Abstract

Mechanical metamaterials are a class of artificial materials whose geometry is engineered to have peculiar mechanical properties or programmed responses that are difficult to find in conventional materials. Typically, metamaterials are periodic, but incorporating disorder into their design can provide improved functionalities over ordered structures. In this Perspective article, we use examples of biological materials with disordered structures to elucidate how disorder can enhance the mechanical performance of engineered mechanical metamaterials. We clarify opportunities and pitfalls posed by randomness, highlight the increasingly prominent role played by disorder in novel design strategies for mechanical metamaterials and discuss recently developed algorithmic and data-driven strategies for the design of disordered optimized metamaterials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$99.00 per year

only $8.25 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bertoldi, K., Vitelli, V., Christensen, J. & van Hecke, M. Flexible mechanical metamaterials. Nat. Rev. Mater. 2, 17066 (2017). This review discuses the main fundamental mechanisms underlying mechanical metamaterials.

Barchiesi, E., Spagnuolo, M. & Placidi, L. Mechanical metamaterials: a state of the art. Math. Mech. Solids 24, 212–234 (2019).

Ashby, M. F. & Medalist, R. M. The mechanical properties of cellular solids. Metall. Trans. A 14, 1755–1769 (1983).

Ashby, M. The properties of foams and lattices. Phil. Trans. R. Soc. A 364, 15–30 (2006). This study is a discussion of bending-dominated and stretching-dominated density scaling of mechanical properties in cellular solids.

Xia, X., Spadaccini, C. M. & Greer, J. R. Responsive materials architected in space and time. Nat. Rev. Mater. 7, 683–701 (2022).

Nicolaou, Z. G. & Motter, A. E. Mechanical metamaterials with negative compressibility transitions. Nat. Mater. 11, 608–613 (2012).

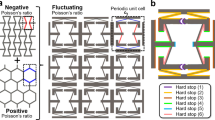

Bertoldi, K., Reis, P. M., Willshaw, S. & Mullin, T. Negative Poisson’s ratio behavior induced by an elastic instability. Adv. Mater. 22, 361–366 (2010).

Babaee, S. et al. 3D soft metamaterials with negative Poisson’s ratio. Adv. Mater. 25, 5044–5049 (2013).

Lakes, R. Foam structures with a negative Poisson’s ratio. Science 235, 1038–1040 (1987). This paper provides an introduction to auxetic materials showing negative Poisson’s ratio.

Li, Y. & Zeng, C. Room-temperature, near-instantaneous fabrication of auxetic materials with constant Poisson’s ratio over large deformation. Adv. Mater. 28, 2822–2826 (2016).

Coulais, C., Kettenis, C. & van Hecke, M. A characteristic length scale causes anomalous size effects and boundary programmability in mechanical metamaterials. Nat. Phys. 14, 40–44 (2017).

Rayneau-Kirkhope, D. & Dias, M. A. Embracing failure. Phys. World 30, 25 (2017).

Florijn, B., Coulais, C. & van Hecke, M. Programmable mechanical metamaterials. Phys. Rev. Lett. 113, 175503 (2014).

Florijn, B., Coulais, C. & van Hecke, M. Programmable mechanical metamaterials: the role of geometry. Soft Matter 12, 8736–8743 (2016).

Rayneau-Kirkhope, D. J. & Dias, M. A. Recipes for selecting failure modes in 2-d lattices. Extreme Mech. Lett. 9, 11–20 (2016).

Paulose, J., Meeussen, A. S. & Vitelli, V. Selective buckling via states of self-stress in topological metamaterials. Proc. Natl Acad. Sci. USA 112, 7639–7644 (2015).

La Porta, C. A. et al. Metamaterial architecture from a self-shaping carnivorous plant. Proc. Natl Acad. Sci. USA 116, 18777–18782 (2019).

Wu, H. et al. Three dimensional printing of bioinspired crossed-lamellar metamaterials with superior toughness for syntactic foam substitution. ACS Appl. Mater. Interfaces 14, 42504–42512 (2022).

Giorgio, I., Spagnuolo, M., Andreaus, U., Scerrato, D. & Bersani, A. M. In-depth gaze at the astonishing mechanical behavior of bone: a review for designing bio-inspired hierarchical metamaterials. Math. Mech. Solids 26, 1074–1103 (2021).

