Abstract

In the shift to cleaner technologies, coal thermal power plants and mines will be decommissioned earlier than planned. These open-pit coal mines show potential as a geothermal source/sink for space heating and cooling, yet this post-closure use option remains unexplored. Here, we assess the techno-economic feasibility of providing heating and cooling using a decommissioned mine pit as a source or sink of heat for nearby population centres. Mixed integer quadratically constrained programming is employed for operational optimisation. The results show that thermal provisioning, considering centralised and decentralised arrangements, is economically competitive under specific scenarios regarding commodities prices, thermal demands and pit source temperature. Notably, a higher pit temperature reduces the overall thermal provisioning costs for residential thermal demands. Improvements in the economics due to transmission pipeline insulation are limited. While an expected decline in the system lifecycle costs occurs for decreasing electricity prices, the results highlight that the relative economic competitiveness of the thermal systems is tied to the individual alternatives’ performance at the same commodities prices. Overall, this paper identifies general conditions for techno-economic competitiveness for the implementation of shallow geothermal systems in the context of mine closure.

Similar content being viewed by others

Introduction

Competitive low-emissions technologies for electricity generation already exist in the market, yet coal supplied around one-third of the global energy demand in 20211,2,3. All unabated coal power plants must close or be repurposed before 2040 to meet emission targets according to refs. 4,5. With the reduction of coal demand for power generation, premature decommission of open-pit coal mines will follow within this time frame around the World1,6. Historically, open-pit mine decommissioning minimised physical–chemical risks originating from the massive void left after mine operation ceased7. Nowadays, the decommissioning solution should consider post-mining land use and its role in the economic transition of formerly coal-dependent nearby population centres8.

A solution for pit closure is the rapid flooding of the mine void using an external water source to create an artificial lake or pit lake9. The active rapid flooding of the pit stabilises the pit walls, may improve the quality of acid mine waters and also allows for earlier reuse of the mined land area after decommissioning, providing socio-economic benefits for nearby communities10. A review of post-mine land reuse cases worldwide (313 in total) shows a focus on ecological conservation and recreational services, with few projects considering light industry (energy harness, waste disposal, manufacturing) in their solution11. Similarly, most successful pit-lake end uses have concentrated on landscape restoration, development for recreation and tourism, and water or waste storage12. Identifying additional end-uses for pit lakes that provide opportunities for socio-economic transition is an ongoing research challenge13. One such potential end-use is harnessing low-enthalpy geothermal energy from pit lakes13,14.

Low-enthalpy (shallow) geothermal energy systems operate by extracting or rejecting heat to the ground or a water body, using heat pumps to elevate/decrease the temperature to the consumer-required levels15. A shallow geothermal system may be embedded in the mine infrastructure without requiring significant modifications of the closure solutions already addressing physical-chemical stability requirements, which are of the utmost priority in the closure phase16. The infrastructure and buildings sector is an excellent example of the adaptability of shallow geothermal systems. Closed loop systems are embedded in footings and other geo-structures without compromising the serviceability of the structural elements17. In contrast, the mining sector has seen relatively little uptake of the technology14,18.

A database of active shallow geothermal projects in mining environments published in 201414 found 20 documented examples, later extended to 45 cases in 202119. Only two cases of pit lake geothermal reuse were found. Overall, geothermal project development has focused on reusing abandoned mine infrastructure rather than implementation in a mine closure phase. In this context, underground coal mines have an advantage over open-pit mines, often located under dense population centres and having naturally built geothermal reservoirs for geothermal exploitation20,21. On the other hand, open-pit mines are commonly located farther away from population centres due to their disruptive effects on the landscape, hindering their consideration as potential geothermal sources without appropriate planning14.

Shallow geothermal energy is broadly attainable, conditioned to accessible copious ground or water volumes and significant capital costs for drilling or excavation15. Although ref. 22 highlighted that proximity to water bodies is critical for the economic feasibility of large-scale heat-pumps feeding district heating systems, details about cut-off distances are missing. Other studies have focused on analysing the water source behaviour for thermal provisioning23,24,25, or simplified assessments for source identification on the regional and national scale26,27. Cut-off distance criteria can be found in excess heat reuse literature, where a value of 0.5 EUR GJ−1 (1.0 EUR GJ−1 = .6 EUR MWh−1) is given as maximum total cost per fed unit of thermal energy for the transmission systems with a maximum distance of 50 km based on Danish transmission systems experience28. Overall, no studies for long-distance, low-temperature, heating and cooling provisioning have been found by the authors.

The new focus on the future reuse of the land and economic transition during mine closure, the lack of awareness of shallow geothermal energy in the mining sector, and the infrequency of mining projects next to dense population centres are hypothesised to be the main reasons for the lack of geothermal reuse of pits. Considering that project economics are essential for the success of mine closure projects16, and the lack of specific literature or guidelines about low-temperature energy transport, a more in-depth study to assess the potential of mines as a low-temperature source is needed.

In this paper, we evaluate the techno-economic feasibility of heating and cooling provisioning using a decommissioned open pit as a source or sink of heat for nearby residential centres. A framework based on optimising the operation of potential thermal systems is developed using COMANDO29 and applied for the assessment. The study starts by considering two locations of analysis where open-pit coal mines will be decommissioned in the coming decades (base cases): the Latrobe Valley, located in the Latrobe-Gippsland area, Victoria (VIC), Australia, and the Rhenish Coal Mining Area (Rheinisches Braunkohlerevier) located in North-Rhine Westphalia (NRW), Germany, (Fig. 1a). Both regions have three open pit coal mines each, set for decommissioning in the next two decades30,31. Assessment of the impact of other influencing parameters representing a variety of conditions that may be encountered worldwide completes the work.

a Latrobe Valley in Victoria, Australia (VIC) and Rhenish Coal Mine Area in North-Rhine Westphalia, Germany (NRW). A red diamond marks the main population centres. A green circle denotes other cities and towns. A grey polygon identifies open-pit coal mines. A black star denotes a representative population centre close to the maximum number of consumers considered in the analysis (20,000). 1, 5 and 10 km of distance to any mine is represented by a blue continuous, magenta dashed and brown dotted line, respectively. Ambient air Tair (red), ground temperature Tg (blue) and thermal loads \({\dot{Q}}_{{{{{{{{\rm{H}}}}}}}}}\) (red) and \({\dot{Q}}_{{{{{{{{\rm{C}}}}}}}}}\) (blue) for each SFH located in (b) Rhenish area and (c) Latrobe Valley. Basemap for panel (a) obtained from OpenMapTiles.org75.

Basis for the techno-economic assessment

The residential thermal demand for each zone is studied by considering clusters of single-family houses (SFHs). Freely available Typical meteorological year (TMY) datasets obtained from refs. 32,33 are used as weather forcing (Fig. 1b and c). The hourly thermal demand (Fig. 1b and c) of the SFHs is calculated using the 5R1C circuit simplified method implemented in34 as described in the EN-ISO 13790 standard35. This study focuses on residential use for SFHs but can be extended to other residential building typologies, and commercial and industrial uses (affecting the thermal load profiles).

