Abstract

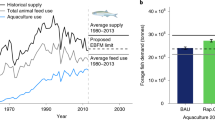

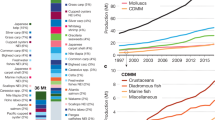

Methane emitted and flared from industrial sources across the United States is a major contributor to global climate change. Methanotrophic bacteria can transform this methane into useful protein-rich biomass, already approved for inclusion into animal feed. In the rapidly growing aquaculture industry, methanotrophic additives have a favourable amino acid profile and can offset ocean-caught fishmeal, reducing demands on over-harvested fisheries. Here we analyse the economic potential of producing methanotrophic microbial protein from stranded methane produced at wastewater treatment plants, landfills, and oil and gas facilities. Our results show that current technology can enable production, in the United States alone, equivalent to 14% of the global fishmeal market at prices at or below the current cost of fishmeal (roughly US$1,600 per metric ton). A sensitivity analysis highlights technically and economically feasible cost reductions (such as reduced cooling or labour requirements), which could allow stranded methane from the United States alone to satisfy global fishmeal demand.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data used in the analysis and figures are publicly available. The data on flaring from oil and gas facilities are available through the Earth Observation Group (https://eogdata.mines.edu/download_global_flare.html). All data on methane emissions from oil and gas facilities and landfills, flaring from landfills, and unit processes at wastewater treatment plants are available from the US EPA through the following programmes: Facilities Level Information on GreenHouse gases Tool (https://ghgdata.epa.gov/ghgp/main.do), Landfill Methane Outreach Program (https://www.epa.gov/lmop/lmop-landfill-and-project-database) and Clean Watersheds Needs Survey for 2004 (https://www.epa.gov/cwns/clean-watersheds-needs-survey-cwns-2004-report-and-data), 2008 (https://www.epa.gov/cwns/clean-watersheds-needs-survey-cwns-2008-report-and-data) and 2012 (https://www.epa.gov/cwns/clean-watersheds-needs-survey-cwns-2012-report-and-data).

Code availability

Code supporting the current study is available at https://github.com/sahar-elabbadi/methane-to-protein.

References

Mbow, C. et al. in Special Report on Climate Change and Land (eds Shukla, P. R. et al.) 437–550 (IPCC, 2019).

GLOBEFISH Highlights January 2020 Issue, with Jan.–Sep. 2019 Statistics (FAO, 2020).

Edwards, P., Zhang, W., Belton, B. & Little, D. C. Misunderstandings, myths and mantras in aquaculture: its contribution to world food supplies has been systematically over reported. Mar. Policy 106, 103547 (2019).

Willett, W. et al. Food in the Anthropocene: the EAT-Lancet commission on healthy diets from sustainable food systems. Lancet 393, 447–492 (2019).

Shah, M. R. et al. Microalgae in aquafeeds for a sustainable aquaculture industry. J. Appl. Phycol. 30, 197–213 (2018).

Naylor, R. L. et al. A 20-year retrospective review of global aquaculture. Nature 591, 551–563 (2021).

Ortuño Crespo, G. & Dunn, D. C. A review of the impacts of fisheries on open-ocean ecosystems. ICES J. Mar. Sci. 74, 2283–2297 (2017).

Malcorps, W. et al. The sustainability conundrum of fishmeal substitution by plant ingredients in shrimp feeds. Sustainability 11, 1212 (2019).

Boucher, O., Friedlingstein, P., Collins, B. & Shine, K. P. The indirect global warming potential and global temperature change potential due to methane oxidation. Environ. Res. Lett. 4, 044007 (2009).

Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2018 Technical Report No. 430-R-20-002 (US Environmental Protection Agency, 2020).

Clomburg, J. M., Crumbley, A. M. & Gonzalez, R. Industrial biomanufacturing: the future of chemical production. Science 355, eaag0804 (2017).

Øverland, M., Tauson, A.-H., Shearer, K. & Skrede, A. Evaluation of methane-utilising bacteria products as feed ingredients for monogastric animals. Arch. Anim. Nutr. 64, 171–189 (2010).

El Abbadi, S. H. & Criddle, C. S. Engineering the dark food chain. Environ. Sci. Technol. 53, 2273–2287 (2019).

Our products. Calysta http://www.feedkind.com/products/ (2021).

Protein. Unibio https://www.unibio.dk/end-product/protein/ (2021).

Levett, I. et al. Techno-economic assessment of poly-3-hydroxybutyrate (PHB) production from methane—the case for thermophilic bioprocessing. J. Environ. Chem. Eng. 4, 3724–3733 (2016).

Pikaar, I. et al. Decoupling livestock from land use through industrial feed production pathways. Environ. Sci. Technol. 52, 7351–7359 (2018).

Matassa, S. et al. Upcycling of biowaste carbon and nutrients in line with consumer confidence: the ‘full gas’ route to single cell protein. Green Chem. 22, 4912–4929 (2020).