Pham, M.-S., Liu, C., Todd, I. & Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 565, 305–311 (2019).

Rayneau-Kirkhope, D., Bonfanti, S. & Zapperi, S. Density scaling in the mechanics of a disordered mechanical meta-material. Appl. Phys. Lett. 114, 111902 (2019). This work shows the presence of anomalous density scaling of mechanical parameters induced by disorder.

Nguyen, C., Peetz, D., Elbanna, A. E. & Carlson, J. M. Characterization of fracture in topology-optimized bioinspired networks. Phys. Rev. E 100, 042402 (2019).

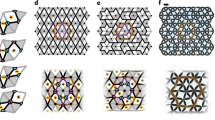

Reid, D. R. et al. Auxetic metamaterials from disordered networks. Proc. Natl Acad. Sci. USA 115, E1384–E1390 (2018).

Hanifpour, M., Petersen, C. F., Alava, M. J. & Zapperi, S. Mechanics of disordered auxetic metamaterials. Eur. Phys. J. B 91, 271 (2018). This is a systematic study of the role of disorder in auxetic metamaterials.

Studart, A. R. Biologically inspired dynamic material systems. Angew. Chem. Int. Ed. 54, 3400–3416 (2015).

Zaiser, M. & Zapperi, S. in Understanding Innovation Through Exaptation (eds La Porta, C. A. M., Zapperi, S. & Pilotti, L.) 35–45 (Springer, 2020).

Qin, Z., Dimas, L., Adler, D., Bratzel, G. & Buehler, M. J. Biological materials by design. J. Phys. Condens. Matter 26, 073101 (2014).

Feng, L. et al. Super-hydrophobic surfaces: from natural to artificial. Adv. Mater. 14, 1857–1860 (2002).

Autumn, K. et al. Adhesive force of a single gecko foot-hair. Nature 405, 681–685 (2000).

Green, D. W. et al. High quality bioreplication of intricate nanostructures from a fragile gecko skin surface with bactericidal properties. Sci. Rep. 7, 1–12 (2017).

Broedersz, C. P. & MacKintosh, F. C. Modeling semiflexible polymer networks. Rev. Mod. Phys. 86, 995 (2014).

Ashby, M. The properties of foams and lattices. Phil. Trans. R. Soc. A 364, 15–30 (2006).

Launey, M. E. & Ritchie, R. O. On the fracture toughness of advanced materials. Adv. Mater. 21, 2103–2110 (2009).

Reznikov, N., Bilton, M., Lari, L., Stevens, M. M. & Kröger, R. Fractal-like hierarchical organization of bone begins at the nanoscale. Science 360, eaao2189 (2018).

Gao, H. in Advances in Fracture Research (eds Carpinteri, A., Mai, Y. W. & Ritchie, R. O.) 101–137 (Springer, 2006).

Koester, K. J., Ager Iii, J. & Ritchie, R. The true toughness of human cortical bone measured with realistically short cracks. Nat. Mater. 7, 672–677 (2008).

Fields, A. J. et al. Vertebral fragility and structural redundancy. J. Bone Miner. Res. 27, 2152–2158 (2012).

Huiskes, R. If bone is the answer, then what is the question? J. Anat. 197, 145–156 (2000).

Lakes, R. Materials with structural hierarchy. Nature 361, 511–515 (1993).

Fudge, D. S., Gardner, K. H., Forsyth, V. T., Riekel, C. & Gosline, J. M. The mechanical properties of hydrated intermediate filaments: insights from hagfish slime threads. Biophys. J. 85, 2015–2027 (2003).

Aizenberg, J. et al. Skeleton of Euplectella sp.: structural hierarchy from the nanoscale to the macroscale. Science 309, 275–278 (2005).

Hamza, S., Slimane, N., Azari, Z. & Pluvinage, G. Structural and mechanical properties of the coral and nacre and the potentiality of their use as bone substitutes. Appl. Surf. Sci. 264, 485–491 (2013).

Krauss, S., Monsonego-Ornan, E., Zelzer, E., Fratzl, P. & Shahar, R. Mechanical function of a complex three-dimensional suture joining the bony elements in the shell of the red-eared slider turtle. Adv. Mater. 21, 407–412 (2009).

Gibson, L. J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 9, 2749–2766 (2012).