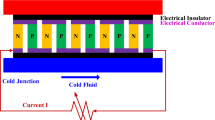

Two potential network configurations are considered for the analysis. First, a decentralised case representing an ambient temperature network (Fig. 2a) where a transmission pipeline connects the mine through a heat exchanger (HX) to the consumers. The consumers satisfy their heating (QH) and cooling (QC) demands using a reversible heat pump (HP), extracting or rejecting heat back to the mine. Secondly, a centralised case, representing a Fourth Generation District Heating (4GDH) network, is modelled (Fig. 2b). The transmission pipeline connects the mine-water source to a centralised HP operating only on heating mode. The consumer exchanges heat with the centralised HP through an heat interface unit (HIU) to fulfil its QH demand, while an individual reverse cycle air conditioner (RCAC) must satisfy the QC demand. The decentralised and centralised cases consider the availability of electricity at different prices: electricity sold at industrial/commercial consumer price (ELind) for shared components and electricity sold at residential consumer price (ELcons) for individual consumer components.

a Decentralised Case: consumers extract or reject heat to satisfy their heating QH and cooling QC demand using an individual reversible HP directly onto the thermal network. The network is composed of two pipes supplying and retrieving water for heat exchange with the mine using a centralised heat exchanger (HX). b Centralised Case: a centralised HP connected to the thermal network fulfils the cluster of consumers heating demand QH through a HIU, while an individual RCAC satisfies the cooling demand QC. c The individual consumer considered as a benchmark for the study includes a RCAC to satisfy its cooling demand QC and a RCAC plus/or a gas boiler to satisfy its heating demand QH.

The decommissioned mine acts as a free low-grade thermal source connected to the cluster of consumers through a transmission pipeline. Given its spatial dependence, the distribution network among the consumers is not considered. A benchmark case is also modelled, where residential consumers meet their heating and cooling needs using individual thermal sources as shown in Fig. 2c. The main parameters of the model are presented in Table 1.

The economic assessment is performed considering the investment costs Cinv, operation and maintenance costs Co&m, and commodities costs Ccomm, using the equivalent annual cost CEAC, defined as the sum36:

The investment costs Cinv comprise the annualised cost of the materials and installation of the components. Because different components have a different lifetime duration, Cinv considers repeated investments over time, as defined in the OEMOF tools subpackage37, assuming no changes in capital costs over time:

where Ccap corresponds to the total capital investment costs, i represents the interest rate, set to 3% for the analysis, n is the assessment’s time horizon, set to 30 years for the present study, and u corresponds to the lifetime duration of each component. The operation and maintenance costs Co&m refer to the annual maintenance and operation (in addition to commodities) required for the correct network operation. A summary of the components’ investment, operation and maintenance cost is presented in Table 2 and Supplementary Tables 1 and 2 for the transmission pipes. The commodities cost Ccomm is incurred by the consumption of commodities, electricity and gas, determined by the operation optimisation in the model. Each location’s electricity and gas prices are also summarised in Table 2.

The results of the simulations presented in the following section are reported utilising the Levelised cost of energy (LCOE), which allows the comparison of cases with varying thermal demands (number of consumers), defined as:

where the total thermal demand Qtot in the case of a full year of operation corresponds to the sum of the annual heating and cooling energy demand:

To ease the visualisation of the economic competitiveness assessment of the thermal system, a LCOEnorm is defined:

where the difference between the LCOE for the thermal system LCOEthermal system and the LCOE for the individual sourcing system LCOEind. source is normalised by the LCOEind. source, considering the same conditions in both cases. A positive LCOEnorm means a thermal system with a lower LCOE than the individual source system, thereby economically competitive under the analysed conditions.

Each analysed region is characterised by a base case of study, where the commodities price match the values presented in Table 2, and the thermal network utilises non-insulated PE pipes for the transmission. The source temperature depends on each region’s water extraction method, location, and specific weather conditions, as described in the “Methods” section. To simplify the comparison between both areas, a value of 10 °C is defined as the base case for both. Multiple transmission lengths and consumer cluster sizes are considered for each base case.

Sensibility analyses are carried out to understand the role of the temperature of the source Tsource given the extensive range of potential values available, the type of pipes used for the transmission, insulated or non-insulated, and the cost of electricity, as a critical commodity in the operation of the network. A summary of the considered values for sensibility is presented in Supplementary Table 3.

Results and discussion

Base scenario

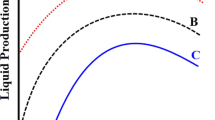

The number of consumers connected to the thermal network provides two critical inputs for the transmission design and operation: the total annual thermal demand Qtot and maximum peak loads \({\dot{Q}}_{{{{{{{{{\rm{c}}}}}}}}}_{-p}}\) and \({\dot{Q}}_{{{{{{{{{\rm{H}}}}}}}}}_{-p}}\). To understand the relationship between the consumer’s thermal demand, the transmission length and the system costs, the LCOE values are plotted against the Qtot per transmission length in semi-log scale (Q/L) for the base scenario in Fig. 3. Supplementary Fig. 1 presents the LCOE as a function of the transmission length for the same scenario, for varying number of consumers.

a NRW, Germany—decentralised case, b VIC, Australia—decentralised case, c NRW, Germany—centralised case, d VIC, Australia—centralised case. Base source temperature and electricity prices are considered for all the presented results. Different numbers of consumers are shown in different colours and markers, as summarised in panel (b). The shaded grey area represents the economic competitiveness of the geothermal systems.

As a general trend, in Fig. 3, the LCOE decreases sharply until it reaches around 1 MWh m−1, where it begins to stabilise in both cases of analysis for both regions. For a Q/L larger than 1 MWh m−1, the LCOE decreases at a lower rate until it reaches around 1 × 102 MWh m−1 where the LCOE stabilises almost wholly. This last transition relates to the point where the preponderance of the transmission investment costs in the LCOE subsides. Since the set of assessed transmission lengths is fixed, the range of the LCOE for each consumer cluster is determined by the Qtot value, directly dependent on the number of consumers.

The centralised case presents an overall lower LCOE (Fig. 3c) relative to the decentralised case (Fig. 3a) for NRW. On the other hand, the centralised case (Fig. 3d) in VIC fares worse when compared to the decentralised case (Fig. 3b). These results are attributed to the economies of scale in the heat pump costs per kW for centralised vs. decentralised configurations (Table 2), but more importantly, to the industrial/consumer electricity price ratio, estimated as 0.56 for NRW and 0.81 for VIC (Table 2). A lower industrial electricity cost allows the centralised heat pump to operate at a cheaper rate when compared to individual heat pumps affected by consumer electricity costs. Nevertheless, the higher electricity price ratio is not enough to offset the additional investment required for an RCAC for cooling purposes in the centralised case in VIC (almost four times the peak cooling load to the SFH in the NRW region, see Table 1) and its lower efficiency, visualised in the overall lower competitiveness of the centralised thermal network in VIC.

