Abstract

Quantitative analysis of superoxide anion (O2·−) has increasing importance considering its potential damages to organism. Herein, a novel Mn-superoxide dismutase (MnSOD) mimics, silica-manganous phosphate (SiO2-Mn3(PO4)2) nanoparticles, were designed and synthesized by surface self-assembly processes that occur on the surface of silica-phytic acid (SiO2-PA) nanoparticles. The composite nanoparticles were characterized by fourier transform infrared spectroscopy (FTIR), transmission electron microscopy (TEM), scanning electronic microscopy (SEM), electron diffraction pattern, energy dispersive spectroscopy (EDS) and elemental mapping. Then the electrochemical measurements of O2·− based on the incorporation of SiO2-Mn3(PO4)2 onto the surface of electrodes were performed and some satisfactory results were obtained. This is the first report that manganous phosphate (Mn3(PO4)2) nanoparticles with shape-controlled, but not multilayer sheets, were utilized for O2·− detection. The surface self-assembly technology we proposed will offer the ideal material to construct more types biosensor and catalytic system for its nanosized effect.

Similar content being viewed by others

Introduction

Active reactive oxygen species (ROS) containing oxygen atoms are the substances with strong oxidizing ability, which can cause or aggravate cancer, cardiovascular diseases, asthma, cataract, ulcer disease, Alzheimer’s disease, Parkinson’s disease and other diseases. O2·−, the critical important part of the so-called ROS, is implicated in many physiological and pathological processes1,2,3. Under normal physiological conditions, O2·− maintains the relatively balanced level in vivo. Once the cell produces excessive O2·− in response to external stimulus or pathological changes, it will lead to etiology of aging, cancer and progressive neurodegenerative diseases such as Parkinson’s disease. Thus, real-time analysis and detection of O2·− have great significance. A variety of approaches have been tried to measure O2·− concentration, such as electron spin resonance4,5,6, spectrophotometry7, chemiluminescence8, colorimetry9,10, chromatograph11,12 and fluorescence13,14,15. However, these methods cost much and usually occupy too much space. In comparison with other methods, the electrochemical method has recently attracted a great deal of attention owing to its advantages including high sensitivity, low detection limit, simplicity, direct, real-time detection and so on.

Up to date, the commonly used electrochemical enzyme sensors are fabricated by immobilizing superoxide dismutase (SOD) and cytochrome (cyt c) onto the electrode surface. However, the enzymatic O2·− sensors are easily affected by pH and temperature changes, which limit their practical applications due to the poor stability of nature enzyme. Nanozymes, possessing enzymatic activities with nanostructure, have attracted particular attention as emerging natural enzyme mimics, they offer the possibility of lowered cost, improved stability and excellent recyclability16,17,18. Meanwhile, bionic concept has gained more and more attention19,20,21. Mn-superoxide dismutase (MnSOD) mimics, manganous phosphate (Mn3(PO4)2), manganous pyrophosphate (Mn2P2O7) and manganese (II) complexes are usually used to fabricate biosensors for O2·− detection22,23. Cabelli have studied the antioxidant mechanism of aggregated Mn3(PO4)2 particles in organic vivo24. Li used DNA as a template to produce Mn3(PO4)2 nanosheets and decorated this biomimetic enzyme onto the electrode surface for sensitive in-situ detection of O2·− 25. However, the intrinsic drawbacks of DNA, including high cost, instability and storage difficulty, may limit their widely applications of electrochemical sensors. Dai also reported the high efficient catalysis of Mn2P2O7, which was used as a SOD mimic for O2·− detection26. There is a serious problem in dealing with the preparation of these reported MnSOD mimics. It is that the conventional synthesized MnSOD mimics that reported in the previous literatures have multilayer sheet structure with uncontrolled shape, thickness and size. This approach will bring resources waste and low catalytic efficiency. We wonder how it is possible to utilize surface self-assembly technology and nanotechnology to construct a more efficient MnSOD mimic for promoting analytical properties.

In this paper, SiO2-Mn3(PO4)2 NPs were synthesized by surface self-assembly processes that occur on the surface of SiO2-phytic acid (SiO2-PA). To the best of our knowledge, there are no reports employing surface coating technique to immobilize Mn3(PO4)2 onto the surface of NPs for O2·− detection. The SiO2-Mn3(PO4)2 NPs have many advantages, like controllable shape with nanoscale, high specificsurface area than that of nano-sheet structure, low cost, simple preparation process, non-toxic and so on. This novel MnSOD mimic we prepared is utilized to fabricate biosensors and the electrochemical measurements of O2·− based on the incorporation of SiO2-Mn3(PO4)2 onto the electrodes surface are performed.

