Abstract

The formation of oxygen vacancies is one of the most critical factors that can improve the electronic and catalytic properties of metal oxides, in which an important challenge is to lower the formation energy of oxygen vacancies at the interface structure. Here we show that clay surfaces rich with hydroxyl groups can induce the formation of oxygen vacancies in metal oxide catalysts. Based on density functional theory calculations, kaolinite is shown to hinder the surface dehydration process of Co3O4 nanoparticles, and enhances the charge transfer process at the interface by the highly diffusible protons. Experimental results confirm that vacancy-rich Co3O4 is easily produced by a reduction method and kaolinite enhances the formation of oxygen vacancies and divalent cobalt on the nanoparticle surface. As expected, the defective Co3O4/kaolinite exhibits enhanced catalytic and electrocatalytic performances. This finding provides an improved way to design efficient clay-based catalysts.

Similar content being viewed by others

Introduction

The presence of several oxygen vacancies (VO) is of great importance for nanocomposites to be used in nanomaterials.1,2,3 The electronic structure and catalytic properties of metal oxides (MO) can be tuned by introducing defect sites such as a vacancy and heteroatom, which manipulate their donor densities in transition metal oxides4,5,6. In catalytic systems, intrinsic structural defects can distinctly enhance the catalytic activity of nanocrystals7,8,9. Motivated by the advantages for oxygen vacancies, many researchers have focused on the development of new methods and approaches to generate appropriate density of defects on nanocrystals10,11,12. Owing to its low-cost, outstanding redox capability and favorable electrical conductivity, Co3O4 represents a promising candidate in various fields, including water splitting13, lithium-ion battery14, and particularly the field of heterogeneous catalysis15,16. In addition, the specific crystal structure of spinel Co3O4 with tetrahedral Co2+ ions and octahedral Co3+ ions have excellent environmental stability17. In some of the previous studies, oxygen vacancies were introduced into MO by an efficient Ar plasma strategy or a simple heat treatment to achieve enhanced electrocatalytic reduction18,19,20. As a reductant, NaBH4 was used to produce oxygen vacancies on the surface of reducible MO, which provide more active sites for oxygen evolution reaction catalysis21. Normally, the amount of oxygen vacancies would be increased by increasing the concentration of NaBH4. Tailoring oxygen vacancy of transition MO in the interface still remains a challenge.

Currently, clay minerals are considered as promising supporting materials with uniform morphology and environmental friendly properties22,23. Kaolinite (Kaol), a silicate mineral with chemical composition of Al2Si2O5(OH)4, is a typical 1:1 layered material with high crystallinity and special surface properties formed by stacking Al–O octahedral and Si–O tetrahedral structure24,25. Specifically, a pivotal intrinsic surface property on kaolinite is the existence of plenty of hydroxyl groups, which are beneficial for catalytic reactions26,27. This clay mineral has been widely applied to assemble functional nanoparticles due to its special surface properties, such as highly hydrophilic surface, large surface area and high stability.

Here, we report density functional theory (DFT) calculations on the interface structure and reduction properties of MO/clay interface, and propose a rational design of Co3O4/kaolinite (Co3O4/Kaol) composite catalyst for oxidation of pollutants. VO-rich Co3O4/Kaol composites with ultrafine-sized Co3O4 anchored on clay surface are synthesized by the reduction method. In addition, the Co2+/Co3+ redox behavior could also contribute to the high-catalytic activity. It is found that the Al–OH hydroxyl groups on kaolinite surface play a pivotal role in modulating the amount of oxygen vacancy and Co2+ on Co3O4 surface, and thus improving electronic structure and catalytic performance of Co3O4. The clay-supported oxide catalyst is clarified by a rational relationship between clay-modulated active sites and the enhanced catalytic activity, which could shed some light on future design of clay-supported catalysts.

Results

Support effect on the formation of oxygen vacancies

Although clay minerals have been used as support materials during the past decades to load varies functional particles for adsorption and catalytic applications, however, no detailed mechanism at atomic level was revealed so far. The reactions at the mineral–aqueous solution interface have attracted much attention during recent years28. Theoretical descriptions of interface structures between kaolinite and supported transition MO are still open questions due to several factors, such as the cluster structures of transition oxide, the charge and spin of TM ions, adsorption configurations, the influence of water molecules, and the diffusion of hydrogen atoms.

Based on DFT calculations, we have explored three typical processes involved in the synthesis of clay-supported oxides, i.e., adsorption, calcination, and reduction processes (Fig. 1). The interfacial structure is rather complicated since the Co–OH groups at Co3O4 cluster surface and the Al–OH groups at kaolinite surface are distorted under the influence of dispersion force (including hydrogen bonding) and interface charge transfer during the adsorption and calcination processes. During the adsorption process at Co3O4/Kaol interface, the adsorption energy is influenced by the distribution and specific contact configuration of Co3O4 nanocluster on kaolinite surface, such as spatial rotation (Supplementary Figure 1a) and translation at vertical and horizontal space (Supplementary Figure 1b). It is demonstrated that the hydrated Co3O4 nanoclusters can be strongly bonded to the entire surface of kaolinite, although the adsorption energy varies from −1.0 to −3.0 eV upon the spatial distribution of Co3O4 cluster on kaolinite surface, as influenced by interface bonding and structure distortions. The configurations with lowest adsorption energy come from configurations with most of their hydroxyl groups of Co3O4 closely adhered on kaolinite surface. Slight distortion of hydroxyl groups on Co3O4 cluster and kaolinite surface were identified as the main cause, due to the charge transfer at Co3O4/kaolinite interface (Fig. 2a). Occasionally, diffusions of one or two H atoms, i.e., redistribution of H bonding network on Co3O4 will lower the energy by ~0.5 eV. The calculated adsorption energies of Co3O4 cluster on kaolinite surface (Supplementary Figure 1c) are much lower than that of Co3O4 cluster on graphene (−0.88 eV)29, which is mainly attributed to the higher hydrophilic surface of clay mineral compared to other widely studied support materials.

Atomic structure evolution and charge transfer of Co3O4/kaolinite interface. Illustration of the support effect of clay on the atomic structure and energetics of MO (Co3O4 in this case) during the adsorption, calcination, and reduction processes, based on DFT calculations. During the adsorption of Co3O4 clusters on kaolinite, the strong interface bonding leads to the partial reduction of Co3+ (Co(Oh)3+ → Co(Oh)3−) due to the charge transfer (h+) and dispersion force between Co3O4 and kaolinite surface. The partial dehydration of Co3O4 occurs when calcined at the temperature where full dehydration should occur, due to surface distortion and bond shrink of Co3O4 (Co(Oh)3−δ → Co(V)3−) when supported on kaolinite. The VO formation energy of Co3O4 decreased significantly under the charge compensation of protons (H+) from the hydroxyl groups retained by clay surface, as predicted by DFT calculations. And low spin (LS) Co3-δ reduced to high spin (HS) Co2+. Dehydration energy and VO formation energy of Co3O4 with and without kaolinite support are given in Supplementary Figures 2 and 3. The support effect of kaolinite leads to the easier formation of VO on Co3O4/kaolinite interface.

