Abstract

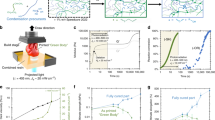

Digital assembly via extrusion-based additive manufacturing, or three-dimensional (3D) printing, grants the opportunity to attain exquisite control over material structure and composition at the local (‘voxel’) level. The synthetic incorporation of a diverse array of chemistries into 3D-printed soft materials has expanded its use into many application areas. However, substantial opportunity exists for synthesizing materials in which the functional microstructure (at both filler and molecular levels) interacts with the processing flows of extrusion-based manufacturing to achieve unique and enhanced properties. Here we articulate principles for designing and synthesizing soft materials with the potential to generate printed structures with superlative mechanical and stimuli-responsive properties. Specifically, we consider the rheological requirements of printing via direct ink writing and materials extrusion, and examine materials that show printing-directed alignment or trapping of tailored non-equilibrium structures. Finally, we discuss characterization approaches that connect filament-level microstructure with macroscopic behaviour, thus ‘closing the loop’ of material development. Collectively, these create the potential for additive manufacturing to achieve voxel-level control of composition, microstructure and properties.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Wong, B. H. Invisalign A to Z. Am. J. Orthod. Dentofacial Orthop. 121, 540–541 (2002).

Najmon, J. C., Raeisi, S. & Tovar, A. in Additive Manufacturing for the Aerospace Industry (eds Froes, F. & Boyer, R.) 7–31 (Elsevier, 2019).

Hosny, A. et al. From improved diagnostics to presurgical planning: high-resolution functionally graded multimaterial 3D printing of biomedical tomographic data sets. 3D Print. Addit. Manuf. 5, 103–113 (2018).

Nelson, A. Z. et al. Designing and transforming yield-stress fluids. Curr. Opin. Solid State Mater. Sci. 23, 100758 (2019).

Park, K. S. et al. Tuning conformation, assembly and charge transport properties of conjugated polymers by printing flow. Sci. Adv. 5, eaaw7757 (2019).

Patel, B. B. et al. Tunable structural color of bottlebrush block copolymers through direct-write 3D printing from solution. Sci. Adv. 6, eaaz7202 (2020).

Truby, R. L. & Lewis, J. A. Printing soft matter in three dimensions. Nature 540, 371–378 (2016).

Mackay, M. E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 62, 1549–1561 (2018).

Zhu, J. Z., Zhang, Q., Yang, T. Q., Liu, Y. & Liu, R. 3D printing of multi-scalable structures via high penetration near-infrared photopolymerization. Nat. Commun. 11, 3462 (2020).

McIlroy, C. & Olmsted, P. D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 123, 376–391 (2017).

Levenhagen, N. P. & Dadmun, M. D. Interlayer diffusion of surface segregating additives to improve the isotropy of fused deposition modeling products. Polymer 152, 35–41 (2018).

Smay, J. E., Gratson, G. M., Shepherd, R. F., Cesarano, J. & Lewis, J. A. Directed colloidal assembly of 3D periodic structures. Adv. Mater. 14, 1279–1283 (2002).

Smay, J. E., Cesarano, J. & Lewis, J. A. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 18, 5429–5437 (2002).

Trigg, E. B. et al. Revealing filler morphology in 3D-printed thermoset nanocomposites by scanning microbeam X-ray scattering. Addit. Manuf. 37, 101729 (2021).

Hausmann, M. K. et al. Dynamics of cellulose nanocrystal alignment during 3D printing. ACS Nano 12, 6926–6937 (2018).

Wang, C., Rubakhin, S. S., Enright, M. J., Sweedler, J. V. & Nuzzo, R. G. 3D particle-free printing of biocompatible conductive hydrogel platforms for neuron growth and electrophysiological recording. Adv. Funct. Mater. 31, 2010246 (2021).

Rauzan, B. M., Nelson, A. Z., Lehman, S. E., Ewoldt, R. H. & Nuzzo, R. G. Particle-free emulsions for 3D printing elastomers. Adv. Funct. Mater. 28, 1707032 (2018).

Xie, R. et al. Room temperature 3D printing of super-soft and solvent-free elastomers. Sci. Adv. 6, eabc6900 (2020).

Olsen, B. D., Kornfield, J. A. & Tirrell, D. A. Yielding behavior in injectable hydrogels from telechelic proteins. Macromolecules 43, 9094–9099 (2010).

Highley, C. B., Rodell, C. B. & Burdick, J. A. Direct 3D printing of shear-thinning hydrogels into self-healing hydrogels. Adv. Mater. 27, 5075–5079 (2015).

Sather, N. A. et al. 3D printing of supramolecular polymer hydrogels with hierarchical structure. Small 17, 2005743 (2021).

Lee, S. C., Gillispie, G., Prim, P. & Lee, S. J. Physical and chemical factors influencing the printability of hydrogel-based extrusion bioinks. Chem. Rev. 120, 10797–10849 (2020).

Ouyang, L., Highley, C. B., Rodell, C. B., Sun, W. & Burdick, J. A. 3D printing of shear-thinning hyaluronic acid hydrogels with secondary cross-linking. ACS Biomater. Sci. Eng. 2, 1743–1751 (2016).

