Abstract

A facile process to prepare multi-layered nanopatterned photoanodes (MNPs) is presented with well-arrayed mesoporous inorganic oxide layers. The MNPs were prepared with multiple stacking of nanopatterned TiO2 layers using a sacrificial polystyrene (PS)-thin film layer, which not only guided the stacking TiO2 layer but also was removed completely by calcination without generating cracks. The prepared MNPs exhibited large enhancement of the light harvesting property by increasing the number of nanopatterned TiO2 layers, through multiple reflection of the incident light from the periodic embedded channels formed between the nanopatterned layers. The photovoltaic efficiency was optimized with a 3-layered nanopatterned photoanode exhibiting a 73% Jsc and a 65% power conversion efficiency enhancement compared with a cell with a flat TiO2 layer for I2-free solid-state dye-sensitized solar cells.

Similar content being viewed by others

Introduction

Micro- and nano-patterned structures have demonstrated unprecedented light modulation effects; these structures have received considerable attention in metamaterial structures1 and various light harvesting devices.2, 3, 4, 5, 6, 7, 8, 9, 10 In this context, patterned photoanodes in solar cells have been studied as a line structure,11 a 3D micro-pyramid,12 an embedded micro-line,13 and moth-eye structures14 in an effort to improve light harvesting efficiency in photovoltaic devices.2, 3, 15 In addition, the photonic crystal7, 16, 17 and plasmonic nanostructures18, 19 have been explored intensively. Nonetheless, the absorption of incident light is still low, and a challenge remains to create light harvesting structures that provide high-light reflection and absorption over a broader range. Patterned structures exhibit enhanced surface area and are able to trap the incident light to enhance light harvesting;20, 21 therefore, patterned structures are a key component in a solar cell. Among the various solar cells, iodine-free solid-state dye-sensitized solar cells (ssDSSCs) based on a conductive polymer as hole transporting materials have been attracting much interest recently owing to their low toxicity, light overall weight, long-term durability and processibility.11, 22, 23 However, the photoconversion efficiency of ssDSSCs is low due to the wasted light that is transmitted through the photoanode. In our previous work, we introduced a nanopatterned TiO2 photoanode, showing 40% and 33% enhancements of the short-circuit current (Jsc) and power conversion efficiency (PCE), respectively, compared with a flat TiO2 photoanode in ssDSSCs.11 However, the light harvesting capabilities of ssDSSCs, which have only one nanopatterned layer, are limited because a significant amount of light could still be transmitted through the single nanopatterned layer. Therefore, a challenge worth addressing is to build multi-layered nanopatterned photoanodes (MNPs) for higher light harvesting.

Herein, for the first time, we present a method of multi-stacking of nanopatterned mesoporous TiO2 layers and the application of them in an I2-free ssDSSC. The light harvesting was found to be significantly enhanced by multi-reflection of the incident light from the periodic embedded channels formed between the nanopatterned layers in the photoanode of an I2-free ssDSSC. Furthermore, a complementary effect between light harvesting and electron transport in MNPs was analyzed to optimize the stacking of the nanopatterned TiO2 layers.

Experimental procedure

Nanopatterning photoanode

Nanopatterning of TiO2 films: The dense, compact TiO2 blocking layer (Figure 1) with a 200-nm thickness was prepared by spin-coating a titanium diisopropoxide bis(acetylacetonate) solution (2 wt% in butanol) onto FTO (fluorine-doped tin oxide) glass (Pilkington, St Helens, UK, 8 Ω) at 2000 r.p.m. for 30 s, followed by calcination at 450 °C for 30 min. Commercially available paste (TiO2 Paste 18NR-T, Dyesol, Queanbeyan, Australia) was cast onto the compact TiO2 layer using a doctor-blade technique, and then, the polydimethylsiloxane (PDMS) stamp was manually placed onto a paste-coated photoanode with proper pressure. The thickness of the MNPs was controlled by diluting the original TiO2 paste with organic solvent (terpineol), whereas the flat sample was fabricated by the TiO2 paste without dilution. Thus, the weight percentage of TiO2 pastes in terpineol were 100 wt% (1NP), 80 wt% (2NP), 65 wt% (3NP) and 50 wt% (4NP). The photoanode was maintained at 25 °C for 16 h or 70 °C for 3 h, and then, the stamp was peeled off. The nanopatterned photoanode was annealed at 60 °C for 1 h and then sintered at 500 °C for 30 min before cooling to 30 °C for 8 h. After successive sintering processes, the polymer-thin film was formed by spin-coating of 0.5 wt% polystyrene (PS, Sigma Aldrich, St Louis, MO, USA) solution in tetrahydrofuran (Aldrich Chemicals, 99.8%), ~50 μl each cell at 2000 r.p.m. for 30 s. The MNPs were produced by repeating the nanopatterning process with rotation of the PDMS nanostamp (2NP: 90°, 3NP: 45° and 90°, 4NP: 45°, 90° and 135°). The used PDMS was washed with ethanol and could be reused.

