Abstract

Surface mining is inherently linked to climate change, but more precise monitoring of carbon dioxide (CO2) emissions is necessary. Here we combined the geolocation of mine sites and carbon stock datasets to show that if all legal active mining sites in Brazil are exploited over the next decades, 2.55 Gt of CO2 equivalent (CO2eq) will be emitted due to the loss of vegetation (0.87 Gt CO2eq) and soil (1.68 Gt CO2eq). To offset these emissions, we propose constructing soils (Technosols) from mine and other wastes for mine reclamation. We show that this strategy could potentially offset up to 60% (1.00 Gt CO2eq) of soil-related CO2 emissions. When constructed with suitable parent materials, Technosols can also restore important soil-related ecosystem services while improving waste management. The construction of healthy Technosols stands out as a promising nature-based solution towards carbon-neutral mining and should, therefore, be considered in future environmental policies of major mining countries.

Similar content being viewed by others

Introduction

Brazil is a country of continental scale with a vast diversity of mineral reserves where mining has been carried out since colonial times in the early 1700s. Currently, Brazil ranks as the 9th largest producer of mineral commodities1, and its economy relies heavily on the mining industry as the foundation of the manufacturing sector. Although mining is pivotal for economic development, it is also known as one of the most harmful anthropogenic activities, causing large-scale ecosystem degradation, such as pollution of soil and water, and loss of biodiversity2,3,4. In Brazil, poor waste management practices have resulted in some of the world’s largest mining disasters with high human, economic, and environmental costs, such as the Mariana and Brumadinho dam collapses). This situation has increased the urgency for mining companies to align with the United Nations (UN) 2030 Agenda and its Sustainable Development Goals (SDGs) demanding the implementation of cleaner production methods that prioritize social and environmental sustainability. To achieve these goals, joint efforts between the scientific community and the industry are necessary.

The mitigation of climate change is a pressing concern for the United Nations. In the pursuit of cleaner energy production, mining activities are expected to increase since current renewable energy strategies depend on further ore extraction (for example, lithium for electric car batteries and silver for electric conductors)5. Therefore, in order to restrict the harmful effects of mining, it will be necessary to monitor and reduce the greenhouse gas emissions and other environmental impacts associated with this activity6. However, to date, only emissions related to fuel and electricity consumption for mineral exploration have been assessed, whereas indirect emissions (for example, from soil and vegetation removal) have largely been ignored7.

Surface mining is the most used method for ore exploration, accounting for more than 80% of explored ore per year8. This type of mining involves the complete removal of soil and vegetation, causing a loss of ecosystem carbon stocks through the oxidation of organic matter9,10,11. As evidenced by Brazil’s Fourth National Communication to the United Nations Framework Convention on Climate Change (UNFCC), the carbon dioxide (CO2) emissions related to vegetation removal for mining have increased since the 1990s, with 8.9 Mt of CO2 equivalent (CO2eq) emitted in 2016 alone, which is equivalent to 0.4% of the country’s total CO2 annual emissions. However, this is an underestimation because it only considers vegetation and excludes soils. Soils can contain up to three times more carbon than vegetation and can play a significant role in carbon sequestration12.

In this context, future CO2 emissions from soil and vegetation removal during surface mining will have significant consequences for climate change. Thus, new strategies to offset these emissions are crucial for promoting greener mining, particularly in continental countries like Brazil. One emerging strategy for post-mine reclamation is the (re)construction of soils using mine waste and other residues, such as domestic and industrial waste13,14,15,16. These soils, known as Technosols, can help address many environmental problems related to mining, including soil pollution, loss of fertility and biodiversity17,18,19,20. Moreover, Technosols have the potential to accumulate significant amounts of carbon21, although their ability to recover ecosystem carbon stocks on a large scale has yet to be evaluated. In this context, the aim of this study was to estimate the ecosystem carbon stocks lost due to surface mining in Brazil and the amount that could be recovered through the construction of Technosols. We hypothesized that using Technosols to reclaim post-mine land could mitigate future mining-related emissions.

