Abstract

Isolating large-areas of atomically thin transition metal chalcogenide crystals is an important but challenging task. The mechanical exfoliation technique can provide single layers of the highest structural quality, enabling to study their pristine properties and ultimate device performance. However, a major drawback of the technique is the low yield and small (typically < 10 μm) lateral size of the produced single layers. Here, we report a novel mechanical exfoliation technique, based on chemically enhanced adhesion, yielding MoS2 single layers with typical lateral sizes of several hundreds of microns. The idea is to exploit the chemical affinity of the sulfur atoms that can bind more strongly to a gold surface than the neighboring layers of the bulk MoS2 crystal. Moreover, we found that our exfoliation process is not specific to MoS2, but can be generally applied for various layered chalcogenides including selenites and tellurides, providing an easy access to large-area 2D crystals for the whole class of layered transition metal chalcogenides.

Similar content being viewed by others

Introduction

Layered transition metal chalcogenides (TMCs) display strong intra-layer metal-chalcogenide bonds and a weak inter-layer bonding between neighboring planes of chalcogenide atoms1. The recent interest in studying their two-dimensional (2D) form (consisting of triple to quintuple atomic sheets) is driven by the fact that the properties of the atomically thin crystals can drastically differ from their well-characterized bulk counterparts. An eloquent example is the transition in the MoS2 band structure from indirect to direct bandgap as the number of layers is reduced from bulk to a single layer2 opening the way towards optoelectronic applications3. Furthermore, the family of transition metal chalcogenides is large, covering a broad range of properties from semiconductors (MoS2, WSe2) to semimetals (TiS2, TiSe2), from topological insulators (Bi2Te3, Bi2Se3) to correlated materials (NbS2, NbSe2). Such large variety of properties holds a huge potential for both fundamental studies and applications, even graphene cannot compete with in spite of the unique versatility of its properties.

The easy access to large TMC single layers is of key importance for exploring their properties, in a similar manner as the facile isolation of large and high-quality graphene flakes enabled the outstanding pace of the graphene research. As several bulk TMC crystals are layered materials, similar to graphite, individual TMC layers can be isolated by mechanical exfoliation4. However, by using the most widely-spread micromechanical cleavage (“scotch-tape”) technique, the lateral size of the exfoliated TMC single layers is typically of the order of micrometers2,3,4,5, which is about an order of magnitude smaller than the lateral size of the graphene flakes that can be routinely obtained by the same technique. The reason for this probably originates from the unique mechanical strength6 and ultra-strong adhesion7 of graphene to SiO2 that cannot be matched by the otherwise still excellent mechanical properties of TMCs8.

Alternative methods for producing single layers of various TMC materials are the chemical9,10 and liquid-phase exfoliation11 of single layers from their bulk crystals, as well as the Chemical Vapor Deposition (CVD) growth12,13 of TMC layers. The CVD technique in principle enables the growth of macroscopic areas of TMC films; however it is still difficult to grow single layers continuous on a macroscopic scale. Furthermore, the CVD growth of various TMC materials requires the development of a dedicated experimental setup and optimization for the growth of each TMC material separately. Chemically exfoliated TMC layers usually undergo irreversible chemical modification of their structure and properties and their lateral size is generally below 1 micron9. Recently, the electrochemical exfoliation of MoS2 flakes with up to 50 microns lateral size has been demonstrated; however even these layers undergo a partial oxidation10. Sonication assisted liquid phase exfoliation in various solvents yields large quantities of such exfoliated TMC layers, but most of the flakes are multilayers and their lateral size is typically of order of only a few hundreds of nanometers.

Compared to other methods, mechanical exfoliation provides 2D TMC sheets of high structural quality enabling the fundamental study of their pristine properties and ultimate device performance, similar to graphene, where most of the fundamental discoveries have been achieved on exfoliated samples, owing to their superior structural and electronic quality14,15. The major limitation of the micromechanical exfoliation of various TMC materials is the small yield of single layers and their relatively small lateral size, typically of a few microns, rendering the subsequent investigations and device fabrication more difficult.

