Abstract

The European Solvents Industry Group (ESIG) Generic Exposure Scenario (GES) Risk and Exposure Tool (EGRET) was developed to facilitate the safety evaluation of consumer uses of solvents, as required by the European Union Registration, Evaluation and Authorization of Chemicals (REACH) Regulation. This exposure-based risk assessment tool provides estimates of both exposure and risk characterization ratios for consumer uses. It builds upon the consumer portion of the European Center for Ecotoxicology and Toxicology of Chemicals (ECETOC) Targeted Risk Assessment (TRA) tool by implementing refinements described in ECETOC TR107. Technical enhancements included the use of additional data to refine scenario defaults and the ability to include additional parameters in exposure calculations. Scenarios were also added to cover all frequently encountered consumer uses of solvents. The TRA tool structure was modified to automatically determine conditions necessary for safe use. EGRET reports results using specific standard phrases in a format consistent with REACH exposure scenario guidance, in order that the outputs can be readily assimilated within safety data sheets and similar information technology systems. Evaluation of tool predictions for a range of commonly encountered consumer uses of solvents found it provides reasonable yet still conservative exposure estimates.

Similar content being viewed by others

INTRODUCTION

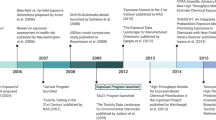

The first registrations under the European Union’s Registration, Evaluation, and Authorization of Chemicals (REACH) regulation had to be submitted by December 2010.1 For substances classified as dangerous, REACH requires manufacturers to identify safe use conditions for all uses that the substance is sold into in the European Union. These conditions must be communicated along the supply chain, with the main communication vehicle being exposure scenarios that are included in an annex to the extended safety data sheets.2 The exposure scenarios are expected to cover all the identified uses of the substance. Downstream users need to assess if their uses fall within the specified conditions of safe use, and are expected to do this via a process termed ‘scaling’ under REACH (i.e., modifying use conditions to ensure that safe use can be confirmed).

A process that results in consistent recommendations for safe use across different suppliers, allows for efficient safety data sheet generation in multiple languages, and provides a transparent straight-forward process for scaling is critical for achieving these requirements. Furthermore, guidance documents of the European Chemical Agency (ECHA) also indicate the importance of the generic exposure scenario (GES) concept.3 The GESs are groupings of common consumer uses that enable efficient evaluation and facilitate downstream communication of exposure information under REACH. The implementation of GESs can facilitate the efficient communication of information on risk management measures (RMMs) within the supply chain.4 Thus, an approach which provides the ability to assess multiple situations (exposure scenarios) at once, in alignment with the GES concept, would maximize efficiency.

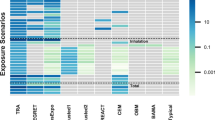

A tiered approach for exposure assessment has been proposed by ECHA to meet REACH reporting requirements.5 Assessments should start with a lower tier model designed to provide conservative estimates of exposure and risk. A lower tier model is one that utilizes assumptions and methodologies that provide higher-end exposure estimates. If the predicted exposures are below relevant hazard benchmarks, then safety is indicated and no further assessment is needed. However, if the exposure predictions fall above relevant hazard benchmarks then a higher tier model, which often requires more substance- and use-specific information, can be utilized to further refine the exposure estimate. For consumer exposure assessment, ECHA has recommended two tools within its guidance documents. The first is the ECETOC (European Center for Ecotoxicology and Toxicology of Chemicals) TRA (Targeted Risk Assessment) tool for screening-level assessment,6 and the second is the National Institute for Public Health and the Environment of the Netherlands (RIVM) Consumer Exposure (ConsExpo) Model for higher tier assessments.7 Other tools are also available to address specific exposure scenarios (the International Association for Soaps, Detergents and Maintenance Products REACH Exposure Assessment Consumer Tool-A.I.S.E.’s REACT,8 etc), but they are not intended for application outside of a relatively well-defined and restricted domain.

Although each of these models is useful, none meet all of the useful characteristics described above. The TRA tool has been widely applied by various industry sectors and has several advantages when carrying out consumer exposure assessments under REACH.9, 10, 11 It provides a conservative screening level estimate of exposure with minimal information and time requirements. However, it neither provides output in the form required by EU safety data sheets nor for authoring the outputs in an automated manner to avoid errors and minimize user variation. In addition, due to the TRA’s inherently conservative nature, it may frequently indicate that a higher tier assessment is necessary. The refinements described within the Appendix F of the TRA’s documentation,12 if implemented, would result in exposure estimates still conservative but closer to those of higher tier tools.

