Abstract

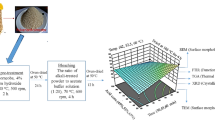

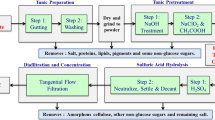

The daily use of synthetic detergents at a global scale is responsible for substantial environmental impacts but managerial and policy strategies to address them are largely inadequate. More sustainable and eco-friendly detergents are an appealing solution to reduce environmental impacts. Here, we developed a detergent based on cellulose nanospheres (CNSs) from agricultural waste corncob, an overlooked abundant and cheap natural source that is often discarded. Compared with conventional surfactants, CNSs stabilize at oil–water interfaces and form Pickering emulsions with enhanced stability and antiredeposition properties. CNSs show higher cleaning efficiency in removing stains from various surfaces compared with powder and liquid commercial detergents. In contrast to high toxicity of commercial detergents, CNSs are non-toxic to several mammalian cell lines, zebrafish and hydroponic lettuce. Overall, our results demonstrated the feasibility of using agriculturally derived waste CNSs as a safer, more cost-effective and sustainable alternative to commercial synthetic detergents.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Laundry Detergent Market Analysis by Product (Powder, Liquid, Fabric Softeners, Detergent Tablets), by Application (Household, Industrial or Institutional), by Region, and Segment Forecasts, 2018–2025 (Grand View Research, 2017); https://go.nature.com/3aH1aJy

Güven, K. C., Çetintürk, K., Alpaslan, M. & Tekinay, A. A. Oil and detergent pollution of sea water in Dardanelles in 2001–2002. Turkish J. Mar. Sci. 8, 121–130 (2002).

Qureshi, S. T., Soomro, A. G., Bux, H. & Yasmeen, A. Genotoxic and carcinogenic effects of house hold detergents using chromosomal aberration assay in chickpea (Cicer arietinum L.) root tip cells. World Appl. Sci. J. 32, 1381–1387 (2014).

Valdez, A. L. et al. Pediatric exposure to laundry detergent pods. Pediatrics 134, 1127–1135 (2014).

Mehta, P. S. & Bhatt, K. C. Traditional soap and detergent yielding plants of Uttaranchal. Indian J. Tradit. Know. 6, 279–284 (2007).

Gong, W. et al. Optimization of saponin extraction conditions with Camellia sinensis var. assamica seed and its application for natural detergent. J. Sci. Food Agric. 98, 2312–2319 (2018).

Tripodo, G. & Mandracchia, D. Inulin as a multifaceted (active) substance and its chemical functionalization: from plant extraction to applications in pharmacy, cosmetics and food. Eur. J. Pharm. Biopharm. 141, 21–36 (2019).

Ja’afar, S. M., Khalid, R. M., Othaman, R., Mokhtar, W. N. A. W. & Ramli, S. Coconut oil based microemulsion formulations for hair care product application. Sains Malays. 48, 599–605 (2019).

Gautam, K. K. & Tyagi, V. K. Microbial surfactants: a review. J. Oleo Sci. 55, 155–166 (2006).

Jensen, N. E. Severe dermatitis and “biological” detergents. Br. Med. J. 1, 299 (1970).

Cortez, J., Bonner, P. L. R. & Griffin, M. Transglutaminase treatment of wool fabrics leads to resistance to detergent damage. J. Biotechnol. 116, 379–386 (2005).

Berton-Carabin, C. C. & Schroen, K. Pickering emulsions for food applications: background, trends, and challenges. Annu. Rev. Food Sci. Technol. 6, 263–297 (2015).

Mohammed, N., Grishkewich, N. & Tam, K. C. Cellulose nanomaterials: promising sustainable nanomaterials for application in water/wastewater treatment processes. Environ. Sci. Nano 5, 623–658 (2018).

Capron, I. & Cathala, B. Surfactant-free high internal phase emulsions stabilized by cellulose nanocrystals. Biomacromolecules 14, 291–296 (2013).

Hu, S. et al. Improved properties and drug delivery behaviors of electrospun cellulose acetate nanofibrous membranes by introducing carboxylated cellulose nanocrystals. Cellulose 25, 1883–1898 (2018).

Saito, T., Kimura, S., Nishiyama, Y. & Isogai, A. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8, 2485–2491 (2007).

Satyamurthy, P. & Vigneshwaran, N. A novel process for synthesis of spherical nanocellulose by controlled hydrolysis of microcrystalline cellulose using anaerobic microbial consortium. Enzym. Microb. Technol. 52, 20–25 (2013).

Cheng, M. et al. Efficient extraction of carboxylated spherical cellulose nanocrystals with narrow distribution through hydrolysis of lyocell fibers by using ammonium persulfate as an oxidant. J. Mater. Chem. A 2, 251–258 (2014).

Yan, C. F., Yu, H. Y. & Yao, J. M. One-step extraction and functionalization of cellulose nanospheres from lyocell fibers with cellulose ii crystal structure. Cellulose 22, 3773–3788 (2015).