Forterre, Y., Skotheim, J. M., Dumais, J. & Mahadevan, L. How the venus flytrap snaps. Nature 433, 421–425 (2005).

Overvelde, J. T. B., Kloek, T., D’haen, J. J. A. & Bertoldi, K. Amplifying the response of soft actuators by harnessing snap-through instabilities. Proc. Natl Acad. Sci. USA 112, 10863–10868 (2015).

Rafsanjani, A., Akbarzadeh, A. & Pasini, D. Snapping mechanical metamaterials under tension. Adv. Mater. 27, 5931–5935 (2015).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Rayneau-Kirkhope, D. Stiff auxetics: hierarchy as a route to stiff, strong lattice based auxetic meta-materials. Sci. Rep. 8, 12437 (2018).

Lumpe, T. S. & Stankovic, T. Exploring the property space of periodic cellular structures based on crystal networks. Proc. Natl Acad. Sci. USA 118, e2003504118 (2021).

Gibson, L. J. & Ashby, M. F. Cellular Solids: Structure and Properties (Cambridge Univ. Press, 1999).

Fleck, N., Deshpande, V. & Ashby, M. Micro-architectured materials: past, present and future. Proc. R. Soc. A 466, 2495–2516 (2010).

Ogata, S., Li, J. & Yip, S. Ideal pure shear strength of aluminum and copper. Science 298, 807–811 (2002).

Aifantis, E. C. On the role of gradients in the localization of deformation and fracture. Int. J. Eng. Sci. 30, 1279–1299 (1992).

Bauer, J., Kraus, J. A., Crook, C., Rimoli, J. J. & Valdevit, L. Tensegrity metamaterials: toward failure-resistant engineering systems through delocalized deformation. Adv. Mater. 33, 2005647 (2021).

Zhang, X. Y., Ren, X., Zhang, Y. & Xie, Y. M. A novel auxetic metamaterial with enhanced mechanical properties and tunable auxeticity. Thin Wall. Struct. 174, 109162 (2022).

Cheng, X. et al. Design and mechanical characteristics of auxetic metamaterial with tunable stiffness. Int. J. Mech. Sci. 223, 107286 (2022).

Ren, X., Shen, J., Ghaedizadeh, A., Tian, H. & Xie, Y. M. Experiments and parametric studies on 3d metallic auxetic metamaterials with tuneable mechanical properties. Smart Mater. Struct. 24, 095016 (2015).

Zaiser, M., Mill, F., Konstantinidis, A. & Aifantis, K. E. Strain localization and strain propagation in collapsible solid foams. Mater. Sci. Eng. A 567, 38–45 (2013).

Tüzes, D., Ispánovity, P. D. & Zaiser, M. Disorder is good for you: the influence of local disorder on strain localization and ductility of strain softening materials. Int. J. Fract. 205, 139–150 (2017).

Koyama, M. et al. Bone-like crack resistance in hierarchical metastable nanolaminate steels. Science 355, 1055–1057 (2017).

Nepal, D. et al. Hierarchically structured bioinspired nanocomposites. Nat. Mater. 22, 18–35 (2022).

Gao, H., Ji, B., Jäger, I. L., Arzt, E. & Fratzl, P. Materials become insensitive to flaws at nanoscale: lessons from nature. Proc. Natl Acad. Sci. USA 100, 5597–5600 (2003).

Meza, L. R. et al. Resilient 3d hierarchical architected metamaterials. Proc. Natl Acad. Sci. USA 112, 11502–11507 (2015).

Zaiser, M. et al. Hierarchical slice patterns inhibit crack propagation in brittle sheets. Phys. Rev. Appl. 18, 044035 (2022). This paper discusses how to design hierarchical structures to inhibit crack propagation.

Pournajar, M. et al. Failure precursors and failure mechanisms in hierarchically patterned paper sheets in tensile and creep loading. Phys. Rev. Applied 20, 024008 (2023).

Hosseini, S. A., Moretti, P., Konstantinidis, D. & Zaiser, M. Beam network model for fracture of materials with hierarchical microstructure. Int. J. Fract. 227, 243–257 (2021).

Li, D., Yin, J., Dong, L. & Lakes, R. S. Strong re-entrant cellular structures with negative Poisson’s ratio. J. Mater. Sci. 53, 3493–3499 (2018).