The RIVM ConsExpo model is a higher tier model for consumer exposure assessment. It can also be used as a first tier (i.e., screening) tool by using the instantaneous release model for inhalation exposure, or the instant application model for dermal loading, or the direct ingestion model for oral exposure. The ConsExpo model only allows users to estimate exposure predictions for one use of a single substance at a time. Furthermore, ConsExpo does not provide a risk characterization for the substance, which is a required element in a chemical safety report (CSR) under REACH. The A.I.S.E REACT model, on the other hand, provides a quantitative estimation of systemic consumer exposure and associated risk characterization ratios (RCRs) but is limited in scope to cleaning products. Models developed by the United States Environmental Protection Agency, such as the Exposure and Fate Assessment Screening Tool (E-FAST), require individual scenario assessment, have a limited set of defined scenarios, and do not provide output consistent with REACH reporting formats.13

The objective of this work was to utilize the TRA as a starting base and implement several of the refinements described within its background documentation.12 The goal was to develop an efficient, easy-to-use tool that can not only derive predicted exposure concentrations (PECs) and RCRs but also describe appropriate RMMs to meet REACH expectations linked to the safe consumer uses of solvents. Further, the tool was designed to align with the GESs that have been developed for solvents, that is, groupings of common uses to enable efficient and consistent evaluation and downstream communication under REACH. The ability to assess multiple scenarios at once and auto-populate output in REACH exposure scenario format were incorporated into tool development. The exposure-based risk assessment tool developed was named the European Solvents Industry Group (ESIG) Generic Exposure Scenario (GES) Risk and Exposure Tool (and will be referred to as EGRET). Although designed for solvent use, the EGRET tool can readily be utilized for non-solvents by adjusting default values as appropriate.

MATERIALS AND METHODS

The TRA tool (version 2) was used as a starting basis and modified as detailed below to create EGRET.6 (TRA version 2 was the current TRA consumer model at the time of EGRET development and 2010 REACH submissions; a TRA version 3 was released in 2012.) The TRA is a spreadsheet, and EGRET retains the spreadsheet format and vapor pressure bands of the TRA. Within EGRET, the recommendations for TRA refinement in Appendix F of ECETOC TR10712 are implemented. For algorithm refinement, equations presented within ECETOC TR107 and the ConsExpo model documentation14 were evaluated and then incorporated as detailed below. For default value refinement, in order of consideration, standard exposure references, literature data, and other sources of product use information (internet, trade group, etc) were consulted. Standard exposure references for EU populations (e.g., RIVM Fact Sheets15) were consulted first but then supplemented with US standard references or other sources depending upon data availability and completeness across parameters. REACH documentation for consumer exposure and risk characterization reporting requirements served as the basis for designing tool output.3, 5, 16 The banding approach to support autopopulation was developed based upon concepts practiced in occupational exposure assessment, modified for consumer GES application.4, 17, 18

To maintain transparency, EGRET displays the original TRA defaults, PECs, and RCRs in Table 2a of the tool, also called the “TRA” section. Updated algorithms and refined exposure factors and their bases are presented in Table 2b of the tool, also known as the “TRA+” section. Associated PECs and RCRs then follow, along with RMMs when needed. To preserve transparency and credibility, it is important that any modifications to the tool defaults, such as may be made during scaling, are substantiated with the basis for the new value. EGRET automatically prompts the user to provide this basis when a modification to product ingredient, amount used per event, use dilution factor, dermal factor, or inhalation factor is made. All other parameters in EGRET Table 2b, as well as all of the equations and structures in the tool, are protected to maintain its integrity and functionality.

TRA Algorithm Refinements

Parameters were added to provide the capability to refine exposure estimates when data are available to support their use: a dilution factor due to air exchange rate (AER), a dermal transfer factor, a use dilution factor, an inhalation exposure factor, and a glove efficiency factor. The model algorithms remain linear, so each of these factors represents the fractional adjustment of the original exposure estimate due to consideration of the factor (e.g., if considering dilution due to air exchange would reduce the original exposure prediction by 25%, the ventilation dilution factor implemented in the algorithm is 1−0.25=0.75). The defaults for all of these parameters are set to “1” so that they have no impact on the exposure estimate unless they are modified.

