Abstract

Nano-sized gold has become an important material in various fields of science and technology, where control over the size and crystallography is desired to tailor the functionality. Gold crystallizes in the face-centered cubic (fcc) phase, and its hexagonal closed packed (hcp) structure is a very unusual and rare phase. Stable Au hcp phase has been reported to form in nanoparticles at the tips of some Ge nanowires. It has also recently been synthesized in the form of thin graphene-supported sheets which are unstable under electron beam irradiation. Here, we show that stable hcp Au 3D nanostructures with well-defined crystallographic orientation and size can be systematically created in a process of thermally induced self-assembly of thin Au layer on Ge(001) monocrystal. The Au hcp crystallite is present in each Au nanostructure and has been characterized by different electron microscopy techniques. We report that a careful heat treatment above the eutectic melting temperature and a controlled cooling is required to form the hcp phase of Au on a Ge single crystal. This new method gives scientific prospects to obtain stable Au hcp phase for future applications in a rather simple manner as well as redefine the phase diagram of Gold with Germanium.

Similar content being viewed by others

Introduction

Gold is a noble material and has been extensively used in many areas of science and technology such as nanoelectronics1,2, catalysis3, nanophotonics4 and medicine5, for its unique properties6,7 (non-reactive, highly conductive, biocompatible) over the last decades. The hexagonal closed packed (hcp) structure of Au is a very rare form of gold as it naturally occurs in the cubic face centered (fcc) phase. Single-phase crystals of this unusual form of gold were solely obtained as graphene-supported nanometer-thick Auhcp sheets8 or as nanoribbons9 by wet chemistry synthesis, but so far little is known about its properties. It is important to remark that the Auhcp nanosheeets were reported by the authors to be unstable under electron irradiation reverting their structure to the conventional Aufcc phase8,9. Recently, Marshall et al.11,12 reported on synthesis of stable Au hcp nanoparticles on top of some germanium nanorods via quenching of Au/Ge liquid. Only ~30% of the resulted nanoparticles were made of Au hcp phase. Since this form of Au is so rare and very difficult to obtain, its properties were never studied. Nonetheless it was theoretically explored recently by Wang et al.13, who has shown the possibility of hcp to fcc phase transition by first principle calculations. The elastic constants for Au hcp were also calculated, confirming the possibility of fabricating pure and stable hcp Au under ambient conditions. The method we propose here gives the possibility to synthesize stable 3D Auhcp nanostructures with tunable size via thermally-induced Au self-assembly on a Ge(001) surface. In our work, the Auhcp crystallite is present in each formed nanostructure as evidenced by electron microscopy i.e. Electron-Back-Scattered Diffraction (EBSD) and high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM). This gives unique scientific prospects to obtain in a simple way a stable Auhcp phase for future applications and studies in microelectronics or catalysis. The Au/Ge(001) surface itself is also very interesting for the applications of future mono-molecular devices since it may exhibit 1D and 2D conductivity channels in the form of atomic chains1 and a subsurface layer2. The deposited Au thin films show a preferential growth in the <110> direction when deposited on (001) germanium single crystal surfaces14 and annealed at temperatures below the eutectic point of the Au/Ge system of ~634 K15. As the annealing temperature of the sample reaches ~634 K, part of the germanium substrate melts and forms a Au-Ge eutectic liquid, which then recrystallizes during cooling of the sample to room temperature (RT)15. Here, the structure and composition of nanostructures formed after RT deposition of 6 mono layers (ML) of Au on (2 × 1) reconstructed Ge(001) in UHV16 and subsequent post-annealing at different temperatures (below and above the eutectic melting temperature of Au/Ge (634 K)–Te) and cooling rates were investigated using a combination of electron microscopy techniques. The structure and formation of Au nanoparticles on a single crystal have garnered a renewed interest in nanotechnology6 as these are the key catalysts in the growth of Ge, Si and III/V nanowires with tremendous applications for a new generation of nanoscale electronics and optoelectronics devices such as solar cells and battery electrodes17. The formed Au hcp 3D nanostructures could be also used as a growth template for hexagonal semiconductors18.

