Abstract

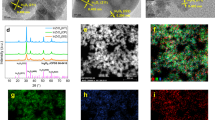

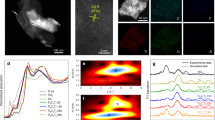

Selective hydrogenation of CO2 into value-added hydrocarbons, particularly single products, is of great interest. However, this is a challenge because of the simultaneous occurrence of numerous competing elementary reactions. Here a GaZrOx/H-SSZ-13 composite is developed, which shows propane selectivity in hydrocarbons of 79.5%, along with butane selectivity of 9.9% and CO selectivity of 31.8%, at CO2 conversion of 43.4%. Such catalytic performance can be well maintained within 500 h. Incorporation of proper amounts of Ga into ZrO2 promotes methanol formation due to generation of high concentrations of surface oxygen vacancies with moderate CO2 adsorption strength. The large number of strong-acid sites of H-SSZ-13 seriously restricts conversion of generated methanol into aromatics at high H2 pressure, suppressing the aromatics-based cycle and favouring the alkene-based cycle instead. Accordingly, far more propene and butene are obtained than ethene, although they are rapidly hydrogenated to corresponding alkanes on the strong-acid sites of H-SSZ-13.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data used to plot the figures are provided with the paper and the Supplementary Information, and are also available in the ScienceDB repository at https://doi.org/10.57760/sciencedb.02988 or available from the author upon reasonable request.

References

Centi, G., Quadrelli, E. A. & Perathoner, S. Catalysis for CO2 conversion: a key technology for rapid introduction of renewable energy in the value chain of chemical industries. Energy Environ. Sci. 6, 1711–1731 (2013).

Bushuyev, O. S. et al. What should we make with CO2 and how can we make it? Joule 2, 825–832 (2018).

Porosoff, M. D., Yan, B. & Chen, J. G. Catalytic reduction of CO2 by H2 for synthesis of CO, methanol and hydrocarbons: challenges and opportunities. Energy Environ. Sci. 9, 62–73 (2016).

Liu, Y. T., Deng, D. H. & Bao, X. H. Catalysis for selected C1 chemistry. Chem. 6, 2497–2514 (2020).

Alvarez, A. et al. Challenges in the greener production of formates/formic acid, methanol, and DME by heterogeneously catalyzed CO2 hydrogenation processes. Chem. Rev. 117, 9804–9838 (2017).

Wang, W., Wang, S., Ma, X. & Gong, J. Recent advances in catalytic hydrogenation of carbon dioxide. Chem. Soc. Rev. 40, 3703–3727 (2011).

Zhong, J. W. et al. State of the art and perspectives in heterogeneous catalysis of CO2 hydrogenation to methanol. Chem. Soc. Rev. 49, 1385–1413 (2020).

Bao, J., Yang, G. H., Yoneyama, Y. & Tsubaki, N. Significant advances in C1 catalysis: highly efficient catalysts and catalytic reactions. ACS Catal. 9, 3026–3053 (2019).

Ye, R. P. et al. CO2 hydrogenation to high-value products via heterogeneous catalysis. Nat. Commun. 10, 5698 (2019).

Studt, F. et al. Discovery of a Ni–Ga catalyst for carbon dioxide reduction to methanol. Nat. Chem. 6, 320–324 (2014).

Wu, C. Y. et al. Inverse ZrO2/Cu as a highly efficient methanol synthesis catalyst from CO2 hydrogenation. Nat. Commun. 11, 5767 (2020).

Zhu, Y. F. et al. Copper–zirconia interfaces in UiO-66 enable selective catalytic hydrogenation of CO2 to methanol. Nat. Commun. 11, 5849 (2020).

Wang, L. X. et al. Silica accelerates the selective hydrogenation of CO2 to methanol on cobalt catalysts. Nat. Commun. 11, 1033 (2020).