Atomic structure and electronic structure of Co3O4/Kaolinite interfaces. a Charge density difference of Co3O4/kaolinite and b R-Co3O4/kaolinite. Blue corresponds to charge depletion and red to charge gain. Isosurfaces are shown in the range [−0.08 to 0.08] (e/Å3). c The top view of R-Co3O4/kaolinite. The partial density of states (PDOSs) of d Co3O4 cluster, e Co3O4/kaolinite interface, and f R-Co3O4/kaolinite interface. The PDOSs of Co3O4 in the last two structures are highlighted by gray area

The adsorption energy (Eads) of Co3O4 clusters on the surface of kaolinite is calculated as \({\rm{E}}_{\rm{ads}} = {\rm{E}}_{{\rm{Co}}_{3}{\rm{O}}_{4}/{\rm{kaolinite}}} - ({\rm{E}}_{{\rm{kaolinite}}} + {\rm{E}}_{{\rm{Co}}_{3}{\rm{O}}_{4}})\), where \({\rm{E}}_{{\rm{Co}}_{3}{\rm{O}}_{4}/{\rm{kaolinite}}}\), Ekaolinite and \({\rm{E}}_{{\rm{Co}}_{3}{\rm{O}}_{4}}\) is the total energies of the relaxed Co3O4/Kaol interface, kaolinite surface and Co3O4 cluster, respectively. Highly negative adsorption energy indicates it is energetically favorable for kaolinite to load hydrated metal oxide clusters. It is well-known that the deprotonation ability of hydrated oxide surface increases with the increase of metal ions sorption30. Similar to previous work31, we have defined the dehydration formation energy as \({\rm{E}}_{\rm{f}} = 1/n[{\rm{E}}_{{\rm{Co}}_{3}{\rm{O}}_{4}/{\rm{kaolinite}}-n{\rm{H}}_{2}{\rm{O}}}-({\rm{E}}_{{\rm{Co}}_{3}{\rm{O}}_{4}/{\rm{kaolinite}}} + n{\rm{E}}_{{\rm{H}}_{2}{\rm{O}}})]\), where \(E_{{\rm{Co}}_{3}{\rm{O}}_{4}/{\rm{kaolinite}}}\), \(E_{{\rm{H}}_{2}{\rm{O}}}\), and \(E_{{\rm{Co}}_{3}{\rm{O}}_{4}/{\rm{kaolinite}}-{\rm{H}}_2{\rm{O}}}\) are total energies of Co3O4/kaolinite interface, water molecule and Co3O4/kaolinite interface with n H2O removed.

The support effect of kaolinite on Co3O4 greatly facilitates the surface hydrogen bonding, charge transfer and proton diffusion between neighboring hydroxyls for the Co3O4/kaolinite (Fig. 2a) and R-Co3O4/kaolinite interfaces (Fig. 2b, c). In consideration of the charge compensation, it is observed that hydrogen atoms favor the deprotonated OH sites on Co–O–Co corner structure and tend to diffuse on Co3O4 clusters (Supplementary Movie 1). Similarly, the adsorption of Co3O4 clusters on kaolinite surface are much more complicated due to the large number of reactive surface hydroxyl groups. The dehydration energy of kaolinite supported Co3O4 nanoparticle was found around 1.3–2.2 eV, which is slightly higher than that of Co3O4 nanoparticle (0.7–1.6 eV, Supplementary Figure 2) or Co3O4 surface32. The dynamics study demonstrates that less number of H2O molecules break their bond with Co atoms on supported Co3O4 nanoparticle compared to unsupported Co3O4 nanoparticle (Supplementary Movie 2). Most significantly, the formation energy of VO for kaolinite supported Co3O4 clusters (around −0.6 to 2.4 eV) is much lower than that of unsupported Co3O4 clusters (2.5–3.6 eV, Supplementary Figure 3), or bulk Co3O4 (3.3 eV)33. And, the negative formation energy indicates that the reduction process can occur spontaneously even without additional reduction additives.

The oxygen vacancies introduce defect states in the band gap which are easily excited, create more catalytic and electrochemically active sites, and enhance catalytic reactions or the electrocatalytic activity for oxygen reduction reaction (OER) as reported previously. To illustrate the role of oxygen vacancies in modifying the electronic structure of Co3O4/kaolinite, the total densities of states and the projected densities of states of both the unsupported Co3O4 (Fig. 2d) and the kaolinite supported Co3O4 are compared (Fig. 2e). The calculated bandgap of hydrated Co3O4 clusters (1.4–1.8 eV) and hydrated Co3O4/kaolinite interface (1.4–1.8 eV), which are close to each other are slightly lower than that of bulk Co3O4 (1.8 eV)34. Notably, the bandgap of R-Co3O4/kaolinite (Fig. 2f) is much lowered (0.52–1.0 eV) due to the formation of oxygen vacancies under strong interface interaction between dangling bonds on dehydrated MO surface and hydroxyl groups on kaolinite. Besides, the band level of defect states in kaolinite supported Co3O4 is more hybridized and diffusive than that in unsupported Co3O4.