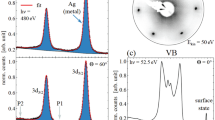

In the present study, Au islands of rectangular shape with edges oriented along [110] and [1–10] directions of the Ge(001) substrate (called Ge <110> in the rest of the text) are created for a post-annealing temperature of 573 K (bellow Te), as seen in Fig. 1a. When the post-annealing temperature exceeds Te, the islands reshape into an asymmetric polyhedral (see Supplementary Fig. S1), indicating the formation of a AuGe eutectic liquid during the high-temperature stage of the treatment19. The longest edge of the island is aligned along the Ge <110> direction (as observed in Fig. 1b). EBSD measurements are performed to determine the crystallographic orientation and phase of each island. It is important to realize that the EBSD technique probes the subsurface region down to a depth of a few nanometers for gold. In Fig. 1(c,d), the resulting inverse pole figures (IPF) in the Z (out of plane) sample direction of the EBSD measurements for the sample post-annealed bellow (Fig. 1c) and above (Fig. 1d) Te are shown, respectively. For a low temperature, the Au crystallites were indexed unequivocally as belonging to the Aufcc structure, while for the sample annealed at a higher temperature, the Au crystallites could not be indexed in the cubic system, and the Auhcp phase has to be considered. Common orientations, independent of the annealing temperatures, of the Au crystallites are observed in the X, Y and Z sample directions, as depicted in Fig. 1e. For the case of temperatures lower than Te, the obtained EBSD results can be described as being constituted by two equivalent configurations of Au crystallites rotated by 90° in-plane, due to the substrate surface symmetry, (for details see Supplementary Figs S2 and S3, experimental and simulated pole figures and inverse pole figures) with epitaxial relation (101)Aufcc//(001)Ge and [001]Aufcc//[110]Ge (Fig. 1e). This crystallographic texturing was never directly observed but can be attributed to the preferential orientation of Au crystallites parallel to the germanium <110> direction14,20. For the samples annealed at 673 K (see Fig. 1d), the EBSD results shows a combination of four possible different configurations of the Au crystallites rotated by 90° (for details see Supplementary Figs S2, S4 and S5, experimental and simulated pole figures and inverse pole figures) with the following two main orientation relationships: case I−(10-11)tilted by ~8deg Auhcp//(001)Ge, [2-1-10]Auhcp//[110]Ge and case II–(0001)tilted by ~30deg Auhcp//(001)Ge, [2-1-12]Auhcp//[110]Ge, see schematic in Fig. 1e. The relationship between the average grain size of the Au crystallites’ crystallographic structure and the post annealing temperature, as revealed by EBSD, is presented in Fig. 1f. Here, two temperature regions are clearly visible: 1) For annealing temperatures below Te, the crystallites belong to the Aufcc phase, and their size (around 40 nm) is weakly dependent on the annealing temperature; 2) For annealing temperatures above Te, Au crystallites containing the Auhcp phase are formed. The size behavior of these crystallites presents a strong temperature dependence increasing from ~40 nm to ~120 nm in the studied temperature range (for details, see Supplementary Fig. S6). In addition, we have checked that the hexagonal form of gold was also present for different Au coverage i.e. 3, 12 and 18 ML as presented in Fig. 1g–i.

(a,b) HR-SEM micrographs for post annealing of 6 ML Au/Ge(001) at 573 K (below Au/Ge eutectic) and 673 K (above Au/Ge eutectic); germanium substrate crystallographic directions are indicated. (c,d) corresponding EBSD Inverse Pole Figures (Au fcc and Au hcp phase respectively) in the Z direction. (e) schematic of orientation relationships for Au nanostructures below and above Au/Ge eutectic. (f) Average Au crystalline grain size as a function of the post annealing temperature. Exemplary SEM micrographs and EBSD IPF maps for post annealing at 673 K (above Au/Ge eutectic) for 3 ML (g), 12 ML (h) and 18 ML of Au (g). In all cases the hexagonal phase of Au was present. For all experiments, the temperature during the cooling down of the sample was decreased at rate of 15 K/min.

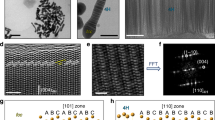

The rectangular islands observed below Te result from a self-assembling process induced by the surface diffusion of Au atoms. On the contrary, above the eutectic temperature, the Au islands form from a liquid AuGe alloy droplets as observed previously by Sutter et al.21, inferring that the observed polyhedral Au islands originates from a recrystallization process accompanied by a necessary Ge segregation during cooling of the sample to room temperature. As the Au islands possess a defined crystallographic orientation relative to the Ge substrate, the Au/Ge interface has to play an important role for directing the growth and crystallographic orientation of the Au islands. This is different from the observation of randomly oriented Au nanostructures supported by a Ge pedestal when annealing Au clusters deposited on a Ge(111) single crystal22. To examine the exact atomic structure of this Au/Ge(001) interface, cross-sectional samples have been analyzed by high-resolution HAADF STEM imaging, where the contrast is proportional to the atomic number (thus, Au appears brighter than Ge). The HAADF STEM images revealed that on the samples annealed at 498 K (below Te), only a small part of the Au island (~1 nm) is submerged into the germanium substrate, as presented in Fig. 2a. A similar effect of Au atoms migrating into the germanium substrate has been observed earlier by Wang et al.23 and was attributed to the Au/Ge mixing14. Moreover, the HAADF STEM image demonstrates, in Fig. 2a, that the epitaxial relationship between the island and the substrate is (101)Aufcc//(001)Ge in agreement with the EBSD results presented above.