Nadgorny, M., Collins, J., Xiao, Z., Scales, P. J. & Connal, L. A. 3D-printing of dynamic self-healing cryogels with tuneable properties. Polym. Chem. 9, 1684–1692 (2018).

Cai, L., Dewi, R. E. & Heilshorn, S. C. Injectable hydrogels with in situ double network formation enhance retention of transplanted stem cells. Adv. Funct. Mater. 25, 1344–1351 (2015).

Zhang, M. et al. Hierarchical-coassembly-enabled 3D-printing of homogeneous and heterogeneous covalent organic frameworks. J. Am. Chem. Soc. 141, 5154–5158 (2019).

Kolesky, D. B. et al. 3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs. Adv. Mater. 26, 3124–3130 (2014).

Zhang, M. S. et al. Dual-responsive hydrogels for direct-write 3D printing. Macromolecules 48, 6482–6488 (2015).

Newby, G. E., Hamley, I. W., King, S. M., Martin, C. M. & Terrill, N. J. Structure, rheology and shear alignment of pluronic block copolymer mixtures. J. Colloid Interface Sci. 329, 54–61 (2009).

Sebastian, J. M., Lai, C., Graessley, W. W. & Register, R. A. Steady-shear rheology of block copolymer melts and concentrated solutions: disordering stress in body-centered-cubic systems. Macromolecules 35, 2707–2713 (2002).

Xie, R. et al. Yielding behavior of bottlebrush and linear block copolymers. Macromolecules 54, 5636–5647 (2021).

Fratzl, P. & Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 52, 1263–1334 (2007).

Wagner, N. J. & Mewis, J. in Theory and Applications of Colloidal Suspension Rheology Cambridge Series in Chemical Engineering (eds Mewis, J. & Wagner, N. J.) 1–43 (Cambridge Univ. Press, 2021).

Baek, S. G., Magda, J. J. & Larson, R. G. Rheological differences among liquid‐crystalline polymers. I. The first and second normal stress differences of PBG solutions. J. Rheol. 37, 1201–1224 (1993).

Compton, B. G. & Lewis, J. A. 3D-printing of lightweight cellular composites. Adv. Mater. 26, 5930–5935 (2014).

Frka-Petesic, B. & Vignolini, S. So much more than paper. Nat. Photon. 13, 365–367 (2019).

Siqueira, G. et al. Cellulose nanocrystal inks for 3D printing of textured cellular architectures. Adv. Funct. Mater. 27, 1604619 (2017).

Sydney Gladman, A., Matsumoto, E. A., Nuzzo, R. G., Mahadevan, L. & Lewis, J. A. Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016).

Raney, J. R. et al. Rotational 3D printing of damage-tolerant composites with programmable mechanics. Proc. Natl Acad. Sci. USA 115, 1198–1203 (2018).

Zhang, Q., Yan, D., Zhang, K. & Hu, G. Pattern transformation of heat-shrinkable polymer by three-dimensional (3D) printing technique. Sci. Rep. 5, 8936 (2015).

Gantenbein, S. et al. Three-dimensional printing of hierarchical liquid–crystal–polymer structures. Nature 561, 226–230 (2018).

Sol, J. A. H. P. et al. Anisotropic iridescence and polarization patterns in a direct ink written chiral photonic polymer. Adv. Mater. 33, 2103309 (2021).

Zhou, N. et al. Perovskite nanowire-block copolymer composites with digitally programmable polarization anisotropy. Sci. Adv. 5, eaav8141 (2019).

Valentine, C. S., Jayaraman, A., Mahanthappa, M. K. & Walker, L. M. Shear-modulated rates of phase transitions in sphere-forming diblock oligomer lyotropic liquid crystals. ACS Macro Lett. 10, 538–544 (2021).

Jiang, H. Y., Kelch, S. & Lendlein, A. Polymers move in response to light. Adv. Mater. 18, 1471–1475 (2006).

Li, J., Nagamani, C. & Moore, J. S. Polymer mechanochemistry: from destructive to productive. Acc. Chem. Res. 48, 2181–2190 (2015).

Epstein, E., Kim, T. A., Kollarigowda, R. H., Sottos, N. R. & Braun, P. V. Force-modulated equilibria of mechanophore-metal coordinate bonds. Chem. Mater. 32, 3869–3878 (2020).

Park, T. J. et al. Electrically tunable soft-solid block copolymer structural color. ACS Nano 9, 12158–12167 (2015).

Kocak, G., Tuncer, C. & Bütün, V. pH-responsive polymers. Polym. Chem. 8, 144–176 (2017).

Kramer, J. R. & Deming, T. J. Glycopolypeptides with a redox-triggered helix-to-coil transition. J. Am. Chem. Soc. 134, 4112–4115 (2012).

Liu, R., Fraylich, M. & Saunders, B. R. Thermoresponsive copolymers: from fundamental studies to applications. Colloid. Polym. Sci. 287, 627–643 (2009).