Results and Discussion

Figure 1 showed the fourier transform infrared (FTIR) spectroscopy of SiO2 NPs (a) and SiO2-PA NPs (b). For curve (a), the appearance of characteristic peak at 1106 cm−1 and 957 cm−1 were attributed to the O-Si-O bonds stretching vibration, indicating that SiO2 NPs were successfully synthesized27. Compared with unmodified SiO2 NPs, the SiO2-PA NPs illustrated three extra peaks at 2928, 1552 and 695 cm−1, which should be attributed to -C-NH2 stretching, symmetric -NH2 stretching and the bending vibrations of -NH in APTES, respectively28. The results indicated that APTES was successfully modified onto the surface of SiO2 NPs29. More importantly, an adsorption peak at 1092 cm−1 was observed due to the overlap of the characteristic peak of phosphate group (PO43−) and the peak of asymmetric O-Si-O stretching30. The results confirmed that the SiO2 NPs were successfully modified by APTES and PA.

As shown in Fig. 2a, the Zeta potential of SiO2 surface was −38.5 mV, which was attributed to many -OH and other oxygen-containing groups that present in the SiO2 NPs surface. When modified with APTES, the Zeta potential of APTES-SiO2 NPs increased to +22.3 mV that due to the amine groups on the surface of the particles (Fig. 2b). However, the Zeta potential measurements for SiO2-PA NPs (Fig. 2c) showed a negative surface charge that owing to the six phosphate groups of PA. When Mn2+ ions in solution were self-assembled onto the surface of SiO2-PA NPs, the zeta potential increased to −14.1 mV. The change of Zeta potential indicated that SiO2-Mn3(PO4)2 NPs were successfully synthesized by self-assembly technology based on the electrostatic interaction that between Mn2+ ions and the phosphate groups31.

The TEM and SEM images were also employed to further confirm the formation of SiO2-Mn3(PO4)2 NPs. Figure 3A revealed that the spherical SiO2 NPs were obtained with the average particle size of 75 nm. After surface self-assembly of PA and Mn2+ sequentially, the two sizes of SiO2-PA NPs and SiO2-Mn3(PO4)2 NPs showed a slight increase (Fig. 3B,C), respectively. Furthermore, the electron diffraction pattern displayed an amorphous diffraction pattern of Mn3(PO4)2 that deposited on the surface of silica (see the inset from Fig. 3C). And the corresponding elemental mapping of oxygen (O), silicon (Si), phosphorus (P) and manganese (Mn) from the SiO2-Mn3(PO4)2 NPs were indicated in Fig. 3D. The energy dispersive spectroscopy (EDS) of SiO2-Mn3(PO4)2 NPs showed that the different atomic percentages were 85.32% (O), 13.10% (Si), 1.47% (P) and 0.11% (Mn), respectively. It can be concluded that Mn3(PO4)2 was firmly coated onto the outer surface of the SiO2-PA NPs. Mn3(PO4)2 layer has little effect on the size growth of SiO2 NPs because it was only monolayer of Mn3(PO4)2 molecular that self-assembled onto the outer surface of SiO2 NPs based on the electrostatic interaction. Here, the stability of Mn3(PO4)2 supported on SiO2 NPs was evaluated by Zeta potential measurement after three weeks of storage. As was shown in Figure S1, the Zeta potential of the SiO2-Mn3(PO4)2 NPs had almost no change after three weeks of storage, indicating the Mn3(PO4)2 NPs have long-term stability. SEM images were also used to investigate the surface texture change after Mn3(PO4)2 coating on SiO2 NPs and the particle size of Mn3(PO4)2. Figure S2 showed the SEM images of the SiO2 NPs, SiO2-PA NPs and SiO2-Mn3(PO4)2 NPs, respectively. It can be observed from the SEM results that the samples with Mn3(PO4)2 coating can remain its original spherical morphology. Meantime, it can also be seen in this figure that particle size of the samples showed a slight increase after Mn3(PO4)2 coating on SiO2 NPs, which was in consistence with the results obtained by TEM images as showed in Fig. 3. Figure 4A illustrated the synthesis process of SiO2-Mn3(PO4)2 NPs. The formational mechanism of this biomimetic enzyme could be explained as follows: After dropping into MnSO4 solution, PO43− ions, derived from the surface of SiO2-PA NPs, were in combination with Mn2+ions by electrostatic interaction to form Mn3(PO4)2. When the PO43− ions were consumed, the monolayer of Mn3(PO4)2 molecular was self-assembly on the outer surface of SiO2-PA NPs with controllable morphology. In addition, only aggregated Mn3(PO4)2 particles were observed in the absence of SiO2 NPs with the same reaction conditions (Supplementary Figure S3).

