Abstract

Plant bodies consist of many cells. Each cell contains a cell wall and a cell membrane, which are involved in maintaining the turgor pressure to bear the weight of the plant body. Inspired by this framework, we prepared a gel material enclosed in many compartments. According to this concept, hydrogels reinforced by polymer foam were fabricated using a simple method, and their mechanical properties were investigated. A piece of polymer foam was immersed in an aqueous solution of a water-soluble monomer in the presence of an initiator and a crosslinker. We used sodium acrylate as a monomer, N,N′-methylenebisacrylamide as a crosslinker, 2,2′-azobis(2-methylpropionamidine) dihydrochloride as an initiator and polyurethane foam as a reinforcing material. After gelation, the mechanical properties of the composite gel were analyzed by compression testing. The compression strength of the composite gel was ∼2 MPa, which was much higher than that of the poly(sodium acrylate) (PSA) hydrogel alone. The compression modulus was also considerably higher than for each constituent material alone (both hydrogel and foam). When melamine foam was used in place of polyurethane foam, the mechanical properties of the composite gel significantly deteriorated.

Similar content being viewed by others

Introduction

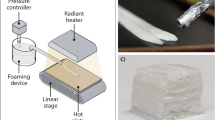

A plant cell is composed of a cell wall, a cell membrane, cytoplasm and a nucleus. The growing plant body is mechanically supported by living cells. Each living cell provides turgor pressure to bear the weight of the plant as it grows. We hypothesized that soft matter can be imparted with good mechanical resistance to compression by enclosing small gel pieces in compartments that are linked to each other. To test this hypothesis, we fabricated a polymer foam-reinforced hydrogel, that is, a ‘gel-in-sponge material’, to serve as a high-performance soft material, in which the cell-wall structure of plants is mimicked by the cell walls of the polymer foam (Figure 1). After a careful search of the literature for other polymer foam-reinforced hydrogels, we found only one research study by Liu et al.1 concerning polymer foam-reinforced gels. In this previous report, the researchers studied the modulus of a composite gel, but did not describe the strength of the composite gel in detail. Therefore, we undertook this study to revisit and advance the previous work from our standpoint.

Recently, several high-performance hydrogels have been developed, including double network,2 topological,3 nanocomposite4 and tetra-PEG5 hydrogels. Some of these hydrogels are highly flexible and stretchable, while others are highly tough under compressive stress. Hydrogels consist of large amounts of water and a small amount of hydrophilic 3D polymers that form a network. Because most solutes can diffuse in hydrogels, they are applicable as biomaterials. The possible applications of high-performance hydrogels in the medical field include medically useful membranes, artificial organs (such as artificial articular cartilage), scaffolds for living cells and wound-dressing materials.6, 7, 8, 9 However, high-performance hydrogels prepared using simple strategies are needed.

Fiber-reinforced hydrogels have been investigated for over one decade. In 1998, Young et al.10 reported fiber-reinforced poly(2-hydroxyethyl methacrylate) hydrogels as materials for artificial skin. They used three types of commercial fabrics: fibers containing nylon and elastic spandex, gauze and low lint wipes. The mechanical properties were strongly affected by the type of fabrics. Zhou and Wu11 fabricated a polyacrylamide hydrogel reinforced with chitosan nanofibers with improved mechanical properties. Our research group12 reported imogolite nanofiber-reinforced fish gelatin hydrogels. High-performance composite gel materials with polyurethane fibers were reported by Agrawal.13 Cellulose fibers in the form of bacterial cellulose or nanofibrils have also been used as a reinforcing material.14, 15, 16

Porous materials containing hydrogel have been reported by several research groups. Bokhari et al.17 reported enhanced osteoblast growth and differentiation on a hybrid material composed of a peptide hydrogel and highly porous polymeric foam. Niazi and Karegoudar18 and Sone et al.19 prepared composite materials from calcium alginate and polyurethane foam for immobilization of Bacillus sp. cells and selective elimination of lead (II) ions, respectively. However, these researchers did not describe (and perhaps did not measure) the mechanical properties of the materials.