He, M. Y., Sun, Y. H. & Han, B. X. Green carbon science: scientific basis for integrating carbon resource processing, utilization, and recycling. Angew. Chem. Int. Ed. 52, 9620–9633 (2013).

von der Assen, N., Voll, P., Peters, M. & Bardow, A. Life cycle assessment of CO2 capture and utilization: a tutorial review. Chem. Soc. Rev. 43, 7982–7994 (2014).

Gutterod, E. S. et al. Hydrogenation of CO2 to methanol by Pt nanoparticles encapsulated in UiO-67: deciphering the role of the metal−organic framework. J. Am. Chem. Soc. 142, 999–1009 (2020).

Frei, M. S. et al. Role of zirconia in indium oxide-catalyzed CO2 hydrogenation to methanol. ACS Catal. 10, 1133–1145 (2020).

Jiang, X., Nie, X. W., Guo, X. W., Song, C. S. & Chen, J. G. G. Recent advances in carbon dioxide hydrogenation to methanol via heterogeneous catalysis. Chem. Rev. 120, 7984–8034 (2020).

Xie, S. J. et al. Photocatalytic and electrocatalytic transformations of C1 molecules involving C–C coupling. Energy Environ. Sci. 14, 37–89 (2021).

Torres Galvis, H. M. et al. Supported iron nanoparticles as catalysts for sustainable production of lower olefins. Science 335, 835–838 (2012).

Wei, J. et al. Directly converting CO2 into a gasoline fuel. Nat. Commun. 8, 16170 (2017).

Ramirez, A. et al. Effect of zeolite topology and reactor configuration on the direct conversion of CO2 to light olefins and aromatics. ACS Catal. 9, 6320–6334 (2019).

Xu, Y. et al. Highly selective olefin production from CO2 hydrogenation on iron catalysts: a subtle synergy between manganese and sodium additives. Angew. Chem. Int. Ed. 59, 21736–21744 (2020).

Wang, C. T. et al. Product selectivity controlled by nanoporous environments in zeolite crystals enveloping rhodium nanoparticle catalysts for CO2 hydrogenation. J. Am. Chem. Soc. 141, 8482–8488 (2019).

Paalanen, P. P., Van Vreeswijk, S. H. & Weckhuysen, B. M. Combined in situ X‑ray powder diffractometry/Raman spectroscopy of iron carbide and carbon species evolution in Fe(–Na–S)/α-Al2O3 catalysts during Fischer–Tropsch synthesis. ACS Catal. 10, 9837–9855 (2020).

Li, J. et al. Integrated tuneable synthesis of liquid fuels via Fischer–Tropsch technology. Nat. Catal. 1, 787–793 (2018).

Torres Galvis, H. M. & de Jong, K. P. Catalysts for production of lower olefins from synthesis gas: a review. ACS Catal. 3, 2130–2149 (2013).

Zhou, W. et al. New horizon in C1 chemistry: breaking the selectivity limitation in transformation of syngas and hydrogenation of CO2 into hydrocarbon chemicals and fuels. Chem. Soc. Rev. 48, 3193–3228 (2019).

Jiao, F. et al. Selective conversion of syngas to light olefins. Science 351, 1065–1068 (2016).

Cheng, K. et al. Direct and highly selective conversion of synthesis gas to lower olefins: design of a bifunctional catalyst combining methanol synthesis and carbon–carbon coupling. Angew. Chem. Int. Ed. 55, 4725–4728 (2016).

Wang, S. et al. Selective conversion of CO2 into propene and butene. Chem 6, 3344–3363 (2020).

Ni, Y. M. et al. Selective conversion of CO2 and H2 into aromatics. Nat. Commun. 9, 3457 (2019).

Wei, J., Yao, R. W., Han, Y., Ge, Q. J. & Sun, J. Towards the development of the emerging process of CO2 heterogeneous hydrogenation into high-value unsaturated heavy hydrocarbons. Chem. Soc. Rev. 50, 10764–10805 (2021).