Atomically resolved STEM-HAADF images of the Au nanostructures formed on a Ge(001) surface after annealing the sample: (a) at 498 K, below the eutectic temperature of Au/Ge and (c) at 673 K, above the eutectic temperature. (b,d) The Au(011)/Ge(001) interface region from the zones marked in (a) and (c). Columns containing only Ge atoms are indicated in green, and columns containing Au atoms are indicated in red. (e) Radial power spectrum density (PSD) of the Auhcp region of the Au island; atomic spacing corresponding to Aufcc and Auhcp are indicated. The two major peaks are identified as (0002) and (10–11) of Au hcp phase. Insert: FFT of the hcp region. (f) tapping-mode AFM 3D topography of the Au island.

The possible diffusion of Au atoms into the Ge substrate is further studied using statistical parameter estimation theory24,25. Here, the total scattered intensity by each atomic column is computed, as it scales with the average atomic number Z of an atomic column26,27. By assuming a constant sample thickness, this measure can be used to distinguish between columns containing Au atoms and pure Ge columns. Due to the noise inherent to the experiment, intermixing between the Au and Ge phases is studied atomic plane-by-plane across the interface using two sample t-tests28 (see Supplementary Fig. S7 for details). The results presented in Fig. 2b indicate that no Au atoms are present in the Ge substrate, indicating that the interface is perfectly sharp and confirming the non-miscibility of Au in Ge15,23. For samples annealed above Te, more than half of each of the Au island is buried into the germanium substrate, as shown in Fig. 2c. From HAADF imaging, we determined that the Ge {001} and {111} planes are predominantly interfaced with the buried part of the Au island (for details, see Supplementary Figs S8 and S9). Moreover, for most of the studied Au islands, at the side opposite to their longest edge, a germanium crystalline rim is seen on top of the Ge substrate (Fig. 2c,f). An Auhcp phase, which we will study in details in the following paragraph, is present in the topmost part of the islands. At the bottom of the Au island, the Aufcc(011) plane grows epitaxially on a Ge(001) surface, as shown by several HAADF STEM images. The combination of statistical parameter estimation theory with two-sample t-tests shows that in a small region, pure Ge columns are intermixed with columns containing Au. Note that Au atoms are only present in the columns following the fcc Au lattice. This leads us to the conclusion that Au atoms are most likely not diffusing into the Ge substrate; thus, excluding the presence of an AuGe alloy, as reported in earlier studies21,29 (further detailed analysis is available in the Supplementary material, Fig. S7a). Moreover, our experimental findings indicate that the Au islands formed at annealing temperatures lower than Te can be considered as defect-free single crystals of fcc Au, whereas islands formed at higher annealing temperature contain regions of both the Auhcp and Aufcc crystallographic phases clearly resolved by STEM. At the bottom (earlier stage of the crystallization), the Aufcc phase is observed, forming at the Aufcc(011)/Ge(001) interface. At the regions facing the Ge(111) planes, the Auhcp phase is observed and grows on the Aufcc {111} planes giving the interfacial relationship (0001)Auhcp//(111)Aufcc, as seen in Fig. 2c. This growth results in an orientation relationship relative to the Ge substrate as already observed by EBSD, described as (0001)tilted by ~30deg Auhcp//(001)Ge, [2-1-12]Auhcp//[110]Ge.