Air exchange rate (inhalation specific)

The TRA assumes instantaneous release to air, and to retain this conservatism, instantaneous release is also utilized in EGRET. The dilution factor due to the AER can be calculated by assuming an instantaneous release mode with a first-order decay as suggested in the ConsExpo model.15 Although adding minor complexity to the exposure prediction, this approach was utilized as it provides a slightly more conservative dilution factor than the simpler calculation method used in TR107, Appendix F.12 The equation implemented is:

where DFA is an averaged dilution factor due to air exchange (i.e., 1−percentage of dilution) over time t (hour), AER is air exchange rate (representing air changes per hour, units of 1/h), and ET is exposure time (hour). The DFA calculated by the equation above then can be used as a simple multiplier to linearly scale the exposure estimate.

To calculate the impact of air exchange, a default AER of 0.6/h is used for a residence with closed windows based upon the RIVM general fact sheet.15 The primary default applied within the tool is based upon a closed residential environment, but provision exists to include a garage ventilation rate (1.5/h) for activities that take place in this location, based upon the RIVM general fact sheet.15 For exposures defined to take place outdoors, the effect of ventilation was estimated as 0.6/h with room volume increased to 100 m3, as a conservative representation of outdoor dilution. The tool displays the location, AER, and resulting DFA that is the multiplier in the inhalation algorithm.

Inhalation exposure factor (inhalation specific)

There are cases where only a fraction of the total product amount used in a scenario is released to air during consumer use, such as release during fueling or other transfer activities. The inhalation exposure factor represents the fraction of product that is released during the use scenario: a factor of 0.05 would be used in a case where 5% of a substance is released to air during a consumer use.

Dermal factor (dermal specific)

A dermal factor can be applied in the dermal exposure calculation to further refine the estimated exposure value by accounting for the fraction of a substance available for absorption and/or the dermal absorption rate. The dermal factor represents the multiplicative factor that reduces the original estimate to one that would result based upon inclusion of the availability or absorption information (i.e., 1−the fractional reduction of exposure considering dermal transfer or absorption—if dermal transfer reduces exposure by 25%, the factor is 0.75).

Use dilution factor (dermal specific)

A use dilution factor was added to the dermal exposure equation for products that are typically diluted during use, such as dishwashing detergent. The factor represents the fraction of product found in the diluted mixture.

Glove efficiency (dermal specific)

A factor was added to represent the percentage of reduction in exposure that would result from glove use. If gloves provide 99% reduction, then a factor of 0.01 would be utilized. Although this capability has been built into EGRET, it was not implemented for any of the EGRET exposure scenarios, as the extent to which glove efficiency can be reliably described is generally a function of the glove material and its circumstances of use. In addition, consumer use of gloves is likely to be limited, except for cases where product characteristics would promote glove use, such as dyeing agents.

Solvent Generic Exposure Scenario Alignment

EGRET was developed to align with how ESIG GESs (Table 1) describe consumer exposures.19 To achieve this alignment, the tool includes additional scenarios beyond those in the TRA and implements a set of operational conditions (OCs) and RMMs reflecting common use.

Alignment with ESIG GESs

Each ESIG GES is associated with a defined set of product categories (PCs) that are taken from the REACH use descriptor system.16 Use scenarios were developed for PCs which were not included in version 2 of the TRA. Twenty new scenarios representing 12 additional PCs, some with subcategories, were developed based upon related scenarios already within the TRA. In addition, five fuel exposure scenarios were added to supplement the single fuel scenario of the TRA tool: scooter refueling, garden equipment use, garden equipment refueling, home space heater, and indoor use of lamp oil.

The defaults for these additional scenarios were based upon read-across from TRA scenarios for product with similar use patterns and information from published scientific literature, governmental agency reports, and industry trade groups. The transparency of the resulting scenario was maintained by specifying the origin of the scenario and each of its defaults within EGRET.

Standard OCs and RMMs

A standard list of OCs and RMMs were developed and utilized within EGRET to populate exposure scenario narratives (Table 2). The application of this concept had an important role in helping to efficiently and consistently communicate information on OCs and RMMs within the supply chain.

