Abstract

After an earthquake, faults can recover strength through fault healing, but the mechanisms responsible are not well understood. Seismic slip may induce sintering, a bonding process between solid particles in contact under high temperatures without melting, which could produce a fault rock with elevated strength and chemical stability. Here we present results from electron microscope analyses that show a typical sintered structure in a black disk-shaped rock from the Chelungpu fault, Taiwan. This structure is experimentally reproducible in simulated fault material, prepared from the local host-rock, by heating at 800–900 °C. Through thermal and kinetic analyses of experimental materials, we show that sintering is an exothermic process which can generate energy to enhance post-slip thermochemical reactions in the fault. We propose that sintering substantially contributes to earthquake energetics and fault healing and that its occurrence can be a useful indicator of past seismic slip.

Similar content being viewed by others

Introduction

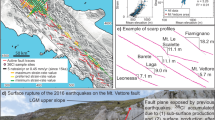

Mechanisms that control the physicochemical properties of fault materials during and after an earthquake are of particular importance, because mechanical and thermochemical processes crucially affect earthquake energetics, the style and magnitude of fault slip, and fault healing1,2. Field and laboratory investigations of fault rocks from exhumed faults and those recovered by drilling of deep fault zones have contributed to our understanding of faulting mechanisms and related physicochemical processes3,4. As part of the Taiwan Chelungpu-fault Drilling Project, undertaken in 2002 under the auspices of the International Continental Scientific Drilling Program (ICDP), borehole rock samples of the Chelungpu fault, which slipped during the 1999 Chi-Chi earthquake, were successfully recovered (Fig. 1a, b). The fault zones are developed within the early Pliocene Chinshui shale5. A disk-shaped black fault rock (black disk) was found at 1194-m depth within one of the Chelungpu-fault zones6 (Fig. 1c). This rock is 2-cm thick, stiffer, and more cohesive than the surrounding fault gouge, and its wet–bulk density is 2.6 g cm−3, higher than that of the gouge (2.2 g cm−3), but similar to that of the Chinshui shale host rock (approximately 2.6 g cm−3)5. It also shows shear foliation and striation (Fig. 1d, e). Bonding structures (referred to here as neck growths), which are partly amorphous, are observed by scanning and transmission electron microscopies (SEM and TEM, respectively, see “Methods”) around the edges of individual ultrafine particles in the black disk (Fig. 1f–h). Such structures are typical in sintered materials7,8, although they have previously been interpreted to result from frictional melting5. Thus, to examine the sintering process in a fault and its role in earthquake mechanism and energetics, we focused on the black disk as a potential sintered fault rock (here named sinterite).

a Geological map of central Taiwan5. The 1999 Chi-Chi earthquake initiated on the southern Chelungpu fault, which ruptured both upward and northward. The Taiwan Chelungpu-fault Drilling Project (TCDP), started in 2002, penetrated the fault and recovered core samples from two holes (Hole A, total depth 2003 m; Hole B, total depth 1353 m)5. b East–west cross section5. Fault rocks were recovered from three dominant fault zones, at depths of 1136, 1194, and 1243 m, in Hole B. c Core photo of a black disk-shaped fault rock, the surrounding fractured rock, and fault gouge from 1194-m depth in Hole B. Microstructures of the black disk observed under an optical microscope (d) and SEM (e, f). g Bright-field TEM image of the neck between two ultrafine particles and h the electron diffraction pattern (within the white circle in g), indicating the imperfect crystalline structure. Arrows in f and areas outlined by dotted red curves in g indicate neck growths. FG fault gouge.

To examine whether sintering can occur as a result of earthquake slip, when heating occurs for only several to several tens of seconds, we carried out a series of heating experiments. A host-rock sample nearby the Chelungpu fault was prepared to simulated fault material, and heated to temperatures from 600 to 1200 °C at 100 °C intervals, and to 850 °C for 30, 90, or 150 s in a tube furnace apparatus (heating rate ~100 °C s−1) (Supplementary Fig. 1). Before heating, the sample was milled for 6 h to produce ultrafine particles with diameters from several tens to several hundreds of nanometers (see “Methods”), and the resulting powder was shaped into pellets with a density of 2.1 g cm−1. We used this sample preparation routine because not only frictional heating but also comminution and densification commonly occur in the slip zone during an earthquake9. For comparison, we also prepared synthetic samples with varied mineral assemblages. Then, we performed comprehensive analyses and observations of the heated samples, and examined the sintering process in these samples.