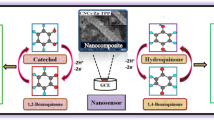

A schematic drawing of the stepwise construction process of modified glassy carbon electrode (GCE) was described in Fig. 4B. The electrochemical properties of the SiO2-Mn3(PO4)2/Multi-walled carbon nanotubes (MWCNTs)/GCE were investigated by cyclic voltammetry (CV) and Electrochemical Impedance Spectroscopy (EIS)32,33,34,35 (Supplementary Figure S4). Figure 5A displayed that all fabrication process of SiO2-Mn3(PO4)2/MWCNTs/GCE were carried out by CV in nitrogen saturated phosphate buffered solution (PBS) at a scan rate of 100 mV·s−1. In the working potential range of 0–0.9 V, there was no electrochemical signal can be observed at the bare GCE (curve a). In contrast, the SiO2-Mn3(PO4)2/GCE exhibited a pair of weakly redox peaks (curve b). When the MWCNTs/GCE was modified with SiO2-Mn3(PO4)2 NPs, the oxidation-reduction peaks were more obviously observed (curve c) that due to the excellent electronic conductivity of MWCNTs (Supplementary Figure S5) and the sensitivity of this biosensor was largely improved36. Moreover, the peak currents of SiO2-Mn3(PO4)2/MWCNTs/GCE (curve c) were much larger than that of Mn3(PO4)2/MWCNTs/GCE (curve d). Results demonstrated that the electro-catalytic effect of SiO2-Mn3(PO4)2 was much higher than that of Mn3(PO4)2 aggregated particles. It can be attributed to that the nanosized SiO2-Mn3(PO4)2 possessed high specific surface area. As a result, it will help improve the catalytic efficiency of O2·− in the electrolyte. When the bare GCE was only modified with MWCNTs, the background current was more clearly observed (curve e).

To study the catalysis effect of the SiO2-Mn3(PO4)2 NPs, the biosensor in PBS and PBS of containing 1.0 μmol L−1 O2·− were measured by CV, respectively. As shown in Fig. 5B, in the PBS containing of 1.0 μmol L−1 O2·− (curve a), both anodic and cathodic peak currents that corresponding to the redox reaction of in PBS (curve b) clearly increased that can be attributed to the oxidation and reduction of O2·−, respectively37. According to the previous reports38,39, O2·− was converted into O2 and H2O2 during the disproportionation reaction that O2·− was catalyzed by Mn2+ in PBS. In the anodic process, O2·− was oxidized to O2 by the oxidation effect of MnO2+, while MnO2+ was reduced to Mn2+. On the contrary, Mn2+ was oxidized to MnO2+ in the cathodic process. As demonstrated above, the SiO2-Mn3(PO4)2/MWCNTs/GCE can be applied to detect O2·− by measuring the oxidation or reduction currents because of the high efficient catalysis of SiO2-Mn3(PO4)2. To further prove this proposed mechanism/reaction, X-ray photoelectron spectroscopy (XPS) analysis was carried out to analyze the composition and chemical configuration of the SiO2-Mn3(PO4)2 NPs before and after electrocatalysis process. More details about the XPS spectra of Mn 2p were presented in Figure S6.

The typical current-time plot of SiO2-Mn3(PO4)2/MWCNTs/GCE at the applied potential of 0.484 V upon successive additions of O2·− was provided in Fig. 6A. In this experiment, while being stirred, O2·− solution was added once per 50 seconds. With the injection of O2·−, the response of this biosensor rapidly achieved 95% of the steady-state current within 2.9 s (Supplementary Figure S7). The SiO2-Mn3(PO4)2/MWCNTs/GCE showed a wide linear range from 0.03 to 0.21 μM and 0.15 to 3.6 μM with the correlation coefficient of 0.9966 and 0.9959, respectively. The relation of the oxidation peak current vs the concentration of O2·− was linear with a detection limit of 0.0175 μM (S/N = 3). The biosensor exhibited more excellent performance than some O2·− biosensors that reported by the previous papers using different electrode materials, such as SOD, Mn3(PO4)2 and Mn2P2O7 (Supplementary Table 1). The corresponding calibration curves for O2·− were depicted in Fig. 6B. The linear equations were i (μA) = 0.00418 − 0.1358c (μM) and i (μA) = −0.01932 − 0.1263c (μM), respectively. The biosensor was applied to the detection of O2·− and displayed excellent electrochemical behavior.

(A) Typical amperometric curve recorded at 0.484 V in PBS (pH 7.4) for SiO2-Mn3(PO4)2/MWCNTs/GCE, From 0.03 to 0.21 μM, the O2·− concentration of each adding step was 0.03 μM, from 0.15 to 3.6 μM, each adding step was 0.15 μM, (B) Linear calibration plot of the response current vs the O2·− concentration.