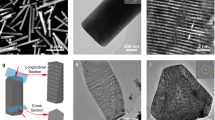

The characterization of oxygen vacancies

The X-ray powder diffraction (XRD) patterns for the samples can be readily indexed to kaolinite, while a weak Co3O4 diffraction peak at 36.8° was observed on 5% R-Co3O4/Kaol and 10% R-Co3O4/Kaol (Supplementary Figure 4a). The scanning electron microscopy (SEM) image reveals that kaolinite possesses a lamellar structure with a hexagonal appearance and a rough surface (Supplementary Figure 4b). Moreover, the anchoring of Co3O4 nanocrystals on 2D kaolinite was confirmed by transmission electron microscopy (TEM) (Fig. 3a, b). The small Co3O4 (4–8 nm) originated from the cobalt cations coordinated with NH3 was anchored on kaolinite surface and further reduction by NaBH4 solution while the particle remain the same size (Fig. 3c, d, Supplementary Figure 5a–d)35. Furthermore, the supported Co3O4 nanoparticles with amorphous surface layer (dashed line) show an interplanar spacing of 0.286 nm, which matches well with the (200) plane of face-centered-cubic phase of spinel Co3O4 (Fig. 3d)36. The gray area near grain boundary indicated strong interface bonding between Co3O4 and kaolinite, which is further confirmed by Raman spectroscopy (Fig. 3e, f). The Raman spectra of Co3O4, Co3O4 calcinated at 300 °C and Co3O4 reduced with NaBH4 (R-Co3O4) in Fig. 3e display characteristic peaks at 189 (F12g), 468 (Eg), 512 (F22g), 607 (F32g), and 673 (A1g) cm−1, in consistent with the standard Raman active modes of the Co3O4 cubic phase37,38. The blue shift of the Raman band around 650 cm−1 for R-Co3O4 sample could be attributed to the phonon confinement and distortion around oxygen vacancies39. Obvious differences were found for the Raman bands of 5% R-Co3O4/Kaol and 5%-Co3O4/Kaol, compared to Co3O4 or kaolinite (Fig. 3f), indicating strong interface interaction between Co3O4 and kaolinite. In order to clarify the nature of this phenomenon, the structures are simulated at atomic level. As can be estimated from the atomic structure of Co3O4 clusters (Fig. 3g), there is a huge decrease (from 40 to 15%) of the surface atoms in Co3O4 with the increase of Co3O4 particle size (from 4 to 10 nm). About one-third of the Co atoms are located in the surface layer of a Co3O4 cluster with particle size of 5 nm (Fig. 3h). Based on DFT calculations, for the bond length distribution of Co3O4, Co3O4/Kaol, and R-Co3O4/Kaol (Fig. 3i), the major difference lies on the shortened Co–O bonds (gray area) at interface structures due to the strong adsorption and the elongated Co–O bonds at the corner structure of Co3O4 cluster due to the formation of oxygen vacancies after reduction process.

Structure characterization of Co3O4/Kaol catalyst. a TEM images of Co3O4, scale bar: 100 nm. b TEM images of 5% R-Co3O4/Kaol, scale bar: 100 nm. c High-resolution TEM images of Co3O4, scale bar: 10 nm. d High-resolution TEM images of 5% R-Co3O4/Kaol, scale bar: 5 nm. The amorphous surface layer of one Co3O4 nanoparticle is indicated in dashed lines. e Raman spectra of the Co3O4, Co3O4 (300 °C), and R-Co3O4. f Raman spectra of the kaolinite, 5%-Co3O4/Kaol and 5% R-Co3O4/Kaol. g The estimated percentage of surface atoms in sphere Co3O4 nanoparticles with size from 4 to 10 nm. h The outmost surface layer of Co3O4 nanoparticles is highlighted in yellow for Co3O4/Kaol interface. i The bond length distribution of Co3O4, Co3O4/Kaol, and reduced Co3O4/Kaol. The major differences are highlighted in gray area. The shortening of O–H bond and elongation of Co–H2O bond are noticeable

Thermogravimetric analysis (TGA) was used to evaluate composition and structural stability (Fig. 4a). For kaolinite, the small mass loss below 110 °C corresponds to the removal of adsorbed water, and the mass loss in the range of 430–600 °C represents the dehydroxylation of the structural Al–OH–Al groups when kaolinite transforms into metakaolinite. After precalcination at 300 °C, the adsorbed water disappears while the bridging Al–OH hydroxyl groups are still retained40. The fastest mass loss process between 480 and 520 °C is attributed to the dehydroxylation of kaolinite. The above results confirm that the existence of abundant hydroxyl groups (about 11%) located on the surface of kaolinite. In addition, the dramatic weight loss of Co3O4 in the range of 250–350 °C suggests noticeable amount of surface hydroxyl (including chemically bonded water) groups removed during the dehydration process, in contrast to precalcined Co3O4 (300 °C) for which the corresponding weight loss is negligible. Notably, compared to pure Co3O4 or kaolinite, the weight loss of 5% R-Co3O4/Kaol slows down in the range of 300–480 °C due to the retarded dehydroxylation process at Co3O4/Kaol interface as demonstrated by DFT calculations (Fig. 1, the calculated dehydration energy of supported Co3O4 is lower than unsupported Co3O4).

The support effect of kaolinite on dehydration and reduction properties of Co3O4. a TGA curves of Co3O4, Co3O4 calcined at 300 °C, kaolinite, kaolinite calcined at 300 °C, and 5% R-Co3O4/Kaol composites. b FT-IR spectra of 5% R-Co3O4/Kaol calcined at different temperatures. c XPS Co 2p spectra of 5%-Co3O4/Kaol, 5% R-Co3O4/Kaol and 5%-Co3O4R/Kaol. d H2-TPR profile of 5% R-Co3O4/Kaol and 5% R-Co3O4/Kaol calcined at different temperatures (300–700 °C).

Moreover, Fourier transform infrared spectroscopy (FT-IR) was employed to analyze surface groups under different calcination conditions. While for kaolinite (Supplementary Figure 6) or Co3O4 nanoparticles (Fig. 4b), the broad bands of adsorbed water (near 3400 and 1600 cm−1) disappeared above 300 °C, for 5% R-Co3O4/Kaol, these adsorbed water are partially retained (Supplementary Figure 7). The stability of these bonded water at interface structure along with the intrinsic hydroxyl groups on kaolinite surface, as a key factor to modulate VO of metal oxide, are tested in water (Supplementary Figure 8).