Results

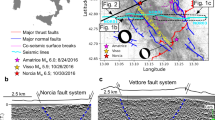

X-ray diffraction analysis

The starting material composition, analyzed by X-ray diffraction (XRD), consists mainly of quartz, feldspar, illite/muscovite, kaolinite, and chlorite, similar to the fault gouge surrounding the black disk10 (Fig. 2a, “Methods”). The intensities of the illite/muscovite peaks on the XRD spectra decreased when the sample was heated to temperatures above 800 °C and disappeared at 900 °C, and the kaolinite/chlorite peak disappeared at 700 °C. Quantitatively, the illite/muscovite content became 0 wt.% above 900 °C, and the quartz and feldspar contents were decreased at temperatures above 1000 °C (Supplementary Fig. 2). Wide, rounded peaks called halos evolved at around 20–30° 2θ on the XRD spectra of samples heated to temperatures above 1000 °C, indicating the presence of imperfect crystal lattices11, and the area of the halo increased in samples heated to higher temperatures (Fig. 2b). The XRD spectrum of the black disk most closely resembles that of the sample heated to 800 °C (Fig. 2a, b; Supplementary Fig. 2).

a X-ray diffraction patterns of samples before and after heating, and of the black disk from the Chelungpu fault. Broad, rounded peaks (halos) at ~20–30° 2θ are shown by orange and pink shading, where the latter represents the increase in the area of the halo compared with the unheated sample. b Change in the halo area (intensity × 2θ) with temperature. The horizontal blue bar indicates the initial size of the halo, which corresponds to the initial amount of minerals with imperfect crystal lattices. SEM images of samples (c) before and after heating for 90 s at d 700 °C, e 800 °C, f 850 °C, g 900 °C, h 1000 °C, i 1100 °C, and j 1200 °C. k Bright-field transmission electron micrograph of the neck between two ultrafine particles and (l) the electron diffraction pattern (within the white circle in k). m Diffraction pattern of an ultrafine particle within the blue circle in k. Red arrows in e, f, and g and area outlined by dotted red curves in k indicate representative examples of neck growth. Kao kaolinite, Chl chlorite, Q quartz, Pl plagioclase, Sp spinel, Al α-alumina.

Electron microscopic observation

Although SEM images of the starting sample and of the samples heated to ≤700 °C show similar structures, the samples heated to 800, 850, and 900 °C for 90 s show neck growths, mainly between ultrafine particles (Fig. 2e–g). The samples heated above 1000 °C show highly connected smooth structures together with thick bridges and hollows where particles are no longer observed (Fig. 2h–j). A bright-field TEM image clearly shows the presence of a neck between two ultrafine particles (Fig. 2k), and the electron diffraction pattern of the neck indicates that it has a noncrystalline structure (Fig. 2l). Some of the ultrafine particles are amorphous because the electron diffraction pattern indicates an imperfect crystalline structure (Fig. 2m); this characteristic is attributed to a distorted mineral structure. The amounts of crystalline quartz, feldspar, and illite/muscovite in the samples decreased after 6 h of milling (Supplementary Fig. 2). The neck structure and its crystallographic features, which were experimentally produced at 800–900 °C, are representative of sintered materials7,8 and also resemble those observed in the black disk (Fig. 1f, g).

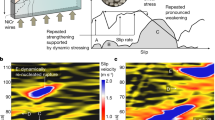

Thermal analysis

To establish that sintering has occurred in the temperature range of 800–900 °C, thermochemical examination is required. A thermogravimetric curve, which depicts the change in the total mass of a sample during heating, is used to determine the temperatures at which dehydration, dehydroxylation, and decomposition of minerals occurs, and the amount of heat required to increase the sample temperature is used to determine not only the specific heat capacity but also the heats of reaction and transformation. The simultaneous thermogravimetry–differential scanning calorimetry (“Methods”) profile of the 6-h-milled host-rock sample shows endothermic peaks at around 100–700 °C together with a mass loss (Fig. 3a). It also exhibits a large endothermic peak without any mass loss at ~920–1000 °C. The former peaks are mainly attributed to dehydration of interlayer water and dehydroxylation of clay minerals, whereas the latter peak corresponds to melting, because a large amount of latent heat is required for melting of silicate minerals12, and because our heated samples displayed a glassy structure under SEM. In contrast, the exothermic peak of 54.8 J g−1 observed at ~800–920 °C is attributed to sintering, which is an exothermic reaction because the associated decrease of surface area releases surface energy7,8. The SEM images of the heated samples in this temperature range in fact show neck growth, causing a decrease of the surface area. Melting of silicate minerals is also accompanied by a decrease of surface area, but its latent heat requirement is much larger than the surface energy release due to this decrease7,8,12. Therefore, the thermochemical profile clearly indicates that sintering occurred at ~800–920 °C, and that melting started above 920 °C, and both results are supported by our crystallographic analysis and microscopic observation.