In the present study, we combined poly(sodium acrylate) (PSA) gel and a polyurethane foam with open cell walls. As it is also a foam material, melamine was also investigated. PSA gel is known as a super absorbent material and has the potential to swell and generate turgor pressure. Polyurethane foam is the most popular polymer foam and it is highly flexible with moderate strength. We used polyurethane foam with open cell walls so that the sodium acrylate aqueous solution could interpenetrate into the cells. We used melamine foam for comparison because it absorbs water. In the present study, the mechanical properties were examined by compression testing.

Materials and methods

Materials

Two types of polyurethane foam with open cell walls were purchased and used as received. The polyurethane foams were CFH-30 with a cell density of 30±4 cells/25 mm and CFS with a cell density of 68±8 cells/25 mm. Both foams were of filter grade from INOAC Corporation (Nagoya, Japan). Melamine foam (MeF) of commercial grade (Basotect) produced by BASF was purchased from Strider (Toyohashi, Japan). Acrylic acid (AAc), N,N′-methylenebisacrylamide (MBAAm) and N,N,N′,N′-tetramethylethylenediamine (TEMED) were purchased from Kanto Chemical (Tokyo, Japan). 2,2′-Azobis(2-methylpropionamidine) dihydrochloride (V-50) was purchased from Wako Pure Chemical Industries (Osaka, Japan). All reagents were used as received.

Preparation of polymer foam-reinforced hydrogel

Prescribed amount of AAc was diluted with water and neutralized with 5 N NaOH. To this solution, we added MBAAm, 0.5 vol% of TEMED and 0.2 wt% of V-50. When the concentration of AAc was varied from 10 to 20 wt%, the molar ratio of MBAAm to AAc remained constant at 1:100. When the molar ratio of MBAAm to AAc was varied from 1:100 to 1:50, the AAc concentration remained constant at 10 wt%. The polymer foam cylinder-shaped samples for the compression testing were prepared by cutting out a polymer foam mat with a thickness of 10 mm using a round-shaped punch with a diameter of 20 mm. The polymer foam samples were immersed in the mixed solution described above and degassed using a vacuum pump. The screw-capped container containing the solution and the foam sample was placed in an electric oven at 70 °C for 12 h to yield a hydrogel containing a foam piece. The excess gel was removed using a round punch with a diameter of 20 mm and a cutter knife. The composition of the as-prepared PSA gel is summarized in Table 1. The foam content was 7 wt%, 3 wt% and 1 wt% for the PSA-CFS, PSA-CFH-30 and PSA-MeF, respectively.

Characterization

The surface morphologies of the lyophilized samples were observed using a Hitachi S-4700 field emission scanning electron microscope (FE-SEM) (Hitachi High-Technologies, Tokyo, Japan). The accelerating voltage was either 1 kV or 5 kV. The samples were coated with gold before observation. The compression test was carried out using either a Shimadzu EZ-S tabletop universal tester (Shimadzu, Kyoto, Japan) with a 100 N load cell or a Shimadzu AG-I tabletop universal tester with a 5 kN load cell at a crosshead speed of 1 mm min−1. The former tester was used for measurement of the weaker samples such as the non-reinforced hydrogels and polymer foams alone. The latter tester was used for testing the stronger samples such as the foam-reinforced hydrogels. In each case, five specimens were tested and the average values were calculated.

Results and Discussion

Preparation of the polymer foam-reinforced hydrogel

Soft matter consisting of a polymer foam and PSA hydrogel was easily prepared by a simple method. The gelation reaction of sodium acrylate (Na-AAc) with MBAAm occurred as usual. A degassing process was required to let the solution soak into the cells of the polymer foam. In our protocol, we could not prepare a gel sample when the concentration of AAc was less than 10%. There was no apparent difference between the polymer foam and the product in terms of appearance (Figure 2). Small gel pieces were observed at the surface of the material. The surface was a little smoother and glossier. When the material was pressed with our fingers, the mechanical properties were markedly different not only from polymer foam but also from the PSA hydrogel. Larger forces were required to deform the material compared with the PSA hydrogel. When the material was immersed in water to reach equilibrium swelling, the swelled hydrogel markedly overhung the polymer foam.