Results and discussion

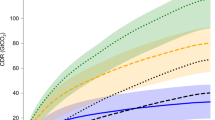

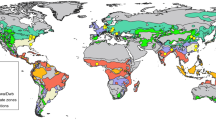

Our analysis revealed that there are currently 5.4 million hectares of legally active mine sites (LAMS) in Brazil, which is equivalent to ~10 million football fields, an area larger than Netherlands. These areas are spread throughout Brazil, with the majority located in tropical and subtropical regions (Fig. 1a). The overall estimated soil organic carbon (SOC) stocks (0–100 cm) in natural soils within LAMS in Brazil are 1.68 Gt CO2eq (Fig. 1b). The tropical region, which is Brazil’s largest climatic area, has the largest SOC stocks, estimated at 1.05 Gt CO2eq (Fig. 1c). The dry climate region, which is the smallest area, has C-poorest soils, containing only 0.04 Gt CO2eq (Fig. 1d), while the temperate region includes the C-richest soils but has a smaller area than the tropical region, resulting in a SOC stock of 0.59 Gt CO2eq (Fig. 1e). When considering both above-ground biomass carbon (AGBC = 0.87 Gt CO2eq) and SOC (=1.68 Gt CO2eq) stocks, the total organic carbon (TOC) stock allocated in all LAMS in Brazil is estimated at 2.55 Gt CO2eq (Fig. 2). This represents the potential CO2 emissions that could result from future exploration of all areas destined to mining in Brazil, which is equivalent to 5% of the total annual anthropogenic emissions worldwide22.

a Map of SOC stocks and the distribution of legally active mine sites (LAMS) in Brazil. b Overall SOC stock loss due to soil removal and the potential recovery using Technosols. Graphs c, d and e show equivalent information regarding the different climatic areas in Brazil: c tropical, d dry, and e subtropical regions. f Relative SOC stock recovery per climatic area. Error bars represent 95% confidence intervals.

“Pristine” represents a scenario where the ecosystem is in equilibrium and conserves full functionality, with the maximum potential for the provision of essential soil-related ecosystem services (e.g., provision of food, fiber, and energy; regulation of the hydrological cycle; nutrient cycling; biodiversity conservation; and climate regulation). In this scenario, the total organic carbon (TOC) stock, i.e., the sum of above-ground biomass carbon (AGBC) and soil organic carbon (SOC), within legally active mine sites in Brazil is estimated to be 2.55 Gt CO2eq. The “degraded” scenario represents the postmine condition after the complete removal of vegetation and soil. In the absence of soil, the system loses its capacity to provide ecosystem services and becomes a source of CO2, with the eventual loss of the previous TOC stocks. CO2 emissions occur through the decomposition of biomass carbon from vegetation and the degradation of organic matter from the stripped soil. In the “reclaimed” scenario, the construction of Technosols from mine waste and possibly other types of waste and residues (e.g., domestic and/or industrial) would favor rapid environmental reclamation, where the reclaimed land could be used for multiple purposes (e.g., agriculture, agroforestry, forestry, and reforestation). Our results indicate that the use of Technosols could lead to an offset of 0.52–1.00 Gt CO2eq, owing to soil carbon sequestration only. Considering the re-establishment of vegetation (data unknown), the recovery of AGBC stocks could lead to TOC stocks greater than 1.00 Gt CO2eq. Importantly, mine reclamation with Technosols would lead to the recovery of soil-related ecosystem services.

To test the hypothesis that the construction of Technosols could help overcome CO2 emissions from surface mining, we estimated the SOC stocks of Technosols within the 0–100 cm depth using data available in the literature (see the Material and Methods section for more details). Our findings shows that the recovery of SOC stocks with Technosols is climate-dependent, with tropical Technosols showing the greatest potential for SOC stock recovery (48–90%; 0.50–0.94 Gt CO2eq), followed by those in the dry (17–63%; 0.01–0.03 Gt CO2eq) and subtropical (23–56%; 0.14–0.34 Gt CO2eq) regions. Overall, the use of Technosols for the reclamation of LAMS in Brazil has the potential to offset 31–60% (0.52–1.00 Gt CO2eq) of soil-related CO2 emissions.