TG–DSC profiles of a a host-rock sample collected near the Chelungpu fault, b simulated non-clay fault materials composed of quartz, plagioclase and K-feldspar, and c simulated clayey fault materials composed of non-clay minerals (quartz, plagioclase, and K-feldspar) and one or all of illite/muscovite, chlorite, kaolinite, and smectite. Dotted and solid curves show the TG and DSC data, respectively. Q quartz, Pl plagioclase, Kspar K-feldspar.

Evaluation of the effect of multicomponent mineral assemblages

Because rock samples in fault zones have multiple components, including comminuted quartz, feldspar, and clay minerals, we also considered the effects of the eutectic system and of mineral distortion (“Methods”). In a comparison of unmilled and 6-h-milled mixtures of quartz, plagioclase, and K-feldspar, neither mixture showed an exothermic peak at temperatures up to 1000 °C nor any neck growth at 850 °C (Fig. 3b; Supplementary Fig. 3a, b). Therefore, in this condition, sintering did not occur even when amorphous particles were included. In comparisons of 6-h-milled mixtures of quartz, plagioclase, and K-feldspar to which clay minerals (illite, chlorite, smectite, or kaolinite, or all of them) were added, only those mixtures that included chlorite showed exothermic peaks and neck growth (Fig. 3c; Supplementary Fig. 3c–g). This result is consistent with a previous thermochemical result that sintering started at 800 °C in slate composed of mica, quartz, feldspar, and chlorite, from Berja, Almería, Spain13. Thus, sintering can occur in a simulated fault material that includes chlorite. Because at ~800–900 °C, chlorite decomposes and is neocrystallized into new minerals such as olivine, spinel, and enstatite14; in our experiments, sintering may be driven by the diffusion of atoms from the decomposed chlorite matrix. In comparisons of 6-h-milled mixtures of quartz, plagioclase, and K-feldspar with unmilled or 6-h-milled chlorite, dehydroxylation of the latter occurred at a relatively lower temperature (ca. 300–600 °C), indicating that the reaction was enhanced mechanochemically, but thermal decomposition and phase transition of the chlorite and sintering occurred at similar temperatures (Supplementary Fig. 4). These findings indicate that, in sedimentary rocks, chlorite can function as an auxiliary sintering agent. We observed no glassy structures at 850 °C in any of these mixtures (Supplementary Fig. 3), so melting associated with eutectic system effects did not occur at ≤850 °C in these mineral assemblages.

Chemical kinetic analysis

To understand when sintering can occur during seismic slip, we conducted a chemical kinetic analysis of neck growth. We focused on sintered spherical or ellipsoidal particles ~300 nm in size on SEM images because neck growth is dependent on particle size7,8. We measured the major long and short axes of the particles and calculated their diameter (D) by assuming them to approximate circles, and we also measured the interparticle neck width (X). The ratio of neck width to particle diameter (X/D) increased with heating time t, and showed a good correlation with the first-order reaction time, expressed by X/D = 1 − exp(−kt), where k is the reaction rate constant (Fig. 4a). Then, using the Arrhenius equation, which relates k to temperature, we determined the activation energy of the sintering reaction to be 60.0 ± 9.5 kJ mol−1 and the pre-exponential factor to be 5.3 ± 2.7 s−1. Because the temperature on a fault during an earthquake is not constant but changes with time, we applied a temperature–time profile estimated based on the chemical kinetics of the thermal decomposition of carbonate minerals15, which compared with the surrounding host rock showed, had nearly disappeared from the black disk. We assumed a 6-s slip time, the same as that of the 1999 Chi-Chi earthquake16 (“Methods”). The simulation results showed that X/D hardly increased during coseismic slip, and that sintering occurred mainly during the post-seismic phase (Fig. 4b). At 1500 s, X/D was 0.30, approximately the same as the X/D value of 0.36 ± 0.07 in the black disk from the Chelungpu fault.

a Changes in the neck-size ratio (X/D) with heating duration. b Simulation of neck growth during coseismic and post-seismic phases based on the temperature–time profile (red curve) for the 1999 Chi-Chi earthquake. Error bars indicate standard deviations from the mean values. The purple curve shows the evolution of the neck-size ratio.