To verify the applicability of SiO2-Mn3(PO4)2 NPs in detection of O2·−, Xanthine/Xanthine Oxidase (XAN/XOD) was selected to generate O2·− (Supplementary Figure S8). In addition, the response of SiO2-Mn3(PO4)2/MWCNTs/GCE toward O2·− generated by XAN/XOD was investigated by amperometric measurements40. As shown in Figure S9, with successive additions of XAN to the solution, a stepwise increase of the current response was observed.

To evaluate the anti-interference performance of detecting O2·−, the biosensor was examined by successive additions of O2·− and interfering substances into a 0.1 M PBS at 0.484 V. Figure 7A indicated that there were obviously current responses of the biosensor during the addition of 1.0 μM O2·−, while no obviously current response could be observed with the addition of the interferences. With the sequential addition of 5.0 μM Cys, 5.0 μM DA, 10 μM H2O2, 10 μM UA and 10 μM AA, the detection current showed changes of 14%, 2.7%, 8.2%, 5.4% and 4.1% with comparison of 1.0 μM O2·−, respectively (Fig. 7B). Figure S10 displayed the amperometric response of the SiO2-Mn3(PO4)2/MWCNTs/GCE by successive additions of 2.0 μM 18-crown-6 once per 50 seconds. Results demonstrated that this biosensor can eliminate the interference and show an excellent selectivity for detection of O2·−. To verify the stability, the biosensor was monitored after being stored for three weeks in a refrigerator. Figure 7C indicated that the current response was no apparent decrease, which was much longer than those obtained for enzyme-based O2·− biosensors41,42,43,44. In order to investigate the binding firmness of SiO2-Mn3(PO4)2 NPs decorated onto the MWCNTs/GCE electrode, the reuse ability of the SiO2-Mn3(PO4)2/MWCNTs/GCE electrode was tested. Figure S11 displayed the CV curves of the biosensor for 20 cycles, which showed almost overlap curves, indicating the biosensor we prepared had a good cycle stability that can attributed to the good binding state of the SiO2-Mn3(PO4)2 NPs and the MWCNTs/GCE electrode.

(A) Interference test of SiO2-Mn3(PO4)2/MWCNTs/GCE, (B) The relative response in PBS (pH = 7.4) at 1.0 μM O2·−, 5.0 μM Cys, 5.0 μM DA, 10 μM H2O2, 10 μM UA and 10 μM AA, (C) CVs of SiO2-Mn3(PO4)2/MWCNTs/GCE, (a) Freshly prepared and (b) after fifteen days in 0.1 M PBS, Scan rate was 100 mV·s−1 and (D) Amperometric response of the SiO2-Mn3(PO4)2/MWCNTs/GCE in the (a) presence and (b) absence of HeLa cells upon sequential additions of PMA to 0.1 M PBS at 0.484 V.

Real-time detection performance of the biomimetic enzyme sensor has also been monitored by detecting O2·− released from the HeLa cells. The amperometric responses of the biosensor were obtained at applied potentials of 0.484 V versus Ag/AgCl in 2 mL 0.1 M PBS (pH 7.4) containing 0.5 × 105 cells·mL−1. After the injection of 4 μg mL−1 phorbol 12-myristate 13-acetate (PMA), which was reported to generate O2·− from live cells45, the current gradually increased at SiO2-Mn3(PO4)2/MWCNTs modified electrode. In this work, PMA was used as a stimulant for the cell to exude O2·− 46,47. Figure 7D indicated that the strong current signal (0.01457 μA, curve a) was caused by O2·− released from the HeLa cells, considering that SiO2-Mn3(PO4)2 could selectively decomposes O2·−. According to the above linear relationship, the O2·− concentration of 0.0765 μM was calculated. Thence, the amount of O2·− releasing from per 105 cells was calculated to be 0.153 nmol. Meanwhile, in the absence of the HeLa cells and the presence of the treatment of PMA, no obvious current response can be seen on the screen (curve b). To test the effectiveness of this technology, the biomimetic enzyme sensor has also been used to detect the concentration of O2·− in plasma (Supplementary Figure S12).

Conclusion

In this case, the SiO2-Mn3(PO4)2 NPs, synthesized via self-assembly technique and nanotechnology, were applied in a biomimetic enzyme biosensor for the detection of O2·−. Results revealed that SiO2-Mn3(PO4)2/MWCNTs/GCE showed high electrocatalytic activity toward O2·−, lower detection limit and wide detection range. Furthermore, the biosensor that assembled under optimal conditions exhibited high selectivity of O2·− in the presence of related interference, such as H2O2, UA, AA, DA and Cys. Meanwhile, the long-term stability and good reproducibility of this biomimetic enzyme biosensor were proved. Compared with the Mn3(PO4)2 multilayer sheets, the modified GCE of SiO2-Mn3(PO4)2 with high specific surface area exhibited more excellent analytical performance. Consequently, the biomimetic enzyme-free sensor was successfully applied to detecting O2·− that released from live cells, which holds a great promising platform for the reliable monitoring of major diseases in future.