The high potential for the recovery of SOC stocks with Technosols, particularly in tropical regions, may be attributed to the high input of plant-derived carbon and the strong potential for carbon stabilization through mineral-organic interactions. During the initial stages of weathering, the high rates of primary mineral dissolution increase the concentrations of Si, Al, and cations (K+, Na+, Ca2+, Mg2+) in the soil solution, which ultimately precipitate as poorly crystalline minerals23. These mineral phases are highly reactive towards SOM and can protect it from decomposers through the formation of mineral-organic associations24,25. Additionally, the presence of polyvalent cations, such as Ca2+ and Mg2+ can favor these associations through a process known as cation-bridging26. In this process, the adsorption of polyvalent cations onto mineral surfaces reverses their negative charges, favoring interactions with negatively charged organic functional groups27. Thus, under high chemical weathering rates such as those found in tropical or subtropical climates, Technosols constructed with significant quantities of easily weatherable minerals have the potential to function as efficient carbon sinks.

Importantly, our data included several Technosol types, many of which were not intentionally constructed for reclamation or CO2 sequestration purposes. Therefore, it is possible to increase estimated SOC stocks by specifically designing Technosols using waste and amendments with favorable chemical properties to stabilize soil organic matter (e.g., Ca- and Fe-rich materials). For example, waste that releases divalent and trivalent cations upon weathering could be a good choice for increasing SOC concentrations in Technosols. This would include the use of limestone waste rich in Ca/Mg, especially considering that Brazil possesses large reserves of limestone (372 ha of land; Supplementary Table S1). Similarly, iron mine tailings may be of great value for SOC sequestration because iron oxides (e.g., goethite and hematite) can effectively immobilize soil organic matter through different interactions that favor its accumulation in soils28. In Brazil, the second largest iron ore producer in the world, iron exploration covers an area of over 240,000 hectares and generates ~184 million tons of iron tailings annually29. These tailings are dumped in more than 200 dams, many of which deemed to be at “high risk“30. Recent studies have shown that Fe-rich tailings are suitable parent materials for the development of Technosols and have great potential for SOC sequestration31. As such, the reuse of iron tailings for the construction of Technosols is an alternative to their disposal in dams, a strategy that could transform potentially hazardous waste into a nature-based solution.

It is important to highlight that certain types of mine wastes may contain potentially toxic elements such as arsenic, mercury, cadmium, copper, and lead. Under such circumstances, their use should be avoided or combined with strategies aimed at preventing pollution and mobilization of heavy metals to surround water bodies32,33. In these cases, remediation techniques such as phytoremediation34,35,36 and the application of soil amendments36,37 can be implemented to immobilize pollutants. In addition to being used as a geochemical barrier for pollutants, soil amendments (such as organic compost, sewage sludge, ashes, and biochar) can also improve soil quality by increasing water retention, cation exchange capacity, and nutrient availability38,39. Therefore, their use is also recommended in combination with less reactive mine wastes (e.g., quartz-rich), which would otherwise not produce fertile Technosols.

The potential for Technosols to recover AGBC stocks, particularly in tropical regions, is high due to their ability to support the growth of both agricultural13 and native plant species40. This suggests that the loss of AGBC stocks due to surface mining could also be recovered in a short time after Technosol construction. Thus, Technosols have great potential for restoring essential ecosystem services, including food and energy production, protection of biodiversity, regulation of air and water quality, and nutrient cycling (Fig. 2). In fact, recent studies have shown that Technosols may have equal or better quality than natural soils13,41.

Another advantage of utilizing this approach for post-mine land reclamation is its economic feasibility since the construction of Technosols from waste and residues can be accomplished at a lower cost in relation to other artificial soils. This is due to the fact that waste materials are often readily accessible near the reclamation site, which reduces the expenses associated with creating other types of artificial soils. (e.g., purchase of raw material and transport)42. Such Technosols typically contain materials that are commonly present in natural soils (e.g., primary and secondary minerals), which makes their soil processes similar to those of natural soils43. Therefore, when designing Technosols, the focus should be on enhancing soil formation and ensuring short-term soil functioning. Based on the initial properties of the wastes, such as small particle size, absence of pollutants, and high levels of easily weatherable minerals, it may be possible to utilize them directly for Technosol construction. However, if these properties are lacking, additional steps such as reducing particle size or adding soil amendments may be required. Since the annual production of mine waste in Brazil is projected to reach 11 billion tons by 203044, it is crucial to explore the potential of various types of mine waste to produce healthy soils with high carbon storage capacity. Thus, with further research in this area, the construction of Technosols could also emerge as a feasible solution for waste management.

