Abstract

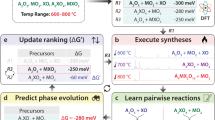

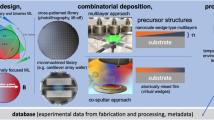

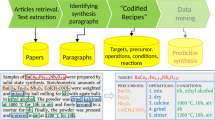

Combinatorial synthesis of solid-state materials comprises the use of automation or parallelization to systematically vary synthesis parameters. This approach to materials synthesis is a natural fit for accelerated mapping of composition–structure–property relationships, a central tenet of materials research. By considering combinatorial synthesis in the context of experimental workflows, we envision a future for accelerated materials science promoted by the co-development of combinatorial synthesis and artificial intelligence (AI) techniques. To evaluate the suitability of a synthesis technique for a given experimental workflow, we establish a collection of ten metrics spanning speed, scalability, scope and quality of synthesis. We summarize select combinatorial synthesis techniques in the context of these metrics, elucidating opportunities for further development. These opportunities span initial deployment in high-throughput experimentation through to seminal demonstrations of automated decision-making using AI. Historical analysis of combinatorial synthesis in the context of the Gartner hype cycle establishes a recent rise in productivity, indicating that the field is poised to realize accelerated materials science workflows that transform materials discovery and development.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ludwig, A. Discovery of new materials using combinatorial synthesis and high-throughput characterization of thin-film materials libraries combined with computational methods. npj Comput. Mater. 5, 70 (2019).

McFarland, E. W. & Weinberg, W. H. Combinatorial approaches to materials discovery. Trends Biotechnol. 17, 107–115 (1999).

Green, M. L. et al. Fulfilling the promise of the materials genome initiative with high-throughput experimental methodologies. Appl. Phys. Rev. 4, 011105 (2017).

Yano, J. et al. The case for data science in experimental chemistry: examples and recommendations. Nat. Rev. Chem. 6, 357–370 (2022).

Li, J. et al. Autonomous discovery of optically active chiral inorganic perovskite nanocrystals through an intelligent cloud lab. Nat. Commun. 11, 2046 (2020).

MacLeod, B. P. et al. Self-driving laboratory for accelerated discovery of thin-film materials. Sci. Adv. 6, eaaz8867 (2020).

Jensen, K. F., Coley, C. W. & Eyke, N. S. Autonomous discovery in the chemical sciences part I: progress. Angew. Chem. Int. Ed. 59, 22858–22893 (2019).

Flores-Leonar, M. M. et al. Materials acceleration platforms: on the way to autonomous experimentation. Curr. Opin. Green Sustain. Chem. 25, 100370 (2020).

Boettcher, A., Haase, G. & Thun, R. Strukturuntersuchung von Mehrstoffsystemen durch kınematische Elektronenbeugung. Int. J. Mater. Res. 46, 386–400 (1955).

Amis, E. J., Xiang, X.-D. & Zhao, J.-C. Combinatorial materials science: what’s new since Edison? MRS Bull. 27, 295–300 (2002).

Koinuma, H. & Takeuchi, I. Combinatorial solid-state chemistry of inorganic materials. Nat. Mater. 3, 429–438 (2004).

Amis, E. J. Reaching beyond discovery. Nat. Mater. 3, 83–85 (2004).

Danielson, E. et al. A combinatorial approach to the discovery and optimization of luminescent materials. Nature 389, 944–948 (1997).

Maier, W. F. Early years of high-throughput experimentation and combinatorial approaches in catalysis and materials science. ACS Comb. Sci. 21, 437–444 (2019).

Green, M. L., Takeuchi, I. & Hattrick-Simpers, J. R. Applications of high throughput (combinatorial) methodologies to electronic, magnetic, optical, and energy-related materials. J. Appl. Phys. 113, 231101 (2013).

Breinbauer, R., Vetter, I. R. & Waldmann, H. From protein domains to drug candidates—natural products as guiding principles in the design and synthesis of compound libraries. Angew. Chem. Int. Ed. 41, 2878–2890 (2002).

Maier, W. F., Stöwe, K. & Sieg, S. Combinatorial and high-throughput materials science. Angew. Chem. Int. Ed. 46, 6016–6067 (2007).

McGinn, P. J. Thin-film processing routes for combinatorial materials investigations—a review. ACS Comb. Sci. 21, 501–515 (2019).

Hanak, J. J. The ‘multiple-sample concept’ in materials research: synthesis, compositional analysis and testing of entire multicomponent systems. J. Mater. Sci. 5, 964–971 (1970).

