Abstract

A fascinating class of patterns, often encountered in nature as meandering cracks on rocks, dried-out fields and tectonic plates, is produced by the fracture of solids1. Here we describe the observation and modelling of an unusual type of pattern consisting of spiral cracks in fragments of a thin layer of drying precipitate. We find that this symmetry-breaking cracking mode arises naturally not from twisting forces, but from a propagating stress front induced by the fold-up of the fragments.

Similar content being viewed by others

Main

Fractured surfaces and lines2,3,4,5,6 typically show a cellular and hierarchical pattern. Twisting forces produce a spiral fracture, like that often seen in a tibia bone broken in a skiing accident7. However, spiral cracks can also be created in other situations, as we show here by drying a fine aqueous suspension of precipitate. During drying, the suspension solidifies and later fragments into isolated parts (Fig. 1a).

Surprisingly, for very fine precipitates in a solidified layer of thickness between 0.2 and 0.5 mm, regular spiral as well as circular cracking pathways show up inside the fragments (Fig. 1b). Depending on the grain size, precipitate type and layer thickness, the size of the spirals varies widely from several hundred micrometres to a few millimetres. To the naked eye, they look like small dots, but their detail is revealed under a microscope (Fig. 1c). These spiral cracks do not occur in one particular material — we were able to generate them in three different precipitates, from nickel phosphate Ni3(PO4)2, ferric ferrocyanide Fe4[Fe(CN)6)]3 and ferric hydroxide Fe(OH)3.

Careful in situ observation suggested a mechanism for the formation of these cracks. The spirals and circle-shaped structures form only after the fragmentation process is over. Owing to the humidity gradient across the thickness, the fragments gradually fold up and detach from the substrate, generating large tensile stresses in the radial direction, at and normal to the front of detachment. The extent of the attached area shrinks as the ring-shaped front advances inwards as a result of ongoing desiccation.

When the stress at the front exceeds the material strength, a crack is nucleated. As the nucleation is seldom symmetrical with respect to the boundaries, the crack tends to propagate along the front in only one direction, where more stresses can be released. By the time the crack growth completes a cycle, the front has already advanced, leading eventually to an inward spiral crack. As the stresses are concentrated at the layer–substrate interface, the spiral is confined there, with a typical penetration of 20–60% of the thickness.

The fact that the patterns are largely spiral suggests that crack propagation is favoured over nucleation, otherwise we would see more cylindrical concentric cracks. Although in a few instances we did observe this type of pattern, the majority are spiral in structure.

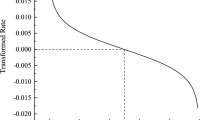

To test the proposed mechanism, we implemented it in a mesoscopic computer model8 that describes fracture on a frictional substrate. In this model, the grains in the layer are represented by blocks on a triangular lattice, interconnected among neighbours by springs. The system is pre-strained, and then relieved quasi-statically in a physical way. The relaxation is dictated by the competition between stick-and-slip and bond-breaking.

Focusing on the post-fragmentation process, we imposed a circular, inwardly propagating stress field to mimic the advancing detachment front. In a rather narrow parameter region, the spiral cracks were successfully reproduced (Fig. 1d). More tightly bound spirals can be obtained for smaller penetration depth, in agreement with experiment and prediction based on screening effects in the stress field. Other evidence has also been reported for the formation of similar spiral crack patterns under specific conditions9.

References

Lawn, B. Fracture of Brittle Solids 2nd edn (Cambridge Univ. Press, New York, 1993).

Skjeltorp, A. T. & Meakin, P. Nature 335, 424–426 (1988).

Yuse, A. & Sano, M. Nature 362, 329–331 (1993).

Groisman, A. & Kaplan, E. Europhys. Lett. 25, 415–420 (1994).

Bai, T., Pollard, D. D. & Gao, H. Nature 403, 753–756 (2000).

Shorlin, K. A., de Bruyn, J. R., Graham, M. & Morris, S.W. Phys. Rev. E 61, 6950–6957 (2000).

Bostman, O. M. J. Bone Joint Surg. 68, 462–466 (1986).

Leung, K.-t & Neda, Z. Phys. Rev. Lett. 85, 662–665 (2000).

Xia, Z. C. & Hutchinson, J. W. J. Mech. Phys. Solids 48, 1107–1131 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leung, KT., Józsa, L., Ravasz, M. et al. Spiral cracks without twisting. Nature 410, 166 (2001). https://doi.org/10.1038/35065517

Issue Date:

DOI: https://doi.org/10.1038/35065517

This article is cited by

-

Formation of wavy-ring crack in drying droplet of protein solutions

Science China Technological Sciences (2018)

-

Cracking-assisted photolithography for mixed-scale patterning and nanofluidic applications

Nature Communications (2015)

-

NURBS distance fields for extremely curved cracks

Computational Mechanics (2014)

-

Guided fracture of films on soft substrates to create micro/nano-feature arrays with controlled periodicity

Scientific Reports (2013)

-

Fracture path in brittle thin sheets: a unifying review on tearing

International Journal of Fracture (2013)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.