Verbeeck, K., De Vrieze, J., Pikaar, I., Verstraete, W. & Rabaey, K. Assessing the potential for up-cycling recovered resources from anaerobic digestion through microbial protein production. Microb. Biotechnol. https://doi.org/10.1111/1751-7915.13600 (2020).

Landfill Gas Energy Project Data and Landfill Technical Data (Environmental Protection Agency, 2020).

Facilities Level Information on GreenHouse Gases Tool (Environmental Protection Agency, 2019).

Global Gas Flaring Observed from Space (Earth Observation Group, 2019).

Clean Watersheds Needs Survey (CWNS) 2004 Report and Data (Environmental Protection Agency, 2004).

Clean Watersheds Needs Survey (CWNS) 2008 Report and Data (Environmental Protection Agency, 2008).

Clean Watersheds Needs Survey (CWNS) 2012 Report and Data (Environmental Protection Agency, 2012).

Yanwen, S., Linville, J. L., Meltem, U.-D., Mintz, M. M. & Snyder, S. W. An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: challenges and opportunities towards energy-neutral WWTPs. Renew. Sustain. Energy Rev. 50, 346–362 (2015).

Cho, J. H. & Kim, I. H. Fish meal—nutritive value. J. Anim. Physiol. Anim. Nutr. 95, 685–692 (2011).

Humbird, D., Davis, R. & McMillan, J. D. Aeration costs in stirred-tank and bubble column bioreactors. Biochem. Eng. J. 127, 161–166 (2017).

Electric Power Monthly (US Energy Information Administration, 2021).

Petersen, L. A. H., John, V., Jørgensen, S. B. & Gernaey, K. V. Mixing and mass transfer in a pilot scale U-loop bioreactor. Biotechnol. Bioeng. 114, 344–354 (2017).

Criddle, C. S., Billington, S. L. & Frank, C. W. Renewable Bioplastics and Biocomposites from Biogas Methane and Waste-Derived Feedstock: Development of Enabling Technology, Life Cycle Assessment, and Analysis of Costs Technical Report No. DRRR-2014-1502 (California Department of Resources Recycling and Recovery, 2014).

Cusworth, D. H. et al. Using remote sensing to detect, validate, and quantify methane emissions from California solid waste operations. Environ. Res. Lett. 15, 054012 (2020).

Siegert, M. et al. Comparison of nonprecious metal cathode materials for methane production by electromethanogenesis. ACS Sustain. Chem. Eng. 2, 910–917 (2014).

Kim, A. H. et al. More than a fertilizer: wastewater-derived struvite as a high value, sustainable fire retardant. Green Chem. 23, 4510–4523 (2021).

Commodity Prices—Annual Prices Technical Report (World Bank, 2021).

Jannathulla, R. et al. Fishmeal availability in the scenarios of climate change: inevitability of fishmeal replacement in aquafeeds and approaches for the utilization of plant protein sources. Aquac. Res. 50, 3493–3506 (2019).

Nathan, P., Klinger, D. H., Sims, N. A., Janice-Renee, Y. & Kittinger, J. N. Nutritional attributes, substitutability, scalability, and environmental intensity of an illustrative subset of current and future protein sources for aquaculture feeds: joint consideration of potential synergies and trade-offs. Environ. Sci. Technol. 52, 5532–5544 (2018).

Cumberlege, T., Blenkinsopp, T. & Clark, J. Assessment of Environmental Footprint of FeedKind Protein Technical Report (Carbon Trust, 2016).

Veiga, P., Mendes, M., Martin, D. & Lee-Harwood, B. Reduction Fisheries: SFP Fisheries Sustainability Overview 2019 Technical Report (Sustainable Fisheries Partnership, 2019).

Zhang, W. et al. Fishing for feed in China: facts, impacts and implications. Fish Fish. 21, 47–62 (2020).

Kok, B. et al. Fish as feed: using economic allocation to quantify the Fish In : Fish Out ratio of major fed aquaculture species. Aquaculture 528, 735474 (2020).

Klinger, D. & Naylor, R. Searching for solutions in aquaculture: charting a sustainable course. Annu. Rev. Environ. Resour. 37, 247–276 (2012).

van der Ha, D., Bundervoet, B., Verstraete, W. & Boon, N. A sustainable, carbon neutral methane oxidation by a partnership of methane oxidizing communities and microalgae. Water Res. 45, 2845–2854 (2011).

Rasouli, Z., Valverde-Pérez, B., D’Este, M., De Francisci, D. & Angelidaki, I. Nutrient recovery from industrial wastewater as single cell protein by a co-culture of green microalgae and methanotrophs. Biochem. Eng. J. 134, 129–135 (2018).

Gingerich, D. B. & Mauter, M. S. Air emission reduction benefits of biogas electricity generation at municipal wastewater treatment plants. Environ. Sci. Technol. 52, 1633–1643 (2018).