Zhang, Z. et al. Polymeric hollow microcapsules (PHM) via cellulose nanocrystal stabilized Pickering emulsion polymerization. J. Colloid Interface Sci. 555, 489–497 (2019).

Ye, S., Yu, H. Y., Wang, D., Zhu, J. Y. & Gu, J. P. Green acid-free one-step hydrothermal ammonium persulfate oxidation of viscose fiber wastes to obtain carboxylated spherical cellulose nanocrystals for oil/water Pickering emulsion. Cellulose 25, 5139–5155 (2018).

Guan, Y. et al. Green one-step synthesis of ZnO/cellulose nanocrystal hybrids with modulated morphologies and superfast absorption of cationic dyes. Int. J. Biol. Macromol. 132, 51–62 (2019).

Qu, W. H., Xu, Y. Y., Lu, A. H., Zhang, X. Q. & Li, W. C. Converting biowaste corncob residue into high value added porous carbon for supercapacitor electrodes. Bioresour. Technol. 189, 285–291 (2015).

Cao, Q., Xie, K. C., Bao, W. R. & Shen, S. G. Pyrolytic behavior of waste corn cob. Bioresour. Technol. 94, 83–89 (2004).

Medronho, B., Romano, A., Miguel, M. G., Stigsson, L. & Lindman, B. Rationalizing cellulose (in)solubility: reviewing basic physicochemical aspects and role of hydrophobic interactions. Cellulose 19, 581–587 (2012).

Moon, R. J., Martini, A., Nairn, J., Simonsen, J. & Youngblood, J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem. Soc. Rev. 42, 3941–3994 (2011).

Habibi, Y., Chanzy, H. & Vignon, M. R. TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose 13, 679–687 (2006).

Braun, B. & Dorgan, J. R. Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromolecules 10, 334–341 (2009).

Okita, Y., Saito, T. & Isogai, A. Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules 11, 1696–1700 (2010).

Yu, H. Y. et al. From cellulose nanospheres, nanorods to nanofibers: various aspect ratio induced nucleation/reinforcing effects on polylactic acid for robust-barrier food packaging. ACS Appl. Mater. Interfaces 9, 43920–43938 (2017).

Tanaka, M., Matsuno, R. & Converse, A. O. n-Butylamine and acid-steam explosion pretreatments of rice straw and hardwood: effects on substrate structure and enzymatic hydrolysis. Enzym. Microb. Technol. 12, 190–195 (1990).

Ouyang, X. et al. Improvement of lignin yield and purity from corncob in the presence of steam explosion and liquid hot pressured alcohol. RSC Adv. 5, 61650–61656 (2015).

Karimi, B., Biglari, A., Clark, J. H. & Budarin, V. Green, transition-metal-free aerobic oxidation of alcohols using a highly durable supported organocatalyst. Angew. Chem. Int. Ed. 119, 7348–7351 (2007).

Jin, Y., Edler, K. J., Marken, F. & Scott, J. L. Voltammetric optimisation of TEMPO-mediated oxidations at cellulose fabric. Green. Chem. 16, 3322–3327 (2014).

Kumar, V. & Yang, T. Analysis of carboxyl content in oxidized celluloses by solid-state 13C CP MAS NMR spectroscopy. Int. J. Pharm. 184, 219–226 (1999).

Zeng, J., Singh, D., Laskar, D. D. & Chen, S. Degradation of native wheat straw lignin by Streptomyces viridosporus T7A. Int. J. Environ. Sci. Technol. 10, 165–174 (2013).

Li, Y. et al. Preparation and characterization of oxidized starch polymer microgels for encapsulation and controlled release of functional ingredients. Biomacromolecules 10, 1931–1938 (2009).

Garvey, C. J., Parker, I. H. & Simon, G. P. On the interpretation of X-ray diffraction powder patterns in terms of the nanostructure of cellulose I fibres. Macromol. Chem. Phys. 206, 1568–1575 (2005).

Han, J. Q., Zhou, C. J., French, A. D., Han, G. P. & Wu, Q. L. Characterization of cellulose II nanoparticles regenerated from 1-butyl-3-methylimidazolium chloride. Carbohydr. Polym. 94, 773–781 (2013).

Keckes, J. et al. Cell-wall recovery after irreversible deformation of wood. Nat. Mater. 2, 810–814 (2003).

Wu, J. et al. Pickering emulsions stabilized by whey protein nanoparticles prepared by thermal cross-linking. Colloids Surf. B 127, 96–104 (2015).

Vignati, E., Piazza, R. & Lockhart, T. P. Pickering emulsions: interfacial tension, colloidal layer morphology, and trapped-particle motion. Langmuir 19, 6650–6656 (2003).

Deshmukh, O. S., Dirk, V. D. E., Martien Cohen, S., Frieder, M. & Duits, M. H. G. Hard and soft colloids at fluid interfaces: adsorption, interactions, assembly & rheology. Adv. Colloid Interface Sci. 222, 215–227 (2014).