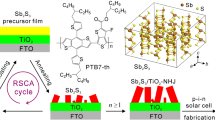

The nanopatterning process for the multi-layered nanopatterned photoanode and the structure of high performance solid-state DSSCs. (a) The first-nanopatterned TiO2 layer was prepared using TiO2 paste and the PDMS nanostamp. (b) Calcination at 500 °C and spin-coating of the polystyrene polymer solution onto the prepared first-nanopatterned TiO2 layer. (c) Coating of the TiO2 paste and nanopatterning after rotating the substrate for the second-nanopatterned TiO2 layer. (d) two-layered, (e) three-layered and (f) four-layered nanopatterned photoanodes after the calcination process at 500 °C. (g) The prepared solid-state DSSCs with nanopatterns and the conductive polymer.

Fabrication of ssDSSCs

The nanopatterned photoanode was immersed in the N719 dye (Solaronix SA, Aubonne, Switzerland) solution (0.5 mM in ethanol) for 24 h at room temperature, washed with ethanol and then dried. For the pore-filling of the HTM, the synthesized monomer (2,5-dibromo-3,4-ethylenedioxythiophene (DBEDOT)) was dissolved in anhydrous ethanol. One drop of dilute solution (1 wt%) was cast and dried under ambient conditions. One drop of a more concentrated solution (3 wt%) in ethanol was directly cast onto the photoanode and then dried under the same conditions. This process was also repeated three times. After complete drying of the solvent, the DBEDOT-incorporated photoanode was placed into a vial and capped, followed by being thermally polymerized at 55 °C for 24 h in an oven to produce a highly conductive polymer (poly(3,4-ethylenedioxythiophene) (PEDOT)). One drop of the ethanol solution, consisting of 1-methyl-3-propylimidazolium iodide (1.0 m, MPII, Aldrich Chemicals), 4-tert-butylpyridine (0.2 m, TBP, Aldrich Chemicals), and lithium bis(trifluoromethane)sulfonimide (0.2 m, LiTFSI, Aldrich Chemicals), was cast onto the dye-sensitized TiO2 photoanode with conductive polymers. After complete evaporation of the solvent in a vacuum oven, sandwich-type ssDSSCs were fabricated through the attachment of the Pt-coated counter electrode and sealing.

Characterization

The morphology and energy-dispersive x-ray spectrometry mapping of MNPs were observed using a field-emission scanning electron microscope (model JSM-7001F, JEOL, Tokyo, Japan). The reflectance and transmittance were measured via an UV/Vis/NIR spectrophotometer equipped with a Spectralon coated integrating sphere (60-mm diameter) using BaSO4 (PerkinElmer, Waltham, MA, USA, model: Lambda 750). The photoelectrochemical performance characteristics were measured using an electrochemical workstation (Keithly Model 2400, Cleveland, OH, USA) and a solar simulator (1000 W xenon lamp, Oriel, 91193, Irvine, CA, USA). The light distribution was homogeneous over an 8 in × 8 in area, and the illumination intensity was calibrated using a Si solar cell (Fraunhofer Institute for solar Energy System, Mono-Si+KG filter, Certificate No. C-ISE269, Freiburg, Germany) to a sunlight intensity of 1 sun (100 mW cm−2). This calibration was re-verified using a NREL-calibrated Si solar cell (PV Measurements, Boulder, CO, USA). The incident photon-to-current efficiency (IPCE) measurement was performed using a 300-W Xe light source and a monochromator (Polaronix K3100 IPCE Measurement System, McScience, Suwon, Korea). The amount of adsorbed dye was determined via a dye desorption experiment after immersion of the TiO2 film in a solution of NaOH (5 mm) in an ethanol/water (1:1 v/v) mixture. The concentration of desorbed dye in solution was analyzed using a UV/Vis/NIR spectrophotometer (Supplementary Figure S6 and Supplementary Table S3). Intensity-modulated photovoltage spectroscopy and intensity-modulated photocurrent spectroscopy measurements were performed on an electrochemical workstation equipped with a frequency response analyzer under a modulated green-light emitting diode (535 nm) driven by a source supply, which could provide both DC and AC illumination components (frequency range: from 10 000 to 0.01 Hz).