Mechanical properties of the polymer foam-reinforced hydrogel

The mechanical properties were assayed by compression tests using a universal tester. The stress-strain curve of the polyurethane foam-reinforced hydrogel (PSA10-CFS) is shown in Figure 3, compared with the polyurethane foam alone and the PSA hydrogel alone. Although the polyurethane foam alone was not broken in the compression test, the stress did not exceed 100 kPa until the test stopped at the limit of the strain (97%). The PSA hydrogel alone was broken easily at a stress of less than 100 kPa. Compared with the PSA hydrogel, the polyurethane foam-reinforced hydrogel had very high mechanical strength. The stress at breakage of the PSA hydrogel composite was above 1 MPa for CFH-30 (PSA10-CFH-30) and above 2 MPa for PSA10-CFS. The stress value of the polyurethane foam-reinforced hydrogel was obviously different from the simple sum of the stress of the PSA hydrogel alone and the polyurethane foam alone. The strength of our composite hydrogel was somewhat lower than the double network, nanocomposite and tetra-PEG gels, but was comparable to other high-performance hydrogels reported recently.11, 13, 20, 21, 22

Figure 4 shows the stress–strain curves for the compression test of the polyurethane foam-reinforced hydrogel with varying AAc concentration. The strength of the hydrogel increased slightly with an increase in the concentration of AAc. Interestingly, the slope of the stress–strain curve (reflecting the modulus of the hydrogel) of the polyurethane foam-reinforced hydrogel was not significantly affected by the concentration of AAc. The break point was not obvious for the PSA10-CFH-30. Notably, the PSA10-CFH-30 retained the compression stress without any drop off after breakage. Figure 5 shows the stress–strain curves for the compression test of PSA10-CFS with varying molar ratio of MBAAm to AAc. The stress–strain curve of the hydrogel was also not significantly affected by the increase in the feed ratio of MBAAm, that is, the crosslinking density. These results imply that the toughness of the material depends largely on the polyurethane foam, which has a critical role in enduring the compression force. At the last stage of the compression test, the compression force was converted to the force that enlarge the hydrogel sample in the lateral direction. The polymer foam prevented the hydrogel from fracture, similar to the role of the cell walls in plants (Figure 6). The water retained by the hydrogel in the foam cells also had an important role, similar to the water present in the vacuoles of plant cells that produces turgor pressure. We also carried out compression tests on the melamine foam-reinforced hydrogel. The stress–strain curves for this material are shown in Figure 7. We found that the melamine foam made the composite more brittle. Thus, melamine foam is not suitable for supporting hydrogels.

After the compression tests, we observed the broken sample specimens and found that some parts of hydrogel came out as small pieces from the cells of the polymer foam at a compression strain above 80%. This phenomenon was observed more significantly for CFH-30, whose cells are larger than CFS.

Cyclic compression tests

The sequential compression-unloading tests on the PSA10-CFS samples were carried out cyclically. The cyclic stress–strain curves are shown in Figure 8. The maximum strain was limited to 75% for each cycle. The maximum stress was 0.88 MPa in the first cycle. The maximum stress decreased to ∼94% in the second cycle. This phenomenon may be caused by the structural rearrangement of the hydrogel in the foam cells. Specifically, we hypothesized that the gel was partially broken at the interconnection points between the foam cells such that the flexibility for deformation increased. Related to this phenomenon, hysteresis was also observed, especially in the first cycle, implying energy loss during deformation. The decrease in the stress after the first cycle and the large hysteresis were previously reported in the literature.23, 24, 25 In the third cycle, the compression-unloading curve was almost the same as in the second cycle.

Morphology of the polymer foam-reinforced hydrogel

Figure 9 shows SEM images of the foam cells and the lyophilized gels with the foam cells. We used polyurethane foam with open cell walls. The CFH-30 had cells of ∼600 μm in diameter and the CFS had cells of ∼300 μm in diameter. Each cell had several pores. The aqueous hydrogel monomers passed through the pores before gelation. The pore size of the CFH-30 was relatively large compared with the cell size of the CFS. Melamine foam is known as a water-absorbent material. It exhibits a fiber-like morphology. We suspect that melamine foam makes the hydrogel more brittle because melamine fibers are not intrinsically flexible, unlike the polyurethane cell walls. After lyophilization, the dried PSA gel covered the cell walls. It did not show a porous structure, although lyophilized gels are typically porous. The dried PSA gel covering the cell walls may have formed because of inappropriate lyophilization. PSA gels have large osmotic pressures and may thaw under reduced pressures during lyophilization.