Role of source temperature and insulation

Figure 4 presents the variation in LCOE by Q/L for varying temperature source values. There is a general decrease in the LCOE as the source temperature increases, as expected for heating-dominated thermal demands. Interestingly, the stabilisation behaviour discussed in the previous section still withstands different Tsource temperatures. This agrees with the selection of Q/L as a control variable for the assessment, even when particularities around heat loss arise, as discussed next.

a NRW, Germany—decentralised case, b VIC, Australia—decentralised case, c NRW, Germany—centralised case, d VIC, Australia—centralised case. Base electricity prices are considered for all the presented results. Different source temperatures are shown in different colours and markers, as summarised in panel (b). The shaded grey area represents the economic competitiveness of the geothermal systems.

In the case of the decentralised case in VIC (Fig. 4b), a convergence in the LCOE values for Tsource around 40 and 50 °C is observed for larger Q/L values. The operational efficiency is determined by the fluid temperature that reaches the HP. The losses along the transmission are governed by the pipe properties and the ground temperature, which is, on average, 3.3 °C higher on VIC than on NRW (Table 1). It follows then that thermal losses along the transmission system have minimal impact on the efficiency of the heating coefficient of performance (COP) for temperatures above 40 °C, while they remain significant for NRW due to the reduced ground temperature and consequently higher heat losses.

The increase in the source temperature also affects the cooling efficiency of the HP for the decentralised case. At the same point, for the decentralised case in the NRW region, the cooling load is too low to impact the LCOE significantly (Table 1). The relevance of the higher ground temperature and cooling COP in the VIC decentralised case results in overall lower improvements of the LCOE with increasing Tsource, and thus a tighter band of results relative to NRW. In the rest of the cases, only the heating COP efficiency of the thermal network remains relevant, showing an initially larger LCOE results band shrinking with increasing Q/L.

Interestingly, in the centralised cases (Fig. 4c and d), little benefit is obtained from higher temperature sources (>10 °C) for low Q/L values (below 1 × 10−2 MWh m−1). Given the considerable transmission length in these cases (5000 and 10,000 m), significant heat losses occur through the fluid passing by the transmission. Although the mass flow could be increased to reduce the thermal losses in the interaction with the ground, the solver found no further benefit in the LCOE due to the large pumping costs required to overcome the pressure losses. The transmission pipeline for both cases corresponds to a PE pipe (non-insulated), considering the source temperature close to shallow ground temperatures for the base scenario. In the case of higher temperatures, we are interested in studying the role of insulated pipes in the system.

Figure 5a and b shows the variation in the LCOE as a function of Tsource for selected transmission lengths between 100 to 10,000 m for 1000 consumers and two types of insulation for the decentralised case in both regions. In general, the use of insulated pipes for transmission shows negligible improvement in the LCOE in VIC (Fig. 5b); either the insulated pipe case barely reduces the LCOE or end-ups more expensive overall. In the NRW case (Fig. 5a), the role of insulation in the LCOE is dissimilar for the transmission lengths and Tsource combinations. The insulated LCOE is higher in the case of the insulated pipe for Tsource below 20 °C for transmission lengths 5000 and 10,000 m but remains the same as the non-insulated case for lower transmission lengths. While for Tsource above 30 °C, transmission lengths equal to 1000 m and below show a reduction in the LCOE, while for lengths 5000 and 10,000 m, practically identical LCOEs are achieved for both cases of transmission insulation.

a Total LCOE for NRW, Germany, b Total LCOE for VIC, Australia, c Disaggregated LCOE for NRW, Germany, transmission length = 100 m, d Disaggregated LCOE for VIC, Australia, transmission length = 100 m, e Disaggregated LCOE for NRW, Germany, transmission length = 10,000 m, f Disaggregated LCOE for VIC, Australia, transmission length = 10,000 m. Results for 1000 consumers, decentralised case. Base electricity prices are considered for all the presented results. In panels (a) and (b), different colours and markers are used for transmission length values and the use of insulation (no insulation—No Ins or insulation—S3), respectively, as summarised in the legend to the right of the figure. The shaded grey area in panels (a) and (b) represents the economic competitiveness of the geothermal systems. LCOE is disaggregated among maintenance (blue), investment (pink) and commodities (green) costs in panels (c)–(f).

Delving further into the impact of insulation, Fig. 5c–f shows the cost disaggregation in terms of investment, maintenance and commodities cost as a proportion of the LCOE. Maintenance cost mostly represents a fixed annual value and, as such, remains almost a constant contribution to the LCOE for all cases. Regarding investment costs, their contribution to the LCOE is more significant for the 10,000 m transmission length due to the additional cost of the insulated pipes. For the commodities costs, dependent on the operational performance, an overall reduction of its contribution to the LCOE is observed as temperature increases for all cases, as expected.

Comparing insulated and non-insulated commodities costs, for the length equal to 100 m case, a slight improvement by the insulated pipe case is observed for temperatures equal to 30 °C or above. At lower temperatures, performance by the non-insulated case is similar or slightly better, attributed to the heat gains from the ground allowed by the pipe’s higher thermal conductivity. For the scenario with a length equal to 10,000 m, the relevance of thermal performance is exacerbated, allowing further improvements in the commodities costs for high-temperature conditions with insulated pipes, which are, in turn, neglected by the higher investment costs.

Notably, the previous behaviour occurs due to the optimisation model’s disregard for the system heat losses. The cost of obtaining the thermal source is assumed to be null, so using additional mass flow from the source only incurs additional transmission pumping costs while reducing heat losses. Another relevant consideration is that the insulated pipe considered in this study corresponds to steel pipes. In contrast, the non-insulated pipes are made from polyethylene (PE), with the latter having a lower surface roughness and, as such, having a larger maximum available mass flow when compared to insulated pipes of the same diameter (Supplementary Tables 1 and 2). This results in insulated pipes with a larger inner diameter than their non-insulated counterpart for the same thermal load. The addition of a variable accounting for temperature source production cost could provide further insights into the value of insulation, which falls outside the scope of the current study.

Similar behaviour is appreciated in the centralised thermal network scenario, as shown in Supplementary Fig. 2. For a fixed temperature and varying electricity price, a linear increase of 25–40 EUR MWh−1 in the LCOE per 0.1 EUR kWh−1 for all cases, as shown in the Supplementary Fig. 3.