Results and Discussion

Nanostructures and morphologies of MNPs

The MNPs were prepared via multiple stacking of nanopatterned TiO2 layers using sacrificial PE-thin film layers, each of which was removed upon calcination after the stacking of the subsequent nanopatterned TiO2 layer onto the bottom TiO2 layer. Figure 1 shows a schematic illustration of the MNP fabrication process using a PDMS elastic nanostamp (3 cm × 4 cm) with a period of 600 nm. First, an electron-blocking layer was prepared on a FTO substrate, after which the substrate was coated with a commercially available TiO2 paste (Dyesol 18NR-T) using a doctor-blade method. The PDMS nanostamp was pressed firmly with pressure onto the TiO2 paste-coated substrate. After drying at room temperature, the nanostamp was removed, and then, the patterned TiO2 layer was annealed for 30 min at 80 °C to remove the remaining solvent. Next, the patterned TiO2 photoanode was sintered at 500 °C for 30 min. Figure 2a shows the image of the one-layered nanopatterned photoanode (1NP), showing a clear periodic pattern over the entire large area (Supplementary Figure S1).

SEM images of the TiO2 multi-layered nanopatterned photoanodes (MNPs). (a) The top surface of the nanopatterned TiO2 layer after the first nanopatterning (scale bar, 1 μm) and a photograph of the light diffraction of the nanopatterned photoanode (inset). (b) The two-layered nanopatterned photoanode (2NP; scale bar, 1 μm), (c) 3NP (scale bar, 5 μm) and (d) 4NP (scale bar, 7 μm). Photographic images of light diffraction of the MNPs (inset, left top) and actual photoanodes at different directions (left bottom). Cross-sectional SEM image of (e) 4NP (scale bar, 5 μm) and of (f) the interface of the MNPs (scale bar, 300 nm).

To stack an additional nanopatterned TiO2 layer, a PS polymer solution (0.5 wt%) was spin-coated onto the 1NP to form nano-channels between the 1NP and the incoming nanopatterned TiO2 layers. As the PS can be removed by sintering at 500 °C, it can preserve void channels for the efficient trapping of light in MNPs. After coating with PS, TiO2 paste was coated onto the PS-coated 1NP, and the same patterning process used for the preparation of 1NP was performed with the same PDMS nanostamp. The PDMS pattern direction for the second TiO2 layer was rotated from the base layer (1NP) to increase the length of the light path. After peeling-off the PDMS nanostamp, the double-layered photoanode was sintered at 500 °C for 30 min, resulting in a two-layered nanopatterned photoanode (2NP). During the calcination step, the solvent and the PS were completely removed, as verified by Fourier-transform infrared spectroscopy: the vibrational peaks for the PS (1028, 1601, 2850 and 3027 cm−1) disappeared after 30 min of calcination at 500 °C (Supplementary Figure S3). Furthermore, removal of PS from the MNPs upon calcination was directly observed energy-dispersive x-ray spectrometry mapping results (Supplementary Figure S4 and Supplementary Table S1). The carbon content was undetected from the composition of PS-coated MNPs after calcination, indicating that PS and any carbon residue from the decomposition of PS were removed completely by the calcination at 500 °C for 30 min.