Methods

Materials

Tetraethyl orthosilicate (TEOS) was purchased from Sinopharm Chemical Reagent Co. Ltd. Cetyltrimethylammonium bromide (CTAB) was obtained from Shanghai Lingfeng Chemical Reagent Co. Ltd. (3-Aminopropyl) triethoxysilane (APTES), phytic acid (PA, 70 wt%) solution and phytic acid sodium salt hydrate were received from Aladdin Chemistry Co. Ltd (Shanghai, China). Potassium phosphate tribasic trihydrate (K3PO4·3H2O), manganese sulfate monohydrate (MnSO4·H2O) and dimethyl sulfoxide (DMSO) were obtained from Sinopharm Chemical Reagent Co. Ltd. Potassium hyperoxide (KO2) was purchased from Alfa Aesar. Multi-walled carbon nanotubes (MWCNTs) was purchased from Shenzhen Nanotech Port Co. Ltd. Triton X-100, nafion (5 wt% solution in lower aliphatic alcohol), 18-crown-6, phorbol 12-myristate 13-acetate (PMA), dopamine (DA), cysteine (Cys), ascorbic acid (AA) and uric acid (UA) were acquired from Aladdin Sigma-Aldrich Co. (USA). Hydrogen peroxide (H2O2, 30%) was received from Beijing Chemical Works (China). Phosphate buffer solution (PBS) was obtained by dissolving 8.0 g NaCl, 0.2 g KCl, 1.44 g NaH2PO4 and 0.24 g KH2PO4 in 1000 mL double-distilled water.

Apparatus

The morphologies of the samples were recorded by transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HITACHI H-7650, Japan). Scanning electron microscope (SEM) images were obtained by a Scanning electron microscope (JSM-6300, Japan). XPS measurements were performed on a Thermo ESCALAB 250 using a monochromic Al X-ray source (1486.6 eV). All the electrochemicals data were measured by CHI 760D electrochemical workstation (Shanghai Chenhua, China). Fourier transform infrared (FTIR) spectra of the SiO2 NPs and SiO2-PA NPs were obtained from a VARIAN Cary 5000 Fourier transform infrared spectrophotometer (VARIAN, USA). Surface potential of the samples was performed by Zeta potential analyzer (Malvern Instruments ZS90). All experiments were carried out using a three-electrode cell equipped, which consisted of a platinum electrode, saturated calomel electrode (SCE) and working electrode.

Culture of Cells

The HeLa cells were cultured in Dulbecco’s Modified Eagle’s medium (DMEM) containing 10% fetal bovine serum (FBS), 100 units·mL−1 penicillin and 100 μg·mL−1 streptomycin at 37 °C. Then, the HeLa cells were centrifuged for the electrochemical experiments. Real sample measurements were performed by the addition of 100 μg·mL−1 PMA in PBS containing 50 mM glucose.

Preparation of SiO2-Mn3(PO4)2 NPs

Firstly, SiO2 NPs were synthesized by the reverse microemulsion method as reported previously by Bagwe48. In a typical synthesis, triton X-100 (10.62 g), hexanol (9.6 mL) and cyclohexane (45 mL) were mixed in a 100 mL round-bottomed flask under stirring for 10 min and then water (2.88 mL) was added to the mixture at room temperature. After being stirred for 0.5 h, NH3·H2O (600 μL) and TEOS (1200 μL) were dropped into the above clear solution, respectively. Next, the mixture was allowed to stir for a further 24 h at room temperature. The resulting NPs were collected by centrifugation and dried at 60 °C under vacuum condition for 24 h. Then, the modified process of SiO2 was briefly described as follows: SiO2 NPs (0.05 g) was dissolved in double-distilled water (20 mL) and TEOS (100 μL) was added to the SiO2 suspension with continuously stirring for 30 min at room temperature49. Then, the SiO2-NH2 NPs were obtained by feeding appropriate amount of APTES. After stirring for 30 min, 120 μL of PA/PA sodium salt hydrate buffer solution (pH = 7) was injected into the above solution with continues stirring for 24 h. The resulting NPs were washed with alcohol and double-distilled water. Finally, the SiO2-PA NPs were redispersed in water (10 mL) and then MnSO4 aqueous solution (10 mL, 12 mM) was injected to the round-bottomed flask containing the SiO2-PA NPs under constant stirring for 1 h at 60 °C. After completion of the reaction, the obtained products were collected by centrifugation, washed with double-distilled water and dried in a vacuum oven at 60 °C for 24 h.