Mullin, T., Deschanel, S., Bertoldi, K. & Boyce, M. C. Pattern transformation triggered by deformation. Phys. Rev. Lett. 99, 084301 (2007).

Zhang, Y. et al. One-step nanoscale assembly of complex structures via harnessing of an elastic instability. Nano Lett. 8, 1192–1196 (2008).

Shim, J., Perdigou, C., Chen, E. R., Bertoldi, K. & Reis, P. M. Buckling-induced encapsulation of structured elastic shells under pressure. Proc. Natl Acad. Sci. USA 109, 5978–5983 (2012).

Ren, C., Yang, D. & Qin, H. Mechanical performance of multidirectional buckling-based negative stiffness metamaterials: an analytical and numerical study. Materials 11, 1078 (2018).

Grima, J. N., Mizzi, L., Azzopardi, K. M. & Gatt, R. Auxetic perforated mechanical metamaterials with randomly oriented cuts. Adv. Mater. 28, 385–389 (2016).

Bonfanti, S., Guerra, R., Zaiser, M. & Zapperi, S. Digital strategies for structured and architected materials design. APL Mater. 9, 020904 (2021).

Aage, N., Andreassen, E., Lazarov, B. S. & Sigmund, O. Giga-voxel computational morphogenesis for structural design. Nature 550, 84–86 (2017). This study is a large-scale structural design using topology optimization.

Sigmund, O. Tailoring materials with prescribed elastic properties. Mech. Mater. 20, 351–368 (1995).

Bendsoe, M. P. & Sigmund, O. Topology Optimization: Theory, Methods, and Applications (Springer, 2013).

Plocher, J. & Panesar, A. Review on design and structural optimisation in additive manufacturing: towards next-generation lightweight structures. Mater. Des. 183, 108164 (2019).

Cadman, J. E., Zhou, S., Chen, Y. & Li, Q. On design of multi-functional microstructural materials. J. Mater. Sci. 48, 51–66 (2013).

Long, K., Du, X., Xu, S. & Xie, Y. M. Maximizing the effective Young’s modulus of a composite material by exploiting the Poisson effect. Compos. Struct. 153, 593–600 (2016).

Zhang, H., Luo, Y. & Kang, Z. Bi-material microstructural design of chiral auxetic metamaterials using topology optimization. Compos. Struct. 195, 232–248 (2018).

Yang, X. & Kim, Y. Y. Topology optimization for the design of perfect mode-converting anisotropic elastic metamaterials. Compos. Struct. 201, 161–177 (2018).

Ai, L. & Gao, X.-L. Topology optimization of 2-d mechanical metamaterials using a parametric level set method combined with a meshfree algorithm. Compos. Struct. 229, 111318 (2019).

Schwerdtfeger, J. et al. Design of auxetic structures via mathematical optimization. Adv. Mater. 23, 2650–2654 (2011).

Goodrich, C. P., Liu, A. J. & Nagel, S. R. The principle of independent bond-level response: tuning by pruning to exploit disorder for global behavior. Phys. Rev. Lett. 114, 225501 (2015).

Reyes-Martinez, M. A. et al. Tuning the mechanical impedance of disordered networks for impact mitigation. Soft Matter 18, 2039–2045 (2022).

Yan, L., Ravasio, R., Brito, C. & Wyart, M. Architecture and coevolution of allosteric materials. Proc. Natl Acad. Sci. USA 114, 2526–2531 (2017).

Yan, L., Ravasio, R., Brito, C. & Wyart, M. Principles for optimal cooperativity in allosteric materials. Biophys. J. 114, 2787–2798 (2018).

Pashine, N., Hexner, D., Liu, A. J. & Nagel, S. R. Directed aging, memory, and nature’s greed. Sci. Adv. 5, eaax4215 (2019).

Rocks, J. W. et al. Designing allostery-inspired response in mechanical networks. Proc. Natl Acad. Sci. USA 114, 2520–2525 (2017).

Liu, J., Nie, Y., Tong, H. & Xu, N. Realizing negative Poisson’s ratio in spring networks with close-packed lattice geometries. Phys. Rev. Mater. 3, 055607 (2019).

Bonfanti, S., Guerra, R., Font-Clos, F., Rayneau-Kirkhope, D. & Zapperi, S. Automatic design of mechanical metamaterial actuators. Nat. Commun. 11, 4162 (2020). This paper shows how to generate disordered metamaterials using Monte Carlo simulations combined with deep learning.

