows the logarithmic change-transfer resistance (LogRct)—temperature (left ordinate) and logarithmic exchange current density (LogJ0)—temperature data (right ordinate) in the Arrhenius coordinates. The exchange current density, J0, was calculated from impedance spectroscopy data to be 5.3 and 3.6 mA cm−2 at 20 °C for the α-Fe2O3 CE and Pt CE, respectively. Compared with the Pt catalysts, the α-Fe2O3 shows better catalytic activity for triiodide reduction, being consistent with the theoretical result given in Fig. 2g. The exchange current density (J0) shows temperature dependence (Fig. 4b, right ordinate), following the Arrhenius equation (4)12:

where I0 is the exchange current density at T=infinite and Ea is the activation energy. These results demonstrate that the electrochemical triiodide reduction reaction on the α-Fe2O3 CEs is comparatively enhanced, which is in good accordance with the theoretical calculations. Therefore, α-Fe2O3 can be expected to replace the expensive Pt in DSCs as a promising CE catalyst.

Discussion

In summary, using theoretical calculations, a general principle is developed in this report for screening Pt-free alternative CE materials for triiodide reduction reaction in DSCs. The screening principle not only offers a promising approach to advance the insight into the inherent catalysis on the CE materials but also helps to predict the new compounds that could serve as highly efficient CE materials. Importantly, this work also illustrates the power of combining first-principle calculations and experimental techniques to achieve the rational design of low-cost and high-efficiency CE materials for DSCs.

Methods

DFT calculations

All the spin-polarized calculations were performed with Perdew–Burke–Ernzerhof (PBE) functional within the generalized gradient approximation using the Vienna ab-initio simulation package code, unless otherwise specified34,35. The project-augmented wave method was used to represent the core-valence electron interaction. The valence electronic states were expanded in plane-wave basis sets with energy cutoff at 450 eV. The occupancy of the one-electron states was calculated using the Gaussian smearing for non-metal compounds and Methfessol–Paxton smearing for Pt(111). The ionic degrees of freedom were relaxed using the Broyden–Fletcher–Goldfarb–Shanno minimization scheme until the Hellman–Feynman forces on each ion were <0.05 eV Å−1. The transition states were searched using a constrained optimization scheme36 and were verified when (i) all forces on atoms vanish and (ii) the total energy is a maximum along the reaction coordination but a minimum with respect to the rest of the degrees of freedom. The force threshold for the transition-state search was 0.05 eV/Å. The dipole correction was performed throughout the calculations to take the polarization effect into account.

With respect to some specific oxides, such as Fe2O3, MnO2 and CeO2, it should be noted that one may consider other approaches for self-interaction correction, such as DFT+U. However, DFT+U presents its own limitations in terms of different U value that have to be chosen for the specific surface configurations or different oxide in principle, and thereby the results could be difficult to directly compare with. Herein, we checked the self-interaction corrections by utilizing hybrid functional HSE06 for Fe2O3, although it is very time-consuming. It showed that HSE06 gives an almost same barrier for the I* removal from the electrode surface (the rate-determining step) with that calculated using PBE functional, indicating that PBE may reasonably identify the reaction mechanisms. In addition, it should be noted that in the optimization of α-Fe2O3, we test the effect of spin state of d electrons in Fe3+, which showed that the high-spin antiferromagnetic arrangement is the most stable state and gives the lowest free energy37.

To calculate the adsorption energy of surface species in the realistic solution, we take the effect of solvent implicitly into account by introducing several CH3CN solvent molecules into the surface model. The adsorption energy of I (EadI) is defined as:

where E(interface), E(I2) and E(I/interface) are the energies of the liquid/electrode interface, I2 in the gas phase and I adsorbed on the liquid/electrode interface, respectively. The larger EadI is, the more strongly the species I binds on surface.

Synthesis of α-Fe2O3

Commercial iron (III) nitrate nonahydrate (4.04 g, ≥98.5%, Sinopharm) was dissolved in deionized water (33 ml) under stirring for 1 h. Then sodium-hydroxide aqueous solution (6 M) was added dropwise until the pH value of the mixed solution was 1.5 and then stirred for 30 min at 20 °C. Subsequently, the mixture was transferred into a Teflon-lined stainless autoclave and hydrothermally treated at 200 °C for 24 h. The product was cooled to room temperature by removing the heat source. Under ambient conditions, nanoparticles were separated by centrifugation at 9500, r.p.m. for 6 min and washed several times with deionized water and absolute ethanol.