Fabrication of SiO2-Mn3(PO4)2/MWCNTs/GCE

Firstly, MWCNTs (8.0 μL, 2.5 mg·mL−1) were cast onto the electrode surface and dried at room temperature. After that, SiO2-Mn3(PO4)2 (8.0 mg·mL−1) and 2.5% Nafion with the volumetric ratio of 1:1 were mixed and 8.0 μL of above solution was dropped onto the surface of MWCNTs/GCE. After drying in air, the SiO2-Mn3(PO4)2/MWCNTs/GCE was obtained. During the experimental period, the modified electrodes were stored at 4 °C until use.

Generation of superoxide anion

A stable O2·− solution was prepared by dispersing KO2 to DMSO (containing 18-crown-6). In accordance with the molar absorptivity of O2·− in DMSO, the concentration of O2·− was monitored by recording the absorbance of ferricytochrome c spectrophotometrically at 550 nm50. In particular, spectrophotometric measurement of the amount of ferricytochrome c that reduced by O2·− referred to the following reaction: cytochrome c (FeIII) +O2·− = ferrocytochrome c (FeII) +O2, in which ferrocytochrome c exhibits a strong absorbance at 550 nm51. The linear relationship of the absorbance vs the ferrocytochrome c concentration was depicted in Figure S13. The linear equations were A550 = 20.6c − 0.0044, R = 0.9986. The concentration of O2·− can be calculated by the concentration of the formed ferrocytochrome c according to the above reaction formula52.

Additional Information

How to cite this article: Shen, X. et al. Manganese Phosphate Self-assembled Nanoparticle Surface and Its application for Superoxide Anion Detection. Sci. Rep. 6, 28989; doi: 10.1038/srep28989 (2016).

References

Tian, Y., Mao, L. Q., Okajima, T. & Ohsaka, T. Superoxide dismutase-based third-generation biosensor for superoxide anion. Anal. Chem. 74, 2428–2434 (2002).

Karakoti, A. et al. Redox-active radical scavenging nanomaterials. Chem. Soc. Rev. 39, 4422–4432 (2010).

Zhang, W. et al. Elucidating the relationship between superoxide anion levels and lifespan using an enhanced two-photon fluorescence imaging probe. Chem. Commun. 51, 9710–9713 (2015).

Wang, Q., Yang, X. Q. & Qu, D. Y. In situ ESR spectro-electrochemical investigation of the superoxide anion radical during the electrochemical O2 reduction reaction in aprotic electrolyte. Carbon 61, 336–341 (2013).

Pieta, P., Petr, A., Kutner, W. & Dunsch, L. In situ ESR spectroscopic evidence of the spin-trapped superoxide radical, O2·−, electrochemically generated in DMSO at room temperature. Electrochim. Acta 53, 3412–3415 (2008).

He, W. et al. Intrinsic catalytic activity of Au nanoparticles with respect to hydrogen peroxide decomposition and superoxide scavenging. Biomaterials 34, 765–773 (2013).

Liu, S. et al. Ultrahigh performance liquid chromatography-triple quadrupole mass spectrometry inhibitors fishing assay: A novel method for simultaneously screening of xanthine oxidase inhibitor and superoxide anion scavenger in a single analysis. Anal. Chim. Acta 715, 64–70 (2012).

Li, N. et al. A highly selective and sensitive nanoprobe for detection and imaging of the superoxide anion radical in living cells. Chem. Commun. 48, 2507–2509 (2012).

Naito, K., Tachikawa, T., Fujitsuka, M. & Majima, T. Single-molecule observation of photocatalytic reaction in TiO2 nanotube: importance of molecular transport through porous structures. J. Am. Chem. Soc. 131, 934–936 (2009).

Hu, J. J. et al. Fluorescent probe HKSOX-1 for imaging and detection of endogenous superoxide in live cells and in vivo. J. Am. Chem. Soc. 137, 6837–6843 (2015).

Tsukagoshi, K., Taniguchi, T. & Nakajima, R. Analysis of antioxidants using a capillary electrophoresis with chemiluminescence detection system. Anal. Chim. Acta 589, 66–70 (2007).

Diez, L. et al. High-performance liquid chromatographic assay of hydroxyl free radical using salicylic acid hydroxylation during in vitro experiments involving thiols. J. Chromatogr. B 763, 185–193 (2001).

Gao, X., Ding, C. Q., Zhu, A. W. & Tian, Y. Carbon-dot-based ratiometric fluorescent probe for imaging and biosensing of superoxide anion in live cells. Anal. Chem. 86, 7071–7078 (2014).

Yu, F. B., Gao, M., Li, M. & Chen, L. X. A dual response near-infrared fluorescent probe for hydrogen polysulfides and superoxide anion detection in cells and in vivo. Biomaterials 63, 93–101 (2015).