Barber, Z. H. & Blamire, M. G. High throughput thin film materials science. Mater. Sci. Technol. 24, 757–770 (2008).

Xiang, X.-D. et al. A combinatorial approach to materials discovery. Science 268, 1738–1740 (1995).

van Dover, R. B., Schneemeyer, L. F. & Fleming, R. M. Discovery of a useful thin-film dielectric using a composition-spread approach. Nature 392, 162–164 (1998).

Gregoire, J. M., van Dover, R. B., Jin, J., DiSalvo, F. J. & Abruña, H. D. Getter sputtering system for high-throughput fabrication of composition spreads. Rev. Sci. Instrum. 78, 072212 (2007).

Suram, S. K. et al. Combinatorial thin film composition mapping using three dimensional deposition profiles. Rev. Sci. Instrum. 86, 033904 (2015).

Dahn, J. R. et al. Economical sputtering system to produce large-size composition-spread libraries having linear and orthogonal stoichiometry variations. Chem. Mater. 14, 3519–3523 (2002).

Yan, Z., Wu, S., Song, Y., Xiang, Y. & Zhu, J. A novel gradient composition spreading and nanolayer stacking process for combinatorial thin-film materials library fabrication. Rev. Sci. Instrum. 91, 065107 (2020).

Ludwig, A., Zarnetta, R. & Hamann, S. Development of multifunctional thin films using high-throughput experimentation methods. J. Mater. Chem. A 99, 1144–1149 (2008).

Becker, M., Gies, M., Polity, A., Chatterjee, S. & Klar, P. J. Materials processing using radio-frequency ion-sources: ion-beam sputter-deposition and surface treatment. Rev. Sci. Instrum. 90, 023901 (2019).

Guerin, S. & Hayden, B. E. Physical vapor deposition method for the high-throughput synthesis of solid-state material libraries. J. Comb. Chem. 8, 66–73 (2006).

Mardare, A. I., Yadav, A. P., Wieck, A. D., Stratmann, M. & Hassel, A. W. Combinatorial electrochemistry on Al–Fe alloys. Sci. Technol. Adv. Mater. 9, 035009 (2008).

Klemm, S. O. et al. Theoretical simulation and preparation of binary and ternary combinatorial libraries by thermal PVD. Phys. Status Solidi A 207, 801–806 (2010).

Priyadarshini, D., Kondratyuk, P., Miller, J. B. & Gellman, A. J. Compact tool for deposition of composition spread alloy films. J. Vac. Sci. Technol. A 30, 011503 (2012).

Baker, A. A. et al. An ultra-compact, high-throughput molecular beam epitaxy growth system. Rev. Sci. Instrum. 86, 043901 (2015).

Koinuma, H., Aiyer, H. N. & Matsumoto, Y. Combinatorial solid state materials science and technology. Sci. Technol. Adv. Mater. 1, 1–10 (2000).

Ohnishi, T. et al. Parallel integration and characterization of nanoscaled epitaxial lattices by concurrent molecular layer epitaxy and diffractometry. Appl. Phys. Lett. 79, 536–538 (2001).

Christen, H. M. et al. An improved continuous compositional-spread technique based on pulsed-laser deposition and applicable to large substrate areas. Rev. Sci. Instrum. 74, 4058–4062 (2003).

Maruyama, S. et al. Pulsed laser deposition with rapid beam deflection by a galvanometer mirror scanner. Rev. Sci. Instrum. 90, 093901 (2019).

Siol, S. et al. Combinatorial reactive sputtering of In2S3 as an alternative contact layer for thin film solar cells. ACS Appl. Mater. Interfaces 8, 14004–14011 (2016).

Koida, T. et al. Temperature-gradient epitaxy under in situ growth mode diagnostics by scanning reflection high-energy electron diffraction. Appl. Phys. Lett. 80, 565–567 (2002).

Ohkubo, I. et al. High-throughput growth temperature optimization of ferroelectric SrxBa1−xNb2O6 epitaxial thin films using a temperature gradient method. Appl. Phys. Lett. 84, 1350–1352 (2004).

Meyer, R. et al. Microgradient-heaters as tools for high-throughput experimentation. ACS Comb. Sci. 14, 531–536 (2012).

Lahr, D. L., Hertz, J. L. & Semancik, S. A combinatorial study of thin-film process variables using microhotplates. J. Microelectromech. Syst. 19, 239–245 (2010).

Gregoire, J. M. et al. In Integrated Solar Fuel Generators (eds Sharp, I. D. et al.) 305–340 (Royal Society of Chemistry, 2018).