Economic competitiveness

Figure 6 presents the economic competitiveness of the decentralised and centralised thermal systems, characterised by the LCOEnorm (Eq. (5)), as a function of the consumer electricity price, for both regions of analysis. As Q/L increases, the average competitiveness of the system rises while the variance for a given range reduces. All cases of analyses show a clear maximum of LCOEnorm relative to the individual consumer thermal provisioning around an electricity price of 0.3 EUR kWh−1. This hinge point is where the individual thermal source optimal design switches from only an RCAC to a gas boiler as the main component satisfying heating demand plus an RCAC to meet cooling demand and provide additional heating for peak demand (Supplementary Fig. 4). The almost identical hinge point occurs due to the study simplification of considering equal component costs in both regions. The increasing competitiveness below 0.3 EUR kWh−1 is attributed to the comparative better operational performance of the thermal networks to the RCAC. This result highlights the importance of sensitivity analysis, as the distance of the considered base price (Table 2) to the hinge point has a significant impact on the assessed competitiveness of the system for a base case scenario.

Decentralised cases: a VIC—Tsource: 10 °C, b VIC—Tsource: 30 °C, c VIC—Tsource: 50 °C, d NRW—Tsource: 10 °C, e NRW—Tsource: 30 °C, f NRW—Tsource: 50 °C. Centralised cases: g VIC—Tsource: 10 °C, h VIC—Tsource: 30 °C, i VIC—Tsource: 50 °C, j NRW—Tsource: 10 °C, k NRW—Tsource: 30 °C, l NRW—Tsource: 50 °C. Different Q/L ranges are shown in different colours, as appreciated in the legend at the bottom of the figure. The plotted LCOEnorm values correspond to the lower LCOEnorm between both analysed insulation cases, a circle when the non-insulated transmission is cheaper and a triangle otherwise. Results for varying Q/L are displaced horizontally for clarity but correspond to the same electricity price considered in each analysis. The grey and light brown shaded area corresponds to results above and below the economic competitiveness line, respectively. Results for cases with Q/L below 1.0 MWh m−1 are excluded for clarity. Due to maximum flow restrictions, only non-insulated pipes were considered for cases with consumers equal to 20,000.

The economic competitiveness of the thermal system improves with increasing Tsource, for all Q/L cases. For the base Tsource equal to 10 °C, all the decentralised thermal system configurations are found below the LCOEnorm nil line (economic competitiveness frontier) for VIC (Fig. 6a), while few cases with Q/L larger than 10 MWh m−1 are found above the frontier for NRW (Fig. 6d). When the results for both regions are compared, similar trends are appreciated between 0.1 and 0.3 EUR kWh−1, where the higher efficiency of the thermal system gains more value, relative to the higher investment requirements. In contrast, a higher decrease in competitiveness is seen at electricity costs above 0.3 EUR kWh−1 for NRW relative to VIC, particularly for Tsource equal to 30 °C (Figs. 5b and 6d). This behaviour is attributed to the higher cooling demand in VIC, causing the electricity cost in the individual thermal sourcing to remain relevant. Conversely, most thermal needs are satisfied by sourcing gas for the boiler in the individual NRW benchmark case.

Economic competitiveness for the centralised cases is shown in Fig. 6g–l. Relative to the decentralised case, a lower increase in the competitiveness of the system occurs with increasing Tsource. At the same time, for the results for Tsource equal to 50 °C (Fig. 6c, f, i and l), a larger variance among the results for the same Q/L range is observed. This is explained by the differences in the design consideration for both networks, while the decentralised cases allow for a variable temperature change on the evaporator side (for heating), assuming that the consumers would operate independently, while the centralised case uses a fixed value for the temperature decrease on the centralised heat pump evaporator, as it would be limited by the heat exchanger design, which reduces the HP COP.

In line with the analysis in the previous subsection, no clear trend is observed for the need for transmission insulation in both centralised and decentralised cases. Therefore, the need for insulation should be assessed on a case-by-case basis. These results reflect the behaviour of a system with a free temperature source in this techno-economical study. From an exergy point of view, however, higher temperature sources would benefit significantly from insulation.

Conclusions

This study provides a first approach to assessing the provisioning of heating and cooling using decommissioned open pit mines for nearby population centres and identifies general conditions for techno-economic competitiveness for implementation. Two locations of analysis with the same climate classification have been assessed, considering identical component costs to facilitate the assessment. Still, significant differences in the performance and competitiveness of the thermal networks were observed. It follows then that extrapolation to other locations must be done with care, performing an accurate assessment of its particular conditions, such as these required inputs.

Overall, geothermal networks with larger transmission lengths remain competitive for a more significant number of consumers and, consequently, a larger total thermal load. The prevalence of transmission investment costs in the LCOE relates to the ratio between the total thermal load and the transmission length Q/L, where a value around 1 MWh m−1 was found to be the inflection point for the change in the cost curve behaviour for the cases analysed. The current study does not include subsidies, decarbonisation incentives, or penalties, which would improve the thermal system’s economic competitiveness relative to other solutions.

A general decrease in the LCOE with increasing mine temperature was observed, more profoundly for systems with more connected consumers. Interestingly, using insulation for the transmission pipelines improved the system economics for the Rhenish area (NRW) region in limited cases. Negligible improvement was found in the Latrobe Valley (VIC) case. This behaviour is explained by compensation of the efficiency improvements with insulation by increased investment cost in the insulated pipeline. Moreover, since the optimisation model did not account for the system’s efficiency in its objective, and the source temperature is assumed to be of free access, it only incurs additional pumping costs when increasing the transmission fluid mass flow.

The LCOE of the system increases as the electricity price increases, with more considerable differences seen for a lower number of connected consumers. Compared to individual thermal supply sources, it is highlighted that changes in commodity prices may significantly impact the individual system costs, thus reducing the thermal network’s relative economic competitiveness. For the case of analysis in particular, a hinge point in economic competitiveness occurs around consumer electricity prices close to 0.3 EUR kWh−1, which depends on the components’ cost and the relation between the commodities prices.

Among the current model’s limitations are the consideration of a constant temperature source and commodities prices. Regarding transmission operation, steady-state conditions have been considered for the hydraulic balances and calculating thermal transfer between the transmission pipelines and the ground. A more detailed assessment could be performed38, although increasing model complexity and computational costs. In the case of ambient temperature networks designed following the 5th generation thermal network definitions39, an additional consideration is the demand balancing among the prosumers, which reduces overall costs and increases the system efficiency40. This is not considered in this study since thermal balance is impossible when consumers/prosumers have a similar heating and cooling demand profile41. Demand balancing among consumers would improve the prospects of the ambient temperature networks (decentralised), as the operational and investment costs given the increase in the Q/L for the thermal system.

The study includes realistic economic evaluations, given its relevance for the successful implementation of future mine closure projects. The thermal system may be economically competitive under the assessment’s source temperature conditions and commodities prices. However, distribution costs and additional source exploitation costs must also be assessed on a case-by-case basis. The dynamics of the source temperature, the available thermal energy, and the best way to exchange heat with the mine during its many closure phases and associated costs, depending on the time of geothermal project implementation, are crucial to producing more detailed assessments. This topic will be the object of future studies by the authors.