Tachikawa, T., Wang, N., Yamashita, S., Cui, S. C. & Majima, T. Design of a highly sensitive fluorescent probe for interfacial electron transfer on a TiO2 surface. Angew. Chem. Int. Edit . 49, 8593–8597 (2010).

Walkey, C. et al. Catalytic properties and biomedical applications of cerium oxide nanoparticles. Environ. Sci.: Nano 2, 33–53 (2015).

Gale, E. M. et al. Toward functional Ni-SOD biomimetics: achieving a structural/electronic correlation with redox dynamics. Inorg. Chem. 50, 9216–9218 (2011).

Cheng, H. J. et al. Integrated nanozymes with nanoscale proximity for in vivo neurochemical monitoring in living brains. Anal. Chem., doi: 10.1021/acs.analchem.6b00975 (2016).

Wei, Hui. & Wang, E. K. Nanomaterials with enzyme-like characteristics (nanozymes): next-generation artificial enzymes, Chem. Soc. Rev. 42, 6060–6093 (2013).

He, W. et al. Enzyme-like activity of nanomaterials, J. Environ. Sci. Heal. C 32, 186–211 (2014).

Wang, X. Y., Hu, Y. H. & Wei, H. Nanozymes in bionanotechnology: from sensing to therapeutics and beyond. Inorg. Chem. Front. 3, 41–60 (2016).

Deng, Z., Rui, Q., Yin, X., Liu, H. & Tian, Y. In vivo detection of superoxide anion in bean sprout based on ZnO nanodisks with facilitated activity for direct electron transfer of superoxide dismutase. Anal. Chem. 80, 5839–5846 (2008).

Hu, F. X. et al. Living cells directly growing on a DNA/Mn3(PO4)2-immobilized and vertically aligned CNT array as a free-standing hybrid film for highly sensitive in situ detection of released superoxide anions. Adv. Funct. Mater. 25, 5924–5932 (2015).

Barnese, K., Gralla, E. B., Cabelli, D. E. & Valentine, J. S. Manganous phosphate acts as a superoxide dismutase. J. Am. Chem. Soc. 130, 4604–4606 (2008).

Ma, X. Q. et al. DNA-templated biomimetic enzyme sheets on carbon nanotubes to sensitively in situ detect superoxide anions released from cells. Adv. Funct. Mater. 24, 5897–5903 (2014).

Yuan, L. et al. Biomimetic superoxide dismutase stabilized by photopolymerization for superoxide anions biosensing and cell monitoring. Anal. Chem. 86, 4783–4790 (2014).

Cheang, T. Y. et al. Promising plasmid DNA vector based on APTES-modified silica nanoparticles. Int. J. Nanomed. 7, 1061–1067 (2012).

Hsiao, V. K. et al. Aminopropyltriethoxysilane (APTES)-functionalized nanoporous polymeric gratings: fabrication and application in biosensing. J. Mater. Chem. 17, 4896–4901 (2007).

Zhao, W. B. et al. Innovative biocompatible nanospheres as biomimetic platform for electrochemical glucose biosensor. Biosens. Bioelectron . 44, 1–5 (2013).

Dong, J. et al. A nanoporous zirconium phytate film for immobilization of redox protein and the direct electrochemical biosensor. Sensor Actuat. B 150, 141–147 (2010).

Tang, F. et al. Phytic acid doped nanoparticles for green anticorrosion coatings. Colloid Surface A 369, 101–105 (2010).

Sun, C. et al. Hemocompatible and antibiofouling PU-F127 nanospheres platform for application to glucose detection in whole blood. J. Mater. Chem. B 1, 801–809 (2013).

Maji, S. K. et al. Immobilizing gold nanoparticles in mesoporous silica covered reduced graphene oxide: A hybrid material for cancer cell detection through hydrogen peroxide sensing. ACS Appl. Mater. Interfaces 6, 13648–13656 (2014).

Cao, H. M. et al. Protein-inorganic hybrid nanoflowers as ultrasensitive electrochemical cytosensing Interfaces for evaluation of cell surface sialic acid. Biosens. Bioelectron . 68, 329–335 (2015).

Aravindan, V. et al. Influence of carbon towards improved lithium storage properties of Li2MnSiO4 cathodes. J. Mater. Chem. 21, 2470–2475 (2011).

Stankovich, S. et al. Graphene-based composite materials. Nature 442, 282–286 (2006).

Luo, Y. P., Tian, Y. & Rui, Q. Electrochemical assay of superoxide based on biomimetic enzyme at highly conductive TiO2 nanoneedles: from principle to applications in living cells. Chem. Commun. 21, 3014–3016 (2009).