Results

We have developed a novel mechanical exfoliation technique that overcomes the limitations of the scotch-tape technique enabling the exfoliation of TMC single layers with lateral size in the range of hundreds of microns. During the mechanical exfoliation process, the isolation of single layers is possible because the adhesion of the bottom layer to the substrate becomes stronger than the adhesion to its own bulk crystal. Graphene displays an ultra-strong adhesion to SiO27, which can play an important role during the exfoliation process, facilitating the exfoliation of large (typically tens of microns) single layers. To improve the exfoliation process of MoS2 single layers we propose to improve their adhesion to the substrate. To achieve this, instead of the usually employed SiO2/Si, we used gold substrates exploiting the chemical affinity of the sulfur to gold16 to achieve a stronger adhesion. The gold substrates with large, atomically flat and clean Au (111) surfaces have been prepared by epitaxial growth of about 100 nm thick gold films on mica that were freshly cleaved from the mica surface before the experiments17. Next, thick multilayer flakes had been peeled off from a bulk MoS2 crystal using a thermal release tape. These flakes had been placed on the top of the freshly cleaved gold substrates. By heating up the sample to 90 °C the thick MoS2 flakes have been released from the tape onto the gold substrate. We used a short ultrasonic treatment (70 W, 1–10 s) in acetone to remove the thick MoS2 flakes from the gold surface. We found that after a few seconds of sonication several thick flakes have been detached; however, underneath them, the last (bottom) MoS2 layer remained attached to the gold substrate.

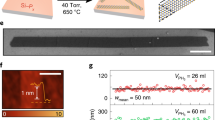

In optical microscopy images the MoS2 single layers can be identified as the areas of the faintest color contrast as shown in Fig. 1. The optical images revealed several hundreds of microns large areas covered by thin MoS2 layers. To confirm that these areas of faintest optical contrast are indeed single layers of MoS2 we have performed confocal Raman spectroscopy measurements (λ = 532 nm, 1 mW) as shown in the inset of Fig. 1b. We have observed the characteristic MoS2 peaks18 (E2g, A1g) around 384 and 404 cm−1, wavenumbers respectively. This indicates that the several hundreds of microns large areas observed by optical microscopy can be identified as MoS2 single layers4,18,19. The exfoliated large flakes on top of the conductive Au substrate enabled us to perform Scanning Tunneling Microscopy (STM) measurements on mechanically exfoliated single layer MoS2 flakes. The height of the investigated layers relative to the Au substrate was found to be about 0.7 +/− 0.1 nm from the STM measurements (Fig. 2a), confirming the single layer thickness of the exfoliated flakes. Atomic resolution images could be routinely achieved even under ambient conditions (Fig. 2b). A hexagonal atomic lattice has been revealed with 3.1 +/− 0.1 Å periodicity, corresponding to the lattice constant of the top layer of sulfur atoms20.

Mechanical exfoliation through chemically enhanced adhesion of large area MoS2 single layers.

Optical microscopy images (a,b) of MoS2 single layer areas (1L, outlined by dotted lines) with several hundreds of microns lateral size exfoliated on gold (Au 111) substrate. The flakes of blue color are thick MoS2 multilayers (ML). The large areas of the faintest optical contrast have been confirmed to be single layers by Raman spectroscopy (inset).

Atomic structure of MoS2 single layers.

(a) STM image (500 mV, 1 nA) of a MoS2 single layer exfoliated onto a gold substrate. The relative height of the MoS2 layer was found to be 0.7 +/− 0.1 nm evidencing its single layer nature. The line cut displayed was taken along the direction marked by the green line across the edge. The darker areas of several tens of nanometers are atomic scale pits in the gold surface. (b) Atomic resolution STM image (5 mV, 2 nA) of a MoS2 single layer revealing a hexagonal lattice with 0.31 +/− 0.01 nm (see inset) periodicity corresponding to the crystal lattice of the top sulfur atoms.