Considering the large areas dedicated to surface mining in Brazil and other mining countries (e.g., China, the USA and Australia), the construction of climate smart Technosols is a promising, yet overlooked, nature-based solution for climate change mitigation. This green technology relies on natural processes such as weathering, soil formation, and SOC stabilization to reclaim degraded land and produce healthy soils that ensure key ecosystem services and sequester carbon. Moreover, Technosols may serve as an effective waste management strategy, reducing the risk of waste-related environmental disasters. Thus, the construction of Technosols for mine reclamation could simultaneously address three of the major challenges of the 21st century: waste management, soil degradation and climate change mitigation45,46,47. This strategy deserves further evaluation, and its implementation should be considered in future environmental policies of major mining countries.

Methods

To calculate the carbon stocks in Brazilian mining areas, we first determined the geolocation and areas of all legal mining sites in the country. We downloaded a dataset that includes the geolocation of the mining sites from the National Mining Agency’s SIGMINE platform (see Data Availability). The SIGMINE is an online platform that is developed and maintained by the National Mining Agency. It shows the location and information of all active legal mining sites in Brazil. The information in this system is georeferenced and presented as satellite images and digital maps in vector and raster formats, using SIRGAS 2000 data as a reference. We extracted all available data and preprocessed it into groups of similar mineral substances (see the list in the Supplementary Information file). We selected mining processes with the following stages: mining concession (“Concessão de lavra”), authorization and permits (“Licenciamento”), extraction register (“Registro de extração”), and artisanal and small-scale mining (“Lavra garimpeira”), which are representative of active mining sites. Duplicate entries were filtered according to process ID and process number, and offshore mining processes were excluded. Finally, from ~205,000 raw entries, representing ~1.8 million km2 of mine sites, we used ~33,000 entries (54 thousand km2) in this study (Supplementary Table S1). These mining areas are referred as (LAMS) and were used to estimate the carbon stocks lost due to mining activities.

We used the aboveground carbon map of Brazil48 to estimate the above-ground biomass carbon (AGBC) and the Soil Grids v2 dataset49 to estimate the (SOC) stocks (Supplementary Fig. S1) within LAMS. We uploaded the polygon dataset from SIGMINE to Google Earth Engine to sample the raster values at the original spatial resolution for both layers within LAMS polygons. We exported the results as text files for exploratory data analysis and visualization using the R programming language. Carbon stocks in each pixel were obtained by multiplying the carbon stock values (in kg m−2) by the pixel area in m2. The final carbon stocks in mass unit were estimated as the sum of all carbon stocks in each pixel within the LAMS polygons for the tropical, subtropical (i.e., temperate), and dry climatic regions. Since the dataset for SOC stock only contained information for the 0–30 cm layer, we estimated the stocks at 0–100 cm depth by applying a conversion factor of 1.887 (i.e., 1/0.53)50. We applied this factor considering that the SOC found in the 0–30 cm layer represented 53% of the total stock found in the 0–100 cm profile50. The SOC stocks were then converted from C to CO2 by multiplying by 3.67. Detailed data on SOC stocks in natural soils within LAMS are available in Supplementary Table S2.

To estimate the SOC stocks in Technosols, we utilized an updated dataset for Technosols carbon stocks21 (see Data Avaialbility). The dataset includes several parameters for each observation, such as climate type, SOC, soil organic matter content (SOM), bulk density (BD), and layer depth. For each climate type (tropical, subtropical, and dry), we extracted observations from soil samples that were identified as “Technosols” or “constructed soil” and contained information on SOC or SOM, BD, and soil sampling to a depth of 30 cm. When SOC was missing, we converted SOM to SOC by multiplying it by 0.58 (the Van Bemmelen conversion factor, widely used in SOM studies, including those on Technosol SOC stocks21) The SOC stocks at the 0–30 cm depth were calculated using Eq. (1)50:

where \({{SO}{C\; stock}}_{0-30{cm}}\) represents the soil organic carbon stock in Technosols between 0 and 30 cm, expressed in t C ha−1. SOC is the soil organic carbon content for each observation within 0 and 30 cm, expressed as % (more precisely, g of C per 100 g of soil); \({BD}\) is the bulk density for each observation within 0 and 30 cm, expressed in g cm−3; and \({thickness}\) is the soil layer thickness for each observation within 0 and 30 cm (see the results in Supplementary Table S3). We obtained n = 9 for tropical climates, n = 15 for dry climates, and n = 25 for subtropical climate regions, where n represents the number of soil profiles (0–30 cm).

