Abstract

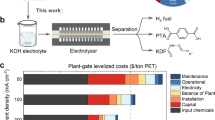

Polyethylene furandicarboxylate (PEF) is considered as a renewable-based solution to its fossil-based counterpart polyethylene terephthalate (PET). However, due to its lengthy and energy-intensive production process, PEF has not been established at a commercial scale. Here we present a new study on PEF produced from industrial carbon dioxide (CO2) emissions and non-food-derived biomass to provide an alternative for PET. We assess PEF production from an energy consumption, environmental impacts and production cost point of view at an industrial scale using mass and energy balance, life-cycle assessment and payback period. The results show that emissions and energy consumption can be reduced up to 40.5% compared with PET. Abiotic depletion (fossil) (6.90 × 104 MJ), global-warming potential (3.75 × 103 kg CO2-equivalent) and human toxicity potential (2.18 × 103 kg 1,4-dichlorobenzene equivalent) are the three most substantial impacts in producing one tonne of PEF. By applying optimal design and mature technology, PEF produced from industrial CO2 and biowastes could be a feasible and competitive substitute for PET and other materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Tan, Y., Nookuea, W., Li, H., Thorin, E. & Yan, J. Property impacts on carbon capture and storage (CCS) processes: a review. Energy Convers. Manag. 118, 204–222 (2016).

Jiang, L., Roskilly, A. P. & Wang, R. Z. Performance exploration of temperature swing adsorption technology for carbon dioxide capture. Energy Convers. Manag. 165, 396–404 (2018).

Bui, M. et al. Carbon capture and storage (CCS): the way forward. Energy Environ. Sci. 11, 1062–1176 (2018).

Yang, Z. Z., He, L. N., Zhao, Y. N., Li, B. & Yu, B. CO2 capture and activation by superbase/polyethylene glycol and its subsequent conversion. Energy Environ. Sci. 4, 3971–3975 (2011).

Yang, Z. Z., Zhao, Y. N. & He, L. N. CO2 chemistry: task-specific ionic liquids for CO2 capture/activation and subsequent conversion. RSC Adv. 1, 545–567 (2011).

Cuéllar-Franca, R. M. & Azapagic, A. Carbon capture, storage and utilisation technologies: a critical analysis and comparison of their life cycle environmental impacts. J. CO2 Util. 9, 82–102 (2015).

Pérez-Fortes, M., Schöneberger, J. C., Boulamanti, A. & Tzimas, E. Methanol synthesis using captured CO2 as raw material: techno-economic and environmental assessment. Appl. Energy 161, 718–732 (2016).

Energy and Climate Change (IEA, 2015).

Sharifzadeh, M., Wang, L. & Shah, N. Integrated biorefineries: CO2 utilization for maximum biomass conversion. Renew. Sustain. Energy Rev. 47, 151–161 (2015).

Aresta, M. Carbon Dioxide as Chemical Feedstock (Wiley, 2010).

Al-Mamoori, A., Krishnamurthy, A., Rownaghi, A. A. & Rezaei, F. Carbon capture and utilization update. Energy Technol. 5, 834–849 (2017).

Rodriguez, F., Cohen, C., Ober, C. K. & Archer, L. Principles of Polymer Systems 6th edn (Taylor & Francis, 2014).

Welle, F. Twenty years of PET bottle to bottle recycling—an overview. Resour. Conserv. Recycl. 55, 865–875 (2011).

Eerhart, A. J. J. E., Faaij, A. P. C. & Patel, M. K. Replacing fossil based PET with biobased PEF; process analysis, energy and GHG balance. Energy Environ. Sci. 5, 6407–6422 (2012).

Polyethylene Furanoate Production - Cost Analysis Report ID PEF E11A (Intratec, 2016).

Banerjee, A., Dick, G. R., Yoshino, T. & Kanan, M. W. Carbon dioxide utilization via carbonate-promoted C–H carboxylation. Nature 531, 215–219 (2016).

National Research Council Committee on Biobased Industrial Products Biobased Industrial Products: Priorities for Research and Commercialization (National Academy Press, 1999).

Bipp, H. & Kieczka, H. in Ullmann’s Encyclopedia of Industrial Chemistry 1–12 (Wiley‐VCH, 2011).

Lange, J. P. & Price, R. Furfural—a promising platform for lignocellulosic biofuels. ChemSusChem 5, 150–166 (2012).

Ecoprofile of Polyethylene Terephthalate (PET) (Bottle Grade) (PlasticsEurope, 2001).

Chen, L., Pelton, R. E. O. & Smith, T. M. Comparative life cycle assessment of fossil and bio-based polyethylene terephthalate (PET) bottles. J. Clean. Prod. 137, 667–676 (2016).

Speck, R., Selke, S., Auras, R. & Fitzsimmons, J. Life cycle assessment software: selection can impact results. J. Ind. Ecol. 20, 18–28 (2016).

Eerhart, A. J. J. E., Patel, M. K. & Faaij, A. P. C. Fuels and plastics from lignocellulosic biomass via the furan pathway: an economic analysis. Biofuel. Bioprod. Biorefin. 9, 307–325 (2015).

Font-Palma, C. & Díaz, A. G. Prospects for petcoke utilization with CO2 capture in Mexico. Energy Procedia 142, 3517–3523 (2017).

Rubin, E. S. & Zhai, H. The cost of carbon capture and storage for natural gas combined cycle power plants. Environ. Sci. Technol. 46, 3076–3084 (2012).