In order to clarify the formation of oxygen vacancies at the interfacial structure between MO and clay material, X-ray photoelectron spectroscopy (XPS) analysis were performed. High-resolution Co 2p spectra verify the ratio of Co2+/Co3+ in three samples follows the order: 5% R-Co3O4/Kaol > 5%-Co3O4R/Kaol ≈ 5%-Co3O4/Kaol (Fig. 4c), which reflects that more vacancies were generated in 5% R-Co3O4/Kaol41. The peaks at ~780.1 eV and ~781.6 eV are indexed to Co3+ (Co 2p3/2) and Co2+ (Co 2p3/2), respectively42. The slight shift of Co 2p peak of 5% R-Co3O4/Kaol to higher binding energy could be attributed to the strong interface bonding between Co3O4 and kaolinite. In addition, the emergence of satellite peak (sat.) implies the generation of more Co2+ species43. As the concentration of reductants increases from 0.05 to 0.2 M, the Co2+ species increase slowly (Supplementary Figure 9a). Notably, very low concentration of reducing agent is needed for the kaolinite supported Co3O4 (5% R-Co3O4/Kaol 0.05 M) to produce similar amount of Co2+ for Co3O4 (0.5 M) (Supplementary Figure 9b), which demonstrated the easy formation of oxygen vacancies at Co3O4/Kaol interface as predicted by DFT calculations. Although metal cation vacancies would have a significant effect on the catalytic activity44, cation vacancies are not detected during the reduction under NaBH4, which excluded the simultaneous formation of cation vacancies. The XPS survey spectra of the different samples are given in Supplementary Figure 10. We also measured the change of binding energy of Co 2p and O 1s in R-Co3O4/Kaol under different calcination temperature (Supplementary Figure 11). The increase of Co2+ in R-Co3O4/Kaol under higher calcination temperature suggests the further modulation of oxygen vacancy by dehydroxylation process. No obvious shift of the binding energy of O1s, C1s, Al 2p, and Si 2p are found (Supplementary Figures 12 and 13)45. Besides, the existence of Vo in the R-Co3O4/Kaol was also measured by electron paramagnetic resonance (EPR) spectroscopy46. Generally, the intensity means the concentration of Vo. The reduced Co3O4/Kaol shows a much stronger EPR signal than pristine Co3O4/Kaol, revealing the generation of abundant oxygen vacancies in R-Co3O4/Kaol47 (Supplementary Figure 14).

To obtain a deeper understanding of how hydroxyl group interacts with oxygen vacancies, the reduction properties of samples were tested using H2-temperature programmed reduction (H2-TPR) (Fig. 4d). For 5% R-Co3O4/Kaol (300 °C), the reduction peaks in the range of 280–410 °C could be attributed to the Co3+ → Co2+ reduction of Co3O4 nanoparticles under the retardant effect of hydroxyl group, which are much higher than that of unsupported Co3O4 nanoparticles with size of about 20 nm48. For 5% R-Co3O4/Kaol (500 °C), three peaks are shifted to the lower region due to the weakening of the retardant effect since hydroxyl groups are partially removed. Finally, for 5% R-Co3O4/Kaol (700 °C), the separated peaks are merged into one reduction peak (358 °C) due to the complete removal of the hydroxyl groups on kaolinite. The peak at 714 °C can be assigned to the reduction of cobalt silicate generated at Co3O4/Kaol interface49. In a word, the above results further confirm that kaolinite can modulate the reducibility of Co3O4 by controlling the amount of hydroxyl groups on kaolinite to modulate vacancy defects.

Catalytic performance evaluation

Orange II (C16H11N2NaO4S) dyes belong to a class of organic compounds known as an anionic azo-dyes50, which are widely used in industries51. In addition, they are stable with respect to biological degradation and sometimes may produce more hazardous intermediates in wastewater treatment processes52. Advanced oxidation processes are effective remediation to degrade orange II azo-dye from an aqueous solution53. As shown in the degradation test of Orange II, 5% R-Co3O4/Kaol exhibited higher catalytic activity compared to 5%-Co3O4/Kaol and 5%-Co3O4R/Kaol (Fig. 5a), and good regeneration stability (Fig. 5b). The reduced Co3O4/Kaol samples showed enhanced catalytic activity compared to pristine samples (Supplementary Figure 15), which can be attributed to the facilitated reactive oxygen production by oxygen vacancies when react with peroxymonosulfate (PMS). Note that the samples prepared at higher temperature which have less hydroxyl groups at Co3O4/Kaol interface showed decreased catalytic efficiency, implying the importance of hydroxyl groups on modulating catalytic activities (Fig. 5c)54. Besides, the negligible degradation of Orange II over PMS or 5% R-Co3O4/Kaol indicated the crucial role of their synergistic effect on the degradation reactions (Supplementary Figure 16). Based on above results, it could be speculated that a great enhancement in the catalytic activity could be possibly attributed to the following reasons: the coupled interface of Co3O4/Kaol, the generation of oxygen vacancies and the frequent cycle reaction between divalent cobalt ion and trivalent cobalt ion.

Catalytic performance evaluation of Co3O4/Kaol catalyst. a Effect of different catalysts on Orange II removal. b Recycle test of the catalyst. The catalyst is recycled from the reaction system by simple washing and drying. The decrease of the catalytic efficiency is mainly caused by the mass loss of catalyst during this simple recycle process. Reaction conditions: [Orange II] = 50 mg L−1, [PMS] = 0.5 g L−1, [Catalyst] = 0.1 g L−1. c Effects of 5% R-Co3O4/Kaol catalysts with different calcination temperatures on Orange II removal. d Cyclic voltammetric (CV) curves of the 5%-Co3O4/Kaol and the 5% R-Co3O4/Kaol on glassy carbon electrodes in 1 M KOH. e Linear sweep voltammetry (LSV) curves of the 5%-Co3O4/Kaol and the 5% R-Co3O4/Kaol. f Tafel plots of 5% Co3O4/Kaol and the 5% R-Co3O4/Kaol

Benefiting from its PMS activation behavior, the effects of different conditions such as NaBH4 concentrations, catalyst dosages, PMS dosage, reaction temperatures, and solution pH (Supplementary Figures 17 and 18) as well as coexisting anions (Supplementary Figure 19) on the catalytic efficiency were also investigated. To confirm the reactive oxygen species, the radical scavenger tests were conducted using tert-butyl alcohol (TBA) and methanol (Supplementary Figure 20). Methanol exhibited an obvious inhibitory effect on the degradation of Orange II, due to the scavenge of sulfate radical by methanol (MeOH)55,56. The possible mechanism of the highly efficient catalyst could be summarized (Supplementary Note 1). These results confirm the significant practical application of as-prepared catalyst in the treatment of wastewater with various anions and also provide a reasonable evidence to support the role of oxygen vacancies.

To further verify the role of kaolinite for modulate oxygen vacancy of MO, the samples were also investigated as electrocatalyst for oxygen evolution reactions. According to the CV curves of pristine 5%-Co3O4/Kaol and reduced 5% R-Co3O4/Kaol samples (Fig. 5d), the VO-rich 5% R-Co3O4/Kaol shows a distinct current density, which suggests massive electrochemically active site existed on the surface of catalyst57. Moreover, the VO-rich catalyst possesses much higher OER catalytic activity than pristine catalyst (Fig. 5e). At a potential of 1.65 V (vs. RHE), the reduced Co3O4/Kaol exhibit a current density of 1.05 mA cm−2, i.e., >4 times higher than the pristine one (0.26 mA cm−2)58. Similarly, VO-rich Co3O4/Kaol exhibits a smaller Tafel slope than pristine sample (Fig. 5f)59, which means a faster increase of the OER rate with the increasing potential and could benefit the OER performance of Co3O4.