Discussion

Our experimental results revealed that sintering occurs at ~800–920 °C in simulated gouges of the Chelungpu fault, and the microstructural and crystallographic features of the heated samples coincide with those observed in the black disk. In addition, the black disk lacked the major and trace- element signatures that would be produced by melting of sediment-hosted fault zone rocks17 (Supplementary Methods and Supplementary Figs. 5 and 6). Therefore, the black disk should be identified as sinterite rather than as pseudotachylyte, a solidified friction-induced melt that has been considered as earthquake fossil because it records past activity on a fault18,19. The sinterite from the Chelungpu fault might have experienced 800–900 °C during a seismic event.

Total energy released from a fault during an earthquake is generally partitioned into energy radiated as seismic waves, frictional heat, surface fracture energy (which creates a new rupture surface), and energy for endothermic chemical reactions20. However, during the post-seismic phase, the exothermic sintering reaction may serve as an energy source for thermochemical reactions. In the case of the black disk, we calculated the energy released by sintering to be 1.03 MJ m−2 (=54.8 J g−1 exotherm × 2.6 g cm−3 density × 0.36 reacted fraction × 2-cm thickness), which is almost the same as the amount of surface fracture energy used (0.65 MJ m−2)21 during the 1999 Chi-Chi earthquake. Thus, the exothermic energy associated with sintering has the potential to enhance post-seismic healing processes, such as pressure-solution welding22 and mineral precipitation23. In addition, sintered materials generally have high bulk density, stiffness, strength, and chemical stability7,8, e.g., sintered kaolinitic clay, a possible sinterite analog, has a high flexural strength of ~30 MPa, whereas the initial kaolinitic powder, an analog of fault gouge, has a flexural strength of close to zero24. Changes in the mechanical properties of fault rock caused by sintering may affect the post-seismic fault healing. Friction-induced melting of fault rocks, that is, formation of pseudotachylyte, may also contribute to fault healing25,26, but pseudotachylyte formation consumes a large amount of latent heat12. Thus, sintering may be a central reaction in fault healing, one that not only promotes other healing mechanisms, but also contributes directly to strength recovery7,8,24.

At present, reports of sintered fault rocks are scarce. However, Currewitz and Karson27 interpreted pseudotachylyte from normal faults developed in gneiss in East Greenland that exhibit interlocking particles as sintered ultracataclasite, and were the first to propose a role of sintering in fault healing. On the mirror-like surfaces of carbonate-bearing faults associated with the Dead Sea transform, coatings were observed on tightly packed nanoparticles28; these coatings, together with structural traces of neck growth between nanoparticles, were experimentally reproduced by using a rotary shear apparatus29. Similar structures have been observed in synthetically heated carbonate minerals at >600 °C (ref. 30) and also in experimentally sheared calcite gouge when the temperature reached ca. 700 °C (ref. 31). Formation of connected nanoparticles might be controlled by thermally activated dislocation and decomposition of carbonate minerals30. Densification and a decrease in the specific surface area of experimentally sheared quartz gouge and sheared clayey gouge, collected from the Nojima fault, have also been attributed to sintering induced by flash heating at particle contacts32,33. In addition, connected hematite polygonal nanocrystals are observed on a fault mirror that cuts Fe ore, reflecting sintering and interlocking of crystals across the slip surface during and after seismic slip34. Moreover, sinter hardening of materials by subjecting fine powders to heat and pressure is a frequently applied industrial process35. The temperature range, process, and mechanism of sintering might vary greatly, depending on the mineral or rock type, the sintering agent, and environmental conditions, such as stress and fluid content.