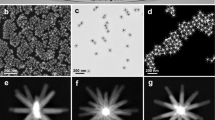

Figure 2e shows the radial power spectrum density (PSD) of this Auhcp region. There are two main peaks at 2.442 Å and at 2.233 Å, which can be uniquely identified as the (0002) and (10–11) reflections of the Auhcp phase8. The derived experimental lattice constants for Auhcp are a = 2.90 Å and c = 4.88 Å, which are in good agreement with other experimental8 and theoretical values13. STEM images show that the Auhcp phase is always present at the top part of the island, which explains the absence of Aufcc phase in the EBSD measurements presented above. In light of the HAADF STEM images, models of the interfaces Aufcc(011)/Ge(001) and (0001)Auhcp//(111)Aufcc have been analyzed. At the bottom of the islands, the Aufcc(011) plane is growing epitaxial to a Ge(001) surface. In the plane of the interface, the Aufcc(100) and the Ge(110) lattice planes are in good agreement (4.078 Å/4.000 Å = 1.0195), and the two structures match well in this projection (see Fig. 3a). The Auhcp and Aufcc structures represent two different stacking sequences of close packing; hence, the interface between (0001)Auhcp and (111)Aufcc will be in perfect registry (see Fig. 3b). In contrast to the free standing Auhcp square sheets studied by Huang et al.8, the Auhcp nanostructures formed on Ge(001) are stable under electron irradiation. Furthermore, it has been found that both the annealing temperature and cooling rate are important in order to control the final phase content of Au nanostructures. Here, two series of measurements have been used: annealing at 673 K and 773 K and then cooling down to RT with constant rates of 0.1 K/min, 15 K/min and 700 K/min. The analysis of samples annealed at 673 K shows the existence of three different regions in the island structures: a pure unfaulted Auhcp phase; a hexagonal intergrowth domain consisting of a mixture of different stacking sequences which could be attributed to the pure Auhcp and Aufcc atomic planes simultanously; and a pure Aufcc phase close to the germanium substrate. For samples annealed at 773 K, significantly less regions having the Auhcp phase are observed in favor of an intergrowth domain content (see Figs S10 and S11). The structure of the pure unfaulted Auhcp phase can be seen in Fig. 4a. The interface between the intergrowth domain and the pure Auhcp is presented in Fig. 4b. The formed Au nanostructures were free of any germanium content within the precision of the performed EELS spectroscopy measurements Fig. 4c–e. Furthermore, the cooling rate is important in order to improve the formation of the pure Aufcc and Auhcp phases. At a fast cooling rate (i.e., 700 K/min), the domains of intergrowth between Aufcc and Auhcp are significantly increased compared to slower cooling, where the pure phase domains are larger, dictating this phenomenon to be thermodynamically controlled.

(a) atomistic model of the interface between Aufcc (yellow) and Ge(001) (green)viewed along Ge[-1-10] zone axis (top) and Ge[1–10] zone axis (bottom) on the right four sections of marked atomic planes (I, II, III, IV) at the interface. Ge bulk crystallographic directions indicated; (b) atomistic model of the interface between Auhcp (on red) and Aufcc (on blue) viewed along the Aufcc [10−1] zone axis (top) and the Aufcc [1–21] zone axis (bottom) on the right four sections of marked atomic planes (I, II, III, IV). Aufcc crystallographic directions are indicated.

Atomically resolved HAADF STEM of pure Au hcp phase (a) together with FFT of that region. Au intergrowth region (b) made of two Au domains fcc and hcp. A black guide line is added following the stacking of the horizontal layers. The stacking sequence is labeled with the letters A, B and C in order to define the stacking sequence. Results of the EELS spectroscopy measurements of the Au islands: ADF-STEM of the examined area (c) and corresponding EELS Ge L2,3 (green) and Au M4,5 (red) map (d). In (e) EELS spectrum is presented from area 1 (the Au island) and area 2 (germanium). It is seen that within the precision of the EELS spectroscopy the Au island is free of any germanium. (f) Change of the RHEED intensity, recorded during sample cooling, after post annealing of 6 ML Au/Ge(001) to temperature higher then Au/Ge eutectic. Monotonic increase of the intensities is seen for all type of surface reconstruction spots. In the temperature range of 470 K–423 K a drop of the intensity occurs, which takes ~8 min, later the intensities increase monotonically in the same way. The observed drop of RHEED intensity is assigned to the decay of the beta-Au-Ge metastable phase leading to formation of Au hcp and pure germanium.

According to the experimental findings discussed here, a model explaining the formation of the observed half-buried Au islands on the Ge(001) substrate can be proposed, as presented in Fig. 5a–d. It is separated into 4 steps.

-

i

At the beginning of the annealing process, the deposited Au atoms aggregate into clusters due to surface diffusion of Au atoms on an Au rich surface and particle coarsening19. When the temperature exceeds the eutectic temperature of the system, a liquid Au-Ge droplet is formed by incorporation of Ge atoms from the substrate into the hot Au clusters, as described previously in nanowires12. According to the Au/Ge phase diagram, the concentration of germanium in the Au-Ge droplets is dependent on the annealing temperature15. In the process of germanium incorporation into the Au droplet, some truncated pyramid-like germanium pits are formed, similarly to ones observed in the metal-assisted etching process30, with the lowest surface energy Ge {001} facets at the bottom and the slightly more energetic Ge {111} planes on the pit’s sides31.