Zhou, J. Q. et al. A reliable and durable approach for real-time determination of cellular superoxide anion based on biomimetic superoxide dismutase stabilized by a zeolite. Analyst 136, 1594–1598 (2011).

Preda, G. et al. Formation of superoxide anions on ceria nanoparticles by interaction of molecular oxygen with Ce3+ sites. J. Phys. Chem. C 115, 5817–5822 (2011).

Barroso, M. F., Delerue-Matos, C. & Oliveir, M. B. P. P. Electrochemical DNA-sensor for evaluation of total antioxidant capacity of flavours and flavoured waters using superoxide radical damage. Biosens. Bioelectron . 26, 3748–3754 (2011).

Zhu, X., Niu, X. H., Zhao, H. L., Tang, J. & Lan, M. B. Immobilization of superoxide dismutase on Pt-Pd/MWCNTs hybrid modified electrode surface for superoxide anion detection. Biosens. Bioelectron . 67, 79–85 (2015).

Wang, L. et al. A novel amperometric biosensor for superoxide anion based on superoxide dismutase immobilized on gold nanoparticle-chitosan-ionic liquid biocomposite film. Anal. Chim. Acta 758, 66–71 (2013).

Liu, H. Q., Tian, Y. & Xia, P. P. Pyramidal, rodlike, spherical gold nanostructures for direct electron transfer of copper, zinc-superoxide dismutase: application to superoxide anion biosensors. Langmuir 24, 6359–6366 (2008).

Tang, J. et al. Anamperometric superoxide anion radicalbiosensor based on SOD/PtPd-PDARGO modified electrode. Talanta 137, 18–24 (2015).

Luo, Y. P. et al. A biomimetic sensor for the determination of extracellular O2·− using synthesized Mn-TPAA on TiO2 nanoneedle film. Biosens. Bioelectron . 29, 189–194 (2011).

Wang, T., Peng, Z., Wang, Y., Tang, J. & Zheng, G. MnO Nanoparticle@mesoporous carbon composites grown on conducting substrates featuring high-performance lithium-ion battery, supercapacitor and sensor. Sci. Rep . 3, 2693 (2013).

Zhang, W. et al. Prussian blue banoparticles as multienzyme mimetics and reactive oxygen species scavengers. J. Am. Chem. Soc., doi: 10.1021/jacs.5b12070 (2016).

Bagwe, R. P., Hilliard, L. R. & Tan, W. Surface modification of silica nanoparticles to reduce aggregation and nonspecific binding. Langmuir 22, 4357–4362 (2006).

Zhao, W. B. et al. Laccase biosensor based on phytic acid modification of nanostructured SiO2 surface for sensitive detection of dopamine. Langmuir 30, 11131–11137 (2014).

Thandavan, K., Gandhi, S., Sethuraman, S., Rayappan, J. B. B. & Krishnan, U. M. A novel nano-interfaced superoxide biosensor. Sensor Actuat. B 176, 884–892 (2013).

Tian, Y. et al. A facilitated electron transfer of copper-zinc superoxide dismutase (SOD) based on a cysteine-bridged SOD electrode. Biochimica et Biophysica Acta 1569, 151–158 (2002).

Hirata, F. & Hayaishi, O. Studies on indoleamine 2,3-dixygenase. I. Superoxide anion as substrate. J. Biol. Chem. 250, 5960–5966 (1975).

Acknowledgements

This work was supported by Jiangsu Collaborative Innovation Center of Biomedical Functional Materials, National Natural Science Foundation of China (21571104, 2015M580446), Natural Science Foundation of and Jiangsu Province of China (BK 20131396) and the Priority Academic Program Development of Jiangsu Higher Education Institution.

Author information

Authors and Affiliations

Contributions

C.M. and M.W. proposed and supervised the project. X.S. and F.W. wrote the main manuscript text and discussed the results and experimental conditions with all other authors. X.S., Q.W. and L.M. designed and set up the experimental setup. X.S., Q.W., W.X. and Y.L. carried out the experiments. X.S., W.X. and S.F. designed and carried out the data analysis. All authors have given approval to the final version of the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Shen, X., Wang, Q., Liu, Y. et al. Manganese Phosphate Self-assembled Nanoparticle Surface and Its application for Superoxide Anion Detection. Sci Rep 6, 28989 (2016). https://doi.org/10.1038/srep28989

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep28989

This article is cited by

-

Surface modification toward luminescent and stable silica-coated quantum dots color filter

Science China Materials (2019)

-

Nanostructured MXene-based biomimetic enzymes for amperometric detection of superoxide anions from HepG2 cells

Microchimica Acta (2019)

-

Electrochemical detection of superoxide anions in HeLa cells by using two enzyme-free sensors prepared from ZIF-8-derived carbon nanomaterials

Microchimica Acta (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.