Some previously reported cataclasites/ultracataclasites, especially within plate-subduction faults with a chlorite component, may actually be sinterites. In the Nankai Trough, a shear-localized dark fault gouge retrieved from the megasplay fault that branches from the plate interface included ~10 wt.% chlorite36 and showed an exothermic peak when heated to 750 °C (Supplementary Fig. 7). Therefore, this gouge has the potential to become sinterite during seismic slip. In sediment-hosted fault zones with low permeability, fault strength may often be dramatically decreased by friction heating-induced pressurization of interstitial fluid during an earthquake (i.e., thermal pressurization37), thereby preventing the fault from attaining the high temperatures required for sintering and melting. However, recent successive discoveries of pseudotachylytes in exhumed accretionary complexes38,39,40 imply that the occurrence of sinterites, which can be generated at lower temperatures than pseudotachylytes, may not be so rare.

Our discovery of the role of sintering in faults has important implications not only for estimating earthquake energetics, but also for evaluating fault healing and earthquake cycles. Moreover, we expect the presence of sinterite in a fault zone to become a new useful indicator of rapid slip associated with past seismic events.

Methods

Grinding procedure

A laboratory planetary mill (Pulverisette 6, Fritsch, Germany) was used to grind samples for 6 h at 600 rpm. For each milling, a 5-g air-dried sample was placed in a 45-cm3 sintered alumina pot with eight alumina balls (10-mm diameter). Grinding was suspended for 5 min after 20 min of milling to prevent the sample temperature from rising; thus, the temperature at the end of each experiment, measured with a needle-probe thermometer, was only slightly higher than room temperature (~40 °C).

Electron microscopy

Submicrometer-scale structures of the natural and experiment samples before and after heating were examined under an SEM (JSM-7600F, JEOL, Japan) operated at an acceleration voltage of 15 kV, and a transmission electron microscope (JSM-2100, JEOL, Japan) operated at 200 kV. However, it has been technically difficult to identify neck structures in natural fault rocks, probably because of the use of resin in the sample preparation: when our heated host-rock sample at 850 °C and 90 s was fixed by using an epoxy resin, no neck structure was identifiable under either optical or electron microscopes (Supplementary Fig. 8).

X-ray diffraction spectroscopy

X-ray diffraction patterns of the samples before and after heating were obtained by using a Spectris PANalytical X’Pert PRO MPD spectrometer with monochromatized CuKα radiation operated at 45 kV and 40 mA, with a step width of 0.004° (Δ2θ), 0.25° divergence and antiscattering slits, and a high-speed semiconductor array detector. The samples were blended with α-alumina (20 wt.%) as an internal standard and mounted on XRD glass holders by the side-load method to minimize any preferred alignment of phyllosilicates. The mineral assemblage of the host-rock sample, collected from the Chinshui Shale at 1104.76-m depth in Hole A (40 m southeast of Hole B)5, was quantitatively determined to be composed of quartz, plagioclase, K-feldspar, illite, chlorite, kaolinite and smectite (40.0, 11.5, 6.9, 21.1, 13.1, 5.0, and 2.4 wt.%, respectively10) by using the XRD RockJock program41, which are similar to the fault gouge surrounding the black disk (43.4, 11.3, 7.7, 19.0, 10.8, 2.2, and 5.6 wt.%, respectively10). The mineral amounts of quartz, feldspar, and illite/muscovite in the samples before and after heating were determined by the reference-intensity ratio method42,43.

Simultaneous thermogravimetry–differential scanning calorimetry

A Netzsch STA 449 C Jupiter balance was used; the resolutions of TG, DSC, and temperature were 1 µg, 1.25 µW, and 0.01 °C, respectively. An approximately 30-mg powder sample was placed in a covered Pt90Rh10 crucible and heated at a rate of 20 °C min−1 from room temperature to 1000 °C under a flow of argon gas (50 mL min−1).

Evaluation of the effect of multicomponent mineral assemblages

As an additional heating experiment to evaluate the eutectic system, standard mineral samples of quartz, plagioclase, K-feldspar, illite, chlorite, kaolinite, and smectite were obtained from quartz sand (Wako Pure Chemical Industries, Japan), pegmatite (Shinyashiki, Fukushima, Japan), and the Clay Mineral Society (IMt-2, illite, Silver Hill Montana, USA; CCa-2, chlorite, Flagstaff Hill, USA; KGa-1b, kaolinite, Warren County Georgia, USA; SWy-2, Na-rich montmorillonite, Crook County Wyoming, USA). The minerals were mixed so that their mass ratios were the same as in the host-rock sample, and then heating experiments were performed as follows: (1) the sample mixtures were milled for 6 h, (2) the resulting particles were shaped into pellets, (3) the pellets were inserted into a quartz tube under vacuum condition, and (4) the pelleted samples were heated to 850 °C for 90 s in a tube furnace apparatus.