The sacrificial PS layer was useful, as it was removed completely by calcination without generating cracks to produce the periodic void channels inside the 2NP, which are useful for the trapping of light. In contrast, the acrylate polymers, in this case poly(methyl methacrylate), generated cracks after calcination, possibly because the brittleness of poly(methyl methacrylate). Therefore, PS was used to form the MNPs (Supplementary Figure S2).

To prepare the MNPs, the processes described above were repeated. The pattern directions were rotated against the first-nanopatterned TiO2 layer by rotating the direction of the PDMS nanostamp. Thus, the 3-layered nanopatterned photoanode (3NP) and 4-layered nanopatterned photoanode (4NP) have a rotated direction of the nanopatterns from the bottom first-nanopatterned TiO2 layer to harvest more light from the light transmitted through the patterned layers.

The prepared MNPs showed a homogenous top surface without cracks (Figures 2 and 3a), despite the fact that it was subjected to multiple patterning-calcination cycles. Figures 2a–d show scanning electron microscopy images of the patterned TiO2 photoanodes, with periodic lines 300-nm wide on average and a height ranging from ca. 190 to ca. 50 nm. Note that the feature sizes are in good agreement with the wavelength of the visible light to ensure efficient trapping of sunlight. Furthermore, well-formed multi-stacked nanopatterns with a layer-by-layer structure with two to four layers in the nanopatterned photoanode were produced (Figures 2a–d). As the pattern directions of the nanopatterned TiO2 layers were rotated with respect to each other, the MNPs should provide greater light harvesting by trapping the light inside of the nano-channels of the TiO2 layer. As shown in the insets of Figures 2a–d, the diffracted light from the MNPs was rotated according to the number of patterned layers. Interestingly, both 3NP and 4NP showed clear pattern structures at the surface and cross-section of all layers (Figure 2). The cross-sectional scanning electron microscopy image of the 4NP structure showed that the multi-stacking process afforded well-adhered nanopatterned layers (Figures 2e and f).

Optical analysis of multi-layered nanopatterned photoanodes (MNPs). (a) Photograph of a large-area four-layered nanopatterned photoanode (4NP) with light harvesting capabilities in all directions (scale bar, 1 cm). (b) Schematic illustration of light trapping with MNPs. (c) Light absorption spectra of dye-adsorbed MNPs. (d) Reflection spectra of the MNPs without dye-adsorption. Flat (black), 1NP (red), 2NP (blue), 3NP (magenta) and 4NP (green).

The as-prepared MNPs were dipped into a solution of N719 dye in acetonitrile and tert-butanol to adsorb a sensitizer. Next, a solution containing 2,5-dibromo-3,4-ethylenedioxythiophene (DBEDOT) was directly dropped onto the dye-adsorbed TiO2 photoanode, followed by a solid-state polymerization11, 22, 23 at 60 °C to produce the conductive polymer, PEDOT as a HTM, to prepare an I2-free ssDSSC.

Enhanced light harvesting properties of MNPs

As shown in Figure 2a, the 1NP sample showed light reflection only in one direction. However, the MNPs showed multi-direction reflections according to the number of pattern layers, as shown in Figures 2b–d. The 3NP and 4NP samples showed light reflection in three and four different directions with the rotation of the photoanodes. The incident light reaching the patterned layer can be diffracted at the first pattern layer from the top. The transmitted light from the first patterned layer is reflected back toward the first layer by the second patterned layer. The light harvesting mechanism with multi-reflection at the interface between the first and second, the second and third, and the third and fourth nanopatterned TiO2 layers is illustrated in Figure 3b. Thus, the periodic MNPs can reflect the light back multiple times to the stacked patterned layers. For this reason, the optical path length and light absorption properties can be enhanced significantly by the MNPs, and thus, these MNPs can trap and harvest more light compared with the 1NP, although the thickness of these structures is the same: 12 μm. The optical properties of the MNPs prove that our approach for highly light-harvestable photoanodes of DSSCs is feasible. The incident light reaching the grating is diffracted in a backward direction from the periodic line-patterned photoanode. The angle of the diffracted light can be determined from the following equation (1),