Parker, N., Williams, R., Dominguez-Faus, R. & Scheitrum, D. Renewable natural gas in California: an assessment of the technical and economic potential. Energy Policy 111, 235–245 (2017).

Rittmann, B. E. & McCarty, P. L. Environmental Biotechnology: Principles and Applications 2nd edn (McGraw-Hill Education, 2020).

Vo, T. T. Q., Wall, D. M., Ring, D., Rajendran, K. & Murphy, J. D. Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex-situ methanation. Appl. Energy 212, 1191–1202 (2018).

Wendlandt, K.-D., Jechorek, M., Helm, J. & Stottmeister, U. Producing poly-3-hydroxybutyrate with a high molecular mass from methane. J. Biotechnol. 86, 127–133 (2001).

Garrett, D. E. Chemical Engineering Economics (Van Nostrand Reinhold, 1989).

CPI for All Urban Consumers (CPI-U) Technical Report (US Bureau of Labor Statistics, 2020).

Weighted Average Cost of Capital (WACC): Explanation and Examples Technical Report (New Constructs, 2016).

Retail Sales of Electricity to Ultimate Customers (Annual) Technical Report (US Energy Information Administration, 2020).

Yang, S. et al. Global molecular analyses of methane metabolism in methanotrophic Alphaproteobacterium, Methylosinus trichosporium OB3b. Part II. Metabolomics and 13C-labeling study. Front. Microbiol. 4, 70 (2013).

Czyrnek-Delêtre, M. M., Ahern, E. P. & Murphy, J. D. Is small-scale upgrading of landfill gas to biomethane for use as a cellulosic transport biofuel economically viable? Biofuels Bioprod. Biorefin. 10, 139–149 (2016).

Tansel, B. & Surita, S. C. Managing siloxanes in biogas-to-energy facilities: economic comparison of pre- vs post-combustion practices. Waste Manage. 96, 121–127 (2019).

Aguilera, P. G. & Gutiérrez Ortiz, F. J. Techno-economic assessment of biogas plant upgrading by adsorption of hydrogen sulfide on treated sewage-sludge. Energy Convers. Manage. 126, 411–420 (2016).

Pipatmanomai, S., Kaewluan, S. & Vitidsant, T. Economic assessment of biogas-to-electricity generation system with H2S removal by activated carbon in small pig farm. Appl. Energy 86, 669–674 (2009).

United States Natural Gas Industrial Price (Dollars per Thousand Cubic Feet) (US Energy Information Administration, 2020).

Pieja, A. J., Rostkowski, K. H. & Criddle, C. S. Distribution and selection of poly-3-hydroxybutyrate production capacity in methanotrophic proteobacteria. Microb. Ecol. 62, 564–573 (2011).

Noreddine, G., Missimer, T. M. & Amy, G. L. Technical review and evaluation of the economics of water desalination: current and future challenges for better water supply sustainability. Desalination 309, 197–207 (2013).

U.S. Refinery Utilization and Capacity (US Energy Information Administration, 2019).

Jorge Luis, M., Dubrawski, K. L., El Abbadi, S. H., Choo, K.-H. & Criddle, C. S. Membrane and fluid contactors for safe and efficient methane delivery in methanotrophic bioreactors. J. Environ. Eng. 146, 03120006 (2020).

Jinghua, X. & VanBriesen, J. M. Expanded thermodynamic true yield prediction model: adjustments and limitations. Biodegradation 19, 99–127 (2008).

Acknowledgements

This study was funded by the Stanford Center for Innovation in Global Health (S.H.E., C.S.C. and S.P.L.) and the Stanford Natural Gas Initiative (S.H.E., E.D.S., C.S.C. and A.R.B.), an industry consortium that supports independent research at Stanford University. We thank R. Hickey for input on industrial bioreactor scaling.

Author information

Authors and Affiliations

Contributions

S.H.E. and E.D.S. conceptualized the project. S.H.E. and E.D.S. devised the methodology with feedback from A.R.B., C.S.C. and S.P.L. S.H.E. and E.D.S. validated the methodology, conducted the investigation and wrote the original draft of the paper. S.H.E., E.D.S., A.R.B., S.P.L. and C.S.C. reviewed and edited the paper. E.D.S., A.R.B. and C.S.C. supervised the project. S.H.E. and E.D.S. conducted the project administration. S.H.E., E.D.S., A.R.B., S.P.L. and C.S.C. acquired the funding.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Sustainability thanks Richard Cottrell, Richard Newton and Jo De Vrieze for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–14, Figs. 1–7, Notes 1–3 and Methods.

Rights and permissions

About this article

Cite this article

El Abbadi, S.H., Sherwin, E.D., Brandt, A.R. et al. Displacing fishmeal with protein derived from stranded methane. Nat Sustain 5, 47–56 (2022). https://doi.org/10.1038/s41893-021-00796-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-021-00796-2

This article is cited by

-

Feeding fish with fumes

Nature Sustainability (2021)