TRA Functionality Enhancements

The following code enhancements were made:

Calculation of local dermal and inhalation exposures and RCRs

Two equations were added to expand the functionality of the original TRA, making it possible to estimate local exposure concentrations and RCRs for the dermal and inhalation routes when needed, for example, for irritant substances. These two equations were based upon the ConsExpo model algorithms for the dermal loading and inhalation exposure under instantaneous release mode.

Dermal exposure in mg/cm2 (local):

where, PI: production ingredient (weight fraction), TL: thickness of layer (cm), GE: glove efficiency (default=1), UDF: use dilution factor (default=1), and DTF: dermal transfer factor (default=1)

Inhalation mean event concentration in mg/m3 (local):

where, PI: production ingredient (weight fraction), A’use: use amount (gram), Fe: release fraction to air, IEF: fraction loss due to spill/pour (default=1), ACH: air exchange rate, ET: exposure duration (hour), and SVC: saturated vapor concentration.

Saturated vapor concentration as upper bound for inhalation exposure concentrations

When the user inputs the vapor pressure and molecular weight, the saturated vapor concentration for the substance is automatically calculated and used as an upper bound for the inhalation exposure concentration. The saturated vapor concentration at normal temperature and pressure was calculated based on the two equations in Appendix F, Section A.1 of ECETOC:12

where SVC is the saturated vapor concentration; VP is the vapor pressure (in Pascals) of the substance; 101.325 × 103 Pa is the VP of ambient air, that is, ambient atmospheric pressure; MW is the molecular weight of the substance (g/mole), and 24.45 is the molar volume of air in liters at normal temperature and pressure conditions.

Autopopulation of RMMs

An approach that is based upon the banding of consumer derived no effect levels (DNELs) was implemented to provide an efficient mechanism to generate consistent RMMs for a group of substances with a similar risk profile. This approach is based upon the control banding concept, an approach that is widely applied by regulatory agencies for worker’s health.17 EGRET is set up such that if a systemic RCR is >1, the tool automatically populates a set of RMMs that result in a systemic RCR<1. The approach taken was to first develop a set of four separate DNEL ranges (Table 3), each referred to as a DNEL band. The DNEL bands in total were developed to cover the full range of general population DNELs for typically encountered solvents. Then, for each band, a set of RMMs was developed that would result in a RCR<1 for the most stringent (lowest) DNEL value of the band. This approach ensures that a RCR<1 would be calculated for any DNEL value within the band. For transparency, the tool displays systemic PECs and RCRs both with and without RMMs.

Autopopulation of exposure scenario narratives in CSR format

Two custom functions were developed for the EGRET tool to generate narrative outputs in the format that is expected of CSRs and that are required to be submitted as part of substance REACH registrations. These two functions reside in a normal visual basic for application (VBA) module and can be used as Microsoft Excel built-in functions. The functions followed are as described below.

Function “OCpopulating” (Figure 1) generates OCs for each exposure scenario. First, the function looks up the relevant OC standard phrase for the first exposure factor (or TRA+ modifiers) in the Table 2b section within EGRET. For example, the OC standard phrase for concentration is “covers concentrations up to x% [ConsOC1]”. The function then replaces “x” in the standard phrase with the exposure factor value. This process is repeated within the same exposure scenario until the last exposure factor in the Table2b section of EGRET has been concatenated with its corresponding standard phrase. Each of the concatenated standard phrases is separated by a semicolon and outputted as a complete set of OCs for the scenario.

Function “RMMpopulating” (Figure 2) generates RMMs for a particular exposure scenario to result in a RCR<1, when a set of default OCs results in a RCR prediction >1. First, the function checks the total systemic RCR (column BT in EGRET) calculated by the EGRET tool based upon default OCs. If the total RCR is <1, the function will display as an output “No specific RMMs identified beyond those OCs stated.” If the total RCR is >1, then RMMs are needed to bring the total systemic RCR to <1 for the specific scenario. In this case, the function compares the DNEL bands for all relevant exposure routes of the scenario, and determines the lowest DNEL band to be used to assign RMMs (Table 3). For example, if there are only two exposure routes for a scenario which has a dermal DNEL in band 2 and an inhalation DNEL in band 3, band 2 is selected as it is the lowest band. Each of the parameter values in the lowest DNEL band then replaces the “x” in the corresponding RMM standard phrase. Finally, the RMMpopulating function populates all of the RMMs as a complete set of concatenated RMM standard phrases for the exposure scenario.