Methods

Location of analysis

The coal mines in the Latrobe Valley are within the Latrobe City Regional Area, with three main cities along the valley: Moe, Morwell, and Traralgon; and smaller towns located on the periphery, with the more densely populated Melbourne located 200 km away from the area, (Fig. 1a). On the other hand, the Rhenish Area has more numerous and densely populated population centres, with Aachen, Cologne and Leverkusen being the largest ones.

The residential building stock in the Latrobe-Gippsland region in Australia consists primarily of SFHs, totalling 88% of the total number of dwellings42, with the rest 12% of the dwellings divided between terraced houses and multi-family houses. On the contrary, SFHs correspond to 34% of the total dwellings in the Rhenish Area, while terraced houses and multi-family houses have the remaining 14% and 52%43, respectively. The proportions in the building stock are consistent with the higher population density observed in the Rhenish Area relative to the Latrobe Valley region. A black star in Fig. 1a marks the population centre at a distance of 10 km or less from a mine, closer to the maximum number of consumers assessed in this study for each region. The number of consumers analysed in the study was kept to 20,000 or less due to a restriction imposed by the maximum inner diameter of the pipes found in the catalogue (994 mm for PE pipes, see Supplementary Tables 1 and 2).

Meteorological conditions and thermal loads

The residential thermal demand for each zone is assessed considering clusters of one or more SFHs under representative meteorological conditions determined by TMY obtained from freely available data sets for the location of interest in32,33. The hourly thermal demand of the SFHs is calculated using the 5R1C circuit simplified method implemented in ref. 34, described in the EN-ISO 13790 standard in the ‘simple hourly method’ section35. The method was selected as a compromise between complexity and available parameters to use as inputs for the modelling of representative buildings.

The method considers the building as a single thermal zone, modelled by a ‘five resistances—one capacitance’ thermal circuit. The model allows for the consideration of sensible heat transfer between the thermal zone and the environment. Five thermal nodes are considered: external temperature, thermal mass temperature, heat pump supply temperature, internal air temperature and internal room surface temperature. A single capacitance value models the building’s thermal mass. Additionally, heat gains of solar and internal origin are also accounted for in the calculations. As detailed in ref. 34, an ordinary differential equation is solved in terms of the thermal mass temperature Tm, using a Crank–Nicholson discretisation. A thermostat temperature is set between 20 and 22 °C. The calculation estimates the required heat pump heat flux to avoid Tm exceeding the thermostat range, which serves as input for this study.

The standard SFH described in ref. 44 is used as a reference for the Australian case. In the German case, the geometrical and thermal properties of a typical SFH were sourced from the TABULA database43 for a property built between 1995 and 2001, with the minimal required insulation standard. The ambient temperature and heating and cooling loads time series are presented in Fig. 1b and c. Table 1 summarises the input data required for the thermal load’s calculations for the 5R1C method, the estimated peak load for each location’s SFH, and the total heating/cooling demand.

The ambient temperature and heating and cooling loads time series are presented in Fig. 1b and c. The residential thermal demand in both regions is heating-dominated. Even though lower ambient air temperatures occur in the Rhenish Area when compared with the Latrobe Valley, the estimated total heating load for the Australian case is significantly higher (18.7 MWh relative to 15.4 MWh). This is attributed to the poor insulation of the Australian representative building, as noted already in ref. 44.

Hourly ambient air temperature (Tair) and solar irradiance data are needed to estimate the houses’ thermal performance. TMY data sets provide representative time series of both parameters and additional meteorological data (relative humidity, wind speed, etc.) for every hour in a year. Both regions have a temperate oceanic climate (Cfb)45. A temperate climate means both areas have moderate annual average temperatures and significant temperature differences between summer and winter, as visualised in Fig. 1b and c for the air temperature Tair.

The undisturbed ground temperature (Tg) is used to calculate the thermal interaction between the ground and the transmission pipes. Using the approach proposed by Düber et al.46, the hourly undisturbed ground temperature Tg(z) at a depth z is estimated by convolution in the frequency space between the increase of the ambient air temperature ΔTair and the thermal response function of the ground gair(t) over time t47:

with gair(t) equal to:

and \({\overline{T}}_{{{{{{{{\rm{g}}}}}}}}}\):

where \({{{{{{{\mathcal{F}}}}}}}}\) and \({{{{{{{{\mathcal{F}}}}}}}}}^{-1}\) are the Direct Fourier Fast Transform (FFT) and inverse Fourier Fast Transform (iFFT). \({\overline{T}}_{{{{{{{{\rm{air}}}}}}}}}\) is the yearly mean ambient temperature and α is the thermal diffusivity of the soil. The ground temperature Tg time histories obtained for each region are presented in Fig. 1b and c.

In the case of the thermal source, the water would come from pumped groundwater before its treatment or directly from the pit lake utilising an open or closed loop system. The water temperature will vary depending on its origin. In the case of pumped groundwater, extracted temperatures of 26 °C have been documented in the Hambach mine in Rhenish Area48, while temperatures between 30 and 70 °C are found in water pumped from aquifers below the open pits at the Latrobe Valley49.

For thermal exchange with the pit lake, extracted fluid temperatures will depend on the pit lake thermal regime, extraction depth and time in the stratification season, if applicable. When lakes experience cold winters, deep constantly cold waters (4–5 °C) are a common occurrence at the hypolimnion50. In contrast, the surface water (epilimnion) experiences shifts in the water temperature in concordance with the ambient temperatures. Between the hypolimnion and the epilimnion, a sharp temperature gradient occurs (thermocline). Pit lakes in temperate regions are commonly holomictic, where the pit lake water experiences a complete water mix due to circulation between upper and bottom layers one or more times per year51. The cold waters at the lake’s surface begin to warm in the autumn progressively into the summer, where a clear stratification is observed. With the arrival of winter, the temperature differences between the surface and the bottom of the lake reduce until its eventual mix as the surface waters go below the 4 °C threshold50,51.

Thermal provisioning and model formulation

The economic feasibility calculation requires a model for the operation of the proposed thermal systems. An optimisation approach is selected to perform this study, where technical requirements are added as mathematical constraints. The obtained solution optimality is guaranteed for the desired objective function (minimisation of costs), within the specified tolerances. A common optimisation approach used in thermal systems is mixed integer linear programming (MILP) formulations52, such as the open-source general energy system tools OEMOF37, PyPSA53 or Calliope54. These frameworks come with predefined components already available for model generation and with the potential to implement user-defined models if required. Integer variables allow the model to account for the operational status of the components (on/off) and different modes of operation.