Reconstruction of the earthquake’s temperature–time profile

The disk-shaped black fault rock had a low inorganic carbon content (mainly carbonaceous minerals such as calcite)5, which was attributed to the thermal decomposition of calcite during the earthquake5,15. The amounts of carbonaceous minerals in and around the fault zone at 1194-m depth were measured by coulometric titration with a CO2 coulometer (UIC Inc., Coulometrics model CM5012)44. The amount of carbonate minerals, mainly calcite, in the disk-shaped black fault rock, was 0.05 wt.%, compared with 0.43 wt.% of carbonate minerals in the surrounding host rocks15; therefore, the fraction of carbonate minerals lost by thermal decomposition from the black disk was 0.88.

The degree of thermal decomposition of calcite α (0 ≤ α ≤ 1, where α = 1 means total decomposition), is expressed as

where t is the reaction time, and k is the reaction rate35. The relationship between the reaction rate and temperature is expressed by the Arrhenius equation

where A is a constant (pre-exponential term), Ea is the activation energy necessary for a reaction to occur, R is the gas constant (8.31447 JK−1 mol−1), and T is temperature (K). By solving simultaneously the equations for chemical kinetics, frictional heating and heat conduction, and one-dimensional diffusion under the constraint provided by the reacted fraction (i.e., the mass fraction of decomposed calcite, α = 0.88), the temperature–time profile (and also shear stress) could be uniquely determined15.

The temperature–time profile recorded in the disk-shaped black fault rock was reconstructed, and shear stress during the earthquake was determined to be 1.31 MPa (ref. 15), by applying the kinetic parameters A = 2.68 × 107 s−1 and Ea = 187 kJ mol−1 (ref. 45) for the thermal decomposition reaction, and along with other parameters during the earthquake [in situ initial temperature, 46.5 °C (ref. 46); total displacement, 8.3 m (ref. 21); slip time, 6 s (ref. 16); specific heat capacity, 300 J kg−1 K−1 (ref. 47); density, 2200 kg m−3 (ref. 48); thermal diffusivity, 1.0 × 10−6 m2 s−1 (ref. 47)] (Fig. 4b).

Data availability

Data of TEM, XRD, TG–DSC, and chemical kinetic analyses in this paper are available at https://doi.org/10.5281/zenodo.3903901.

References

Niemeijer, A. et al. Inferring earthquake physics and chemistry using an integrated field and laboratory approach. J. Struct. Geol. 39, 2–36 (2012).

Rice, J. R. Heating and weakening of faults during earthquake slip. J. Geophys. Res. 111, B05311 (2006).

Scholz, C. H. The Mechanics of Earthquakes and Faulting (Cambridge University Press, 2002).

Zoback, M. Scientific drilling Into the San Andreas fault zone—An overview of SAFOD’s first five years. Sci. Drill 11, 14–28 (2011).

Hirono, T. et al. Nondestructive continuous physical property measurements of core samples recovered from hole B Taiwan Chelungpu-Fault Drilling Project. J. Geophys. Res. 112, B07404 (2007).

Hirono, T. et al. Evidence of frictional melting from disk-shaped black material discovered within the Taiwan Chelungpu fault system. Geophys. Res. Lett. 33, L19311 (2006).

German, R. M. Sintering Theory and Practice (John Wiley & Sons, New York, 1996).

German, R. M. Sintering: From Empirical Observations to Scientific Principles (Butterworth-Heinemann, Oxford, 2014).

Mair, K. & Abe, S. Breaking up: comminution mechanisms in sheared simulated fault gouge. Pure Appl. Geophys. 168, 2277–2288 (2011).

Hirono, T., Kameda, J., Kanda, H., Tanikawa, W. & Ishikawa, T. Mineral assemblage anomalies in the slip zone of the 1999 Taiwan Chi-Chi earthquake: ultrafine particles preserved only in the latest slip zone. Geophys. Res. Lett. 41, 3052–3059 (2014).