In the present study, we fabricated ‘gel-in-sponge materials’ using open-cell polyurethane foams. To be exact, the composite gels do not perfectly recapitulate the structure of plant cells, which are completely closed by cell membranes and cell walls. We expect that, if we can prepare completely closed ‘gel-in-sponge materials’, the strength of the material will be further improved. The fabrication of closed-cell composite gels is a technical challenge that will be a future theme for our research.

Conclusion

We prepared a polymer foam-reinforced hydrogel as a new type of high-performance soft matter with inspiration from plant body frameworks. The material is composed of many small compartments of polymer foam filled with hydrogel. A piece of polyurethane foam was swelled in an aqueous solution of monomers to create a hydrogel in the presence of an initiator for gelation. We used sodium acrylate as a monomer, N,N′-methylenebisacrylamide as a crosslinker, 2,2′-azobis(2-methylpropionamidine) dihydrochloride as an initiator and polyurethane foam as a reinforcing material. The composite hydrogels with polymer foam were easily obtained by heating the polymer foam in the monomer solution. The strength and modulus of the composite material were much higher than those of the PSA hydrogel alone. The compression strength of PSA10-CFS was over 2 MPa, which is comparable to some high-performance hydrogels. The cyclic compression-unloading test revealed that the composite hydrogel has hysteresis, especially in the first cycle. SEM observation of the lyophilized polyurethane foam-reinforced hydrogel indicated the presence of the dried PSA hydrogel covering the cell walls of the foam. This morphology was likely formed during lyophilization, with the cell walls uniformly filled with hydrogel before lyophilization. We are continuing to study the physical properties and morphologies of the polymer foam-reinforced hydrogels. Our method for reinforcing hydrogels can be applied to all types of hydrogels except those that are photocured. Future experiments will determine how the polymer foams can be applied and find the optimum combinations for biomaterials, shock-absorbing materials and phantom materials.

References

Liu, K., Ovaert, T. C. & Mason, J. J. Preparation and mechanical characterization of a PNIPA hydrogel composite. J. Mater. Sci.: Mater. Med. 19, 1815–1821 (2008).

Gong, J. P., Katsuyama, Y., Kurokawa, T. & Osada, Y. Double-network hydrogels with extremely high mechanical strength. Adv. Mater. 15, 1155–1158 (2003).

Okumura, Y. & Ito, K. The polyrotaxane gel: a topological gel by figure-of-eight cross-links. Adv. Mater. 13, 485–487 (2001).

Haraguchi, K. & Takehisa, T. Nanocomposite hydrogels: a unique organic–inorganic network structure with extraordinary mechanical, optical, and swelling/de-swelling properties. Adv. Mater. 14, 1120–1124 (2002).

Sakai, T., Matsunaga, T., Yamamoto, Y., Ito, C., Yoshida, R., Suzuki, S., Sasaki, N., Shibayama, M. & Chung, U.-i. Design and fabrication of a high-strength hydrogel with ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules 41, 5379–5384 (2008).

DeRossi, D., Kajiwara, K., Osada, Y. & Yamauchi, A. Polymer Gels: Fundamentals and Biomedical Applications eds DeRossi D., Kajiwara K., Osada Y., Yamauchi A., (Plenum Press, New York, NY, USA, 1991).

Jagur-Grodzinski, J. Polymeric gels and hydrogels for biomedical and pharmaceutical applications. Polym. Adv. Technol. 21, 27–47 (2010).

Haque, M. A., Kurokawa, T. & Gong, J. P. Super tough double network hydrogels and their application as biomaterials. Polymer 53, 1805–1822 (2012).

Liu, L. S., Kost, J., Yan, F. & Spiro, R. C. Hydrogels from biopolymer hybrid for biomedical, food, and functional food applications. Polymers 4, 997–1011 (2012).

Young, C.-D., Wu, J.-R. & Tsou, T.-L. High-strength, ultra-thin and fiber-reinforced pHEMA artificial skin. Biomaterials 19, 1745–1752 (1998).

Zhou, C. & Wu, Q. A novel polyacrylamide nanocomposite hydrogel reinforced with natural chitosan nanofibers. Colloids Surf. B: Biointerfaces 84, 155–162 (2011).