Bunn, J. K. et al. Development of an optimization procedure for magnetron-sputtered thin films to facilitate combinatorial materials research. Ind. Eng. Chem. Res. 55, 1236–1242 (2016).

Zhou, L. et al. Combining reactive sputtering and rapid thermal processing for synthesis and discovery of metal oxynitrides. J. Mater. Res. 30, 2928–2933 (2015).

Caskey, M., Richards, S., Ginley, D. & Zakutayev, A. Thin film synthesis and properties of copper nitride, a metastable semiconductor. Mater. Horiz. 1, 424–430 (2014).

Baben, M. et al. Unprecedented thermal stability of inherently metastable titanium aluminum nitride by point defect engineering. Mater. Res. Lett. 5, 158–169 (2017).

Banko, L. et al. Predicting structure zone diagrams for thin film synthesis by generative machine learning. Commun. Mater. 1, 15 (2020).

Meischein, M. & Ludwig, A. Upscaling nanoparticle synthesis by sputter deposition in ionic liquids. J. Nanopart. Res. 23, 129 (2021).

Mišina, M., Shaginyan, L. R., Maček, M. & Panjan, P. Energy resolved ion mass spectroscopy of the plasma during reactive magnetron sputtering. Surf. Coat. Technol. 142–144, 348–354 (2001).

Greczynski, G. & Hultman, L. Time and energy resolved ion mass spectroscopy studies of the ion flux during high power pulsed magnetron sputtering of Cr in Ar and Ar/N2 atmospheres. Vacuum 84, 1159–1170 (2010).

Sharma, S. et al. Measurement of deposition rate and ion energy distribution in a pulsed dc magnetron sputtering system using a retarding field analyzer with embedded quartz crystal microbalance. Rev. Sci. Instrum. 87, 043511 (2016).

Walk, F., Valizadeh, R. & Bradley, J. W. Ion energy analysis of a bipolar HiPIMS discharge using a retarding field energy analyser. Plasma Sources Sci. Technol. 31, 065002 (2022).

Ayguavives, F., Ea-kim, B., Aubert, P., Agius, B. & Bretagne, J. Correlation between in situ optical emission spectroscopy in a reactive Ar/O2 rf magnetron sputtering discharge and Pb(ZrxTi1−x)O3 thin film composition. Appl. Phys. Lett. 73, 1023–1025 (1998).

Drury, D. et al. Understanding reproducibility of sputter-deposited metastable ferroelectric wurtzite Al0.6Sc0.4N films using in situ optical emission spectrometry. Phys. Status Solidi Rapid Res. Lett. 15, 2100043 (2021).

Moon, E. J. & Goyal, A. Combinatorial synthesis of heteroepitaxial, multi-cation, thin-films via pulsed laser deposition coupled with in-situ, chemical and structural characterization. Sci. Rep. 12, 3219 (2022).

Wu, Z.-B. et al. A low-temperature scanning probe microscopy system with molecular beam epitaxy and optical access. Rev. Sci. Instrum. 89, 113705 (2018).

Kumigashira, H. et al. In situ photoemission spectroscopic study on La1−xSrxMnO3 thin films grown by combinatorial laser-MBE. J. Electron. Spectros. Relat. Phenomena 136, 31–36 (2004).

Horiba, K. et al. A high-resolution synchrotron-radiation angle-resolved photoemission spectrometer with in situ oxide thin film growth capability. Rev. Sci. Instrum. 74, 3406–3412 (2003).

Gao, Y., Zhao, B., Vlassak, J. J. & Schick, C. Nanocalorimetry: door opened for in situ material characterization under extreme non-equilibrium conditions. Prog. Mater Sci. 104, 53–137 (2019).

Bell, R. T. et al. Lateral temperature-gradient method for high-throughput characterization of material processing by millisecond laser annealing. ACS Comb. Sci. 18, 548–558 (2016).

Bell, R. T. et al. Rapid identification of synthetic routes to functional metastable phases using X-ray probed laser anneal mapping (XPLAM) time–temperature quench maps. Chem. Mater. 33, 4328–4336 (2021).

Sun, X.-D. et al. Solution-phase synthesis of luminescent materials libraries. Adv. Mater. 9, 1046–1049 (1997).

Reddington, E. et al. Combinatorial electrochemistry: a highly parallel, optical screening method for discovery of better electrocatalysts. Science 280, 1735–1737 (1998).

Woodhouse, M. & Parkinson, A. B. Combinatorial approaches for the identification and optimization of oxide semiconductors for efficient solar photoelectrolysis. Chem. Soc. Rev. 38, 197–210 (2009).