Beretta, L. et al. Automatic design of chiral mechanical metamaterials. APL Mater. 9, 101112 (2021).

Bessa, M. A., Glowacki, P. & Houlder, M. Bayesian machine learning in metamaterial design: fragile becomes supercompressible. Adv. Mater. 31, 1904845 (2019).

Mao, Y., He, Q. & Zhao, X. Designing complex architectured materials with generative adversarial networks. Sci. Adv. 6, eaaz4169 (2020).

Bastek, J.-H., Kumar, S., Telgen, B., Glaesener, R. N. & Kochmann, D. M. Inverting the structure–property map of truss metamaterials by deep learning. Proc. Natl Acad. Sci. USA 119, e2111505119 (2022). This study is an illustration of the generation of a large annotated data set of elementary metamaterial unit cells combined with a deep learning algorithm.

Liu, K., Sun, R. & Daraio, C. Growth rules for irregular architected materials with programmable properties. Science 377, 975–981 (2022). This paper shows how to design disordered metamaterials through a random growth algorithm.

Mansimov, E., Mahmood, O., Kang, S. & Cho, K. Molecular geometry prediction using a deep generative graph neural network. Sci. Rep. 9, 20381 (2019).

Bongini, P., Bianchini, M. & Scarselli, F. Molecular generative graph neural networks for drug discovery. Neurocomputing 450, 242–252 (2021).

Xue, T., Adriaenssens, S. & Mao, S. Learning the nonlinear dynamics of mechanical metamaterials with graph networks. Int. J. Mech. Sci. 238, 107835 (2023).

Wang, L. et al. Deep generative modeling for mechanistic-based learning and design of metamaterial systems. Comput. Methods Appl. Mech. Eng. 372, 113377 (2020).

Dieleman, P., Vasmel, N., Waitukaitis, S. & van Hecke, M. Jigsaw puzzle design of pluripotent origami. Nat. Phys. 16, 63–68 (2020).

Zhai, Z., Wu, L. & Jiang, H. Mechanical metamaterials based on origami and kirigami. Appl. Phys. Rev. 8, 041319 (2021).

Chaudhary, G., Niu, L., Han, Q., Lewicka, M. & Mahadevan, L. Geometric mechanics of ordered and disordered kirigami. Proc. R. Soc. A 479, 20220822 (2023).

Dudte, L. H., Choi, G. P. & Mahadevan, L. An additive algorithm for origami design. Proc. Natl Acad. Sci. USA 118, e2019241118 (2021).

Wu, Y.-y et al. Evaluation of different culture techniques of osteoblasts on 3d scaffolds. Cent. Eur. J. Biol. 5, 456–465 (2010).

Carlquist, S. Living cells in wood 3. Overview; functional anatomy of the parenchyma network. Bot. Rev. 84, 242–294 (2018).

Podroužek, J., Marcon, M., Ninčević, K. & Wan-Wendner, R. Bio-inspired 3d infill patterns for additive manufacturing and structural applications. Materials 12, 499 (2019).

Acknowledgements

The authors acknowledge support from the Deutsche Forschungsgemeinschaft (DFG) under grant no. ZA171/14-1.

Author information

Authors and Affiliations

Contributions

The authors contributed equally to all aspects of the article.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Physics thanks Corentin Coulais, Lisa Manning and Xin Ren for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Glossary

- Auxetic behaviour

-

Lateral compression in response to longitudinal compression or lateral extension in response to longitudinal extension.

- Compaction bands

-

Narrow regions with increased material density.

- Embryonic shear band

-

A narrow region of shear strain localization anticipating the formation of a shear band.

- Meta-precipitates

-

A localized portion of a metamaterial with a lattice structure different from the main lattice structure.

- Process zone

-

The area close to the crack tip where linear elastic behaviour breaks down.

- Soft modes

-

A deformation associated with zero force.

- Tensegrity structures

-

Structures consisting of pre-strained members, some loaded in pure compression and others in pure tension, such that this distinction is maintained under external loading.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zaiser, M., Zapperi, S. Disordered mechanical metamaterials. Nat Rev Phys 5, 679–688 (2023). https://doi.org/10.1038/s42254-023-00639-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s42254-023-00639-3

This article is cited by

-

Creep failure of hierarchical materials

Scientific Reports (2024)