Electrode preparation

The TiO2 was prepared according to the literature38. A 12-μm thick layer of 20 nm-sized TiO2 particles was loaded on the FTO conducting glass (Nippon Sheet Glass, Japan, 8 Ω per square) by screen printer technique. After sintering at 125 °C, the obtained layer was further coated with a 4-μm thick scattering layer of 200 nm-sized TiO2 particles (DHS-NanoT200; Heptachroma) followed by sintering at 500 °C. After cooling to 80 °C, the two layers of TiO2 films were immersed in a 5 × 10−4 M solution of N719 dye (Solaronix SA, Switzerland) in acetonitrile/tert-butyl alcohol (V/V=1/1) for 24 h. A total of 0.5 g α-Fe2O3 powder was mixed with 2.03 g anhydrous terpineol, 2.6 g ethyl celluloses in ethanol (10 wt%) and 8 ml ethanol followed by stirring and sonication. The contents in dispersion were concentrated by evaporator, and then a layer of α-Fe2O3 nanoparticles was loaded on the FTO conducting glass (NSG, 8 Ω per square) by screen printer procedure. The Pt electrode was prepared by drop-casting 0.5 mM H2PtCl6/ethanol solution on the clean FTO conductive glass. Subsequently, the FTO glasses coated with α-Fe2O3 and Pt were then sintered in a muffle furnace at 450 °C for 30 min.

Fabrication of DSCs

DSCs were assembled together with the dye-sensitized TiO2 electrode and the CE by a 25-μm thick hot-melt film (Surlyn 1702; DuPont) and sealed up by heating. The cell internal space was filled with electrolytes using a vacuum pump. The liquid electrolyte composed of 0.60 M 1-butyl-3-methylimidazolium iodide, 0.03 M I2, 0.50 M 4-tert-butyl pyridine and 0.10 M guanidinium thiocyanate with acetonitrile as the solvent. The sealed DSCs were used for the photocurrent–voltage test with an active area of 0.25 cm2. The symmetrical dummy cells used for EIS and Tafel-polarization measurement were assembled by two identical CEs, clipping the electrolyte similar to the one used for fabricating the DSCs.

Material characterization

The morphology and structure of the samples were characterized by high-resolution transmission electron microscopy (JEOL JEM-2010F, F20, 200 kV), field emission scanning electron microscopy (Hitachi S4800) and X-ray diffraction (Bruker D8 Advanced Diffractometer; Cu Kα radiation; 40 kV). The current-voltage tests of DSCs were performed under one sun condition using a solar light simulator (Oriel 91160; air mass 1.5 G). The power of the simulated light was calibrated to 100 mW cm−2 using a Newport Oriel PV reference cell system (model 91150 V). The EIS experiments and Tafel-polarization curves were measured with dummy cells in the dark by using an electrochemical workstation (Parstat 2273; Princeton). The frequency range of EIS experiments was from 100 MHz to 1 MHz with an AC modulation signal of 10 mV and bias DC voltage of 0.60 V. The curves were fitted by the ZSimpWin software. Tafel-polarization measurements were carried out with a scan rate of 50 mV s−1. Cyclic voltammetry was conducted in a three-electrode system in an acetonitrile solution of 0.1 M LiClO4, 10 mM LiI and 1 mM I2 at a scan rate of 20 mV s−1 by using a BAS 100B/W electrochemical analyser. Pt served as a CE, and the Ag/Ag+ couple was used as a reference electrode.

Additional information

How to cite this article: Hou, Y. et al. Rational screening low-cost counter electrodes for dye-sensitized solar cells. Nat. Commun. 4:1583 doi: 10.1038/ncomms2547 (2013).

References

O’Regan, B. & Grätzel, M. . A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991).

Grätzel, M. . Photoelectrochemical cells. Nature 414, 338–344 (2001).

Grätzel, M. . Recent advances in sensitized mesoscopic solar cells. Acc. Chem. Res. 42, 1788–1798 (2009).

Hagfeldt, A., Boschloo, G., Sun, L., Kloo, L. & Pettersson, H. . Dye-sensitized solar cells. Chem. Rev. 110, 6595–6663 (2010).

Yum, J. -H. et al. A cobalt complex redox shuttle for dye-sensitized solar cells with high open-circuit potentials. Nat. Commun. 3, 631–638 (2012).

Ahmad, S., Yum, J. H., Butt, H. J., Nazeeruddin, M. K. & Grätzel, M. . Efficient platinum-free counter electrodes for dye-sensitized solar cell applications. ChemPhysChem 11, 2814–2819 (2010).