Lancia, F., Ryabchun, A. & Katsonis, N. Life-like motion driven by artificial molecular machines. Nat. Rev. Chem. 3, 536–551 (2019).

Kim, Y., Yuk, H., Zhao, R., Chester, S. A. & Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 558, 274–279 (2018).

Kotikian, A., Truby, R. L., Boley, J. W., White, T. J. & Lewis, J. A. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 30, 1706164 (2018).

Ambulo, C. P. et al. Four-dimensional printing of liquid crystal elastomers. ACS Appl. Mater. Interfaces 9, 37332–37339 (2017).

López-Valdeolivas, M., Liu, D., Broer, D. J. & Sánchez-Somolinos, C. 4D printed actuators with soft-robotic functions. Macromol. Rapid Commun. 39, 1700710 (2018).

Davidson, E. C., Kotikian, A., Li, S., Aizenberg, J. & Lewis, J. A. 3D printable and reconfigurable liquid crystal elastomers with light-induced shape memory via dynamic bond exchange. Adv. Mater. 32, 1905682 (2020).

Coasey, K., Hart, K. R., Wetzel, E., Edwards, D. & Mackay, M. E. Nonisothermal welding in fused filament fabrication. Addit. Manuf. 33, 101140 (2020).

Hart, K. R. et al. Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 144, 192–204 (2018).

Frutiger, A. et al. Capacitive soft strain sensors via multicore-shell fiber printing. Adv. Mater. 27, 2440–2446 (2015).

Mueller, J., Raney, J. R., Shea, K. & Lewis, J. A. Architected lattices with high stiffness and toughness via multicore-shell 3D printing. Adv. Mater. 30, 1705001 (2018).

Kotikian, A. et al. Innervated, self-sensing liquid crystal elastomer actuators with closed loop control. Adv. Mater. 33, 2101814 (2021).

Chortos, A. et al. Printing reconfigurable bundles of dielectric elastomer fibers. Adv. Funct. Mater. 31, 2010643 (2021).

Boley, J. W. et al. Shape-shifting structured lattices via multimaterial 4D printing. Proc. Natl Acad. Sci. USA 116, 20856–20862 (2019).

Wang, Z. et al. Stretchable materials of high toughness and low hysteresis. Proc. Natl Acad. Sci. USA 116, 5967–5972 (2019).

Hassan, N. M., Migler, K. B., Hight Walker, A. R., Kotula, A. P. & Seppala, J. E. Comparing polarized Raman spectroscopy and birefringence as probes of molecular scale alignment in 3D printed thermoplastics. MRS Commun. 11, 157–167 (2021).

Northcutt, L. A., Orski, S. V., Migler, K. B. & Kotula, A. P. Effect of processing conditions on crystallization kinetics during materials extrusion additive manufacturing. Polymer 154, 182–187 (2018).

Collins, B. A. et al. Polarized X-ray scattering reveals non-crystalline orientational ordering in organic films. Nat. Mater. 11, 536–543 (2012).

Prévôt, M. E. et al. Synchrotron microbeam diffraction studies on the alignment within 3D-printed smectic-A liquid crystal elastomer filaments during extrusion. Crystals 11, 523 (2021).

Shmueli, Y. et al. In situ time-resolved X-ray scattering study of isotactic polypropylene in additive manufacturing. ACS Appl. Mater. Interfaces 11, 37112–37120 (2019).

Corona, P. T. et al. Bayesian estimations of orientation distribution functions from small-angle scattering enable direct prediction of mechanical stress in anisotropic materials. Phys. Rev. Mater. 5, 065601 (2021).

Visser, C. W., Amato, D. N., Mueller, J. & Lewis, J. A. Architected polymer foams via direct bubble writing. Adv. Mater. 31, 1904668 (2019).

Fu, Q., Saiz, E. & Tomsia, A. P. Direct ink writing of highly porous and strong glass scaffolds for load-bearing bone defects repair and regeneration. Acta Biomater. 7, 3547–3554 (2011).

Yavitt, B. M. et al. Revealing nanoscale dynamics during an epoxy curing reaction with X-ray photon correlation spectroscopy. J. Appl. Phys. 127, 114701 (2020).

Acknowledgements

We thank J. A. Lewis for helpful discussions. This work was partially supported by the MRSEC programme of the National Science Foundation (DMR-2011750) through the Princeton Center for Complex Materials. J.M.T. acknowledges support from an ARO MURI award (no. W911NF-17-1-0351).

Author information

Authors and Affiliations

Contributions

This perspective was conceived by E.C.D., and written by C.L.C.C., E.C.D. and J.M.T.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks the anonymous reviewers for their contribution to the peer review of this work. Primary Handling Editor: Alison Stoddart, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chan, C.L.C., Taylor, J.M. & Davidson, E.C. Design of soft matter for additive processing. Nat. Synth 1, 592–600 (2022). https://doi.org/10.1038/s44160-022-00115-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44160-022-00115-3

This article is cited by

-

Engineering Nano/Microscale Chiral Self-Assembly in 3D Printed Constructs

Nano-Micro Letters (2024)