Teramoto, N., Hayashi, A., Yamanaka, K., Sakiyama, A., Nakano, A. & Shibata, M. Preparation and mechanical properties of photo-crosslinked fish gelatin/imogolite nanofiber composite hydrogel. Materials 5, 2573–2585 (2012).

Agrawal, A., Rahbar, N. & Calvert, P. D. Strong fiber-reinforced hydrogel. Acta Biomater. 9, 5313–5318 (2013).

Nakayama, A., Kakugo, A., Gong, J. P., Osada, Y., Takai, M., Erata, T. & Kawano, S. High Mechanical Strength Double-Network Hydrogel with Bacterial Cellulose. Adv. Funct. Mater. 14, 1124–1128 (2004).

Buyanov, A. L., Gofman, I. V., Revel'skaya, L. G., Khripunov, A. K. & Tkachenko, A. A. Anisotropic swelling and mechanical behavior of composite bacterial cellulose-poly(acrylamide or acrylamide-sodium acrylate) hydrogels. J. Mech. Behav. Biomed. Mater. 3, 102–111 (2010).

Borges, A. C., Eyholzer, C., Duc, F., Bourban, P.-E., Tingaut, P., Zimmermann, T., Pioletti, D. P. & Månson, J.-A. E. Nanofibrillated cellulose composite hydrogel for the replacement of the nucleus pulposus. Acta Biomater. 7, 3412–3421 (2011).

Bokhari, M. A., Akay, G., Zhang, S. & Birch, M. A. The enhancement of osteoblast growth and differentiation in vitro on a peptide hydrogel-polyHIPE polymer hybrid material. Biomaterials 26, 5198–5208 (2005).

Niazi, J. H. & Karegoudar, T. B. Degradation of dimethylphthalate by cells of Bacillus sp. immobilized in calcium alginate and polyurethane foam. J. Environ. Sci. Health, Part A 36, 1135–1144 (2001).

Sone, H., Fugetsu, B. & Tanaka, S. Selective elimination of lead(II) ions by alginate/polyurethane composite foams. J. Hazard. Mater. 162, 423–429 (2009).

Hron, P., Šlechtová, J., Smetana, K., Dvořánková, B. & Lopour, P. Silicone rubber-hydrogel composites as polymeric biomaterials: IX. Composites containing powdery polyacrylamide hydrogel. Biomaterials 18, 1069–1073 (1997).

Zhang, L., Wang, Z., Xu, C., Li, Y., Gao, J., Wang, W. & Liu, Y. High strength graphene oxide/polyvinyl alcohol composite hydrogels. J. Mater. Chem. 21, 10399–10406 (2011).

Qin, X., Zhao, F., Liu, Y., Wang, H. & Feng, S. High mechanical strength hydrogels preparation using hydrophilic reactive microgels as crosslinking agents. Colloid Polym. Sci. 287, 621–625 (2009).

Buyanov, A. L., Gofman, I. V., Khripunov, A. K., Tkachenko, A. A. & Ushakova, E. E. High-strength biocompatible hydrogels based on poly(acrylamide) and cellulose: Synthesis, mechanical properties and perspectives for use as artificial cartilage. Polym. Sci. Ser. A 55, 302–312 (2013).

Petrini, P., Farè, S., Piva, A. & Tanzi, M. C. Design, synthesis and properties of polyurethane hydrogels for tissue engineering. J. Mater. Sci.: Mater. Med. 14, 683–686 (2003).

Djonlagić, J., Žugić, D. & Petrović, Z. High strength thermoresponsive semi-IPN hydrogels reinforced with nanoclays. J. Appl. Polym. Sci. 124, 3024–3036 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teramoto, N., Shigehiro, O., Ogawa, Y. et al. Polymer foam-reinforced hydrogels inspired by plant body frameworks as high-performance soft matter. Polym J 46, 592–597 (2014). https://doi.org/10.1038/pj.2014.41

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.41

Keywords

This article is cited by

-

Viscoelastic properties of a novel hydrogel/foam composites for nucleus pulposus replacement

SN Applied Sciences (2019)

-

Morphing in nature and beyond: a review of natural and synthetic shape-changing materials and mechanisms

Journal of Materials Science (2016)