Abstract

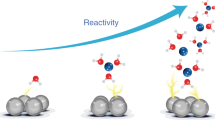

Electrocatalysis of small gas molecules driven by renewable energy sources offers a promising route to carbon-neutral fuels and chemicals. Such small-molecule conversion reactions rely on water as a source of protons and electrons, however, thus limiting energy and power densities owing to the low solubility of gas molecules in water. The oxygen reduction reaction (ORR) is an exemplar of such limitations. Here we demonstrate that the high O2-carrying capacity of aqueous solutions endowed with porosity arising from microporous nanocrystals with hydrophobic internal surfaces and hydrophilic external surfaces—termed microporous water—enhances ORR electrocatalysis in water. Use of silicalite-1 nanocrystals to form an O2-concentrating microporous electrolyte solution increases the ORR current so much that the activity of Pt, typically thought to be an ideal ORR catalyst, is partially limiting, thus allowing the intrinsic catalytic ORR activity of Pt to be measured directly.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Details of BET surface area analysis of zeolite-NCs, O2 solubility in electrolyte solutions, O2 capacity in zeolite-NC solutions, density of zeolite-NC solutions and electrokinetics modelling along with additional physical and electrochemical characterization data are included in Supplementary Information. Other data are available from the corresponding authors upon reasonable request.

References

Nocera, D. G. Proton-coupled electron transfer: the engine of energy conversion and storage. J. Am. Chem. Soc. 144, 1069–1081 (2022).

Stančin, H., Mikulčić, H., Wang, X. & Duić, N. A review on alternative fuels in future energy system. Renew. Sustain. Energy Rev. 128, 109927 (2020).

Weber, R. S. Effective use of renewable electricity for making renewable fuels and chemicals. ACS Catal. 9, 946–950 (2019).

Nocera, D. G. Solar fuels and solar chemicals industry. Acc. Chem. Res. 50, 616–619 (2017).

Lewis, N. S. & Nocera, D. G. Powering the planet: chemical challenges in solar energy utilization. Proc. Natl Acad. Sci. USA 103, 15729–15735 (2006).

Cook, T. R. et al. Solar energy supply and storage for the legacy and nonlegacy worlds. Chem. Rev. 110, 6474–6502 (2010).

Spitler, M. T. et al. Practical challenges in the development of photoelectrochemical solar fuels production. Sustain. Energy Fuels 4, 985–995 (2020).

Staffell, I. et al. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 12, 463–491 (2019).

Battino, R., Seybold, P. G. & Campanell, F. C. Correlations involving the solubility of gases in water at 298.15 K and 101325 Pa. J. Chem. Eng. Data 56, 727–732 (2011).

Higgins, D., Hahn, C., Xiang, C., Jaramillo, T. F. & Weber, A. Z. Gas-diffusion electrodes for carbon dioxide reduction: a new paradigm. ACS Energy Lett. 4, 317–324 (2019).

Rabiee, H., Ge, L., Zhang, X., Hu, S., Li, M. & Yuan, Z. Gas diffusion electrodes (GDEs) for electrochemical reduction of carbon dioxide, carbon monoxide, and dinitrogen to value-added products: a review. Energy Environ. Sci. 14, 1959–2008 (2021).

Lees, E. W., Mowbray, B. A. W., Parlane, F. G. L. & Berlinguette, C. P. Gas diffusion electrodes and membranes for CO2 reduction electrolysers. Nat. Rev. Mater. 7, 55–64 (2022).

Wakerley, D. et al. Gas diffusion electrodes, reactor designs and key metrics of low-temperature CO2 electrolysers. Nat. Energy 7, 130–143 (2022).

Nesbitt, N. T. et al. Liquid–solid boundaries dominate activity of CO2 reduction on gas-diffusion electrodes. ACS Catal. 10, 14093–14106 (2020).

Yang, K., Kas, R., Smith, W. A. & Burdyny, T. Role of the carbon-based gas diffusion layer on flooding in a gas diffusion electrode cell for electrochemical CO2 reduction. ACS Energy Lett. 6, 33–40 (2021).

Tan, Y. C. et al. Pitfalls and protocols: evaluating catalysts for CO2 reduction in electrolyzers based on gas diffusion electrodes. ACS Energy Lett. 7, 2012–2023 (2022).