Papageorgiou, N. . Counter-electrode function in nanocrystalline photoelectrochemical cell configurations. Coord. Chem. Rev. 248, 1421–1446 (2004).

Kay, A. & Grätzel, M. . Low cost photovoltaic modules based on dye sensitized nanocrystalline titanium dioxide and carbon powder. Sol. Energy Mater. Sol. Cells 44, 99–117 (1996).

Gong, F., Wang, H., Xu, X., Zhou, G. & Wang, Z. -S. . In situ growth of Co0.85Se and Ni0.85Se on conductive substrates as high-performance counter electrodes for dye-sensitized solar cells. J. Am. Chem. Soc. 134, 10953–10958 (2012).

Trancik, J. E., Barton, S. C. & Hone, J. . Transparent and catalytic carbon nanotube films. Nano Lett. 8, 982–987 (2008).

Li, Q. et al. Application of microporous polyaniline counter electrode for dye-sensitized solar cells. Electrochem. Commun. 10, 1299–1302 (2008).

Wang, M. et al. CoS supersedes Pt as efficient electrocatalyst for triiodide reduction in dye-sensitized solar cells. J. Am. Chem. Soc. 131, 15976–15977 (2009).

Sun, H. et al. Dye-sensitized solar cells with NiS counter electrodes electrodeposited by a potential reversal technique. Energy Environ. Sci. 4, 2630–2637 (2011).

Li, G. R., Wang, F., Jiang, Q. W., Gao, X. P. & Shen, P. W. . Carbon nanotubes with titanium nitride as a low-cost counter-electrode material for dye-sensitized solar cells. Angew. Chem. Int. Ed. 49, 3653–3656 (2010).

Li, G. R., Song, J., Pan, G. L. & Gao, X. P. . Highly Pt-like electrocatalytic activity of transition metal nitrides for dye-sensitized solar cells. Energy Environ. Sci. 4, 1680–1683 (2011).

Wu, M., Lin, X., Hagfeldt, A. & Ma, T. . Low-cost molybdenum carbide and tungsten carbide counter electrodes for dye-sensitized solar cells. Angew. Chem. Int. Ed. 50, 3520–3524 (2011).

Jang, J. S., Ham, D. J., Ramasamy, E., Lee, J. & Lee, J. S. . Platinum-free tungsten carbides as an efficient counter electrode for dye sensitized solar cells. Chem. Commun. 46, 8600–8602 (2010).

Wu, M., Lin, X., Hagfeldt, A. & Ma, T. . A novel catalyst of WO2 nanorod for the counter electrode of dye-sensitized solar cells. Chem. Commun. 47, 4535–4537 (2011).

Xin, X., He, M., Han, W., Jung, J. & Lin, Z. . Low-cost copper zinc tin sulfide counter electrodes for high-efficiency dye-sensitized solar cells. Angew. Chem. Int. Ed. 50, 11739–11742 (2011).

Wu, M. et al. Economical Pt-free catalysts for counter electrodes of dye-sensitized solar cells. J. Am. Chem. Soc. 134, 3419–3428 (2012).

Hauch, A. & Georg, A. . Diffusion in the electrolyte and charge-transfer reaction at the platinum electrode in dye-sensitized solar cells. Electrochim. Acta 46, 3457–3466 (2001).

Rossmeisl, J., Nørskov, J. -K., Taylor, C. -D., Janik, M. -J. & Neurock, M. . Calculated phase diagrams for the electrochemical oxidation and reduction of water over Pt(111). J. Phys. Chem. B 110, 21833–21839 (2006).

Calogero, G. et al. A new type of transparent and low cost counter-electrode based on platinum nanoparticles for dye-sensitized solar cells. Energy Environ. Sci. 4, 1838–1844 (2011).

Wang, H. -F., Guo, Y. -L., Lu, G. -Z. & Hu, P. . An understanding and implications of the coverage of surface free sites in heterogeneous catalysis. J. Chem. Phys. 130, 224701 (2009).

Cheng, J. & Hu, P. . Brønsted−Evans−Polanyi relation of multistep reactions and volcano curve in heterogeneous catalysis. J. Phys. Chem. C 112, 1308–1311 (2008).

Cheng, J. & Hu, P. . Theory of the kinetics of chemical potentials in heterogeneous catalysis. Angew. Chem. Int. Ed. 50, 7650–7654 (2011).