However, exploratory analyses showed that the data did not follow a normal distribution (Supplementary Fig. S2), which is necessary to construct confidence intervals. Therefore, we performed Box–Cox transformation using Statistica software (version 13.5.0.17) with the maximum likelihood method to define the best λ to bring the data close to normality. After transformation, we confirmed the data for normality using the Shapiro–Wilk test, a powerful and widely available test for normality51. We present the results (means and 95% confidence intervals) as back-transformed data. Finally, the SOC stocks in t C ha−1 were multiplied by the values of the areas of each climatic region to obtain the SOC stocks in mass units. As for natural soils, we expressed the SOC stocks in Technosols in CO2eq by multiplying the C content by the 3.67 conversion factor.

Data availability

The data used to estimate the mining areas in Brazil are available at https://geo.anm.gov.br/portal/apps/webappviewer/index.html?id=6a8f5ccc4b6a4c2bba79759aa952d908. The data used to calculate the soil carbon stocks are available at https://files.isric.org/soilgrids/latest/. The data used to calculate AGBC stocks are available at https://snd.gu.se/sv/catalogue/study/ecds0244/1#dataset. The data used to estimate the Technosol SOC stocks are available at https://doi.org/10.5281/zenodo.7879530.

Code availability

All the codes used in this study are available at https://doi.org/10.5281/zenodo.7879530.

References

Reichl, C. & Schatz, M. World mining data 2022. https://www.world-mining-data.info/wmd/downloads/PDF/WMD2022.pdf (2022).

Giam, X., Olden, J. D. & Simberloff, D. Impact of coal mining on stream biodiversity in the US and its regulatory implications. Nat. Sustain. 1, 176–183 (2018).

Murguía, D. I., Bringezu, S. & Schaldach, R. Global direct pressures on biodiversity by large-scale metal mining: Spatial distribution and implications for conservation. J. Environ. Manage 180, 409–420 (2016).

Perlatti, F. et al. Copper release from waste rocks in an abandoned mine (NE, Brazil) and its impacts on ecosystem environmental quality. Chemosphere 262, 127843 (2021).

Grandell, L. et al. Role of critical metals in the future markets of clean energy technologies. Renew. Energy 95, 53–62 (2016).

Mining’s climate accountability. Nat. Geosci. 13, 97 (2020).

Azadi, M., Northey, S. A., Ali, S. H. & Edraki, M. Transparency on greenhouse gas emissions from mining to enable climate change mitigation. Nat. Geosci. 13, 100–104 (2020).

Ramani, R. V. Surface mining technology: progress and prospects. Proc. Eng. 46, 9–21 (2012).

Kundu, N. K. & Ghose, M. K. Shelf life of stock-piled topsoil of an opencast coal mine. Environ. Conserv. 24, 24–30 (1997).

Ghose, M. K. & Kundu, N. K. Deterioration of soil quality due to stockpiling in coal mining areas. Int. J. Environ. Stud. 61, 327–335 (2004).

Ghose, M. Management of topsoil for geo-environmental reclamation of coal mining areas. Environ. Geol. 40, 1405–1410 (2001).

Eswaran, H., Van Den Berg, E. & Reich, P. Organic carbon in soils of the world. Soil Sci. Soc. Am. J. 57, 192–194 (1993).

Ruiz, F., Cherubin, M. R. & Ferreira, T. O. Soil quality assessment of constructed Technosols: Towards the validation of a promising strategy for land reclamation, waste management and the recovery of soil functions. J. Environ. Manage 276, 111344 (2020).

Ahirwal, J. & Maiti, S. K. Development of Technosol properties and recovery of carbon stock after 16 years of revegetation on coal mine degraded lands, India. Catena 166, 114–123 (2018).