Risk management measure (RMM) population function flow chart. [1] RCR: risk characterization ratio. [2] RMM: risk management measure. [3] DNEL: derived no-effect level. [4] [ConsRMM#]: represents a standard phrase for a consumer risk management measure condition. Each standard phrase is assigned a unique number.

RMMs were not developed for fuel scenarios based on the banding approach as it was not considered appropriate to reduce the weight fraction or further refine other default values. Therefore, for the fuel GES, the RMMpopulating function will only populate “No specific RMMs developed beyond those OCs stated.” If a RCR is >1 for a fuel scenario, the user will need to apply a higher tier modeling approach, or use measured exposure information, to refine the exposure estimates.

Scaling capability

Similar to the TRA tool, EGRET is based upon linear equations. This means that a predicted exposure value will change linearly if a user modifies the value of any of the algorithm variables, and results can be readily scaled based upon the input change (note, for AER, the DFA is the factor modified in scaling to maintain linearity). The algorithm variables that can be modified vary depending upon the route of exposure. Product ingredient (weight fraction), use frequency, and use amount are likely the three parameters for which downstream users will most often have data to refine default values during scaling.

TRA Parameter Default Refinement

Refinement of single parameter values

The TRA parameter defaults were refined based on readily available published scientific literature, supplemented by government and industry trade group data, to improve the realism in the exposure estimates while still providing conservatism in the exposure values. Exposure information from European data sources were searched and used first to refine the original exposure default values. When documents from European sources were not available, data from sources within the United States were used for the refinement. Documents used for the refinements included traditional sources of exposure information such as the RIVM general fact sheets used for the ConsExpo model’s defaults, the US Environmental Protection Agency’s (EPA’s) Exposure Factors Handbook, the US EPA’s E-FAST model defaults, and the US EPA’s dermal exposure assessment guidance.15, 21, 22, 23, 24 Other non-traditional sources such as trade group websites (A.I.S.E.,8 HERA25), manufacturer’s websites, retailer’s websites, and do-it-yourself websites (documented within the tool) were also searched for data. The exposure factors most often refined included the use amount and the use frequency.

Refinement based upon consideration of the scenario as a whole

The TRA and EGRET scenarios are commonly based upon indoor use in a 20 m3-sized room. Many of the products included in these scenarios were meant for in-home do-it-yourself type projects, where the use amount depends upon the size of the room in which the product is used (e.g., carpet adhesive, wall paint, etc). Product specifications that provide information on amount used per surface area were identified via internet searches, and for a given product type the most conservative value (i.e., the highest product amount per area or volume) identified was used in the tool, along with a description of the basis for the refined default value.

Model Evaluation

To evaluate EGRET’s performance as compared with other REACH tools, exposure predictions from the tool were compared with estimates from both the TRA tool and the ConsExpo model. Detailed model input and output can be found in Supplementary Information. Additionally, measured data for several PCs were also compared with exposure estimates from EGRET.

RESULTS

EGRET and its user manual are available for download, free of charge, at http://www.esig.org/en/regulatory-information/reach/ges-library/consumer-gess. The tool was used as the basis for the majority of solvent and petrochemical registrations in 2010 that are associated with consumer uses. EGRET is posted as a master workbook that contains exposure scenarios for all PCs and subcategories included in the solvent GESs. The master file enables quick evaluation of all scenarios at once but, because it includes all scenarios, output is not GES specific. It takes about 30 min to develop a GES-specific workbook from the master file, which can then be repeatedly utilized to assess as many substances as warranted.

The tool design is such that, in either the master or a GES specific workbook, all uses of a substance can be evaluated in less than a minute. This time includes specification of RMMs when warranted, as well as generation of exposure scenario output in narrative format that can be utilized for REACH registration submissions (Figure 3). The quickness of use reflects the minimum data input requirements (substance identity, molecular weight, vapor pressure, and relevant DNELs), DNEL banding approach, and excel macro functions that enable autopopulating of OCs and RMMs into the exposure narratives.

Tool Evaluation

An evaluation of the tool for a range of representative scenarios (Table 4) found that the exposure predictions from EGRET were less conservative than the TRA version 2 but more conservative than those of the ConsExpo model. The results obtained from the ConsExpo model, in turn, were closer to the measured inhalation concentrations than the exposure estimates from either EGRET or the TRA. Thus, EGRET can be seen to deliver an improved realism in the consumer exposure estimates combined with an improved ease of use. Overall, the findings indicate that EGRET provides reasonable yet still conservative exposure estimates (i.e., that are consistent with REACH expectations) for the scenarios being evaluated without recourse to the time and data resources often required for a higher tier model analysis. Furthermore, although the evaluation was based upon EGRET defaults, the additional algorithm parameters built into the tool enable efficient refinement of the default predictions.