Hone, C. A. & Kappe, C. O. Membrane microreactors for the on-demand generation, separation, and reaction of gases. Chem. Eur. J. 26, 13108–13117 (2020).

Luo, T., Abdu, S. & Wessling, M. Selectivity of ion exchange membranes: a review. J. Membr. Sci. 555, 429–454 (2018).

Oener, S. Z., Foster, M. J. & Boettcher, S. W. Accelerating water dissociation in bipolar membranes and for electrocatalysis. Science 369, 1099–1103 (2020).

Sato, T., Hamada, Y., Sumikawa, M., Araki, S. & Yamamoto, H. Solubility of oxygen in organic solvents and calculations of the Hansen solubility parameters of oxygen. Ind. Eng. Chem. Res. 53, 19331–19337 (2014).

Kronberger, H., Bruckner, K. & Fabjan, C. Reduction of oxygen from electrolyte emulsions with high oxygen contents. J. Power Sources 86, 562–567 (2000).

O’Reilly, N., Giri, N. & James, S. L. Porous liquids. Chem. Eur. J. 13, 3020–3025 (2007).

Giri, N. et al. Liquids with permanent porosity. Nature 527, 216–220 (2015).

Fulvio, P. F. & Dai, S. Porous liquids: the next frontier. Chem 6, 3263–3287 (2020).

Bavykina, A., Cadiau, A. & Gascon, J. Porous liquids based on porous cages, metal organic frameworks and metal organic polyhedra. Coord. Chem. Rev. 386, 85–95 (2019).

Erdosy, D. P. et al. Microporous water with high gas solubilities. Nature 608, 712–718 (2022).

Wang, X. et al. Review of metal catalysts for oxygen reduction reaction: from nanoscale engineering to atomic design. Chem 5, 1486–1511 (2019).

Flanigen, E. M. et al. Silicalite, a new hydrophobic crystalline silica molecular sieve. Nature 271, 512–516 (1978).

Díaz, I., Kokkoli, E., Terasaki, O. & Tsapatsis, M. Surface structure of zeolite (MFI) crystals. Chem. Mater. 16, 5226–5232 (2004).

Butt, T. & Tosheva, L. Synthesis of colloidal silicalite-1 at high temperatures. Microporous Mesoporous Mater. 187, 71–76 (2014).

Lazaridis, T., Stühmeier, B. M., Gasteiger, H. A. & El-Sayed, H. A. Capabilities and limitations of rotating disk electrodes versus membrane electrode assemblies in the investigation of electrocatalysts. Nat. Catal. 5, 363–373 (2022).

Bard, A. J. & Faulkner, L. R. Electrochemical Methods: Fundamentals and Applications (Wiley, 2000).

Zhong, G. et al. Effect of experimental operations on the limiting current density of oxygen reduction reaction evaluated by rotating-disk electrode. ChemElectroChem 7, 1107–1114 (2020).

Paulus, U. A., Schmidt, T. J., Gasteiger, H. A. & Behm, R. J. Oxygen reduction on a high-surface area Pt/Vulcan carbon catalyst: a thin-film rotating ring-disc electrode study. J. Electroanal. Chem. 495, 134–145 (2001).

You, B. et al. Bimetal–organic framework self-adjusted synthesis of support-free nonprecious electrocatalysts for efficient oxygen reduction. ACS Catal. 5, 7068–7076 (2015).

Caprani, A., De Ficquelmont-Loizos, M. M., Tamisier, L. & Peronneau, P. Mass transfer in laminar flow at a rotating disc electrode in suspensions of inert particles. J. Electrochem. Soc. 135, 635–642 (1988).

Sonneveld, P. J., Visscher, W. & Barendrecht, E. The influence of suspended particles on the mass transfer at a rotating disc electrode. Non-conducting particles. J. Appl. Electrochem. 20, 563–574 (1990).

He, Q. et al. Influence of phosphate anion adsorption on the kinetics of oxygen electroreduction on low index Pt(hkl) single crystals. Phys. Chem. Chem. Phys. 12, 12544–12555 (2010).

Gómez-Marín, A. M. & Feliu, J. M. in Encyclopedia of Interfacial Chemistry: Surface Science and Electrochemistry Vol. 5.2 (ed. Wandelt, K.) 820–830 (Elsevier, 2018).