Brugger, B. et al. The colloidal suprastructure of smart microgels at oil–water interfaces. Angew. Chem. 48, 3978–3981 (2009).

Zhang, Y., Karimkhani, V., Makowski, B. T., Samaranayake, G. & Rowan, S. J. Nanoemulsions and nanolatexes stabilized by hydrophobically functionalized cellulose nanocrystals. Macromolecules 50, 6032–6042 (2017).

Glaser, N., Adams, D. J., Böker, A. & Krausch, G. Janus particles at liquid–liquid interfaces. Langmuir 22, 5227–5229 (2006).

Aveyard, R., Binks, B. P. & Clint, J. H. Emulsions stabilised solely by colloidal particles. Adv. Colloid Interface Sci. 100–102, 503–546 (2003).

Aslanidou, D., Tsioptsias, C. & Panayiotou, C. A novel approach for textile cleaning based on supercritical CO2 and Pickering emulsions. J. Supercrit. Fluids 76, 83–93 (2013).

Salerno, A. et al. Pickering emulsions for skin decontamination. Toxicol. Vitr. 34, 45–54 (2016).

Fan, X. M. et al. Designing highly luminescent cellulose nanocrystals with modulated morphology for multifunctional bioimaging materials. ACS Appl. Mater. Interfaces 11, 48192–48201 (2019).

Zhang, H. J. et al. A novel cleaning process for industrial production of xylose in pilot scale from corncob by using screw-steam-explosive extruder. Bioprocess. Biosyst. Eng. 37, 2425–2436 (2014).

Jean, B., Dubreuil, F., Heux, L. & Cousin, F. Structural details of cellulose nanocrystals/polyelectrolytes multilayers probed by neutron reflectivity and AFM. Langmuir 24, 3452–3458 (2008).

Segal, L., Creely, J. J. Jr, Martin, A. E. & Conrad, C. M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 29, 786–794 (1959).

Capitani, D., Del Nobile, M. A., Mensitieri, G., Sannino, A. & Segre, A. L. 13C solid-state NMR determination of cross-linking degree in superabsorbing cellulose-based networks. Macromolecules 33, 430–437 (2000).

Garrison, C., Thackeray, R. & Mangum, S. Strength and whiteness retention of stained and treated nurse’s uniform fabrics. Int. J. Cloth. Sci. Tech. 4, 34–39 (1992).

Bao, W. E. et al. Nanolongan with multiple on-demand conversions for ferroptosis-apoptosis combined anticancer therapy. ACS Nano 13, 260–273 (2019).

Guideline for Testing of Chemicals Section, Fish Acute Toxicity Test (OECD, 1992); https://go.nature.com/38BxgVt

Acknowledgements

This work was supported by Natural Science Foundation of China grant nos. NSFC31471577, 31772014 and 31972202, the Beijing Nova Program by Beijing Municipal Science and Technology Commission grant no. Z181100006218071, the Young Elite Scientists Sponsorship Program by China Association for Science and Technology grant no. 2016QNRC001 and the National Key R&D program by Ministry of Science and Technology of China grant no. 2016YFD0400804. Y.L. acknowledges insightful discussions of this manuscript with H. Lin (Cornell University) and H. Ma, J. Wang, G. Cheng, C. Liu and H. Liang (Beijing University of Chemical Technology).

Author information

Authors and Affiliations

Contributions

Y.L. managed the whole project and designed all experiments. F.R. helped with manuscript revising, data analysis and provided experimental conditions. B.L. performed the preparation, characterization and cleaning experiments of CNSs. T.L. performed toxicity experiments and manuscript writing. W.W. assisted with the steam explosion of corncob. L.M.C.S. performed data analysis of interfacial properties. Q.Y. provided the corncob and helped with data analysis. X.L. and M.A.C. revised the manuscript. D.L., C.B. and J.B. helped with cytotoxicity experiments. Z.Y. assisted with the statistical analysis of toxicity data.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary methods, Figs. 1–10, Tables 1–5 and refs. 1–3.

Source data

Source Data Fig. 4b

Statistical Source Data

Source Data Fig. 5a and 5d

Statistical Source Data

Rights and permissions

About this article

Cite this article

Liu, B., Li, T., Wang, W. et al. Corncob cellulose nanosphere as an eco-friendly detergent. Nat Sustain 3, 448–458 (2020). https://doi.org/10.1038/s41893-020-0501-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-020-0501-1

This article is cited by

-

Sustainable polymer coating for stainproof fabrics

Nature Sustainability (2023)

-

A new facile and efficient strategy for high-yield preparation of spherical cellulose nanocrystals via enzymolysis-mechanical synergy

Cellulose (2023)

-

Insights into cellulose deconstruction and pseudo-lignin formation during deep eutectic solvent treatment

Cellulose (2023)

-

Detachable and hierarchical assemblies for recyclable and highly efficient oil-fouling removal

Nano Research (2023)

-

Acidified ZnCl2 molten salt hydrate systems as hydrolytic media for cellulose I and II nanocrystal production: from rods to spheres

Cellulose (2022)