-

ii

During the slow cooling of the sample (0.1–15 K/min), the Au-Ge droplet undergoes recrystallization, beginning with the growth of Au in its preferred Aufcc structure along the [011] direction on the bottom of the pit, since the Ge(001) and Au(011) planes are in registry (a misfit of only 1.94%) as seen in Fig. 3a. The developing Aufcc crystallite grows with little twinning, and its crystallization front is along its {111} facets, which are energetically favorable (i.e., they have the lowest surface energy)32.

-

iii

The formation of these Aufcc crystallites leads to the germanium enrichment of the remaining liquid, so that the metastable hexagonal β-AuGe alloy is formed, similarly as directly first seen in the case of Au nanostructures supported on germanium nanorods by Marshall et al.12 and accordingly to Okamoto et al.15, Sutter et al.21 and Hajjar et al.22.

-

iv

Upon further cooling, the metastable alloy separates into the Auhcp phase and pure Ge due to the easily diffused Ge atoms from the β-AuGe alloy, as was seen in the case of TEM in-situ studies on nanowires12. The formed Au nanostructures are free of any germanium content as checked by the EELS measurements Fig. 4c–e. The excess Ge from the alloy segregates at the opposite of the Aufcc crystallite and forms a crystalline rim at the alloy/Ge interface, as shown in Fig. 2c,f. Moreover, the excess Ge diffuses along the reconstructed substrate surface and extends the atomic terraces. This is evidenced by a drop in the intensity of RHEED spots during the cooling of the sample in the range from ~463 K down to ~433 K, see Fig. 4f. Our findings are consistent with the experimentally observed germanium out-diffusion from Au-Ge metastable phase which begins at ~448K12 and the decay takes ~5 min15.

(a) deposited Au aggregation due to the surface diffusion and formation of Au/Ge liquid droplet. Germanium substrate etching and formation of truncated inverted pyramidal pits; (b) cooling the sample–Au recrystallization from the liquid into the fcc phase with simultaneous Ge enhancement in the remaining liquid; (c) formation of βAuGe hcp alloy; (d) formation of Au hcp phase and Ge rim from the βAuGe hcp alloy decay at sample temperature of ~463 K. (e) Experimentally derived Au/Ge phase diagram for self-assembled Au nanostructures on a Ge(001) surface, sample cooling rate as a function of sample annealing temperature and germanium content in Au/Ge liquid The relative sizes of Auhcp(red), intergrowth domain(green) and Aufcc(blue) regions of the island after recrystallization of the liquid are marked. When changing the sample annealing temperature and sample cooling rate, the Auhcp relative sizes change.

This scenario holds for lower cooling rates of 0.1–15 K/min, which indicates that this mechanism is thermodynamically stable and that our system is at a constant thermodynamic equilibrium during the cooling process. In the case of Au droplets on germanium nanorods, with finite amount of germanium available in the system as limited by the size of the germanium nanorod, the slow cooling resulted in the formation of the single crystalline segments of metastable γ-AuGe alloy21. However, for very fast cooling (i.e., 700 K/min), the pure Auhcp phase is not formed at the expense of an intergrowth of Aufcc and Auhcp. In contrast to fast cooling of the Au droplets on germanium nanorods presented by Marshall et al.12, Auhcp was observed. This might be related to the modification of the Ge diffusion kinetics due to the change of diffusion regime from a finite to an infinite Ge concentration at the source. In fact, the nanoscale Au-droplet phase diagram (valid for the nanorod system), with finite amount of germanium limited by size, deviated significantly from the phase diagram for bulk phase, as shown by E. Sutter and P. Sutter33,34. In our case, for an infinite amount of germanium available, the presence of the β-AuGe alloy, which is a precursor for the formation of pure Auhcp (as suggested by the Au/Ge phase diagram15), is responsible for this change of regime. As the pure Auhcp phase is formed only when the annealing is above Te but below 773 K, we suggest that the formation of the β-AuGe alloy depends on the initial germanium concentration in the hot droplet. Considering our observations and the Au/Ge phase diagram15, the germanium content in the Au-Ge droplet should be higher than 28 at. % (at 663 K) but lower than 38 at. % (at 773 K) to form pure Auhcp. This is summarized in the derived Au/Ge phase diagram for the self-assembled Au nanostructures on the Ge(001) surface presented in Fig. 5e.