Marković, N. M., Gasteiger, H. A. & Ross, P. N. Jr. Oxygen reduction on platinum low-index single-crystal surfaces in sulfuric acid solution: rotating ring–Pt(hkl) disc studies. J. Phys. Chem. 99, 3411–3415 (1995).

Wang, J. X., Markovic, N. M. & Adzic, R. R. Kinetic analysis of oxygen reduction on Pt(111) in acid solutions: intrinsic kinetic parameters and anion adsorption effects. J. Phys. Chem. B 108, 4127–4133 (2004).

Nishikawa, H. et al. Effects of sulfate on the oxygen reduction reaction activity on stabilized Pt-skin/PtCo-alloy catalysts from 30 to 80 °C. Langmuir 34, 13558–13564 (2018).

Persson, A. E., Schoeman, B. J., Sterte, J. & Otterstedt, J.-E. The synthesis of discrete colloidal particles of TPA-silicalite-1. Zeolites 14, 557–567 (1994).

Tsapatsis, M., Lovallo, M., Okubo, T., Davis, M. E. & Sadakata, M. Characterization of zeolite L nanoclusters. Chem. Mater. 7, 1734–1741 (1995).

Nobbmann, U. & Morfesis, A. Light scattering and nanoparticles. Mater. Today 12, 52–54 (2009).

Sakai, K., Hirano, T. & Hosoda, M. Electromagnetically spinning sphere viscometer. Appl. Phys. Express 3, 016602 (2010).

O’Reilly, J. E. Oxidation–reduction potential of the ferro–ferricyanide system in buffer solutions. Biochim. Biophys. Acta 292, 509–515 (1973).

Acknowledgements

This work was supported by a Multidisciplinary University Research Initiative, sponsored by the US Department of the Navy, Office of Naval Research, under grant no. N00014-20-1-2418 (D.G.N. and J.A.M.), Star-Friedman Challenge grant from Harvard University (D.G.N. and J.A.M.), and Labex ARCANE, CBµH-EUR-GS and ANR-17-EURE-0003 from the Agence Nationale de la Recherche (C.C.). J.A.M. acknowledges support from the Arnold and Mabel Beckman Foundation through a Beckman Young Investigator Grant. Part of this work was performed at the Center for Nanoscale Systems (CNS), a member of the National Nanotechnology Coordinated Infrastructure Network (NNCI), which is supported by the National Science Foundation under NSF award no. 1541959. A.E.T. acknowledges the Harvard University Center for the Environment for a postdoctoral fellowship, and D.P.E. acknowledges support from a DoD National Defense Science and Engineering (NDSEG) fellowship. We thank B. Johnston, J. Cho and J. Shen for experimental assistance and M. J. Nava, J. Ryu, M. I. Gonzalez and Z. Yan for helpful discussions. We also thank G. M. Whitesides and M. S. Kodaimati for lending us a mass flow controller for the electrochemical experiments.

Author information

Authors and Affiliations

Contributions

A.E.T., D.P.E., D.G.N. and J.A.M. conceived the project. D.P.E. and J.A.M. designed the zeolite materials, and D.P.E. carried out the synthesis. A.E.T., D.G.N., C.C. and J.A.M. designed electrochemical experiments, and A.E.T. performed the electrochemical experiments. A.E.T. and D.P.E. performed testing and characterizations. C.C. performed electrokinetics modelling. All authors contributed to the manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

D.P.E. and J.A.M. are inventors on a patent application related to O2 concentration in microporous aqueous solutions held and submitted by Harvard University (application number PCT/US21/54267). The other authors declare no competing interests.

Peer review

Peer review information

Nature Catalysis thanks Christopher Batchelor-McAuley, Serhiy Cherevko and the other, anonymous, reviewer for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–5, Figs. 1–33, Tables 1–23 and references.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thorarinsdottir, A.E., Erdosy, D.P., Costentin, C. et al. Enhanced activity for the oxygen reduction reaction in microporous water. Nat Catal 6, 425–434 (2023). https://doi.org/10.1038/s41929-023-00958-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-023-00958-9

This article is cited by

-

Efficient conversion of propane in a microchannel reactor at ambient conditions

Nature Communications (2024)

-

Fully loaded water

Nature Catalysis (2023)