Li, Z. L. et al. Highly selective conversion of carbon dioxide to lower olefins. ACS Catal. 7, 8544–8548 (2017).

Liu, X. L. et al. Tandem catalysis for hydrogenation of CO and CO2 to lower olefins with bifunctional catalysts composed of spinel oxide and SAPO-34. ACS Catal. 10, 8303–8314 (2020).

Gao, P. et al. Direct production of lower olefins from CO2 conversion via bifunctional catalysis. ACS Catal. 8, 571–578 (2018).

Chen, Y. X. et al. C−C bond formation in syngas conversion over zinc sites grafted on ZSM-5 zeolite. Angew. Chem. Int. Ed. 59, 6529–6534 (2020).

Jiao, F. et al. Shape-selective zeolites promote ethylene formation from syngas via a ketene intermediate. Angew. Chem. Int. Ed. 57, 4692–4696 (2018).

Tahir Arslan, M. et al. Single-step conversion of H2‑deficient syngas into high yield of tetramethylbenzene. ACS Catal. 9, 2203–2212 (2019).

Wang, S. et al. Highly effective conversion of CO2 into light olefins abundant in ethene. Chem 8, 1376–1394 (2022).

Sattler, J. J. H. B., Ruiz-Martinez, J., Santillan-Jimenez, E. & Weckhuysen, B. M. Catalytic dehydrogenation of light alkanes on metals and metal oxides. Chem. Rev. 114, 10613–10653 (2014).

Lu, P. et al. Direct syngas conversion to liquefied petroleum gas: importance of a multifunctional metal–zeolite interface. Appl. Energy 209, 1–7 (2018).

Sun, Q. M. et al. Subnanometer bimetallic platinum–zinc clusters in zeolites for propane dehydrogenation. Angew. Chem. Int. Ed. 59, 19450–19459 (2020).

Tong, M. L. et al. Hydrogenation of CO2 to LPG over CuZnZr/MeSAPO-34 catalysts. New J. Chem. 44, 9328–9336 (2020).

Liu, Z. P., Ni, Y. M., Sun, T. T., Zhu, W. L. & Liu, Z. M. Conversion of CO2 and H2 into propane over InZrOx and SSZ-13 composite catalyst. J. Energy Chem. 54, 111–117 (2021).

Li, C. M., Yuan, X. D. & Fujimoto, K. Direct synthesis of LPG from carbon dioxide over hybrid catalysts comprising modified methanol synthesis catalyst and β-type zeolite. Appl. Catal. A 475, 155–160 (2014).

Li, H. J. et al. Well-defined core-shell-structured capsule catalyst for direct conversion of CO2 into liquefied petroleum gas. Chem. Sus. Chem. 13, 2060–2065 (2020).

Ramirez, A. et al. Multifunctional catalyst combination for the direct conversion of CO2 to propane. JACS Au 1, 1719–1732 (2021).

Li, G. et al. Role of SAPO-18 acidity in direct syngas conversion to light olefins. ACS Catal. 10, 12370–12375 (2020).

Lu, Z. et al. Atomic layer deposition overcoating improves catalyst selectivity and longevity in propane dehydrogenation. ACS Catal. 10, 13957–13967 (2020).

Wang, Y. H. et al. Visualizing element migration over bifunctional metal–zeolite catalysts and its impact on catalysis. Angew. Chem. Int. Ed. 60, 17735–17743 (2021).

Zhou, C. Q. et al. Performance improvement of amorphous Ga2O3 ultraviolet photodetector by annealing under oxygen atmosphere. J. Alloy. Compd 840, 155585 (2020).

Wang, J. J. et al. High-performance MaZrOx (Ma = Cd, Ga) solid-solution catalysts for CO2 hydrogenation to methanol. ACS Catal. 9, 10253–10259 (2019).