To maintain linearity of the system constraints, mixed integer linear programming formulations must simplify cooling and (more often) heating as transported thermal energy commodities with a fixed temperature38. This simplification disregards the role of carrier fluid temperature and mass flow on heat losses and the temperature dependence of HP efficiency, particularly relevant for extended pipeline lengths55. The COMANDO29 package offers the possibility to formulate mixed integer quadratically constraint programming (MIQCP), to directly account for energy and mass balances in the system constraints, while retaining its open-source component-oriented and solver agnostic capabilities.

Therefore, the study framework is developed in Python, utilising the COMANDO package. COMANDO has already been successfully used to analyse the design and operation optimisation of district heating networks38,56,57. The optimisation problem is defined through the thermal network components, using symbolic expressions that specify constraints or objective functions. Components are linked through buses, allowing the flow of energy quantities or commodities among them29. The problem objective is to minimise operational costs, considering a one-year operation, using an hourly time step.

To reduce the computational load, a time series aggregation is performed using typical days, utilising the freely available tool TSAM58. The K-medoid method is selected for typical days determination for its documented high-quality output for energy system modelling38,59. Literature suggests at least 12 typical days to model a whole year of operation with good accuracy60. Given the size of the formulated problem, 12 days typical days are used to model the yearly operation, plus two design load days, corresponding to the days of maximum heating and cooling demand at each region. Finally, after the formulation, the commercial solver GUROBI, version 10.0.0.61, is used to solve the problem of optimality for a relative MIP optimality gap (MIPGap) value of 0.0161.

Two potential network configurations are considered for the analysis. The first is a decentralised case that represents the construction of an ambient temperature network (Fig. 2a). The decommissioned mine acts as a low-grade thermal source, connected by a secondary loop to the thermal transmission line through a HX. The transmission line, consisting of an inflow and return pipeline made of polyethylene (PE) without insulation, pumps the low-temperature fluid to the consumers, who use a water source heat pump (HP) to fulfil their heating/cooling demands at their required temperature.

The second alternative is a centralised pump case (Fig. 2b), representing a Fourth generation district heating/low-temperature thermal network. In this case, the temperature is elevated at a centralised heat pump plant installed ahead of the consumers. The water is sent from the mine to the heat pump through non-insulated PE pipes. The heat pump supplies heat to the consumers, who require the installation of a HIU for connection to the network. Since the network only provides heating in this case, the cooling demand of the consumers is satisfied by the installation of an individual RCAC. Finally, an additional case is modelled, where the residential consumers meet their heating and cooling needs by utilising individual thermal sources. This case is used as a baseline for comparison of the economic competitiveness of the thermal networks.

Given its spatial dependence, the distribution network among the consumers is not considered. Additionally, to reduce the computational load, the centralised heat exchanger and the HIU components are not modelled explicitly in the optimisation problem, as their relevance in the operational control and costs is not significant for our purposes. Both components are sized accordingly to each scenario’s conditions to account for the required investment costs.

All the components of an energy network can be classified as sources, sinks, or transformers37. The network sources correspond to the decommissioned mine’s thermal source mass flow rate and the commodities (gas and electricity) from the distribution grids. Previous studies have found that geothermal systems would have negligible impact on the thermal balance of the whole water bodies of large lakes23,62. Then, the source temperature Tsource is an input parameter assumed to be constant during the simulation for simplicity. Consumers are modelled as sinks, imposing a heating and cooling demand in the system that must be satisfied by the optimisation model while minimising costs.

The source and sinks of the system are connected by transformer components, including the pipe that transports the water to the consumers while consuming electricity and incurring thermal gains or losses. The HX and HIU allow the connection of different thermal subsystems. The HP uses electricity to upgrade the temperature of the thermal network to reach the desired temperatures for heating or cooling. The RCAC functions similarly, boosting the outside air temperature to satisfy the consumer’s individual heating and cooling demands. Finally, the boiler uses gas to meet the heating demand of the individual consumer in the benchmark case. The equations describing each component are included in the supplementary material for completeness (Supplementary Note 1), while design parameters are provided in Supplementary Table 4.

Costs and economic analysis

District heating and cooling networks adoption and development is primarily concentrated in Europe39,63. The components investment costs, lifetime values and O&M costs for the RCAC64 and the Centralised HP65 come from datasets where a general price for Europe was considered and were included as such in the study. Other component datasets were specifically developed for Germany or used exclusively German data, such as the Decentralised HP66 and the non-insulated PE pipe67. Finally, the costs of the rest of the components were obtained from the Danish Energy Agency (DEA) technology data sources68 (Gas Boiler and the HIU) or from datasets explicitly developed from the Danish market, such as the insulated pipes69. In the absence of specific information for Germany, DEA technology catalogue prices were adjusted using the purchase power parities index70, considering:

where cGER is the cost of the component in Germany, cDK is the cost in Denmark and PPPDK and PPPGER correspond to purchasing power parities (PPP) for investment values in 202171, equal to 118 and 121, respectively. All component costs are adjusted for inflation in Germany between the source date and June 2022.

The costs of components estimated for the German case are directly used in the case of the Australian analysis, based on the absence of cost sources for most of the components in question (district heating/cooling networks, centralised heat pumps, district heating units) and to facilitate the comparison between the analyses in both locations. Finally, the commodities costs (electricity and gas prices) for industry and consumer prices for Germany and Australia were obtained from freely available sources by refs. 72, 73 for Germany and Australia, respectively.

Data availability

The study has not generated new raw data. The datasets utilised in the analysis are publicly available, with appropriate links for each one found in the reference list. Additionally, simulation data used to generate the figures in this paper is available in .csv format in https://doi.org/10.26188/25440223.

Code availability

The base code that sustains the optimisation model used in this study is available at https://github.com/GUT-Aachen/mine_thermal_energy_transport.

References

IEA. Coal in Net Zero Transitions https://www.iea.org/reports/coal-in-net-zero-transitions (2022).

IEA. World Energy Outlook 2021 https://www.iea.org/reports/world-energy-outlook-2021 (2021).

IRENA. Renewable Energy in District Heating and Cooling: A Sector Roadmap For Remap (International Renewable Energy Agency, 2017). www.irena.org/remap.

IEA. Net Zero by 2050 https://www.iea.org/reports/net-zero-by-2050 (2021).

Yanguas Parra, P. A. et al. Global and Regional Coal Phase Out Requirements of the Paris Agreement Insights from the IPCC Special Report on 1.5°C. https://climateanalytics.org/publications/global-and-regional-coal-phase-out-requirements-of-the-paris-agreement-insights-from-the-ipcc-special-report-on-15c (2019).

Stanley, M. et al. Managing Coal Mine Closure: Achieving a Just Transition for All http://documents.worldbank.org/curated/en/484541544643269894/Managing-Coal-Mine-Closure-Achieving-a-Just-Transition-for-All (2018).

McCullough, C. D. & Lund, M. A. Opportunities for sustainable mining pit lakes in Australia. Mine Water Environ. 25, 220–226 (2006).