Moreover, electrochemical impedance spectroscopy (EIS) analyses were employed to evaluate the charge transfer capability on the surface of catalysts in PMS and Na2SO4 solutions (Supplementary Figure 21a). The 5% R-Co3O4/Kaol has relatively lower charge transfer resistance than the pristine 5%-Co3O4/Kaol sample, because oxygen vacancies play a pivotal role in the charge transfer process. In addition, photoluminescence (PL) measurements were employed to analyze the separation and recombination of charge carriers in Co3O4/Kaol (Supplementary Figure 21b). Compared to the pristine sample, the emission band of 5% R-Co3O4/Kaol at ∼420 nm obviously decreases, which may promote the separation of charge and contribute to the enhanced redox reaction60. The generated oxygen vacancies could not only enhance their catalytic activity, delocalize electrons on/near the nanoparticles surface, but also dramatically increase the electronic conductivity.

Discussion

In conclusion, DFT calculations have revealed that the hydroxyl groups on the clay surface would promote the formation of VO on the supported oxides when they are dehydrated upon calcination process. The enhanced reduction ability of Co3O4/Kaol during the adsorption, dehydration and reduction process is clarified as interface bonding, surface distortion and proton transfer mechanisms at atomic level. The concentration of oxygen vacancies in Co3O4 nanocrystals can be modulated by the hydroxyl groups on clay support, the interface of which can act as active centers for catalytic oxidation reaction. In this work, it is found that the synergistic effect of clay support enhanced the concentration of VO on Co3O4 surface and modified the redox activity of Co (due to the lowered formation energy under charge compensation of protons from hydroxyl groups of kaolinite), and meanwhile lead to the higher dispersion of nano-Co3O4 and stronger adsorption of organic pollutant on kaolinite (due to the hydrophilic surface of kaolinite), which finally lead to the enhanced catalytic activity at Co3O4/clay interface. It should be noted that this finding also applies to other reducible metal oxide. This work not only provides insights into the fundamental understanding of the support effects such as strong adsorption and enhanced reducibility of clay on metal oxide catalysts, but also experimentally demonstrates the modulation of oxygen vacancies, i.e., the redox activity of MO in oxide/clay nanocomposites using earth-abundant clay minerals as support material for enhanced catalytic performance.

Methods

Materials

Natural kaolinite was obtained from China Kaolinite Clay Co., Ltd. (Suzhou, China), and its chemical compositions are as follows: SiO2 53.27%, Al2O3 42.46%, SO3 2.19%, K2O 0.54%, Fe2O3 0.48%, TiO2 0.33%, P2O5 0.26%, MgO 0.16%, CaO 0.09%, and CuO 0.01%. Cobalt acetate tetrahydrate Co(CH3COO)2·4H2O, ethanol (EtOH), orange ΙΙ (C16H11N2NaO4S), ammonium hydroxide (NH3·H2O), methanol (MeOH), sodium borohydride (NaBH4), TBA, and PMS (KHSO5·0.5KHSO4·0.5K2SO4) were purchased from Sinopharm Chemical Reagent Co. Ltd. Deionized water was used in all experiments. All chemicals are of analytical grade reagents and were used as received without further purification.

Synthesis of Co3O4 nanocrystals

In a typical experiment, 3 mL of 0.2 M Co(CH3COO)2·4H2O aqueous solution was added to 48 mL of ethanol to form a clear solution, followed by the addition of 2 ml of NH3·H2O. The above solution was stirred for 8 h at 80 °C. After that, the resulting solution was subsequently transferred to an autoclave for hydrothermal reaction at 150 °C for 3 h. The product was washed with water and ethanol for several times.

Synthesis of Co3O4/Kaol

The Co3O4/kaolinite (Co3O4/kaol) was prepared by mixing two different solutions: solution A contained a certain amount of Co3O4 nanocrystals in 10 mL ethanol and was treated with ultrasound for 30 min. Solution B included 0.2 g kaolinite in 20 mL ethanol and was ultrasonicated for around 30 min. The mass ratios of Co3O4 to kaolinite were kept at 0.5%, 1%, 2%, 5%, and 10%, respectively. Solution B was continuously stirred for 10 min to disperse completely, to which the solution A was added dropwise. After reaction for 1 h, the products were dried in an oven at 80 °C for 12 h, then, calcined in a muffle furnace at 300 °C for 2 h in air with a heating rate of 5 °C min−1 and allowed to cool naturally to room temperature. The final products were labeled as 0.5%-Co3O4/Kaol, 1%-Co3O4/Kaol, 2%-Co3O4/Kaol, 5%-Co3O4/Kaol, and 10%-Co3O4/Kaol.

Synthesis of reduced Co3O4/Kaol

The reduced samples were prepared by stirring pristine Co3O4/Kaol nanocomposites in 0.05 M NaBH4 solution for 30 min, then the suspension was washed with water and ethanol, solid samples were dried at 60 °C for 10 h. The final products were labeled as 0.5% R-Co3O4/Kaol, 1% R-Co3O4/Kaol, 2% R-Co3O4/Kaol, 5% R-Co3O4/Kaol, and 10% R-Co3O4/Kaol, respectively.

Synthesis of reduced Co3O4 and kaolinite nanocomposites

The samples were prepared by stirring Co3O4 calcined at 300 °C for 2 h in 0.05 M NaBH4 solution for 30 min, then the suspension was washed with water and ethanol, solid samples were dried at 60 °C for 10 h. A certain amount of treated Co3O4 nanocrystals were added to 10 mL ethanol and sonicated for 30 min, then, 0.2 g kaolinite was dispersed in 20 mL ethanol and ultrasonically dispersed for 30 min, respectively. The mixture of the above two different solution was stirred 1 h, and the suspension was dried at 60 °C for 10 h. The final product was labeled as 5%-Co3O4R/Kaol, respectively.

Synthesis of R-Co3O4/Kaol (500 and 700 °C)

The synthesis of 5% R-Co3O4/Kaol (500 and 700 °C) was similar to the one of reduced Co3O4/Kaol, and the difference was that 5% R-Co3O4/Kaol (500 and 700 °C) was prepared at different calcination temperatures (500 and 700 °C), otherwise reduced Co3O4/Kaol was prepared at 300 °C calcination.