Akkharaphatthawon, N. et al. Tuning adsorption properties of GaxIn2−xO3 catalysts for enhancement of methanol synthesis activity from CO2 hydrogenation at high reaction temperature. Appl. Surf. Sci. 489, 278–286 (2019).

Liang, F. L., Yu, Y., Zhou, W., Xu, X. Y. & Zhu, Z. H. Highly defective CeO2 as a promoter for efficient and stable water oxidation. J. Mater. Chem. A 3, 634–640 (2015).

Jiang, X. et al. A combined experimental and DFT study of H2O effect on In2O3/ZrO2 catalyst for CO2 hydrogenation to methanol. J. Catal. 383, 283–296 (2020).

Dang, S. S. et al. Role of zirconium in direct CO2 hydrogenation to lower olefins on oxide/zeolite bifunctional catalysts. J. Catal. 364, 382–393 (2018).

Kattel, S., Yan, B. H., Yang, Y. X., Chen, J. G. G. & Liu, P. Optimizing binding energies of key intermediates for CO2 hydrogenation to methanol over oxide-supported copper. J. Am. Chem. Soc. 138, 12440–12450 (2016).

Yu, J. F. et al. Stabilizing Cu+ in Cu/SiO2 catalysts with a shattuckite-like structure boosts CO2 hydrogenation into methanol. ACS Catal. 10, 14694–14706 (2020).

Yao, L. B., Shen, X. C., Pan, Y. B. & Peng, Z. M. Synergy between active sites of Cu–In–Zr–O catalyst in CO2 hydrogenation to methanol. J. Catal. 372, 74–85 (2019).

Wang, Y. H. et al. Exploring the ternary interactions in Cu–ZnO–ZrO2 catalysts for efficient CO2 hydrogenation to methanol. Nat. Commun. 10, 1166 (2019).

Yang, Y., Mims, C. A., Mei, D. H., Peden, C. H. F. & Campbell, C. T. Mechanistic studies of methanol synthesis over Cu from CO/CO2/H2/H2O mixtures: The source of C in methanol and the role of water. J. Catal. 298, 10–17 (2013).

Yan, B. H. et al. Tuning CO2 hydrogenation selectivity via metal-oxide interfacial sites. J. Catal. 374, 60–71 (2019).

Liu, X. L. et al. Selective transformation of carbon dioxide into lower olefins with a bifunctional catalyst composed of ZnGa2O4 and SAPO-34. Chem. Commun. 54, 140–143 (2018).

Feng, O. Y., Kondo, J. N., Maruya, K. & Domen, K. Site conversion of methoxy species on ZrO2. J. Phys. Chem. B 101, 4867–4869 (1997).

Wang, J. J. et al. A highly selective and stable ZnO–ZrO2 solid solution catalyst for CO2 hydrogenation to methanol. Sci. Adv. 3, e1701290 (2017).

Bjørgen, M. et al. Conversion of methanol to hydrocarbons over zeolite H-ZSM-5: on the origin of the olefinic species. J. Catal. 249, 195–207 (2007).

Nieskens, D. L. S., Lunn, J. D. & Malek, A. Understanding the enhanced lifetime of SAPO-34 in a direct syngas-to-hydrocarbons process. ACS Catal. 9, 691–700 (2019).

Arora, S. S., Shi, Z. C. & Bhan, A. Mechanistic basis for effects of high-pressure H2 cofeeds on methanol-to-hydrocarbons catalysis over zeolites. ACS Catal. 9, 6407–6414 (2019).

Wang, S. et al. Polymethylbenzene or alkene cycle? Theoretical study on their contribution to the process of methanol to olefins over H‑ZSM‑5 zeolite. J. Phys. Chem. C 119, 28482–28498 (2015).

Deimund, M. A. et al. Effect of heteroatom concentration in SSZ-13 on the methanol-to-olefins reaction. ACS Catal. 6, 542–550 (2016).

