Abstract

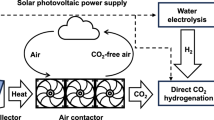

Many research efforts into CO2 reduction to valuable products are motivated by a desire to reduce the atmospheric CO2 concentration. However, it is unclear how laboratory-scale catalytic performance translates to the goal of reducing CO2. In this Perspective, we analyse recently reported thermocatalytic and electrocatalytic performances for reduction of CO2 to methanol in terms of net CO2 reduction, on a mole basis. Our calculations indicate that even an ideal catalytic process needs to be powered by electricity emitting less than 0.2 kg of CO2 per kWh to achieve a net reduction in CO2. We conclude that hybrid processes combining thermocatalysis and electrocatalysis are promising opportunities to reduce CO2 to methanol, as long as practical electrocatalysts achieve reaction rates two orders of magnitude larger than those observed in current laboratory tests. In such a scenario, an increase in the global methanol market could benefit the overall reduction of atmospheric CO2 via conversion of CO2 to methanol.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Change history

24 April 2019

In the version of this Perspective originally published, in Table 1, the selectivity for MeOH and CO (%) values were incorrect at 0.298 and 0.35, respectively, they should have read 29.8 and 35. This has now been corrected.

References

IPCC Climate Change 2014: Synthesis Report (eds Core Writing Team, Pachauri, R. K. & Meyer L. A.) (IPCC, 2014).

Wilcox, J. Carbon Capture (Springer, New York, 2012).

Song, C. Global challenges and strategies for control, conversion and utilization of CO2 for sustainable development involving energy, catalysis, adsorption and chemical processing. Catal. Today 115, 2–32 (2006).

Jovanov, Z. P. et al. Opportunities and challenges in the electrocatalysis of CO2 and CO reduction using bifunctional surfaces: a theoretical and experimental study of Au–Cd alloys. J. Catal. 343, 215–231 (2016).

Artz, J. et al. Sustainable conversion of carbon dioxide: an integrated review of catalysis and life cycle assessment. Chem. Rev. 118, 434–504 (2018).

Wang, S. & Zhu, Z. H. Catalytic conversion of alkanes to olefins by carbon dioxide oxidative dehydrogenation — a review. Energy Fuels 18, 1126–1139 (2004).

Gomez, E. et al. Combining CO2 reduction with propane oxidative dehydrogenation over bimetallic catalysts. Nat. Commun. 9, 1398 (2018).

Yan, B. et al. Dry reforming of ethane and butane with CO2 over PtNi/CeO2 bimetallic catalysts. ACS Catal. 6, 7283–7292 (2016).

Aresta, M., Dibenedetto, A. & Quaranta, E. Reaction Mechanisms in Carbon Dioxide Conversion 1st edn (Springer-Verlag, Berlin, 2016).

Yang, H. et al. A review of the catalytic hydrogenation of carbon dioxide into value-added hydrocarbons. Catal. Sci. Technol. 7, 4580–4598 (2017).

Dincer, I. & Acar, C. Innovation in hydrogen production. Int. J. Hydrog. Energy 42, 14843–14864 (2017).

Gandia, L., Arzamendi, G. & Dieguez, P. (eds) in Renewable Hydrogen Technologies Ch. 1 (Elservier, Amsterdam, 2013).

World Energy Outlook 2017 (OECD Publishing, Paris, 2017).

Szima, S. & Cormos, C.-C. Improving methanol synthesis from carbon-free H2 and captured CO2: a techno-economic and environmental evaluation. J. CO 2 Util. 24, 555–563 (2018).

Abanades, J. C., Rubin, E. S., Mazzotti, M. & Herzog, H. J. On the climate change mitigation potential of CO2 conversion to fuels. Energy Environ. Sci. 10, 2491–2499 (2017).

Pérez-Fortes, M., Schöneberger, J. C., Boulamanti, A. & Tzimas, E. Methanol synthesis using captured CO2 as raw material: techno-economic and environmental assessment. Appl. Energy 161, 718–732 (2016).

Yang, C. et al. Methanol synthesis from CO2-rich syngas over a ZrO2 doped CuZnO catalyst. Catal. Today 115, 222–227 (2006).

Samson, K. et al. Influence of ZrO2 structure and copper electronic state on activity of Cu/ZrO2 catalysts in methanol synthesis from CO2. ACS Catal. 4, 3730–3741 (2014).

Farrauto, R. J. & Bartholomew, C. H. Fundamentals of industrial catalytic processes 2nd ed (Wiley, Hoboken, 2005).

Porosoff, M. D., Yan, B. & Chen, J. G. Catalytic reduction of CO2 by H2 for synthesis of CO, methanol and hydrocarbons: challenges and opportunities. Energy Environ. Sci. 9, 62–73 (2016).

Graaf, G. H., Sijtsema, P. J. J. M. & Joostes, G. E. H. Chemical equilibria in methanol synthesis. Chem. Eng. Sci. 41, 2883–2890 (1986).

Graaf, G., Stamhuis, E. & Beenackers, A. A. C. M. Kinetics of low-pressure methanol synthesis. Chem. Eng. Sci. 43, 3185–3195 (1988).

Graaf, G. H., Scholtens, H., Stamhuis, E. J. & Beenackers, A. A. C. M. Intra-particle diffusion limitations in low-pressure methanol synthesis. Chem. Eng. Res. Des. 45, 773–783 (1990).