ICMM. Integrated Mine Closure: Good Practice Guide https://www.icmm.com/en-gb/guidance/environmental-stewardship/2019/integrated-mine-closure (2019).

McCullough, C. D. Approaches to remediation of acid mine drainage water in pit lakes. Int. J. Min.Reclam. Environ. 22, 105–119 (2008).

Schultze, M., Geller, W., Benthaus, F.-C. & Jolas, P. Filling and management of pit lakes with diverted river water and with mine water—German experiences. In Mine Pit Lake Closure and Management (ed. McCullough, C. D.) 107–120 (Australian Centre for Geomechanics, 2011).

Keenan, J. & Holcombe, S. Mining as a temporary land use: a global stocktake of post-mining transitions and repurposing. Extr. Ind. Soc. 8, 100924 (2021).

McCullough, C. D., Schultze, M. & Vandenberg, J. Realizing beneficial end uses from abandoned pit lakes. Minerals 10, 133 (2020).

Schultze, M., Vandenberg, J., McCullough, C. D. & Castendyk, D. The future direction of pit lakes: Part 1, Research needs. Mine Water Environ. 41, 533–543 (2022).

Preene, M. & Younger, P. L. Can you take the heat? - Geothermal energy in mining. Mining Technology 123, 107–118 (2014).

Narsilio, G. A. & Aye, L. Shallow geothermal energy: an emerging technology. In Low Carbon Energy Supply, Trends, Technology, Management (eds Aye, L., Sharma, A. & Shukla, A.) (Springer, 2018).

Hattingh, R., Stevens, R. & Bliss, M. Global Review: Financial Assurance Governance for The Post-mining Transition. https://www.iisd.org/system/files/2021-09/financial-assurance-governance-for-post-mining-transition.pdf (2021).

Loveridge, F., McCartney, J. S., Narsilio, G. A. & Sanchez, M. Energy geostructures: a review of analysis approaches, in situ testing and model scale experiments. Geomech. Energy Environ. 22, 100173 (2020).

Patsa, E., Van Zyl, D., Zarrouk, S. J. & Arianpoo, N. Geothermal energy in mining developments: synergies and opportunities throughout a mine’s operational life cycle. In Proc. of the World Geothermal Congress 2015 (eds Horne, R. & Boyd, T.). (International Geothermal Association, 2015-04-19/2015-04-25).

Chu, Z., Dong, K., Gao, P., Wang, Y. & Sun, Q. Mine-oriented low-enthalpy geothermal exploitation: a review from spatio-temporal perspective. Energy Convers. Manag. 237, 114123 (2021).

Loredo, C., Roqueñí, N. & Ordóñez, A. Modelling flow and heat transfer in flooded mines for geothermal energy use: a review. Int. J. Coal Geol. 164, 115–122 (2016).

Banks, D., Athresh, A., Al-Habaibeh, A. & Burnside, N. Water from abandoned mines as a heat source: practical experiences of open- and closed-loop strategies, United Kingdom. Sustain. Water Resour. Manag 5, 29–50 (2019).

David, A., Mathiesen, B. V., Averfalk, H., Werner, S. & Lund, H. Heat roadmap Europe: large-scale electric heat pumps in district heating systems. Energies 10, 578 (2017).

Gaudard, A., Weber, C., Alexander, T. J., Hunziker, S. & Schmid, M. Impacts of using lakes and rivers for extraction and disposal of heat. WIREs Water 5, e1295 (2018).

Pieper, H., Ommen, T., Elmegaard, B. & Brix Markussen, W. Assessment of a combination of three heat sources for heat pumps to supply district heating. Energy 176, 156–170 (2019).

Kindaichi, S., Nishina, D., Wen, L. & Kannaka, T. Potential for using water reservoirs as heat sources in heat pump systems. Appl. Therm. Eng. 76, 47–53 (2015).

Gaudard, A., Wüest, A. & Schmid, M. Using lakes and rivers for extraction and disposal of heat: Estimate of regional potentials. Renew. Energy 134, 330–342 (2019).

Wang, G., Wang, W., Luo, J. & Zhang, Y. Assessment of three types of shallow geothermal resources and ground-source heat-pump applications in provincial capitals in the Yangtze River Basin, China. Renew. Sustain. Energy Rev. 111, 392–421 (2019).

Möller, B. et al. Heat Roadmap Europe: towards EU-Wide, local heat supply strategies. Energy 177, 554–564 (2019).

Langiu, M. et al. COMANDO: a next-generation open-source framework for energy systems optimization. Comput. Chem. Eng. 152, 107366 (2021).

Teague, B., Catford, J. & Roper, A. Hazelwood Mine Fire Inquiry Report 2015/2016 Volume IV - Mine Rehabilitation http://hazelwoodinquiry.archive.vic.gov.au/wp-content/uploads/2015/09/Hazelwood-Mine-Fire-Inquiry-Report-2015-2016-Volume-IV-%E2%80%93-Mine-Rehabilitation-web.pdf (2016).

Gesley, J. Germany: Law on Phasing-out Coal-powered Energy by 2038 Enters into Force www.loc.gov/item/global-legal-monitor/2020-08-31/germany-law-on-phasing-out-coal-powered-energy-by-2038-enters-into-force (2020).

European Commission JRC. PVGIS—Photovoltaic Geographical Information System. Version 5.2.https://re.jrc.ec.europa.eu/pvg_tools/es/#TMY (2022).

Muñoz-Sabater, J. et al. ERA5-Land: A state-of-the-art global reanalysis dataset for land applications. Earth Syst. Sci. Data 13, 4349–4383 (2021).

Jayathissa, P. et al. Optimising building net energy demand with dynamic BIPV shading. Appl. Energy 202, 726–735 (2017).

ISO. EN ISO 13790: Energy Performance of Buildings: Calculation of Energy Use for Space Heating and Cooling (ISO, 2008).

Nussbaumer, T. & Thalmann, S. Influence of system design on heat distribution costs in district heating. Energy 101, 496–505 (2016).

Hilpert, S. et al. The Open Energy Modelling Framework (OEMOF)—a new approach to facilitate open science in energy system modelling. Energy Strat. Rev. 22, 16–25 (2018).

Hering, D., Faller, M. R., Xhonneux, A. & Müller, D. Operational optimization of a 4th generation district heating network with mixed integer quadratically constrained programming. Energy 250, 123766 (2022).

Buffa, S., Cozzini, M., D’Antoni, M., Baratieri, M. & Fedrizzi, R. 5th generation district heating and cooling systems: a review of existing cases in Europe. Renew. Sustain. Energy Rev. 104, 504–522 (2019).

Wirtz, M., Kivilip, L., Remmen, P. & Müller, D. 5th Generation District Heating: A novel design approach based on mathematical optimization. Applied Energy 260, 114158 (2020).

Millar, M.-A., Yu, Z., Burnside, N., Jones, G. & Elrick, B. Identification of key performance indicators and complimentary load profiles for 5th generation district energy networks. Applied Energy 291, 116672 (2021).