Uzarowicz, Ł. et al. Technogenic soils (Technosols) developed from mine spoils containing Fe sulphides: microbiological activity as an indicator of soil development following land reclamation. Appl. Soil Ecol. 156, 103699 (2020).

Watkinson, A. D., Lock, A. S., Beckett, P. J. & Spiers, G. Developing manufactured soils from industrial by-products for use as growth substrates in mine reclamation. Restor. Ecol. 25, 587–594 (2017).

Hedde, M., Nahmani, J., Séré, G., Auclerc, A. & Cortet, J. Early colonization of constructed Technosols by macro-invertebrates. J. Soils Sediments 19, 3193–3203 (2019).

Vergnes, A. et al. Initial conditions during Technosol implementation shape earthworms and ants diversity. Landsc. Urban Plan 159, 32–41 (2017).

Asensio, V., Vega, F. A., Andrade, M. L. & Covelo, E. F. Technosols made of wastes to improve physico-chemical characteristics of a copper mine soil. Pedosphere 23, 1–9 (2013).

Rodríguez-Vila, A., Forján, R., Guedes, R. S. & Covelo, E. F. Nutrient phytoavailability in a mine soil amended with technosol and biochar and vegetated with Brassica juncea. J. Soils Sediments 17, 1653–1661 (2017).

Allory, V., Séré, G. & Ouvrard, S. A meta-analysis of carbon content and stocks in Technosols and identification of the main governing factors. Eur. J. Soil Sci. https://doi.org/10.1111/EJSS.13141 (2021).

IPCC. Summary for policymakers. In: Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change (eds Shukla, P. R. et al.) (Cambridge University Press, 2022). https://doi.org/10.1017/9781009157926.001.

Wilson, M. J. The origin and formation of clay minerals in soils: past, present and future perspectives. Clay Miner. 34, 7–25 (1999).

Mikutta, R., Kleber, M. & Jahn, R. Poorly crystalline minerals protect organic carbon in clay subfractions from acid subsoil horizons. Geoderma 128, 106–115 (2005).

Mikutta, R. et al. Microbial and abiotic controls on mineral-associated organic matter in soil profiles along an ecosystem gradient. Sci. Rep. 9, 10294 (2019).

Rowley, M. C., Grand, S. & Verrecchia, É. P. Calcium-mediated stabilisation of soil organic carbon. Biogeochemistry 137, 27–49 (2018).

Wang, X. et al. Cation bridging studied by specular neutron reflection. Langmuir 29, 5520–5527 (2013).

Wagai, R. & Mayer, L. M. Sorptive stabilization of organic matter in soils by hydrous iron oxides. Geochim. Cosmochim. Acta 71, 25–35 (2007).

Vilaça, A. S. I., Simão, L., Montedo, O. R. K., Novaes de Oliveira, A. P. & Raupp-Pereira, F. Waste valorization of iron ore tailings in Brazil: assessment metrics from a circular economy perspective. Resour. Policy 75, 102477 (2022).

Agência Nacional de Mineração. Barragens, https://www.gov.br/anm/pt-br/assuntos/barragens.

Queiroz, H. M. et al. Early pedogenesis of anthropogenic soils produced by the world’s largest mining disaster, the “Fundão” dam collapse, in southeast Brazil. Catena 219, 106625 (2022).

Zhang, Q. & Wang, C. Natural and human factors affect the distribution of soil heavy metal pollution: a review. Water Air Soil Pollut. 231, 1–13 (2020).

Akhtar, O., Kehri, H. K. & Zoomi, I. Arbuscular mycorrhiza and Aspergillus terreus inoculation along with compost amendment enhance the phytoremediation of Cr-rich technosol by Solanum lycopersicum under field conditions. Ecotoxicol. Environ. Saf. 201, 110869 (2020).

Ferreira, A. D. et al. Screening for natural manganese scavengers: divergent phytoremediation potentials of wetland plants. J. Clean Prod. 365, 132811 (2022).

Asensio, V. et al. Screening of native tropical trees for phytoremediation in copper-polluted soils. Int. J. Phytoremediation 20, 1456–1463 (2018).

Lebrun, M. et al. Effect of biochar amendments on As and Pb mobility and phytoavailability in contaminated mine technosols phytoremediated by Salix. J. Geochem. Explor. 182, 149–156 (2017).