While for STM measurements the gold substrate is ideal, several experimental techniques including electrical transport measurements and device applications require insulating substrates. Furthermore, it is important to get an idea about the nature of the bonding between the MoS2 single layers and the gold substrate and most importantly whether it is fully reversible or not. Raman spectroscopy and atomic resolution STM measurements revealed no significant deviation from the intrinsic structure of MoS2. However, to fully clarify this issue we have transferred the exfoliated MoS2 single layers from gold to SiO2/Si substrate for further investigations. To realize this, a thermal release tape has been placed on top of the exfoliated MoS2/Au sample. Then, using potassium iodide solution we etched away the gold substrate21. The MoS2 flakes supported by the thermal release tape can then be transferred to any desired substrate. Upon heating up the sample the flakes are released onto the surface of the new substrate; in our case SiO2/Si. An atomic force microscopy image of a transferred MoS2 flake on top of SiO2/Si is shown in Fig. 3a. The Raman spectra of the MoS2 flakes transferred from gold to SiO2/Si (Fig. 3b) perfectly match the characteristic spectra of MoS2 single layers directly exfoliated to SiO2/Si substrates18,19, indicating that MoS2 layers can be reversibly detached from the gold surface after exfoliation, without significant structural modification.

MoS2 single layers on insulating substrate.

(a) Atomic Force Microscopy image of a MoS2 layer exfoliated to gold and transferred to a SiO2/Si substrate. (b) Raman spectra (λ = 532 nm, 1 mW) of the transferred single layers evidence that MoS2 layers can be reversibly detached from the Au substrate without modifying their structure.

We have also investigated whether the exfoliation process is specific to MoS2 or can be applied more generally to various layered materials. We found that our exfoliation method yielding large-area MoS2 flakes is not specific to molybdenum disulfide or even sulfides, but works equally well for various layered chalcogenides, including selenides and tellurides. To illustrate this in Fig. 4 we present optical microscopy images of WSe2 and Bi2Te3 single layers with several hundreds of microns lateral scale. However, when we attempted to apply the technique for the exfoliation of graphene, we found that after a short sonication all thick graphite flakes have been removed from the gold substrate leaving behind no graphene layers at all. This further supports that the mechanism behind our exfoliation process is indeed the chemically enhanced adhesion of various layered TMC materials. Furthermore, in contrast to the standard scotch-tape method, the exfoliation technique reported here is in principle able to achieve high coverage rates of macroscopic substrates with various TMC single layers.

In conclusion, we have demonstrated a simple and general method to isolate large-area single layers of various layered transition metal chalcogenides exploiting their chemically enhanced adhesion to gold substrates, opening the way towards the systematic exploration of the novel properties of two dimensional crystals form the whole family of layered chalcogenides.

Methods

Optical imaging has been performed by a Zeiss Axio Imager microscope. Scanning Tunneling Microcopy measurements have been performed on a Nanoscope E instrument under ambient conditions. Atomic resolution images could be routinely achieved with the typical settings of Ub = 5–100 mV bias voltage and It = 1–3 nA tunneling current. Atomic Force Microscopy images have been acquired by a Bruker Multimode 8 AFM, in tapping mode. The contaminations revealed by AFM on the MoS2 flakes transferred to SiO2/Si substrate are most probably gold nanoparticle residues from the wet etching process of the gold substrate. Raman spectra have been acquired by a Witec 300RSA confocal Raman microscope using 532 nm laser wavelength and typical powers of 0.2–2 mW. Raman spectroscopy was also used to confirm the single layer nature of WSe2 flakes, while atomically thin Bi2Te3 layers were found to be very unstable even for low (0.2 mW) laser powers. We found it important to use freshly cleaved stripped gold substrates; however, their source and flame annealing was not crucial for achieving good results. Commercially available thermal release tape has been used for all transfer experiments.

Additional Information

How to cite this article: Magda, G. Z. et al. Exfoliation of large-area transition metal chalcogenide single layers. Sci. Rep. 5, 14714; doi: 10.1038/srep14714 (2015).

References

Butler, S. Z. et al. Progress, Challenges and Opportunities in Two-Dimensional Materials Beyond Graphene. ACS Nano 7, 2898–2926 (2013).

Mak, K. F. et al. Atomically Thin MoS2: A New Direct-Gap Semiconductor. Phys. Rev. Lett. 105, 136805 (2010).

Lopez-Sanchez, O. et al. Ultrasensitive photodetectors based on MoS2. Nature Nanotechnol. 8, 497–501 (2013).

Wang, Q. H. et al. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nature Nanotechnol. 7, 699–712 (2012).