Results of the comparison of EGRET defaults for fuel and lubricant scenarios with data from a recent consumer usage survey31 are presented in Table 5. For automotive refueling and lubricant use, with one exception, the defaults used in EGRET are more conservative than the averaged data in the survey and are close to the 90th percentile survey values for some exposure parameters. The exception was exposure duration in the fuel refueling scenario, which is 3 min in EGRET vs a 4-min average and 7-min 90th percentile in the survey. When EGRET is used with default values, this difference does not significantly impact the total exposure estimate for this scenario. The dermal route, not inhalation, drives the total exposure estimate. The exposure duration is a factor only in the inhalation algorithm and is not a factor in the dermal algorithm. However, if a user utilizes a dermal exposure factor or other default refinement that results in greater significance of the inhalation route to total exposure, the survey exposure duration data should be considered.

DISCUSSION

By retaining the TRA linear spreadsheet format while implementing algorithm refinements and enabling the introduction for more suitable default values, EGRET can quickly provide exposure estimates closer to those of higher tier tools like ConsExpo. Its design also ensures that OCs and RMMs are consistently reported independent of user, both providing assurance on the integrity of the CSR and enhancing the basis for aligned downstream customer communication across manufacturers. The linear nature of the tool also supports its utilization for scaling, that is, ready adjustment of exposure estimates for alternate values of OC parameters.

The tool does have limitations: it is still fairly simplistic; the RMM autopopulation feature is not implemented for local health effects; and further broader validation will only be possible once data collection efforts enable the confirmation of some defaults. However, the tool does provide a simple-to-implement refinement of the TRA that reduces the frequency of the need to move to the individual scenario-by-scenario assessment required by higher tier modeling tools. Further, it demonstrates the utility of extending the exposure banding concept from worker-to-consumer exposure estimation.

The GES concept implemented within the tool was found to be particularly useful, enabling public assessment of numerous substances and products without disclosure of confidential information. Part of the reason for the utility of the GESs no doubt lies in the fact that they have been developed as a partnership between solvent suppliers and the major sectors that represent formulators of solvent-containing consumer products, for example, paints, adhesives, cleaning products, etc. Utilizing a base set of OCs, multiple exposure scenarios can be grouped under a generic category, such as coatings. This allows for a more relevant upper-bound value on substance weight fraction to be ascribed to the product group, which, in turn, provides more relevant (albeit conservative) estimate of potential exposures. The principles underpinning EGRET could be expanded to sectors beyond solvents, by suitably modifying weight fraction and other information to be representative of other functional categories (i.e., biocides, colorants, etc).

Development of EGRET highlighted the need for better communication on exposure information, particularly product use patterns, across the supply chain. Of note is the fact that, in part as a response to REACH, several industrial sectors in Europe now post such information on their websites. Not only does this information help improve the accuracy and relevance on any exposure assessment for the use, but “standardizing” information on exposure determinants in this way also minimizes unnecessary variations in how any supplier of substances for that use (e.g. within formulations) may be assessing and communicating health risks. Future efforts to facilitate public availability of this information, in a generic manner such as that initiated in the GES concept, will further improve the capability of predictive tools for exposure and safety evaluation.

A number of the tool’s useful capabilities were developed not only in response to REACH regulatory requirements but also to recommendations from the broader scientific community. The utility of developing standard descriptors for RMM libraries,32 to facilitate effective information exchange across supply chains, has been well recognized. Recognizing the importance of clear risk communication in general, the standard phrases developed for both OCs and RMMs within the tool were designed to be readily understandable to the general public. In addition, the tool takes a step forward to meeting recommendations put forward for harmonizing consumer exposure models on a global scale.33 The standard phrases facilitate translation to multiple languages. The exposure scenario library implemented within the tool provides a concise way to document key exposure determinants and could possibly serve as a template for scenario development for the other product types. Like the TRA, EGRET provides results for multiple scenarios in a single spreadsheet, enabling quick assessment of relative exposure potential across scenarios and identification of significant exposure routes within a scenario. This information can be used to identify key exposure determinants and thereby inform future research aimed at model improvement.