Materials characterization

XRD patterns (2θ, 5–70°) were recorded by using a Bruker-AXS D8 Advance diffractometer with Cu Kα radiation (λ = 1.5406 Å). SEM was performed on a Tescan Mira3 LMU instrument. Transmission electron microscope (TEM) and high-resolution TEM were obtained on Titan G2 60–300 microscope operating at 300 kV and FEI Tecnai G2 f20 microscope operating at 200 kV, respectively. (FT-IR) was measured using a Bruker Tensor 27 spectrophotometer. (TGA) was carried out on a thermal analyzer (Netzsch sta 449F3). H2-temperature programmed reduction (H2-TPR) was conducted on a Finesorb 3010H physic-chemical adsorption apparatus. Raman test was run on a LabRAM HR (wavelength = 532 nm). (XPS) measurements were obtained using an ESCALAB 250 Xi spectrometer. EPR tests were carried out in Bruker A300. Electrochemical impedance spectroscopy (EIS) measurements were performed in a conventional three-electrode cell using a CHI760D electrochemical workstation. The PL was measured on a Hitachi F-7000 fluorescence spectrophotometer.

Catalytic degradation procedure

For the organic pollutant degradation process, Orange II dye was selected as a model pollutant. In a typical test, 3 mg of catalyst was first added to 30 mL of Orange II solution with an initial concentration of 50 mg L−1 at room temperature without pH adjustment. Then the suspension was stirred for 15 min to establish the adsorption–desorption equilibrium. Afterwards, the catalytic reaction was triggered by adding a small quantity of PMS solution. At various time intervals, 1 mL of mixture solution was extracted from the reactor and quenched with 1 mL of methanol. The concentration of Orange II (λ = 486 nm) was determined using a UV–vis spectrometer.

OER measurements

The oxygen reduction reaction (OER) properties were carried out using an electrochemical workstation (Metrohm, Switzerland) with a three-electrode system in 1 M aqueous KOH solution. The synthesized electrode was applied to the working electrode. A drop casting method was used to prepare catalysts on the glassy carbon (GC). Typically, a sample slurry was prepared by mixing 1 mL of ethanol, 5 mg of sample and 25 µL of Nafion (5 wt%, Aldrich), followed by sonicated for 30 min to obtain the catalyst ink. Then a suitable amount of the slurry was transferred onto the GC electrode working area with a constant catalyst loading of 0.07 mg cm−2. Pt sheet work as the counter electrode, saturated calomel as the reference electrode. The cyclic voltammetric (CV) measurements were conducted performed with the scan rate of 50 mV s−1 and linear sweep voltammetry curves were performed with the scan rate of 20 mV s−1. The Tafel slope can be obtained by using Tafel equation. According to the beginning of the linear region in Tafel plots, the onset potentials can be determined.

Computational details

All calculations were performed with the program CASTEP (Cambridge Sequential Total Energy Package) code, with the exchange-correlation potential by Perdew, Burke and Ernzerhof (PBE)61 and dispersion corrections by Grimme (PBE-D2)62. The ultrasoft pseudo-potential plane-wave formalism with energy cutoff of 500 eV and density-mixing scheme was used63,64. For electronic structure calculations, the GGA + U method was used with the Ueff (=U−J) parameter set to 3 eV for the 3d electrons of Co atom. The Monkhorst–Pack65 grid with 2 × 2 × 1 k points mesh was used for electronic structure calculations, while Gamma point was used for geometrical calculations. During geometry optimizations, the convergence threshold for self-consistent field tolerance was set to 1.0 × 10−6 eV atom−1, all forces on the atoms were converged to less than 0.03 eV Å−1, and the maximum ionic displacement was within 0.001 Å. The original structure of kaolinite Al16Si16O40(OH)32 with 2√2 × √2 × 1 supercell (8 kaolinite units) was taken from previous work. Under Broyden–Fletcher–Goldfarb–Shanno minimization algorithm, the cell parameters and atomic coordination of all structures were fully relaxed. After the relaxation of bulk kaolinite, the slab structure of kaolinite surface are constructed by adding 15 Å vacuum in (001) direction, then the c axial is kept fixed during the relaxation. Co3O4 is adsorbed only on top side of kaolinite slab, and we verified that the dipole correction of kaolinite surface and the image interactions between Co3O4 clusters are negligible. H2O molecules and Co3O4 cluster structures are confined in 20 Å box. The bottom Si–O layer of kaolinite surface is fixed during the adsorption of Co3O4 cluster. For the Co3O4 cluster, two symmetric structures with antiferromagnetic ground state are considered, a small cluster (Co13O38H43) and a large cluster (Co24O64H64). Since the later requires a larger slab structure of kaolinite (Al32Si32O80(OH)64 with 4 × 2 × 1 supercell) to load Co3O4 cluster which is computational demanding, in this work we adopted Co13O38H43 cluster for the Co3O4/Kaol interface structure. During the dehydration process (simulate the calcination process), the −H2O groups are removed gradually from Co3O4 cluster. For the dehydrated Co3O4 (D-Co3O4, Co13O31H29) cluster, about one-third of (the longest) surface −H2O groups are removed from the Co3O4 cluster. Then, we can obtain the reduced Co3O4 (R-Co3O4, Co13O30H29) cluster by removed one O atom from the dehydrated Co3O4 cluster. Ab initio molecular dynamics simulations were carried out at 273 or 573 K by a Nose thermostat set using a statistical ensemble with fixed particle number, volume and temperature. The time step was set to 1 fs, and the systems were equilibrated for more than 1 ps.

Data availability

The authors declare that the main data supporting the findings of this study are available within the paper and its Supplementary Information file. Other relevant data are available from the corresponding author upon reasonable request.

References

Zhang, N. et al. Oxide defect engineering enables to couple solar energy into oxygen activation. J. Am. Chem. Soc. 138, 8928–8935 (2016).

Gao, S. et al. Atomic layer confined vacancies for atomic-level insights into carbon dioxide electroreduction. Nat. Commun. 8, 14503 (2017).

Paier, J., Penschke, C. & Sauer, J. Oxygen defects and surface chemistry of ceria: quantum chemical studies compared to experiment. Chem. Rev. 113, 3949–3985 (2013).

Schmitt, R., Spring, J., Korobko, R. & Rupp, J. L. M. Design of oxygen vacancy configuration for memristive systems. ACS Nano 11, 8881–8891 (2017).

Veal, B. W. et al. Interfacial control of oxygen vacancy doping and electrical conduction in thin film oxide heterostructures. Nat. Commun. 7, 11892 (2016).

Nowotny, J. et al. Defect chemistry and defect engineering of TiO2-based semiconductors for solar energy conversion. Chem. Soc. Rev. 44, 8424–8442 (2015).