In summary, the formation of crystalline Au nanostructures on a germanium substrate during a thermally induced self-assembly process of 6 ML Au deposited on a Ge(001) surface was investigated. The Au islands change from a rectangular shape made of the Aufcc phase to a polyhedral shape belonging mainly to the Auhcp phase while the annealing temperature crosses ~634 K; this temperature corresponds to the eutectic temperature for the Au-Ge system. The formation of the hcp phase of Au was found to result from the decay of the β-AuGe metastable alloy when it is cooled down at a sufficiently slow rate (15 K/min or lower). We can conclude that the Au crystallization starts from one side of the germanium pit, i.e., the Ge(111)/Ge(001) plane corner, into the favorable Aufcc phase with {111} facets followed by the formation of the β-AuGe alloy under the influence of a depletion of Au from this crystallizing liquid. Finally, at a temperature of ~463 K, the metastable β-AuGe alloy separates into the Ge rim surrounding the island and the Auhcp phase on top of the Aufcc {111} facets. Confronting our observations to the known Au/Ge phase diagram, the germanium content in the Au-Ge droplet should be higher than 28 at. % (at 663 K) but lower than 38 at. % (at 773 K) to form pure Auhcp. The presented simple technology of Auhcp growth will enable the new development in the fabrication of defined templates of this very rare phase of Au and will enable investigation and development of new devices based on hcp gold.

Methods

Au/Ge sample preparation

The samples were prepared in a UHV MBE system at Institute of Physics Jagiellonian University, Krakow, Poland. The Ge(001) substrate surfaces were cleaned by cycles of low-energy ion beam bombardment and annealing in order to achieve atomically flat terraces. Deposition of 6 ML of Au by the Molecular Beam Epitaxy with 0.12 ML/min resulted in formation of a crystalline, continuous Au overlayer as verified by RHEED and LEED. Just after the deposition, the 6 ML Au/Ge(001) samples were post-annealed in UHV conditions (10−10 mbar) to temperatures ranging from 498 K to 773 K, for which the initial continuous Au layer can reform into nanoscale Au islands. The temperature was increased with constant rate of 10 K/min and decreased in the cooling process with a rate of 15 K/min. Then, the samples were transferred in-situ by means of a UHV transfer system from a UHV MBE system to the SEM chamber (1*10−6 mbar).

Sample characterization

The Au/Ge(001) samples were characterized by SEM (FEI Quanta 3D FEG) equipped with a EBSD system (EDAX TSL DigiView camera) at the Institute of Physics Jagiellonian University, Krakow, Poland, which allows structural examination from the near surface of the sample (for Au, it is of a few nanometers). The EBSD diffraction patterns were collected at a 70° sample tilt at 15 keV beam energy. The diffraction patterns were automatically indexed by EDAX TSL OIM DC 7.2.1 software, according to the Au fcc phase and the Au hcp phase. The software algorithm during indexing selects the best matching phase automatically35,36. The sample geometry was chosen in a such a way that X, Y and Z are parallel to the [110], [1–10] and [001] crystallographic directions of the Ge single crystal substrate, respectively, as indicated in Fig. 1(a,b). IPF maps were subject to two clean-up algorithm procedures to ensure that reliable data were displayed, where grain CI standardization was applied and neighbor CI correlation with CI (0.4). The analysis of the experimental EBSD pole figures and inverse pole figures resulted in the derivation of the epitaxial relations for the formed nanostructures. The Au grain size was calculated from the EBSD data as an average grain feret diameter. For the 498 K sample, the Au grain size was calculated from the STEM cross section measurements. Samples were also investigated with a 5500 Agilent Atomic Force Microscope at ambient conditions. In order to study the internal structure of the Au/Ge(001), cross section samples were prepared using the FIB technique. At first, a protective carbon layer was deposited on the surface inside the SEM before an exposure to the atmosphere to avoid any change to the native structure of the samples. After this, a Pt protection layer was deposited first by e-beam deposition and then by ion-beam deposition to ensure minimal damage to the surface of the sample.

High Angle Annular Dark Field (HAADF) imaging was performed in a Probe Corrected Scanning Transmission Electron Microscope (STEM) FEI Titan at the University of Antwerp, Belgium, operated at 300 kV. This imaging mode provides structural images where intensities are proportional to both the thickness and mean atomic number Z. Statistical parameter estimation theory was used to calculate the total scattered intensity of the individual projected columns24,25. A linear scaling of these intensities with the atomic number Z was assumed to quantify the chemical structure of the Au/Ge interface26,27. A statistical analysis by two-sample t-test28 using the mean scattered intensity of the different columns in each atomic layers was performed to determine which layers have columns containing Au atoms.