Ungar, T. Microstructural parameters from X-ray diffraction peak broadening. Scr. Mater. 51, 777–781 (2004).

Leth-Miller, R. et al. Experimental investigation and modelling of heat capacity heat of fusion and melting interval of rocks. Thermochim. Acta 406, 129–142 (2003).

Sánchez-Soto, P. J., Ruiz-Conde, A., Bono, R., Raigón, M. & Garzón, E. Thermal evolution of a slate. J. Therm. Anal. Cal. 90, 133–141 (2007).

Földvári M. Handbook of Thermogravimetric System of Minerals and its Use in Geological Practice (Geological Institute of Hungary, 2011).

Hirono, T. et al. A chemical kinetic approach to estimate dynamic shear stress during the 1999 Taiwan Chi-Chi earthquake. Geophys. Res. Lett. 34, L19308 (2007).

Ma, K.-F. et al. Evidence for fault lubrication during the 1999 Chi-Chi Taiwan earthquake (Mw7.6). Geophys. Res. Lett 30, 1244 (2003).

Ishikawa, T. & Ujiie, K. Geochemical analysis unveils frictional melting processes in a subduction zone fault. Geology 47, 343–346 (2019).

Sibson, R. H. Generation of pseudotachylyte by ancient seismic faulting. Geophys. J. R. Astron. Soc 43, 775–794 (1975).

Rowe, C. D. & Griffith, W. A. Do faults preserve a record of seismic slip: a second opinion. J. Struct. Geol. 78, 1–26 (2015).

Hamada, Y., Hirono, T., Tanikawa, W., Soh, W. & Song, S.-S. Energy taken up by co-seismic chemical reactions during a large earthquake: an example from the 1999 Taiwan Chi-Chi earthquake. Geophys. Res. Lett. 36, L06301 (2009).

Ma, K.-F. et al. Slip zone and energetics of a large earthquake from the Taiwan Chelungpu-fault Drilling Project. Nature 444, 473–476 (2006).

Bos, B. & Spiers, C. J. Effect of phyllosilicates on fluid-assisted healing of gouge-bearing faults. Earth Planet. Sci. Lett. 184, 199–210 (2000).

Tenthorey, E., Cox, S. F. & Todd, H. F. Evolution of strength recovery and permeability during fluid-rock reaction in experimental fault zones. Earth Planet. Sci. Lett. 206, 161–172 (2003).

Martin-Marquez, J., Rincon, J. M. & Romero, M. Effect of firing temperature on sintering of porcelain stoneware tiles. Ceram. Inter 34, 1867–1873 (2008).

Mitchell, T. M., Toy, V., Di Toro, G., Renner, J. & Sibson, R. H. Fault welding by pseudotachylyte formation. Geology 44, 1059–1062 (2016).

Proctor, B. & Lockner, D. A. Pseudotachylyte increases the post-slip strength of faults. Geology 44, 1003–1006 (2016).

Curewitz, D. & Karson, J. A. Ultracataclasis sintering and frictional melting in pseudotachylytes from East Greenland. Jour. Struct. Geol 21, 1693–1713 (1999).

Siman-Tov, S., Aharonov, E., Sagy, A. & Emmanuel, S. Nanograins form carbonate fault mirrors. Geology 41, 703–706 (2013).

Siman-Tov, S., Aharonov, E., Boneh, Y. & Reches, Z. Fault mirrors along carbonate faults: formation and destruction during shear experiments. Earth Planet. Sci. Lett. 430, 367–376 (2015).

Pluymakers, A. & Røyne, A. Nanograin formation and reaction-induced fracturing due to decarbonation: implications for the microstructures of fault mirrors. Earth Planet. Sci. Lett. 476, 59–68 (2017).

Pozzi, G. et al. A new interpretation for the nature and significance of mirror-like surfaces in experimental carbonate-hosted seismic faults. Geology 46, 583–586 (2018).

Sawai, M., Shimamoto, T. & Togo, T. Reduction in BET surface area of Nojima fault gouge with seismic slip and its implication for the fracture energy of earthquakes. J. Struct. Geol. 38, 117–138 (2012).

Togo, T. & Shimamoto, T. Energy partition for grain crushing in quartz gouge during subseismic to seismic fault motion: an experimental study. J. Struct. Geol. 38, 139–155 (2012).