where: m, λ, nactive, p, θi and θd are the diffraction order, wavelength of the incident light, refractive index of the TiO2 layer, period of the pattern, incident angle, and diffraction angle, respectively. The value of nactive of the nanopatterned TiO2 layer was determined to be 2.256,24 and p is ~600 nm, as determined from the scanning electron microscopy image in Figure 2. The diffracted light can have m-values of 0, ±1 and ±2 and m-values of 0 and ±1 when 250 nm⩽λ⩽600 nm and 600 nm⩽λ⩽760 nm, respectively. At higher m-values, the θd of the diffracted light can be bent by 90°, leaving the light unable to be absorbed by the dye-adsorbed TiO2 layer. The θd for the first-order reflection was 10.6° and 34.2° at the incident light of λ=250 and 760 nm, respectively. The θd for the second-order reflection was 21.7° and 87.2° when λ=250 and 676 nm, respectively. Therefore, the nanopatterned TiO2 layer can reflect the light back to the photoanode and thus enhance the optical path length, improving light absorption.

The light reflection properties of the MNPs were characterized to evaluate the light harvesting properties, as shown in Figures 3c and d. The MNPs were prepared over a large area (3 × 4 cm−2) of FTO glass using PDMS nanostamps, indicating the enhancement of the light harvesting property by increasing the number of nanopatterned TiO2 layers. As shown in Figure 3, the light was reflected significantly in the nanopatterned TiO2 layer. Because the MNPs multiply reflect light and trap incoming light, they could enhance the optical path length for the broad wavelength range of the incident light.

The reflection was characterized using a UV/Vis/NIR spectrophotometer equipped with an integrating sphere, and the absorption was calculated by the measured transmission (T, Supplementary Figure S5) and reflection (R) (A(%)=100−T−R).12 The reflection spectra of each sample are shown over the spectral range of 350–700 nm in Figure 3d. The flat TiO2 photoanode without a nanopattern exhibited a reflectance that was <20% in the visible range. However, the increases in light reflection of the MNPs were 29% (1NP), 37% (2NP), 43% (3NP) and 51% (4NP) compared with the flat TiO2 photoanode, as determined from the integration of the reflectance in the visible range (Table 1). This increased reflectance of the photoanode provides strong evidence on the light harvesting properties of the multi-stacked nanopattern with an increased number of layers. In addition, the absorption of dye-adsorbed photoanodes was increased according to the increase in the number of nanopatterned TiO2 layers, as shown in Figure 3c. This result indicates that the MNPs provide the significant improvement in light absorption capabilities with enhanced light trapping ability owing to the multi-stacked nanopatterns. The MNPs exhibited a high-light absorption, increasing by 16% (1NP), 24% (2NP), 26% (3NP) and 27% (4NP) compared with a flat TiO2 photoanode (Supplementary Table S2). As a result, the 4NP showed the highest light reflection and absorption among the MNPs.

MNPs in solar cells

The cell performance is characterized and the parameters of the cells are summarized in Figure 4 and Table 1, respectively. By increasing the number of nanopattern layers, the photocurrent (Jsc) also increased, possibly because of the enhanced amount of trapped light, as anticipated from the given absorption and reflection properties. The Jsc of MNP-ssDSSCs were 14.6 mA cm−2 (1NP), 16.8 mA cm−2 (2NP), 18.5 mA cm−2 (3NP) and 19.2 mA cm−2 (4NP), which are ~36% (1NP), 57% (2NP), 73% (3NP) and 79% (4NP) greater than that of the flat TiO2 photoanode. The enhancement of Jsc provides strong evidence of the light harvesting properties in MNP-ssDSSCs because the thickness of the MNPs was controlled by the dilution TiO2 paste. Furthermore, these tendencies are well matched with the IPCE curves of the DSSCs, which were measured at a chopper frequency of 5 Hz in alternating-current mode. (Figure 4b) The IPCE values of the DSSCs with MNPs were always greater than those of the DSSCs without nanopatterns in the wavelength region of 300 to 750 nm, which is the absorption range of the N719. The increase in the IPCE value over the whole visible range resulted in an increase in the Jsc of ssDSSCs with MNPs.