Australian Bureau of Statistics. Latrobe-Gippsland: 2016 Census All Persons—Quick Statistics https://www.abs.gov.au/census/find-census-data/quickstats/2016/205 (2016).

Loga, T., Diefenbach, N., Stein, B. & Born, R. TABULA—Scientific Report Germany Further Development of the National Residential Building Typology www.building-typology.eu (2015).

Aditya, G. R., Mikhaylova, O., Narsilio, G. A. & Johnston, I. W. Comparative costs of ground source heat pump systems against other forms of heating and cooling for different climatic conditions. Sustain. Energy Technol. Assess. 42, 100824 (2020).

Beck, H. E. et al. Present and future Köppen–Geiger climate classification maps at 1-km resolution. Sci. Data 5, 180214 (2018).

Düber, S., Fuentes, R. & Narsilio, G. A. Comparison and integration of simulation models for horizontal connection pipes in geothermal bore fields. Geotherm. Energy 11, 15 (2023).

Carslaw, H. & Jaeger, J. Conduction of Heat in Solids 2nd edn (Clarendon Press, Oxford, 1959).

Petersen, A. B. Handbook—Experiences from Other Urban Waste Heat Recovery Investments https://cordis.europa.eu/project/id/767429 (2017).

Beardsmore, G. Direct Use of Geothermal Energy: Global Market Scan https://lva.vic.gov.au/growth-sectors/energy/Global-Scan-Report-LVA_GS3-June-2021.pdf (2021).

Boehrer, B. & Schultze, M. Stratification of lakes. Rev. Geophys. 46, RG2005 (2008).

Schultze, M., Pokrandt, K.-H. & Hille, W. Pit lakes of the Central German lignite mining district: creation, morphometry and water quality aspects. Limnologica 40, 148–155 (2010).

Sameti, M. & Haghighat, F. Optimization approaches in district heating and cooling thermal network. Energy Build. 140, 121–130 (2017).

Brown, T., Hörsch, J. & Schlachtberger, D. PyPSA: Python for Power System Analysis. Journal of Open Research Software. 6, 4 (2018).

Pfenninger, S. & Pickering, B. Calliope: a multi-scale energy systems modelling framework. J. Open Source Softw. 3, 825 (2018).

Van der Heijde, B. Optimal Integration of Thermal Energy Storage and Conversion in Fourth Generation Thermal Networks. PhD Thesis. (KU Leuven, 2019).

Hering, D., Xhonneux, A. & Müller, D. Design optimization of a heating network with multiple heat pumps using mixed integer quadratically constrained programming. Energy 226, 120384 (2021).

Hering, D., Cansev, M. E., Tamassia, E., Xhonneux, A. & Müller, D. Temperature control of a low-temperature district heating network with model predictive control and mixed-integer quadratically constrained programming. Energy 224, 120140 (2021).

Hoffmann, M., Kotzur, L. & Stolten, D. The Pareto-optimal temporal aggregation of energy system models. Appl. Energy 315, 119029 (2022).

Kotzur, L., Markewitz, P., Robinius, M. & Stolten, D. Impact of different time series aggregation methods on optimal energy system design. Renew. Energy 117, 474–487 (2018).

Van der Heijde, B., Vandermeulen, A., Salenbien, R. & Helsen, L. Representative days selection for district energy system optimisation: a solar district heating system with seasonal storage. Appl. Energy 248, 79–94 (2019).

Gurobi Optimization, L. L. C. Gurobi Optimizer Reference Manual (Gurobi Optimization, L. L. C., 2023).

Fink, G., Schmid, M. & Wüest, A. Large lakes as sources and sinks of anthropogenic heat: capacities and limits. Water Resour. Res. 50, 7285–7301 (2014).

Lund, H. et al. 4th Generation District Heating (4GDH): Integrating smart thermal grids into future sustainable energy systems. Energy 68, 1–11 (2014).

Dittman, F., Riviere, P. & Sabat, P. Cooling Technology Datasheets in the 14 MSs in the EU28 https://cordis.europa.eu/project/id/695989/results (2016).

Pieper, H. et al. Allocation of investment costs for large-scale heat pumps supplying district heating. Energy Procedia 147, 358–367 (2018).

Wolf, S., Fahl, U., Blesl, M. & Voss, A. Analyse des potenzials von industriewärmepumpen in deutschland (University of Stuttgart, Institute for Energy Economics and Rational Energy Use, 2014).

Frank-gmbh. Preisliste pe rohr komplett (Frank-gmbh, 2022).

Danish Energy Agency & Energinet. Technology Data for Individual Heating Plants (Danish Energy Agency & Energinet, 2022).

Bava, F. & Trier, D. Flexynets—Pre-design Support Online Tool https://www.flexynets.eu/en/Results (2018).

Gudmundsson, O., Schmidt, R.-R., Dyrelund, A. & Thorsen, J. E. Economic comparison of 4GDH and 5GDH systems—using a case study. Energy 238, 121613 (2022).

Eurostat. Price Level Indices For Investment, 2021 (prc_ppp_ind) (Eurostat, 2022).

Eurostat. Gas Prices For Household Consumers (nrg_pc_202). Gas Prices For Non-household Consumers (nrg_pc_203). Electricity Prices For Household Consumers (nrg_pc_204). Electricity Prices For Non-household Consumers (nrg_pc_205)—First half 2022 (Eurostat, 2022).

Essential Service Commission. Victorian Energy Market Report https://www.esc.vic.gov.au/ (2022).

Destatis. Germany Consumer Price Index https://www.destatis.de/EN/Themes/Economy/Prices/Consumer-Price-Index/_node.html#sprg481842 (2022).

OpenMapTiles. MapTiler Basic basemap style. https://openmaptiles.org/styles/ (2024).

Acknowledgements

This work was supported by the RWTH Aachen University–University of Melbourne Joint Ph.D. Programme. We also acknowledge the support of the University of Melbourne Research Computing Portal with computational resources for numerical simulations, which significantly contributed to the results of this research.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Mauricio Carcamo-Medel is responsible for conceiving and designing the study, methodology, data collection from the literature, simulations, analysing the results, data visualisation and writing the initial manuscript. Raul Fuentes and Guillermo A. Narsilio jointly supervised the work and reviewed and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Earth & Environment thanks the anonymous reviewers for their contribution to the peer review of this work. Primary Handling Editors: Sadia Ilyas and Martina Grecequet. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Carcamo-Medel, M., Fuentes, R. & Narsilio, G. Decommissioned open-pit mines are potential geothermal sources of heating or cooling for nearby population centres. Commun Earth Environ 5, 292 (2024). https://doi.org/10.1038/s43247-024-01439-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43247-024-01439-y

This article is cited by

-

The role of pit lake thermal dynamics on the thermal performance of ground heat exchangers

Scientific Reports (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.