Ault, A. K., Jensen, J. L., McDermott, R. G., Shen, F.-A. & Van Devener, B. R. Nanoscale evidence for temperature-induced transient rheology and postseismic fault healing. Geology 48, 1203–1207 (2019).

Kang, S.-J. L. Sintering Densification Grain Growth and Microstructure (Butterworth-Heinemann, Oxford, 2005).

Hirono, T. et al. Near-trench slip potential of megaquakes evaluated from fault properties and conditions. Sci. Rep. 6, 28184 (2016).

Sibson, R. H. Interactions between temperature and pore-fluid pressure during earthquake faulting and a mechanism for partial or total stress relief. Nature 243, 66–68 (1973).

Ikesawa, E., Sakaguchi, A. & Kmura, G. Pseudotachylyte from an ancient accretionary complex: evidence for melt generation during seismic slip along a master decollement? Geology 31, 637–640 (2003).

Rowe, C. D., Moore, J. C., Meneghini, F. & Mckeirnan, A. W. Large-scale pseudotachylytes and fluidized cataclasites from an ancient subduction thrust fault. Geology 33, 937–940 (2005).

Mukoyoshi, H., Sakaguchi, A., Otsuki, K., Hirono, T. & Soh, W. Co-seismic frictional melting along an out-of-sequence thrust in the Shimanto accretionary complex: implications on the tsunamigenic potential of splay faults in modern subduction zones. Earth Planet. Sci. Lett. 245, 330–343 (2006).

Eberl, D. D. User’s Guide to RockJock—A program for determining quantitative mineralogy from powder X-ray diffraction data. USGS Open-File Report 03–78 https://pubs.usgs.gov/of/2003/of03-078/ (2003).

Hillier, S. Accurate quantitative analysis of clay and other minerals in sandstones by XRD: comparison of a Rietveld and a reference intensity ratio (RIR) method and the importance of sample preparation. Clay Minerals 35, 291–302 (2000).

Bergaya, F. & Lagaly, G. Handbook of Clay Science (Elsevier, Amsterdam, 2013).

Ikehara, M. et al. Low total and inorganic carbon contents within the Taiwan Chelungpu fault system. Geochem J. 41, 391–396 (2007).

Criado, J. M., Gonzalez, M., Malek, J. & Ortega, A. The effect of the CO2 pressure on the thermal decomposition kinetics of calcium carbonate. Thermochim. Acta 254, 121–127 (1995).

Kano, Y. et al. Heat signature on the Chelungpu fault associated with the 1999 Chi-Chi Taiwan earthquake. Geophys. Res. Lett. 33, L14306 s(2006).

Tanaka, H., Chen, W. M., Kawabata, K. & Urata, N. Thermal properties across the Chelungpu fault zone and evaluations of positive thermal anomaly on the slip zones: are these residuals of heat from faulting? Geophys. Res. Lett. 34, L01309 (2007).

Hirono, T. et al. High magnetic susceptibility of fault gouge within Taiwan Chelungpu fault: nondestructive continuous measurements of physical and chemical properties in fault rocks recovered from Hole B TCDP. Geophys. Res. Lett. 33, L15303 (2006).

Acknowledgements

We thank T. Kondo and G. Uramoto Ito for their technical support during our heating experiments and scanning electron microscope observations. We also thank S.-R. Song, K.-F. Ma, and all other scientists and operation staff on the Taiwan Chelungpu-fault Drilling Project and ICDP. This work was supported by JSPS KAKENHI Grant Number 19K04039.

Author information

Authors and Affiliations

Contributions

T.H. proposed the investigation of the relation between sintering and earthquakes. T.H., S.K., N.T., and A.I. conducted the heating experiments, X-ray diffraction analysis, and microscopic observations, and T.H. and S.K. performed thermochemical and kinetic analyses. T.I. performed geochemical evaluation and modeling of the fault rock sample. J.K. and Y.M. contributed to discussion about mineralogy and thermochemistry associated with sintering process. All authors wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Primary handling editor: Joe Aslin.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hirono, T., Kaneki, S., Ishikawa, T. et al. Generation of sintered fault rock and its implications for earthquake energetics and fault healing. Commun Earth Environ 1, 3 (2020). https://doi.org/10.1038/s43247-020-0004-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43247-020-0004-z

This article is cited by

-

Formation of talc fault gouge analog using high-energy ball mill

Geosciences Journal (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.