Vanden Bussche, K. M. & Froment, G. F. A steady-state kinetic model for methanol synthesis and the water gas shift reaction on a commercial Cu/ZnO/Al2O3 Catalyst. J. Catal. 161, 1–10 (1996).

Portha, J.-F., Parkhomenko, K., Kobl, K., Commenge, J. & Falk, L. Kinetics of methanol synthesis from carbon dioxide hydrogenation over copper−zinc oxide catalysts. Ind. Eng. Chem. Res. 56, 13133–13145 (2017).

Sheng, W. et al. Electrochemical reduction of CO2 to synthesis gas with controlled CO/H2 ratios. Energy Environ. Sci. 10, 1180–1185 (2017).

Lu, Q. et al. A selective and efficient electrocatalyst for carbon dioxide reduction. Nat. Commun. 5, 3242 (2014).

Bandi, A. & Kühne, H. ‐M. Electrochemical reduction of carbon dioxide in water: analysis of reaction mechanism on ruthenium-titanium-oxide. J. Electrochem. Soc. 139, 1605–1610 (1992).

Philibert, C. (ed) Renewable Energy for Industry (OECD Publishing, 2017).

CO 2 Emissions from Fuel Combustion 2017 (OECD Publishing, 2017).

Technical Support Document for Hydrogen Production :Proposed Rule for Mandatory Reporting of Greenhouse Gases (US EPA, 2008).

Spath, P. L. & Mann, M. K. (eds) Life Cycle Assessment of Hydrogen Production via Natural Gas Steam Reforming (NREL, 2001).

Aasberg-Petersen, K., Nielsen, C. S., Dybkjær, I. & Perregaard, J. (eds) Large Scale Methanol Production from Natural Gas (Haldor Topsøe, 2008).

Bertuccioli, L. et al. Development of Water Electrolysis in the European Union (Fuel Cells and Hydrogen Joint Undertaking, 2017).

Durst, J., Simon, C., Hasche, F. & Gasteiger, H. A. Hydrogen oxidation and evolution reaction kinetics on carbon supported Pt, Ir, Rh, and Pd electrocatalysts in acidic media. J. Electrochem. Soc. 162, F190–F203 (2015).

Manning, M. Global Methanol Demand Growth Driven by Methanol to Olefins as Chinese Thirst for Chemical Supply Grows, IHS Markit Says. IHS Market (12 June, 2017); http://news.ihsmarkit.com/press-release/country-industry-forecasting-media/global-methanol-demand-growth-driven-methanol-olefi

Energy Technology Perspectives 2016 (OECD Publishing, 2016).

Methanol: Chemical Economics Handbook (IHS Markit, 2017).

Olah, G. A., Goeppert, A. & Prakash, S. G. K. Beyond Oil and Gas: The Methanol Economy 2nd edn (Wiley-VHC, Weinheim, 2009).

IEA Sankey Diagram (IEA, accessed 30 May 2018); https://www.iea.org/Sankey/

Babic, U., Suermann, M., Büchi, F. N., Gubler, L. & Schmidt, T. J. Critical review—identifying critical gaps for polymer electrolyte water electrolysis development. J. Electrochem. Soc. 164, F387–F399 (2017).

Tackett, B. M., Sheng, W. & Chen, J. G. Opportunities and challenges in utilizing metal-modified transition metal carbides as low-cost electrocatalysts. Joule 1, 328–343 (2017).

Loferski, P. J. (ed) 2014 Minerals Yearbook: Platinum-group Metals (USGS, 2016).

Tackett, B. M. et al. Reducing iridium loading in oxygen evolution reaction electrocatalysts using core−shell particles with nitride cores. ACS Catal. 8, 2615–2621 (2018).

Seitz, L. C. et al. A highly active and stable IrOx/SrIrO3 catalyst for the oxygen evolution reaction. Science 353, 1011–1014 (2016).

Nong, H. N., Gan, L., Willinger, E., Teschner, D. & Strasser, P. IrOx core-shell nanocatalysts for cost- and energy-efficient electrochemical water splitting. Chem. Sci. 5, 2955–2963 (2014).

Arges, C. G. & Zhang, L. Anion exchange membranes’ evolution toward high hydroxide ion conductivity and alkaline resiliency. ACS Appl. Energy Mater. 1, 2991–3012 (2018).

Parrondo, J. et al. Degradation of anion exchange membranes used for hydrogen production by ultrapure water electrolysis. RSC Adv. 4, 9875–9879 (2014).

Kutz, R. B. et al. Sustainion imidazolium-functionalized polymers for carbon dioxide electrolysis. Energy Technol. 5, 929–936 (2017).

Acknowledgements

This work was supported by the US Department of Energy, Office of Science, Catalysis Program (DE-FG02-13ER16381).

Author information

Authors and Affiliations

Contributions

B.M.T. and E.G. contributed equally to this work. E.G. performed the Aspen calculations and any calculations regarding thermocatalysis. B.M.T. performed the calculations regarding electrocatalysis as well as the calculations for the economic considerations and CO2 avoidance. B.M.T., E.G., and J.G.C. wrote the manuscript. J.G.C. developed the concept of the Perspective and supervised the whole project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Discussion; Supplementary Methods; Supplementary Tables 1; Supplementary Figures 1–5; Supplementary References

Rights and permissions

About this article

Cite this article

Tackett, B.M., Gomez, E. & Chen, J.G. Net reduction of CO2 via its thermocatalytic and electrocatalytic transformation reactions in standard and hybrid processes. Nat Catal 2, 381–386 (2019). https://doi.org/10.1038/s41929-019-0266-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-019-0266-y