González Díaz, A., Sánchez Fernández, E., Gibbins, J. & Lucquiaud, M. Sequential supplementary firing in natural gas combined cycle with carbon capture: a technology option for Mexico for low-carbon electricity generation and CO2 enhanced oil recovery. Int. J. Greenh. Gas Control 51, 330–345 (2016).

Rabnawaz, M., Wyman, I., Auras, R. & Cheng, S. A roadmap towards green packaging: the current status and future outlook for polyesters in the packaging industry. Green Chem. 19, 4737–4753 (2017).

Reinshagen, P. Towards Green Growth through Sustainability and Innovation (Bio Based Press, 2012).

van den Oever, M., Molenveld, K., van der Zee, M. & Bos, H. Bio-based and Biodegradable Plastics: Facts and Figures: Focus on Food Packaging in the Netherlands (Wageningen Food & Biobased Research, 2017).

Schut, J. H. Pioneering sustainability; biopolymer applications are expanding, in fits and starts. Plast. Eng. 72, 6–13 (2016).

Berkel, J. V. PEF Packaging opportunities a new value chain from development to commercialization. In Proc. Bio World Congress on Industrial Biotechnology (BIO - Biotechnology Innovation Organization, 2017); https://go.nature.com/2TGvPkj

Schulze, M. Experimental Study about the Influence of Protein in Seaweed on Furfural Production and Design of a Seaweed-Based Biorefinery Concept. MSc thesis, Delft University of Technology (2015).

Marcotullio, G. The Chemistry and Technology of Furfural Production in Modern Lignocellulose-Feedstock Biorefineries. PhD thesis, Delft University of Technology (2011).

Dimitriadis, T., Bikiaris, D. N., Papageorgiou, G. Z. & Floudas, G. Molecular dynamics of poly (ethylene-2,5-furanoate) (PEF) as a function of the degree of crystallinity by dielectric spectroscopy and calorimetry. Macromol. Chem. Phys. 217, 2056–2062 (2016).

Dick, G. R., Frankhouser, A. D., Banerjee, A. & Kanan, M. W. A scalable carboxylation route to furan-2,5-dicarboxylic acid. Green Chem. 19, 2966–2972 (2017).

Rosenboom, J. G., Hohl, D. K., Fleckenstein, P., Storti, G. & Morbidelli, M. Bottle-grade polyethylene furanoate from ring-opening polymerisation of cyclic oligomers. Nat. Commun. 9, 2701 (2018).

Wooley, R. J. & Putsche, V. Development of an ASPEN PLUS Physical Property Database for Biofuels Components NREL/MP-425-20685 (NREL, 1996).

Landrieu, P., Baylocq, F. & Johnson, J. R. Etude thermochimique dans la serie furanique. Bull. Soc. Chim. Fr. 45, 36–49 (1929).

Triebl, C. Simulation and Economic Analysis of 5-Hydroxymethylfurfural Conversion to 2,5-Furandicarboxylic Acid. DI thesis, Leoben Univ. Mining (2012).

Kasmi, N., Majdoub, M., Papageorgiou, G., Achilias, D. & Bikiaris, D. Solid-state polymerization of poly (ethylene furanoate) biobased polyester, I: effect of catalyst type on molecular weight increase. Polymers 9, 607 (2017).

Perry, R. H. & Green, D. W. Perry’s Chemical Engineers’ Handbook 7th edn (McGraw-Hill, 1999).

ISO14040: Environmental Management–Life Cycle Impact Assessment–Principles and Framework (British Standard, 2006).

ISO14044: Environmental Management–Life Cycle Impact Assessment–Requirements and Guidelines (ISO, 2006).

Rahimi, A. & García, J. M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 1, 0046 (2017).

Gotro, J. Polyethylene Furanoate (PEF): 100% Biobased Polymer to Compete with PET? Polymer Innovation Blog (8 April 2013); https://go.nature.com/2ZjrZ46

Peters, M. S., Timmerhaus, K. D. & West, R. E. Plant Design and Economics for Chemical Engineers (McGraw-Hill, 2004).

Searcy, E. & Flynn, P. The impact of biomass availability and processing cost on optimum size and processing technology selection. Appl. Biochem. Biotechnol. 154, 92–107 (2009).

Acknowledgements

This research was supported by CCS from Industrial clusters and their Supply chains (CCSInSupply) funded by Engineering and Physical Science Research Council of UK (EP/N024567/1).

Author information

Authors and Affiliations

Contributions

L.J., A.G.-D., J.L.-C., A.M., A.P.R. and A.J.S. designed the study. L.J., A.G.-D. and J.L.-C. provided the analysis. L.J., A.G.-D. and J.L.-C. interpreted the data and wrote the paper. L.J. finalized the writing of the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–4, Tables 1–13, Notes 1–3, and refs. 1–24.

Rights and permissions

About this article

Cite this article

Jiang, L., Gonzalez-Diaz, A., Ling-Chin, J. et al. PEF plastic synthesized from industrial carbon dioxide and biowaste. Nat Sustain 3, 761–767 (2020). https://doi.org/10.1038/s41893-020-0549-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-020-0549-y

This article is cited by

-

Acetolysis of waste polyethylene terephthalate for upcycling and life-cycle assessment study

Nature Communications (2023)

-

Chemical conversion of furan dicarboxylic acid to environmentally benign polyesters: an overview

Biomass Conversion and Biorefinery (2023)

-

Bioplastics for a circular economy

Nature Reviews Materials (2022)