EGRET provides a unique set of capabilities among commonly used exposure tools (Table 6). It combines the ease of use of lower tier models with next tier predictive capabilities. Even more importantly, it provides the capability to do both exposure and risk estimation quickly and iteratively. Quantitative risk assessments as well as identification of RMMs that may be needed to reduce exposure and risk are readily developed. This capability is not seen among other models.

Increasingly, there is a need not only for the development of exposure and risk information but also for the ability to communicate it in a useful and impactful manner. EGRET is unique in providing output that describes conditions of safe use in a readily understandable and globally translatable risk communication form (Table 6). The tool thus can serve to facilitate the dissemination and practical application of exposure and risk results.

References

European Union Regulation (EC) No 1907/ 2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulations (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC. available at http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32006R1907:EN:NOT 2006.

ECHA Guidance on information requirements and chemical safety assessment, Part G: Extending the SDS. available at http://echa.europa.eu/documents/10162/17224/information_requirements_part_g_en.pdf2012.

ECHA Guidance on information requirements and chemical safety assessment. Part D: Exposure Scenario Building. available at http://echa.europa.eu/documents/10162/13632/information_requirements_part_d_en.pdf2012.

Money C, Margary A, Noij D, Hommes K . Generic exposure scenarios: their development, application, and interpretation under REACH. Ann Occup Hyg 2011; 55 (5): 451–464.

ECHA Guidance on information requirements and chemical safety assessment chapter R.15: consumer exposure estimation (ver2.1) 2012.

ECETOC (European Center for Ecotoxicology and Toxicology of Chemicals) Targeted Risk Assessment Tool. available at http://www.ecetoc.org/tra2010.

RIVM (National Institute for Public Health and the Environment at Netherlands) ConsExpo model, version 4.1 available at http://www.rivm.nl/en/Library/Scientific/Models/Download_page_for_ConsExpo_software2005.

A.I.S.E (International Association for Soaps Detergents and Maintenance Products) REACH Exposure Assessment Consumer Tool (REACT). available at http://www.aise.eu/reach/?page=exposureass_sub32009.

ECETOC (European Center for Ecotoxicology and Toxicology of Chemicals) TRA consumer tool user guidance. available at http://www.ecetoc.org/tra.

ECETOC (European Center for Ecotoxicology and Toxicology of Chemicals) Targeted Risk Assessment, Technical Report No. 93. European Centre for the Ecotoxicology and Toxicology of Chemicals, Brussels. 2004.

Money CD, Jacobi S, Penman MG, Rodriguez C, De Rooij C, Veenstra G . The ECETOC approach to targeted risk assessment; lessons and experiences relevant to REACH. J Expo Sci Environ Epidemiol 2007; 17 (Suppl 1): S67–S71.

ECETOC (European Center for Ecotoxicology and Toxicology of Chemicals) Targeted Risk Assessment, Technical Report No. 107. European Centre for the Ecotoxicology and Toxicology of Chemicals, Brussels. 2009.

USEPA—United States Environmental Protection Agency Exposure and Fate Assessment Screening Tool (E-FAST). available at http://www.epa.gov/oppt/exposure/pubs/efastdl.htm2007.

Delmaar J, Park M, van Engelen J . ConsExpo 4.0 consumer exposure and uptake models program manual. RIVM report 320104004/2005 available at http://www.rivm.nl/en/Library/Scientific/Reports/2006/juli/ConsExpo_Consumer_Exposure_and_Uptake_Models_Program_Manual 2005.

Bremmer H, Prud'homme de Lodder L, van Engelen J . General fact sheet - Limiting conditions and reliability, ventilation, room size, body surface area. Updated version for ConsExpo 4. RIVM report 320104002. available at http://www.rivm.nl/en/Library/Scientific/Reports/2006/augustus/General_fact_sheet_Limiting_conditions_and_reliability_ventilation_room_size_body_surface_area_Updated_version_for_ConsExpo_4?sp=cml2bXE9ZmFsc2U7c2VhcmNoYmFzZTOONig5MDtyaXZtcT1mYWxzZTs=&pagenr=4690 2006; 4: 1–31.

ECHA Guidance on information requirements and chemical safety assessment, Chapter R12: Use descriptor system (ver2) 2010.