To investigate the presence of germanium in the Au nanostructures, EELS measurements were performed. EELS was preferred to EDX due to the possible contribution of secondary fluorescence effects of the highly energetic Au K line giving rise to an artificial germanium signal in the Au. The EELS spectra were acquired at 300 kV with a convergence angle of 20 mrad and a collection angle of 100mrad. The spectra were acquired in Dual EELS with the same exposure time of 0.1 s/pixel and a dispersion of 0.5 eV/pixel. The spectra were then spliced together using the DM routine. The spectra obtained for region 1 and region 2 were power-law background subtracted in the region from 100 to 1150 eV.

Additional Information

How to cite this article: Jany, B. R. et al. Controlled growth of hexagonal gold nanostructures during thermally induced self-assembling on Ge(001) surface. Sci. Rep. 7, 42420; doi: 10.1038/srep42420 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Blumenstein, C. et al. Atomically controlled quantum chains hosting a Tomonaga-Luttinger liquid. Nat Phys 7, 776–780 (2011).

Krok, F. et al. Probing the electronic transport on the reconstructed Au/Ge(001) surface. Beilstein Journal of Nanotechnology 5, 1463–1471 (2014).

Turner, M. et al. Selective oxidation with dioxygen by gold nanoparticle catalysts derived from 55-atom clusters. Nature 454, 981–983 (2008).

Zijlstra, P., Paulo, P. M. R. & Orrit, M. Optical detection of single non-absorbing molecules using the surface plasmon resonance of a gold nanorod. Nat Nano 7, 379–382 (2012).

von Maltzahn, G. et al. Nanoparticles that communicate in vivo to amplify tumour targeting. Nat Mater 10, 545–552 (2011).

Brody, H. Gold. Nature 495, S1–S1 (2013).

Tan, C. & Zhang, H. Wet-chemical synthesis and applications of non-layer structured two-dimensional nanomaterials. Nat Commun 6, 7873 (2015).

Huang, X. et al. Synthesis of hexagonal close-packed gold nanostructures. Nature Communications 2, 292- (2011).

Fan, Z. et al. Synthesis of Ultrathin Face-Centered-Cubic Au@Pt and Au@Pd Core–Shell Nanoplates from Hexagonal-Close-Packed Au Square Sheets. Angewandte Chemie 127, 5764–5768 (2015).

Fan, Z. et al. Stabilization of 4H hexagonal phase in gold nanoribbons. Nat Commun 6, 7684 (2015).

Marshall, A. F. et al. Hexagonal Close-Packed Structure of Au Nanocatalysts Solidified after Ge Nanowire Vapor-Liquid-Solid Growth. Nano Letters 10, 3302–3306 (2010).

Marshall, A. F., Thombare, S. V. & McIntyre, P. C. Crystallization Pathway for Metastable Hexagonal Close-Packed Gold in Germanium Nanowire Catalysts. Crystal Growth & Design 15, 3734–3739 (2015).

Wang, C. et al. Generalized-stacking-fault energy and twin-boundary energy of hexagonal close-packed Au: A first-principles calculation. Scientific Reports 5, 10213- (2015).

Sloope, B. W. & Tiller, C. O. Epitaxial Au films on low index faces of Ge. Appl. Phys. Lett. 8, 223–225 (1966).

Okamoto, H. & Massalski, T. The Au-Ge (Gold-Germanium) system. Bulletin of Alloy Phase Diagrams 5, 601–610 (1984).

Zandvliet, H. J. The Ge(001) surface. Physics Reports 388, 1–40 (2003).

Chang, W., M., A., S., J., Kuemmeth, F., Krogstrup, P., Nygard, J. & M., M. Hard gap in epitaxial semiconductor-superconductor nanowires. Nat Nano 10, 232–236 (2015).

Cassabois G., Valvin P. & Gil B. Hexagonal boron nitride is an indirect bandgap semiconductor. Nat Photon 10, 262–266 (2016).

Nikiel, M. et al. Dynamics of thermally induced assembling of Au nanoislands from thin Au layer on Ge(001). CrystEngComm 18, 5674 (2016).

Benson, J., Hansen, J., McEllistrem, M., Clendening, W. & Tobin, J. An investigation of the Au/Ge(001) interface. Surface Science 193, L37–L46 (1988).

Sutter, E. & Sutter, P. Formation and stabilization of single-crystalline metastable AuGe phases in Ge nanowires. Nanotechnology 22, 295605 (2011).

Hajjar, S. et al. Morphology and composition of Au catalysts on Ge(111) obtained by thermal dewetting. Phys. Rev. B 84, 125325 (2011).