Li, H. et al. Preparation and applications of mechanically exfoliated single-layer and multi-layer MoS2 and WSe2 nanosheets. Acc. Chem Res. 47, 1067–1075 (2014).

Lee, C. et al. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 321, 385–88 (2008).

Koenig, S. P., Bodetti, N. G., Dunn, M. L. & Bunch, J. S. Ultrastrong adhesion of graphene membranes. Nature Nanotech. 6, 543–546 (2011).

Bertolazzi, S. et al. Stretching and Breaking of Ultrathin MoS2 . ACS Nano 5, 9703–09 (2011).

Eda, G. et al. Photoluminescence from chemically exfoliated MoS2 . Nano Lett. 11, 5111–5116 (2011).

Liu, N. et al. Large-area atomically thin MoS2 nanosheets prepared using electrochemical exfoliation. ACS Nano 8, 6902–6910 (2014).

Nicolosi, V. et al. Liquid exfoliation of layered materials. Science 340, 1226419-1-18 (2013).

Lee,Y. H. et al. Synthesis of Large-Area MoS2 Atomic Layers with Chemical Vapor Deposition. Adv. Mater. 24, 2320–25 (2012).

Zhang, Y. et al. Large-area vapor-phase growth and characterization of MoS2 atomic layers on a SiO2 substrate. Small 8, 966–971 (2012).

Huang, P. Y. et al. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature 469, 389–392 (2011).

Yu, Q. et al. Control and characterization of individual grains and grain boundaries in graphene grown by chemical vapour deposition. Nature Mater. 10, 443–449 (2011).

Hakkinen, H. The gold-sulfur interface at the nanoscale. Nat. Chem. 4, 443–455 (2012).

Nemes-Incze, P. et al. Graphene nanoribbons with armchair and zigzag edges prepared by scanning tunneling microscopy lithography on gold substrates. Appl. Surf. Sci. 291, 48–52 (2014).

Li, C. et al. Anomalous Lattice Vibrations of Single- and Few-Layer MoS2 . ACS Nano 4, 2695–2700 (2010).

Li, H. et al. From Bulk to Monolayer MoS2: Evolution of Raman Scattering. Adv. Mater. 22, 1385–90 (2012).

Kobayashi, K. et al. Electronic structure and scanning tunneling microscopy image of molybdenum dichalcogenide surfaces. Phys. Rev. B 51, 17085–95 (1995).

Eidelloth, W. & Sandstrom, R. L. Wet etching of gold films compatible with High-Tc superconducting thin-films. Appl. Phys. Lett. 59, 1632–1634 (1991).

Acknowledgements

The work has been conducted within the framework of the ‘Lendület’ programme of the Hungarian Academy of Sciences and the Korea Hungary Joint Laboratory for Nanosciences through the Korean Research Council of Fundamental Science and Technology L.T. acknowledges OTKA grant K10875. L.P.B. acknowledges OTKA grant K101599. C.H. acknowledges funding by Nano-Material Technology Development Program (2012M3A7B4049888) through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning.

Author information

Authors and Affiliations

Contributions

G.Z.M. and L.T. conceived and designed the experiments. J.P. and G.Z.M. performed the exfoliation and characterization experiments. G.D. performed the transfer experiments to SiO2 substrates. C.H., L.P.B. and L.T. supervised the research. L.T. wrote the paper. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Magda, G., Pető, J., Dobrik, G. et al. Exfoliation of large-area transition metal chalcogenide single layers. Sci Rep 5, 14714 (2015). https://doi.org/10.1038/srep14714

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep14714

This article is cited by

-

Influence of MoS2 film thickness for nitric oxide gas sensing applications

Journal of Materials Science: Materials in Electronics (2023)

-

Optical and structural properties of 2D transition metal dichalcogenides semiconductor MoS2

Bulletin of Materials Science (2023)

-

Controllable growth of two-dimensional quantum materials

Science China Physics, Mechanics & Astronomy (2023)

-

Only gold can pull this off: mechanical exfoliations of transition metal dichalcogenides beyond scotch tape

Applied Physics A (2023)

-

Bolstering functionality in multilayer and bilayer WS2 via focused laser micro-engraving

Science China Information Sciences (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.