Arora, S., Nieskens, D. L. S., Malek, A. & Bhan, A. Lifetime improvement in methanol-to-olefins catalysis over chabazite materials by high-pressure H2 co-feeds. Nat. Catal. 1, 666–672 (2018).

Zhao, X. B. et al. Achieving a superlong lifetime in the zeolite-catalyzed MTO reaction under high pressure: synergistic effect of hydrogen and water. ACS Catal. 9, 3017–3025 (2019).

Wang, S. et al. Direct conversion of syngas into light olefins with low CO2 emission. ACS Catal. 10, 2046–2059 (2020).

Kresse, G. & Hafner, J. Ab initio molecular dynamics simulation of the liquid metal amorphous semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Kresse, G. & Furthmuller, J. Efficiency of ab initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Blochl, P. E. Projector augmented wave method. Phys. Rev. B 50, 17953–17979 (1994).

Frisch, M. J. et al. Gaussian 09, revision E.01 (Gaussian, Inc., 2009).

Chai, J. D. & Head-Gordon, M. Long-range corrected hybrid density functionals with damped atom–atom dispersion corrections. Phys. Chem. Chem. Phys. 10, 6615–6620 (2008).

Goerigk, L. & Grimme, S. A thorough benchmark of density functional methods for general main group thermochemistry, kinetics, and noncovalent interactions. Phys. Chem. Chem. Phys. 13, 6670–6688 (2011).

Acknowledgements

This work was supported by the National Key R&D Program of China (grant nos. 2020YFA0210900 and 2018YFB0604802), National Natural Science Foundation of China (grant nos. U1910203, 21991090 and 21991092), the European Union’s Horizon 2020 research and innovation program (grant no. 837733) and the Youth Innovation Promotion Association of Chinese Academy of Sciences (CAS) (grant no. 2021172). We thank Y. Chen (Institute of Coal Chemistry, CAS) and Y. Su (Taiyuan University of Technology, TYUT) for their kind help with the mechanism analysis.

Author information

Authors and Affiliations

Contributions

S.W. implemented the experiments and theoretical calculations, and completed the original draft. L.Z. and P.W. conducted the isotope-labelled experiment and NMR measurements. W.J. synthesized the zeolite. Z.Q. and M.D. performed part of the catalyst preparation and test. J.W. and U.O. analysed the reaction mechanism. W.F. designed the whole study and revised the paper. All the authors contributed to the discussions on the results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Catalysis thanks Joseph DeWilde and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–60, Tables 1–4, Methods and References.

Supplementary Data 1

Atomic coordinates of the optimized structures.

Supplementary Data 2

Source data for Supplementary Information.

Source data

Source Data Fig. 1

Activity.

Source Data Fig. 2

Activity.

Source Data Fig. 3

In situ DRIFTS.

Source Data Fig. 4

In situ DRIFTS and 13C MAS NMR.

Source Data Fig. 5

GC–MS and thermogravimetric analysis.

Source Data Fig. 6

Activity.

Source Data Fig. 7

Reaction kinetics.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Zhang, L., Wang, P. et al. Highly selective hydrogenation of CO2 to propane over GaZrOx/H-SSZ-13 composite. Nat Catal 5, 1038–1050 (2022). https://doi.org/10.1038/s41929-022-00871-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-022-00871-7

This article is cited by

-

Upgrading CO2 to sustainable aromatics via perovskite-mediated tandem catalysis

Nature Communications (2024)

-

Catalytic role of in-situ formed C-N species for enhanced Li2CO3 decomposition

Nature Communications (2024)

-

Direct time-resolved observation of surface-bound carbon dioxide radical anions on metallic nanocatalysts

Nature Communications (2023)

-

Zeolite-encaged Ultrasmall Pt-Zn Species with Trace Amount of Pt for Efficient Propane Dehydrogenation

Chemical Research in Chinese Universities (2023)