CDC (Centers for Disease Control and Prevention) Workplace safety and health topics: control banding. available at http://www.cdc.gov/niosh/topics/ctrlbanding/2010.

Money CD . European experiences in the development of approaches for the successful control of workplace health risks. Ann Occup Hyg 2003; 47 (7): 533–540.

ESIG (European Solvents Industry Group) GES standard phrase library for solvents. available at http://www.esig.org/en/regulatory-information/reach/ges-library/ges-phrase-library-2.

ESIG (European Solvents Industry Group) General introduction to GES concept. available at http://www.esig.org/en/regulatory-information/reach/ges-library/introduction2010.

USEPA—United States Environmental Protection Agency Exposure Factors Handbook (1997 Final Report). US Environmental Protection Agency, Washington, DC, EPA/600/P-95/002F a-c. 1997.

USEPA—United States Environmental Protection Agency. Dermal exposure assessment: A summary of EPA approaches. National Center for Environmental Assessment: Washington, DC, EPA/600/R-07/040F 2007.

USEPA—United States Environmental Protection Agency. Exposure Factors Handbook 2011 Edition US Environmental Protection Agency: Washington, DC, EPA/600/R-09/052F. 2011.

USEPA—United States Environmental Protection Agency Exposure and Fate Assessment Screening Tool (E-FAST) Documentation Manual. available at: http://www.epa.gov/oppt/exposure/pubs/efast2man.pdf2007.

HERA (human and environmental risk assessment on ingredients of European household cleaning products) Guidance document methodology. available at http://www.heraproject.com/files/Guidancedocument.pdf2002.

USEPA—United States Environmental Protection Agency Wall Paint Exposure Model (WPEM) version3.2 user’s guide. available at http://www.epa.gov/oppt/exposure/pubs/wpem.htm2001.

Hakkola MA, Saarinen LH . Customer exposure to gasoline vapors during refueling at service stations. Appl Occup Environ Hyg 2000; 15 (9): 677–680.

Vainiotalo S, Peltonen Y, Ruonakangas A, Pfaffli P . Customer exposure to MTBE, TAME, C6 alkyl methyl ethers, and benzene during gasoline refueling. Environ Health Perspect 1999; 107 (2): 133–140.

Nilsson CA, Lindahl R, Norstrom A . Occupational exposure to chain saw exhausts in logging operations. Am Ind Hyg Assoc J 1987; 48 (2): 99–105.

Singer BC, Destaillats H, Hodgson AT, Nazaroff WW . Cleaning products and air fresheners: emissions and resulting concentrations of glycol ethers and terpenoids. Indoor Air 2006; 16 (3): 179–191.

Alba Science Ltd Fuels and Lubricants Exposure Questionnaire Survey: final report prepared for CONCAWE. Belgium. Available upon request from CONCAWE 2011.

Bruinen de Bruin Y, Hakkinen PB, Lahaniatis M, Papameletiou D, Del Pozo C, Reina V et al Risk management measures for chemicals in consumer products: documentation, assessment, and communication across the supply chain. J Expo Sci Environ Epidemiol 2007; 17 (Suppl 1): S55–S66.

Kephalopoulos S, Bruinen de Bruin Y, Arvanitis A, Hakkinen P, Jantunen M . Issues in consumer exposure modeling: towards harmonization on a global scale. J Expo Sci Environ Epidemiol 2007; 17 (Suppl 1): S90–100.

ECHA Chemical Safety Assessment and Reporting tool (CHESAR). available at http://chesar.echa.europa.eu/chesar-tool;jsessionid=C278C3174747A0612F2D018B56E61889.live22012.

Acknowledgements

We thank everyone who provided comments on beta versions of EGRET and all who contributed to the development of the ECETOC TRA upon which it is based.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies this paper on the Journal of Exposure Science and Environmental Epidemiology website

Supplementary information

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Zaleski, R., Qian, H., Zelenka, M. et al. European solvent industry group generic exposure scenario risk and exposure tool. J Expo Sci Environ Epidemiol 24, 27–35 (2014). https://doi.org/10.1038/jes.2012.128

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/jes.2012.128

Keywords

This article is cited by

-

Establishing a system of consumer product use categories to support rapid modeling of human exposure

Journal of Exposure Science & Environmental Epidemiology (2020)

-

Perspectives on advancing consumer product exposure models

Journal of Exposure Science & Environmental Epidemiology (2020)