Photovoltaic characterization of an iodine-free ssDSSC with MNPs according to the number of nanopatterning layers of the photoanode. (a) Current–voltage (J–V) curves of DSSCs with MNPs at 100 mW cm−2. (b) IPCE of each device. Flat (black), 1NP (red), 2NP (blue), 3NP (magenta) and 4NP (green). (c) Dependence characteristics of the Jsc, Voc, FF and PCE of the devices with different numbers of nanopatterned layers of the photoanode.

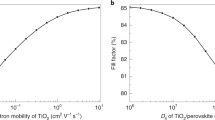

Increasing the number of nanopatterned TiO2 layers has a significant influence on the photovoltaic performance (Figure 4c). The presence of a nanopatterned TiO2 layer has an important role in the facilitation of the photocurrent. The Jsc was significantly improved from ca. 10.7 to 19.2 mA cm−2 with the addition of nanopatterned TiO2 layers. In contrast, the open circuit voltage (Voc) decreased slightly from 0.68 to 0.65 with an increase in the number of nanopatterned TiO2 layers. The slightly decreased Voc is related to recombination owing to the voids of the interfaces between the nanopatterns.

As a result, the PCEs with the 3NP- and 4NP-ssDSSCs reached 8.17 and 8.09%, respectively, at 100 mW cm−2, which were approximately 65 and 63% greater than that without nanopatterns, respectively. The 3NP-ssDSSCs showed the highest PCE of 8.17% at 100 mW cm−2 according to the Voc(0.66), Jsc (18.5 mA cm−2) and FF (0.67). These results represent improvements of 73 and 65% in Jsc and PCE, respectively, compared with the cells without nanopatterns. In contrast, the PCE of 4NP-ssDSSCs was lower than that of 3NP-ssDSSCs, despite the fact that the Jsc of the cell with 4NP was higher than that of 3NP. The Voc of the 4NP-ssDSSCs was lower than that of the 3NP-ssDSSCs, possibly because the electron recombination could be increased due to the nanopatterns. To understand the cause of increased recombination in MNPs, we determined the electron lifetimes, diffusion coefficients and diffusion length by means of intensity-modulated photovoltage spectroscopy and intensity-modulated photocurrent spectroscopy (Supplementary Figure S7). The electron lifetimes decreased with an increase in the number of nanopattern layers. This phenomenon could be attributed to the increased trapping sites and recombination centers originating from the periodic channels embedded inside of the nanopatterned layers of the MNPs. Such voids can disturb the electron transport and lead to recombination of charge carriers in the MNPs of ssDSSCs. The decrease in the electron lifetime was correlated with the decreased Voc upon the increase in the number of nanopatterned layers. In addition, the diffusion coefficients of ssDSSCs with nanopatterns were lower than that of the flat TiO2 photoanode cell. Given that the MNPs were composed of stacked nanopatterns with more embedded voids inside the nanopattern layers, more electrons could be trapped. Accordingly, the higher Jsc and PCE of 3NP can be mainly attributed to (i) the higher light absorption and reflection for high-light harvesting efficiency compared with the flat TiO2 photoanode and (ii) the reduced electron recombination in the ssDSSC with 3NP compared with that of 4NP. These processes result in the optimization of the complementary effect between the light harvesting and the electron recombination process by the nanopatterned layers. The preparation and optimization for multi-stacking of nanopatterned layers could be extended to other applications, such as the photo-catalytic layer25 and transparent conducting oxide substrates.26, 27

Conclusion

In conclusion, nanopatterned mesoporous TiO2 layers were multi-stacked to produce periodic embedded channels between nanopatterned layers using PE-thin film. When the MNPsMNPs were applied, the light harvesting from an I2-free ssDSSC was significantly enhanced by multi-reflection of incident light from the periodic embedded channels. Among the MNPs, the 3NP-ssDSSCs showed the highest PCE with high-light harvesting efficiency. The enhancements were 73% in Jsc and 65% in PCE for the 3NP-ssDSSCs, reaching a PCE of 8.17% at 100 mW cm−2. This result represents one of the highest efficiencies observed for N719 dye based I2-free ssDSSCs. The nano-architecturing approach for MNPs with mesoporous semiconductor nanoparticles represents a promising method that can both facilitate the manufacturing of photovoltaic devices with remarkable light harvesting properties and improvements in light modulation in many optoelectronic devices. Moreover, the results here provide insights into light trapping methods for multi-stacked nanopatterned layers, with a possible complementary effect of light harvesting and electron transport.