Woodhouse, M., Herman, G. S. & Parkinson, B. A. Combinatorial approach to identification of catalysts for the photoelectrolysis of water. Chem. Mater. 17, 4318–4324 (2005).

Fan, J., Boettcher, S. W. & Stucky, G. D. Nanoparticle assembly of ordered multicomponent mesostructured metal oxides via a versatile sol−gel process. Chem. Mater. 18, 6391–6396 (2006).

Liu, X. et al. Inkjet printing assisted synthesis of multicomponent mesoporous metal oxides for ultrafast catalyst exploration. Nano Lett. 12, 5733–5739 (2012).

Haber, J. A. et al. Discovering Ce-rich oxygen evolution catalysts, from high throughput screening to water electrolysis. Energy Environ. Sci. 7, 682–688 (2014).

Shinde, A. et al. High-throughput screening for acid-stable oxygen evolution electrocatalysts in the (Mn–Co–Ta–Sb)Ox composition space. Electrocatalysis 6, 229–236 (2015).

Stein, H. S. et al. Functional mapping reveals mechanistic clusters for OER catalysis across (Cu–Mn–Ta–Co–Sn–Fe)Ox composition and pH space. Mater. Horiz. 6, 1251–1258 (2019).

Guevarra, D. et al. Development of solar fuels photoanodes through combinatorial integration of Ni–La–Co–Ce oxide catalysts on BiVO4. Energy Environ. Sci. 9, 565–580 (2016).

Shinde, A. et al. Discovery of Fe–Ce oxide/BiVO4 photoanodes through combinatorial exploration of Ni–Fe–Co–Ce oxide coatings. ACS Appl. Mater. Interfaces 8, 23696–23705 (2016).

Zhang, Z. et al. Fermi level engineering of passivation and electron transport materials for p-type CuBi2O4 employing a high-throughput methodology. Adv. Funct. Mater. 30, 2000948 (2020).

de Gans, B.-J. & Schubert, U. S. Inkjet printing of polymer micro-arrays and libraries: instrumentation, requirements, and perspectives. Macromol. Rapid Commun. 24, 659–666 (2003).

Li, Z. et al. Fast optimization of LiMgMnOx/La2O3 catalysts for the oxidative coupling of methane. ACS Comb. Sci. 19, 15–24 (2017).

Näsström, H. et al. Combinatorial inkjet printing for compositional tuning of metal-halide perovskite thin films. J. Mater. Chem. A 10, 4906–4914 (2022).

Siemenn, A. E. et al. A machine learning and computer vision approach to rapidly optimize multiscale droplet generation. ACS Appl. Mater. Interfaces 14, 4668–4679 (2022).

Chen, P.-C. et al. Polyelemental nanoparticle libraries. Science 352, 1565–1569 (2016).

Liu, G., Petrosko, S. H., Zheng, Z. & Mirkin, C. A. Evolution of dip-pen nanolithography (DPN): from molecular patterning to materials discovery. Chem. Rev. 120, 6009–6047 (2020).

Sui, J., Yan, J., Liu, D., Wang, K. & Luo, G. Continuous synthesis of nanocrystals via flow chemistry technology. Small 16, 1902828 (2020).

Nette, J., Howes, P. D. & deMello, A. J. Microfluidic synthesis of luminescent and plasmonic nanoparticles: fast, efficient, and data-rich. Adv. Mater. Technol. 5, 2000060 (2020).

Tao, H. et al. Nanoparticle synthesis assisted by machine learning. Nat. Rev. Mater. 6, 701–716 (2021).

Maceiczyk, R. M., Lignos, I. G. & deMello, A. J. Online detection and automation methods in microfluidic nanomaterial synthesis. Curr. Opin. Chem. Eng. 8, 29–35 (2015).

Lignos, I., Maceiczyk, R. & deMello, A. J. Microfluidic technology: uncovering the mechanisms of nanocrystal nucleation and growth. Acc. Chem. Res. 50, 1248–1257 (2017).

Lignos, I. et al. Unveiling the shape evolution and halide-ion-segregation in blue-emitting formamidinium lead halide perovskite nanocrystals using an automated microfluidic platform. Nano Lett. 18, 1246–1252 (2018).

Baek, J., Shen, Y., Lignos, I., Bawendi, M. G. & Jensen, K. F. Multistage microfluidic platform for the continuous synthesis of III-V core/shell quantum dots. Angew. Chem. Int. Ed. 130, 11081–11084 (2018).

Yashina, A., Lignos, I., Stavrakis, S., Choo, J. & deMello, J. A. Scalable production of CuInS2/ZnS quantum dots in a two-step droplet-based microfluidic platform. J. Mater. Chem. C 4, 6401–6408 (2016).