Tong, Y. et al. Oxygen vacancies confined in nickel molybdenum oxide porous nanosheets for promoted electrocatalytic urea oxidation. ACS Catal. 8, 1–7 (2018).

Chen, D. et al. In situ evolution of highly dispersed amorphous CoOx clusters for oxygen evolution reaction. Nanoscale 9, 11969–11975 (2017).

Yan, D. et al. Defect chemistry of nonprecious-metal electrocatalysts for oxygen reactions. Adv. Mater. 29, 1606459 (2017).

Li, G., Blake, G. R. & Palstra, T. T. M. Vacancies in functional materials for clean energy storage and harvesting: the perfect imperfection. Chem. Soc. Rev. 46, 1693–1706 (2017).

Zhang, J.-J. et al. Oxygen vacancy engineering of Co3O4 nanocrystals through coupling with metal support for water oxidation. ChemSusChem 10, 2875–2879 (2017).

Fu, L., Yang, H., Hu, Y., Wu, D. & Navrotsky, A. Tailoring mesoporous γ-Al2O3 properties by transition metal doping: a combined experimental and computational study. Chem. Mater. 29, 1338–1349 (2017).

Zhu, Y. P., Ma, T. Y., Jaroniec, M. & Qiao, S. Z. Self-templating synthesis of hollow Co3O4 microtube arrays for highly efficient water electrolysis. Angew. Chem. Int. Ed. 56, 1324–1328 (2017).

Wu, Z.-S. et al. Graphene anchored with Co3O4 nanoparticles as anode of lithium ion batteries with enhanced reversible capacity and cyclic performance. ACS Nano 4, 3187–3194 (2010).

Yan, D. et al. Engineering the coordination geometry of metal–organic complex electrocatalysts for highly enhanced oxygen evolution reaction. J. Mater. Chem. A 6, 805–810 (2018).

Peng, S. et al. Necklace-like multishelled hollow spinel oxides with oxygen vacancies for efficient water electrolysis. J. Am. Chem. Soc. 140, 13644–13653 (2018).

Tong, Y. et al. A bifunctional hybrid electrocatalyst for oxygen reduction and evolution: cobalt oxide nanoparticles strongly coupled to B,N-decorated graphene. Angew. Chem. Int. Ed. 129, 7227–7231 (2017).

Cheng, F. et al. Enhancing electrocatalytic oxygen reduction on MnO2 with vacancies. Angew. Chem. Int. Ed. 52, 2474–2477 (2013).

Chen, D. et al. Preferential cation vacancies in perovskite hydroxide for the oxygen evolution reaction. Angew. Chem. Int. Ed. 57, 8691–8696 (2018).

Xu, L. et al. Plasma-engraved Co3O4 nanosheets with oxygen vacancies and high surface area for the oxygen evolution reaction. Angew. Chem. Int. Ed. 55, 5277–5281 (2016).

Zhuang, L. et al. Ultrathin iron–cobalt oxide nanosheets with abundant oxygen vacancies for the oxygen evolution reaction. Adv. Mater. 29, 1606793 (2017).

Fu, L., Yan, Z., Zhao, Q. & Yang, H. Novel 2D nanosheets with potential applications in heavy metal purification: a review. Adv. Mater. Interfaces 5, 1801094 (2018).

Peng, K., Fu, L., Ouyang, J. & Yang, H. Emerging parallel dual 2D composites: natural clay mineral hybridizing MoS2 and interfacial structure. Adv. Funct. Mater. 26, 2666–2675 (2016).

Long, M. et al. Fe2O3 nanoparticles anchored on 2D kaolinite with enhanced antibacterial activity. Chem. Commun. 53, 6255–6258 (2017).

Zhang, Y., Tang, A., Yang, H. & Ouyang, J. Applications and interfaces of halloysite nanocomposites. Appl. Clay Sci. 119, 8–17 (2016).

Zhao, Q., Fu, L., Jiang, D., Xi, Y. & Yang, H. A nanoclay-induced defective g-C3N4 photocatalyst for highly efficient catalytic reactions. Chem. Commun. 54, 8249–8252 (2018).

Peng, Y. et al. Molecular-level insight into how hydroxyl groups boost catalytic activity in CO2 hydrogenation into methanol. Chem. 4, 613–625 (2018).

Geckeis, H., Lützenkirchen, J., Polly, R., Rabung, T. & Schmidt, M. Mineral–water interface reactions of actinides. Chem. Rev. 113, 1016–1062 (2013).

Wang, C. et al. Synergistic effect of Co3O4 nanoparticles and graphene as catalysts for peroxymonosulfate-based orange II degradation with high oxidant utilization efficiency. J. Phys. Chem. C 120, 336–344 (2016).

Yan, Z., Fu, L. & Yang, H. Functionalized 2D clay derivative: hybrid nanosheets with unique lead sorption behaviors and interface structure. Adv. Mater. Interfaces 5, 1700934 (2017).

Fu, L., Yang, H., Tang, A. & Hu, Y. Engineering a tubular mesoporous silica nanocontainer with well-preserved clay shell from natural halloysite. Nano Res. 10, 2782–2799 (2017).

Chen, J. & Selloni, A. Water adsorption and oxidation at the Co3O4 (110) surface. J. Phys. Chem. Lett. 3, 2808–2814 (2012).

Shi, X., Bernasek, S. L. & Selloni, A. Formation, electronic structure, and defects of Ni substituted spinel cobalt oxide: a DFT + U study. J. Phys. Chem. C 120, 14892–14898 (2016).

Wang, Y. et al. Reduced mesoporous Co3O4 nanowires as efficient water oxidation electrocatalysts and supercapacitor electrodes. Adv. Energy Mater. 4, 1400696 (2014).

Liang, Y. et al. Co3O4 nanocrystals on graphene as a synergistic catalyst for oxygen reduction reaction. Nat. Mater. 10, 780 (2011).

Zhang, P., Wang, T., Chang, X., Zhang, L. & Gong, J. Synergistic cocatalytic effect of carbon nanodots and Co3O4 nanoclusters for the photoelectrochemical water oxidation on hematite. Angew. Chem. Int. Ed. 55, 5851–5855 (2016).

Xing, L.-L., Chen, Z.-H. & Xue, X.-Y. Controllable synthesis Co3O4 nanorods and nanobelts and their excellent lithium storage performance. Solid State Sci. 32, 88–93 (2014).

Hadjiev, V. G., Iliev, M. N. & Vergilov, I. V. The Raman spectra of Co3O4. J. Phys. C: Solid State Phys. 21, L199 (1988).

Gao, S. et al. Ultrathin Co3O4 layers realizing optimized CO2 electroreduction to formate. Angew. Chem. Int. Ed. 55, 698–702 (2016).