References

Soukoulis, C. M. & Wegener, M. Past achievements and future challenges in the development of three-dimensional photonic metamaterials. Nat. Photon. 5, 523–530 (2011).

Kim, J. B., Kim, P., Pegard, N. C., Oh, S. J., Kagan, C. R., Fleischer, J. W., Stone, H. A. & Loo, Y.-L. Wrinkles and deep folds as photonic structures in photovoltaics. Nat. Photon. 6, 327–332 (2012).

Oregan, B. & Gratzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991).

Stanley, R. Plasmonics in the mid-infrared. Nat. Photon. 6, 409–411 (2012).

Özdemir, A. & Keskin, C. Development of a new sensor material based on crystalline colloidal arrays embedded into polymer network. J. Anal. Chem. 66, 763–769 (2011).

Nelson, E. C., Dias, N. L., Bassett, K. P., Dunham, S. N., Verma, V., Miyake, M., Wiltzius, P., Rogers, J. A., Coleman, J. J., Li, X. & Braun, P. V. Epitaxial growth of three-dimensionally architectured optoelectronic devices. Nat. Mater. 10, 676–681 (2011).

Guldin, S., Hüttner, S., Kolle, M., Welland, M. E., Müller-Buschbaum, P., Friend, R. H., Steiner, U. & Tétreault, N. Dye-sensitized solar cell based on a three-dimensional photonic crystal. Nano Lett. 10, 2303–2309 (2010).

Mihi, A., Beck, F. J., Lasanta, T., Rath, A. K. & Konstantatos, G. Imprinted electrodes for enhanced light trapping in solution processed solar cells. Adv. Mater. 26, 443–448 (2014).

Kim, S., Koh, J. H., Yang, X., Chi, W. S., Park, C., Leem, J. W., Kim, B., Seo, S., Kim, Y., Yu, J. S., Kim, J. H. & Kim, E. Enhanced device efficiency of bilayered inverted organic solar cells based on photocurable P3HTs with a light-harvesting ZnO nanorod array. Adv. Energy Mater. 4, 1301338 (2014).

Qin, P., Domanski, A. L., Chandiran, A. K., Berger, R., Butt, H.-J., Dar, M. I., Moehl, T., Tetreault, N., Gao, P., Ahmad, S., Nazeeruddin, M. K. & Gratzel, M. Yttrium-substituted nanocrystalline TiO2 photoanodes for perovskite based heterojunction solar cells. Nanoscale 6, 1508–1514 (2014).

Kim, J., Koh, J. K., Kim, B., Kim, J. H. & Kim, E. Nanopatterning of mesoporous inorganic oxide films for efficient light harvesting of dye-sensitized solar cells. Angew. Chem. Int. Ed. 51, 6864–6869 (2012).

Wooh, S., Yoon, H., Jung, J.-H., Lee, Y.-G., Koh, J. H., Lee, B., Kang, Y. S. & Char, K. Efficient light harvesting with micropatterned 3D pyramidal photoanodes in dye-sensitized solar cells. Adv. Mater. 25, 3111–3116 (2013).

Lee, J. & Lee, M. Diffraction-grating-embedded dye-sensitized solar cells with good light harvesting. Adv. Energy Mater. 4, 1300978 (2014).

Heo, S. Y., Koh, J. K., Kang, G., Ahn, S. H., Chi, W. S., Kim, K. & Kim, J. H. Bifunctional moth-eye nanopatterned dye-sensitized solar cells: light-harvesting and self-cleaning effects. Adv. Energy Mater. 4, 1300632 (2014).

Polman, A. & Atwater, H. A. Photonic design principles for ultrahigh-efficiency photovoltaics. Nat. Mater. 11, 174–177 (2012).

Mihi, A., Zhang, C. & Braun, P. V. Transfer of preformed three-dimensional photonic crystals onto dye-sensitized solar cells. Angew. Chem. 123, 5830–5833 (2011).