Žic, M., Ristić, M. & Musić, S. . Monitoring the hydrothermal precipitation of α-Fe2O3 from concentrated Fe(NO3)3 solutions partially neutralized with NaOH. J. Mol. Struct. 993, 115–119 (2011).

Yin, J. et al. Low-symmetry iron oxide nanocrystals bound by high-index facets. Angew. Chem. Int. Ed. 49, 6328–6332 (2010).

Fabregat-Santiago, F. et al. Correlation between photovoltaic performance and impedance spectroscopy of dye-sensitized solar cells based on ionic liquids. J. Phys. Chem. C 111, 6550–6560 (2007).

Chen, J. et al. A flexible carbon counter electrode for dye-sensitized solar cells. Carbon 47, 2704–2708 (2009).

Wu, M. et al. High-performance phosphide/carbon counter electrode for both iodide and organic redox couples in dye-sensitized solar cells. J. Mater. Chem. 22, 11121–11127 (2012).

Murakami, T. N. & Grätzel, M. . Counter electrodes for DSC: application of functional materials as catalysts. Inorg. Chim. Acta 361, 572–580 (2008).

Zakeeruddin, S. M. & Grätzel, M. . Solvent-free ionic liquid electrolytes for mesoscopic dye-sensitized solar cells. Adv. Funct. Mater. 19, 2187–2202 (2009).

Kresse, G. & Furthmüller, J. . Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Hafner, J. . Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Alavi, A., Hu, P., Deutsch, T., Silvestrelli, P. L. & Hutter, J. . CO oxidation on Pt(111): an ab initio density functional theory study. Phys. Rev. Lett. 80, 3650–3653 (1998).

Canepa, P., Schofield, E., Chadwick, A. V. & Alfredsson, M. . Comparison of a calculated and measured XANES spectrum of α-Fe2O3 . Phys. Chem. Chem. Phys. 13, 12826–12834 (2011).

Ito, S. et al. Fabrication of thin film dye sensitized solar cells with solar to electric power conversion efficiency over 10%. Thin Solid Films 516, 4613–4619 (2008).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (20973059, 91022023, 21076076 and 21203061), Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning, Shanghai Municipal Natural Science Foundation (12ZR1407500), Major Basic Research Programme of Science and Technology Commission of Shanghai Municipality (10JC1403200), Australian Research Council’s Future Fellowships (FT120100913) and Commission of Science and Technology of Shanghai Municipality (12ZR1442600). P.H. thanks the Chinese Government for the ‘Thousands Talents’ program.

Author information

Authors and Affiliations

Contributions

H.G.Y. and H.F.W. conceived the project and contributed to the design of the experiments and computations, analysis of the data and revising the paper. Y.H. designed and carried out the experiments, analysed the data and contributed to the analysis tools. D.W. built the theoretical modelling and analysed the computational data. Y.H. and D.W. wrote the paper. X.H.Y. carried out part of the synthetic experiments and contributed to the materials. W.Q.F. assisted with some of the experiments and was involved in interpretation of the data. B.Z. and H.J.Z. carried out the electrochemical measurements and analysed the data. P.H. and G.Z.L. participated in a series of DFT investigations in the simulations of CE materials and interpreted the computational data. All authors read and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures S1-S10, Supplementary Tables S1-S3, Supplementary Notes 1-5 and Supplementary References (PDF 1894 kb)

Rights and permissions

About this article

Cite this article

Hou, Y., Wang, D., Yang, X. et al. Rational screening low-cost counter electrodes for dye-sensitized solar cells. Nat Commun 4, 1583 (2013). https://doi.org/10.1038/ncomms2547

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms2547

This article is cited by

-

Photoinduced small electron polarons generation and recombination in hematite

npj Computational Materials (2022)

-

Hydrothermal Preparation of Ni3S4/CoS2 Composite Electrocatalytic Materials for High Performance Counter Electrodes of Dye-Sensitized Solar Cells

Journal of Cluster Science (2022)

-

Enhanced sensitivity of hydrogenated α-Fe2O3 nanoplates having {001} facets and the gas sensing mechanism

Journal of Materials Science: Materials in Electronics (2022)

-

High-Efficiency (Over 10%) Parallel Tandem Dye-Sensitized Solar Cells Based on Tri-Carbon Electrodes

Transactions of Tianjin University (2022)

-

Cost effective dye sensitized solar cell based on novel Cu polypyrrole multiwall carbon nanotubes nanocomposites counter electrode

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.