Almendro-Candel, M. B., Navarro-Pedreño, J., Jordán, M. M., Gómez, I. & Meléndez-Pastor, I. Use of municipal solid waste compost to reclaim limestone quarries mine spoils as soil amendments: effects on Cd and Ni. J. Geochem. Explor. 144, 363–366 (2014).

Moreno-Barriga, F. et al. Organic matter dynamics, soil aggregation and microbial biomass and activity in Technosols created with metalliferous mine residues, biochar and marble waste. Geoderma 301, 19–29 (2017).

Soria, R. et al. Effects of technosols based on organic amendments addition for the recovery of the functionality of degraded quarry soils under semiarid Mediterranean climate: a field study. Sci. Total Environ. 816, 151572 (2022).

Martins, W. B. R. et al. Ecosystem restoration after bauxite mining: favorable indicators for Technosols construction and soil management using liming and subsoiling. New For. 52, 971–994 (2021).

Ahirwal, J., Kumar, A., Pietrzykowski, M. & Maiti, S. K. Reclamation of coal mine spoil and its effect on Technosol quality and carbon sequestration: a case study from India. Environ. Sci. Pollut. Res. 25, 27992–28003 (2018).

Robinson, D. et al. On the value of soil resources in the context of natural capital and ecosystem service delivery. Soil Sci. Soc. Am. J. 78, 685–700 (2014).

Huot, H., Simonnot, M.-O. & Morel, J. L. Pedogenetic trends in soils formed in technogenic parent materials. Soil Sci. 180, 1 (2015).

IPEA. Diagnóstico dos Resíduos Sólidos da Atividade de Mineração de Substâncias Não Energéticas; https://repositorio.ipea.gov.br/bitstream/11058/7702/1/RP_Diagn%C3%B3stico_2012.pdf (2012)

Borrelli, P. et al. An assessment of the global impact of 21st century land use change on soil erosion. Nat. Commun. 8, 1–13 (2017).

Peters, G. P. et al. The challenge to keep global warming below 2 °C. Nat. Clim. Change 3, 4–6 (2012).

Hoornweg, D., Bhada-Tata, P. & Kennedy, C. Environment: waste production must peak this century. Nature 502, 615–617 (2013).

Englund, O. et al. A new high-resolution nationwide aboveground carbon map for Brazil. Geo 4, e00045 (2017).

Hengl, T. et al. SoilGrids250m: global gridded soil information based on machine learning. PLoS One 12, e0169748 (2017).

Balesdent, J. et al. Atmosphere–soil carbon transfer as a function of soil depth. Nature 559, 599–602 (2018).

Razali, N. M. & Wah, Y. B. Power comparisons of Shapiro-Wilk, Kolmogorov-Smirnov, lilliefors and anderson-darling tests. J. Stat. Model. Anal. 2, 21–33 (2011).

Acknowledgements

The authors thank Vanessa Erler Sontag (Illus Scientia) for the designing of figures. F.R. thanks the São Paulo Research Foundation (FAPESP) for the financial support (2019/18324-3). M.R.C and T.O.F. thank the Brazilian National Council for Scientific and Technological Development (CNPq) for their research productivity fellowship (311787/2021-5 and 305013/2022-0) and X.L.O. is thankful for the Consellería de Educación, Universidade e Formación Profesional-Xunta de Galicia (Axudas á consolidación e estruturación de unidades de investigación competitivas do SUG del Plan Galego IDT, Ambiosol Group ref. 2018-PG036).

Author information

Authors and Affiliations

Contributions

F.R. and T.O.F. developed the initial concept and wrote the manuscript. J.L.S and F.P. gathered and pre-processed the data and edited the manuscript. J.S.L. analyzed the geospatial data. F.R. analyzed the Technosol data. F.R., T.O.F. and M.R.C. conceptualized the figures. F.R., T.O.F., J.A.M.D., C.E.P.C., X.L.O. and C.R. developed the final concept, wrote and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Earth & Environment thanks Raviteja KVNS and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Sadia Ilyas and Clare Davis. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ruiz, F., Safanelli, J.L., Perlatti, F. et al. Constructing soils for climate-smart mining. Commun Earth Environ 4, 219 (2023). https://doi.org/10.1038/s43247-023-00862-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43247-023-00862-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.