Lignos, I. et al. Synthesis of cesium lead halide perovskite nanocrystals in a droplet-based microfluidic platform: fast parametric space mapping. Nano Lett. 16, 1869–1877 (2016).

Bezinge, L., Maceiczyk, R. M., Lignos, I., Kovalenko, M. V. & deMello, A. J. Pick a color MARIA: adaptive sampling enables the rapid identification of complex perovskite nanocrystal compositions with defined emission characteristics. ACS Appl. Mater. Interfaces 10, 18869–18878 (2018).

Mekki-Berrada, F. et al. Two-step machine learning enables optimized nanoparticle synthesis. npj Comput. Mater. 7, 55 (2021).

Nikolaev, P. et al. Autonomy in materials research: a case study in carbon nanotube growth. npj Comput. Mater. 2, 16031 (2016).

Ament, S. et al. Autonomous materials synthesis via hierarchical active learning of nonequilibrium phase diagrams. Sci. Adv. 7, eabg4930 (2021).

Li, Z. et al. Robot-accelerated perovskite investigation and discovery. Chem. Mater. 32, 5650–5663 (2020).

Fenn, J. & Raskino, M. Mastering the Hype Cycle: How to Choose the Right Innovation at the Right Time (Harvard Business Press, 2008).

Reyes, K. G. & Maruyama, B. The machine learning revolution in materials? MRS Bull. 44, 530–537 (2019).

Stach, E. et al. Autonomous experimentation systems for materials development: a community perspective. Matter 4, 2702–2726 (2021).

Kusne, A. G. et al. On-the-fly closed-loop materials discovery via Bayesian active learning. Nat. Commun. 11, 5966 (2020).

Friedler, F., Tarján, K., Huang, Y. W. & Fan, L. T. Graph-theoretic approach to process synthesis: axioms and theorems. Chem. Eng. Sci. 47, 1973–1988 (1992).

Mysore, S. et al. Automatically extracting action graphs from materials science synthesis procedures. Preprint at https://arxiv.org/abs/1711.06872 (2017).

Vaucher, A. C. et al. Automated extraction of chemical synthesis actions from experimental procedures. Nat. Commun. 11, 3601 (2020).

Kim, E. et al. Materials synthesis insights from scientific literature via text extraction and machine learning. Chem. Mater. 29, 9436–9444 (2017).

Stein, H. S. & Gregoire, J. M. Progress and prospects for accelerating materials science with automated and autonomous workflows. Chem. Sci. 10, 9640–9649 (2019).

Burger, B. et al. A mobile robotic chemist. Nature 583, 237–241 (2020).

Rahmanian, F. et al. Enabling modular autonomous feedback-loops in materials science through hierarchical experimental laboratory automation and orchestration. Adv. Mater. Interfaces 9, 2101987 (2022).

Allan, D., Caswell, T., Campbell, S. & Rakitin, M. Bluesky’s ahead: a multi-facility collaboration for an a la carte software project for data acquisition and management. Synchrotron Radiat. News 32, 19–22 (2019).

Umehara, M. et al. Analyzing machine learning models to accelerate generation of fundamental materials insights. npj Comput. Mater. 5, 1–9 (2019).

Ziatdinov, M. A. et al. Hypothesis learning in automated experiment: application to combinatorial materials libraries. Adv. Mater. 34, 2201345 (2022).

Cheetham, A. K., Seshadri, R. & Wudl, F. Chemical synthesis and materials discovery. Nat. Synth. 1, 514–520 (2022).

Raccuglia, P. et al. Machine-learning-assisted materials discovery using failed experiments. Nature 533, 73–76 (2016).

Gomes, C. P., Selman, B. & Gregoire, J. M. Artificial intelligence for materials discovery. MRS Bull. 44, 538–544 (2019).

Acknowledgements

This material is primarily based on work performed by the Liquid Sunlight Alliance, which is supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, Fuels from Sunlight Hub under award DE-SC0021266. The analysis of autonomous workflows was supported by the Air Force Office of Scientific Research under award FA9550-18-1-0136.

Author information

Authors and Affiliations

Contributions

J.M.G., L.Z. and J.A.H. planned the review and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks Jason Hattrick-Simpers and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editor: Alexandra Groves, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gregoire, J.M., Zhou, L. & Haber, J.A. Combinatorial synthesis for AI-driven materials discovery. Nat. Synth 2, 493–504 (2023). https://doi.org/10.1038/s44160-023-00251-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44160-023-00251-4