Wang, J., Li, M. & Altman, E. I. Scanning tunneling microscopy study of self-organized Au atomic chain growth on Ge(001). Phys. Rev. B 70, 233312 (2004).

Van Aert, S., Batenburg, K. J., Rossell, M. D., Erni, R. & Van Tendeloo, G. Three-dimensional atomic imaging of crystalline nanoparticles. Nature 470, 374–377 (2011).

Van Aert, S. et al. Procedure to count atoms with trustworthy single-atom sensitivity. Phys. Rev. B 87, 064107 (2013).

Van Aert, S. et al. Quantitative atomic resolution mapping using high-angle annular dark field scanning transmission electron microscopy. Ultramicroscopy 109, 1236–1244 (2009).

Martinez, G. T., Rosenauer, A., De Backer, A., Verbeeck, J. & Van Aert, S. Quantitative composition determination at the atomic level using model-based high-angle annular dark field scanning transmission electron microscopy. Ultramicroscopy 137, 12–19 (2014).

Student. The probable error of a mean. Biometrika 6, 1–25 (1908).

Zitouni, H., et al. Structural examination of the interface between Au catalysts and Ge(1 1 1). Acta Materialia 90, 310–317 (2015).

Nikiel, M., Jany, B. R., Wrana, D., Szajna, K. & Krok, F. SEM studies of vacuum condition influence on thermally induced Au self-organization on Ge(001) surface. Surface and Coatings Technology 277, 165–169 (2015).

Stekolnikov, A. A., Furthmüller, J. & Bechstedt, F. Absolute surface energies of group-IV semiconductors: Dependence on orientation and reconstruction. Phys. Rev. B 65, 115318 (2002).

Vitos, L., Ruban, A., Skriver, H. & Kollár, J. The surface energy of metals. Surface Science 411, 186–202 (1998).

Sutter, E. & Sutter, P. Phase Diagram of Nanoscale Alloy Particles Used for Vapor-Liquid-Solid Growth of Semiconductor Nanowires. Nano. Lett. 8, 411 (2008).

Sutter, E. & Sutter, P. Seze-Dependent Phase Diagram of Nanoscale Alloy Drops Used in Vapor-Liquid-Solid Growth of Semiconductor Nanowires. Nano 4, 4943 (2010).

Adams, B., Wright, S. & Kunze, K. Orientation imaging: The emergence of a new microscopy. Metallurgical Transactions A 24, 819–831 (1993).

Nowell, M. M. & Wright, S. I. Phase differentiation via combined EBSD and XEDS. Journal of Microscopy 213, 296–305 (2004).

Acknowledgements

The authors gratefully acknowledge the financial support from the Polish National Science Center, grant no. DEC-2012/07/B/ST5/00906. N.G., G.V.T. and J.V. acknowledge the European Union (EU) Council under the 7th Framework Program (FP7) ERC Starting Grant 278510 VORTEX for support. The Research Foundation Flanders is acknowledged through project fundings (G.0374.13N, G.0368.15N, G.0369.15N) and for a Ph.D. research grant to K.H.W.v.d.B. The microscope was partly funded by the Hercules Fund from the Flemish Government. T.W. acknowledges the Swedish Research Council for an international postdoc grant. The research leading to these results has received funding from the European Union Seventh Framework Programme under Grant Agreement 312483–ESTEEM2 (Integrated Infrastructure Initiative–I3). Part of the research was carried out with equipment purchased with financial support from the European Regional Development Fund in the framework of the Polish Innovation Economy Operational Program (Contract No. POIG.02.01.00-12-023/08).

Author information

Authors and Affiliations

Contributions

B.R.J. contributed to the characterization of the samples by SEM/EBSD and RHEED/TEM data analysis and interpretation. N.G., G.V.T. and J.V. contributed to the TEM measurements and data analysis. M.N. and A.J. prepared the samples in UHV. B.R.J. together with N.G. and M.N. contributed to discussions about the structures formation. K.H.W.v.d.B. and S.V.A. contributed to statistical analysis of the STEM images. N.G. and T.W. contributed to the crystallographic structure determination from STEM images and the interface modelling. K.S. contributed to the AFM measurements. B.R.J. prepared the manuscript together with N.G. and F.K. in consultation with all authors. F.K. initiated and organized this project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Jany, B., Gauquelin, N., Willhammar, T. et al. Controlled growth of hexagonal gold nanostructures during thermally induced self-assembling on Ge(001) surface. Sci Rep 7, 42420 (2017). https://doi.org/10.1038/srep42420

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep42420

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.