Li, X., Yang, Q., Ouyang, J., Yang, H. & Chang, S. Chitosan modified halloysite nanotubes as emerging porous microspheres for drug carrier. Appl. Clay Sci. 126, 306–312 (2016).

Lei, F. et al. Oxygen vacancies confined in ultrathin indium oxide porous sheets for promoted visible-light water splitting. J. Am. Chem. Soc. 136, 6826–6829 (2014).

Gao, C. et al. Co3O4 hexagonal platelets with controllable facets enabling highly efficient visible-light photocatalytic reduction of CO2. Adv. Mater. 28, 6485–6490 (2016).

Zhai, T. et al. Phosphate ion functionalized Co3O4 ultrathin nanosheets with greatly improved surface reactivity for high performance pseudocapacitors. Adv. Mater. 29, 1604167 (2016).

Huang, L. et al. Rapid cationic defect and anion dual-regulated layered double hydroxides for efficient water oxidation. Nanoscale 10, 13638–13644 (2018).

Liu, D. et al. Hydrogen evolution activity enhancement by tuning the oxygen vacancies in self-supported mesoporous spinel oxide nanowire arrays. Nano Res. 11, 603–613 (2018).

Liang, Z. et al. Quasi-single-crystalline CoO hexagrams with abundant defects for highly efficient electrocatalytic water oxidation. Chem. Sci. 9, 6961–6968 (2018).

Zeng, Y. et al. Oxygen-vacancy and surface modulation of ultrathin nickel cobaltite nanosheets as a high-energy cathode for advanced Zn-ion batteries. Adv. Mater. 30, 1802396 (2018).

Zhu, H., Razzaq, R., Jiang, L. & Li, C. Low-temperature methanation of CO in coke oven gas using single nanosized Co3O4 catalysts. Catal. Commun. 23, 43–47 (2012).

Xie, R. et al. Solvothermally derived Co3O4@m-SiO2 nanocomposites for Fischer–Tropsch synthesis. Catal. Commun. 12, 380–383 (2011).

Yao, Y. et al. Magnetic core–shell CuFe2O4@C3N4 hybrids for visible light photocatalysis of Orange II. J. Hazard Mater. 297, 224–233 (2015).

An, S. et al. High-density ultra-small clusters and single-atom fe sites embedded in graphitic carbon nitride (g-C3N4) for highly efficient catalytic advanced oxidation processes. ACS Nano 12, 9441–9450 (2018).

Cai, C. et al. Visible light-assisted heterogeneous Fenton with ZnFe2O4 for the degradation of Orange II in water. Appl. Catal. B 182, 456–468 (2016).

Li, X. et al. Single cobalt atoms anchored on porous N-doped graphene with dual reaction sites for efficient fenton-like catalysis. J. Am. Chem. Soc. 140, 12469–12475 (2018).

Zhang, J. et al. Cation vacancy stabilization of single-atomic-site Pt1/Ni(OH)x catalyst for diboration of alkynes and alkenes. Nat. Commun. 9, 1002 (2018).

Shao, P. et al. Identification and regulation of active sites on nanodiamonds: establishing a highly efficient catalytic system for oxidation of organic contaminants. Adv. Funct. Mater. 28, 1705295 (2018).

Wang, Y., Cao, D. & Zhao, X. Heterogeneous degradation of refractory pollutants by peroxymonosulfate activated by CoOx-doped ordered mesoporous carbon. Chem. Eng. J. 328, 1112–1121 (2017).

Wang, Y., Yan, D., El Hankari, S., Zou, Y. & Wang, S. Recent progress on layered double hydroxides and their derivatives for electrocatalytic water splitting. Adv. Sci. 5, 1800064 (2018).

Wan, S. et al. Hierarchical Co(OH)F superstructure built by low-dimensional substructures for electrocatalytic water oxidation. Adv. Mater. 29, 1700286 (2017).

Wang, Y., Qiao, M., Li, Y. & Wang, S. Tuning surface electronic configuration of NiFe LDHs nanosheets by introducing cation vacancies (Fe or Ni) as highly efficient electrocatalysts for oxygen evolution reaction. Small 14, 1800136 (2018).

Zhao, Z. et al. Polyaniline-decorated {001} facets of Bi2O2CO3 nanosheets: in situ oxygen vacancy formation and enhanced visible light photocatalytic activity. ACS Appl. Mater. Interfaces 7, 730–737 (2015).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Grimme, S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 27, 1787–1799 (2006).

Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 41, 7892–7895 (1990).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (41572036), the National Science Fund for distinguished Young Scholars (51225403), the Strategic Priority Research Program of Central South University (ZLXD2017005), the Innovation Driven Plan of Central South University (2018CX018), the Hunan Provincial Science and Technology Project (2016RS2004 and 2015TP1006), the Hunan International Scientific and Technological Cooperation Base of Mineral Materials (2018WK4023), and the CSU Graduate Independent Exploration Innovation Program (2017zzts107). Computing resources were provided by High Performance Computing Centre of Central South University and the National Supercomputing Centre of China in Shenzhen.

Author information

Authors and Affiliations

Contributions

Q.Z. and L.F. contributed equally to this work. H.Y. conceived the project. Q.Z. and L.F. wrote initial drafts of the work. Y.X. offered the help in revising the drafts. H.Y. wrote the final paper. L.F. performed the density functional theory calculations and related analysis. Q.Z. designed the experiments, synthesized, and characterized the materials. Q.Z., H.Y., Y.H., D.J., and J.O. analyzed the data. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, Q., Fu, L., Jiang, D. et al. Nanoclay-modulated oxygen vacancies of metal oxide. Commun Chem 2, 11 (2019). https://doi.org/10.1038/s42004-019-0112-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-019-0112-9

This article is cited by

-

Direct methane protonic ceramic fuel cells with self-assembled Ni-Rh bimetallic catalyst

Nature Communications (2023)

-

Effectively Modulating Oxygen Vacancies in Flower-Like δ-MnO2 Nanostructures for Large Capacity and High-Rate Zinc-Ion Storage

Nano-Micro Letters (2023)

-

Ag/TiO2/WO3 nanoparticles with efficient visible light photocatalytic activity

Optoelectronics Letters (2022)

-

Oxygen vacancies in nanostructured hetero-interfacial oxides: a review

Journal of Nanoparticle Research (2022)

-

Nano-mineral induced nonlinear optical LiNbO3 with abundant oxygen vacancies for photocatalytic nitrogen fixation: boosting effect of polarization

Applied Nanoscience (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.