Yip, C. T., Huang, H., Zhou, L., Xie, K., Wang, Y., Feng, T., Li, J. & Tam, W. Y. Direct and seamless coupling of TiO2 nanotube photonic crystal to dye-sensitized solar cell: a single-step approach. Adv. Mater. 23, 5624–5628 (2011).

Ding, I. K., Zhu, J., Cai, W., Moon, S.-J., Cai, N., Wang, P., Zakeeruddin, S. M., Grätzel, M., Brongersma, M. L., Cui, Y. & McGehee, M. D. Plasmonic dye-sensitized solar cells. Adv. Energy Mater. 1, 52–57 (2011).

Brown, M. D., Suteewong, T., Kumar, R. S. S., D’Innocenzo, V., Petrozza, A., Lee, M. M., Wiesner, U. & Snaith, H. J. Plasmonic dye-sensitized solar cells using core−shell metal−insulator nanoparticles. Nano Lett. 11, 438–445 (2010).

Rothemund, R., Umundum, T., Meinhardt, G., Hingerl, K., Fromherz, T. & Jantsch, W. Light trapping in pyramidally textured crystalline silicon solar cells using back-side diffractive gratings. Prog. Photovoltaics. Res. Appl. 21, 747–753 (2013).

Xue, C., Rao, J. & Varlamov, S. A novel silicon nanostructure with effective light trapping for polycrystalline silicon thin film solar cells by means of metal-assisted wet chemical etching. Phys. Status Solidi. A 210, 2588–2591 (2013).

Koh, J. K., Kim, J., Kim, B., Kim, J. H. & Kim, E. Highly efficient, iodine-free dye-sensitized solar cells with solid-state synthesis of conducting polymers. Adv. Mater. 23, 1641–1646 (2011).

Kim, J., Koh, J. K., Kim, B., Ahn, S. H., Ahn, H., Ryu, D. Y., Kim, J. H. & Kim, E. Enhanced performance of I2-free solid-state dye-sensitized solar cells with conductive polymer up to 6.8%. Adv. Funct. Mater. 21, 4633–4639 (2011).

Díaz-Parralejo, A., Caruso, R., Ortiz, A. L. & Guiberteau, F. Densification and porosity evaluation of ZrO2–3 mol.% Y2O3 sol–gel thin films. Thin Solid Films 458, 92–97 (2004).

Kim, D. J., Koh, J. K., Lee, C. S. & Kim, J. H. Mesh-shaped nanopatterning of Pt counter electrodes for dye-sensitized solar cells with enhanced light harvesting. Adv. Energy Mater. 4, 1400414 (2014).

Kong, S. M., Xiao, Y., Kim, K. H., In Lee, W. & Chung, C. W. Performance improvement of dye-sensitized solar cells by surface patterning of fluorine-doped tin oxide transparent electrodes. Thin Solid Films 519, 3173–3176 (2011).

Wang, F., Subbaiyan, N. K., Wang, Q., Rochford, C., Xu, G., Lu, R., Elliot, A., D’Souza, F., Hui, R. & Wu, J. Development of nanopatterned fluorine-doped tin oxide electrodes for dye-sensitized solar cells with improved light trapping. ACS Appl. Mater. Interfaces 4, 1565–1572 (2012).

Acknowledgements

We acknowledge financial support from a National Research Foundation (NRF) grant funded by the Korean government (Ministry of Science, ICT & Future Planning, MSIP) through the Active Polymer Center for Pattern Integration (APCPI) (2007–0056091) and the Pioneer Research Center Program (2010-0019313).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Na, J., Kim, Y., Park, C. et al. Multi-layering of a nanopatterned TiO2 layer for highly efficient solid-state solar cells. NPG Asia Mater 7, e217 (2015). https://doi.org/10.1038/am.2015.105

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2015.105

This article is cited by

-

Geometric Effect of Grating-Patterned Electrode for High Conversion Efficiency of Dye-Sensitized Solar Cells

Multiscale Science and Engineering (2019)

-

Improved light harvest in diffraction grating-embedded TiO2 nanoparticle film

Applied Physics A (2017)