Abstract

Reliable in-vitro digestion models that are able to successfully replicate the conditions found in the human gastrointestinal tract are key to assess the fate and efficiency of new formulations aimed for oral consumption. However, current in-vitro models either lack the capability to replicate crucial dynamics of digestion or require large volumes of sample/reagents, which can be scarce when working with nanomaterials under development. Here, we propose a miniaturised digestion system, a digestion-chip, based on incubation chambers integrated on a polymethylmethacrylate device. The digestion-chip incorporates key dynamic features of human digestion, such as gradual acidification and gradual addition of enzymes and simulated fluids in the gastric phase, and controlled gastric emptying, while maintaining low complexity and using small volumes of sample and reagents. In addition, the new approach integrates real-time automated closed-loop control of two key parameters, pH and temperature, during the two main phases of digestion (gastric and intestinal) with an accuracy down to ± 0.1 °C and ± 0.2 pH points. The experimental results demonstrate that the digestion-chip successfully replicates the gold standard static digestion INFOGEST protocol and that the semi-dynamic digestion kinetics can be reliably fitted to a first kinetic order model. These devices can be easily adapted to dynamic features in an automated, sensorised, and inexpensive platform and will enable reliable, low-cost and efficient assessment of the bioaccessibility of new and expensive drugs, bioactive ingredients or nanoengineered materials aimed for oral consumption, thereby avoiding unnecessary animal testing.

Similar content being viewed by others

Introduction

In the food industry, the increased popularity of functional foods, more precisely through the addition of nano-engineered formulations incorporating bioactive compounds highlights the need for appropriate tools to assess digestibility, bioaccessibility and safety of new delivery systems1. Mimicking human digestion is fundamental to evaluate the fate of new formulations intended for oral administration.

Human digestion is a complex multistage process, where ingested foods or compounds undergo a wide variety of physical and biochemical steps before reaching the intestinal epithelium for absorption2. During digestion, ingested foods are exposed to a harsh environment, which might cause their degradation/disintegration throughout the gastrointestinal tract (GIT) and, therefore affect their bioaccessibility, i.e., the fraction that reaches the small intestine and is available for absorption3. In addition, these compounds must undergo intestinal absorption to reach systemic circulation and become bioavailable4.

As an alternative to in-vivo models, in-vitro digestion models are attracting growing interest as a mean to avoid the challenges associated to animal testing, aiming to increase reliability and reduce failures in human clinical trials2,5,6. These models are usually categorised as static or dynamic7,8,9.

In static digestion models, the different steps of human digestion are mimicked inside closed reservoirs keeping the digestive conditions constant over the incubation period. During each phase, the sample is mixed with simulated digestive fluids and incubated for a specific time at constant temperature, enzyme activity and pH. In 2014, the INFOGEST network proposed a standardised protocol to minimise variability of the experimental conditions used to emulate human digestion in in-vitro models described elsewhere10,11,12, allowing read-across of experimental results between different research teams11,13. The INFOGEST protocol defines a sequential oral, gastric and intestinal digestion process where pH, incubation times, type and activity of enzymes, bile concentration, sample dilution and simulated fluid composition were defined based on available physiological data14. Some studies have validated the convenience of static digestion models due to their simplicity and reduced costs and indicated that they can provide a good end-point accuracy2,11,15. In many cases, they seem too simplistic to deliver reliable results, mainly when kinetics are pertinent to the study. This has been extensively described in several reviews5,8,16,17.

In contrast, dynamic models incorporate relevant features to replicate the complexity of the digestion process17,18. These include continuous flow, controlled addition of enzymes and simulated fluids, monitoring and automatic adjustment of pH, peristalsis, and gastric emptying. Thus, in-vitro dynamic models provide a better approximation to the conditions found in-vivo, enable time-resolved analysis, and provide results that can be directly correlated with in-vivo studies19. There are some examples found in literature, such as the TNO gastrointestinal model (TIM)20 and the Simulator of the Human Intestinal Microbial Ecosystem (SHIME) model21, which combine physiological processes within the stomach and the intestine providing important information regarding the digestibility of food matrices. These models are multi-compartmental, meaning that they contain different compartments for the different parts of the GIT and include real-time monitoring of different variables, such as pH and temperature. Another example is the Gastrointestinal Simulator developed at the Institute of Food Science Research (CIAL, Spain)22, which has recently been used to understand the potential effects of nanoparticles on the simulated digestive tract.

Nevertheless, these sophisticated models are complex, time-consuming and require large amounts of reagents and enzymes2, constituting a major drawback when applied to test expensive nanomaterials. As a compromise, Mulet-Cabero et al.18 from the INFOGEST network proposed a semi-dynamic protocol that, while following harmonised protocols, fills the gap between the reliable but complex dynamic models and the over simplistic but affordable static models. It is named semi-dynamic as it includes dynamics only in the gastric phase keeping the intestinal phase totally static (2 h of incubation using constant conditions: pH and enzyme activities). In the gastric phase, the semi-dynamic protocol simulates the gradual addition of gastric secretions, gradual acidification and performs several gastric emptying, enabling the assessment of the role of these dynamics in the digestion of ingested products. The protocol does not recommend specific apparatus, as an example an auto-titrator including a pH probe and a dosing unit or alternatively a syringe pump with a pH probe, are mentioned. The temperature must be controlled using a vessel with a thermostat jacket or other approach.

Here, we present a novel miniaturised system for in-vitro digestion studies. This versatile platform can be easily adapted to a static or a semi-dynamic protocol, incorporating the key dynamics mentioned above, in the gastric phase, mimicking the transient nature of gastric secretions and emptying. In this regard, our approach focuses on the upper parts of the digestive tract (mouth, stomach and small intestine), alike the DIDGI® system developed at the French National Institute for Agricultural Research (INRA)23,24.

Nevertheless, our miniaturised digestion device brings several benefits over the current in-vitro digestion models. There is a significant reduction of the footprint of the experimental setup when compared to the current dynamic models and minimal user input is required, given its automated operation. The simplicity of the device allows for easy sampling during the simulated digestion and continuous monitoring ensures that pH and temperature are automatically controlled during the experiment. Finally, the small dimensions of the incubation chambers translate into low consumption of sample/reagent volumes.

Finally, it is important to note that the choice of an appropriate in-vitro digestion model depends on the research question being addressed. In some cases, static models may be sufficient to provide accurate end-point digestion assessments. More complex and dynamic models may be necessary to accurately replicate digestion and evaluate the physicochemical changes certain foods undergo along the digestive tract. While our miniaturised system may not be suitable for in-vitro digestion of certain food matrices, it will become particularly attractive to evaluate the bioaccessibility of nano-engineered materials, bioactive ingredients, or even expensive drugs, which are often produced in limited quantities during the development stage25.

Methods

Device design and fabrication

A technical diagram of the digestion-chip can be found in Fig. 1a, together with a description of the different elements integrated. The device comprises three circular compartments (17 mm diameter, 20 mm height) that are two incubation chambers and one reservoir: (1) chamber to emulate the oral and gastric phase, (2) chamber to emulate the intestinal phase and (3) reservoir for simulated intestinal fluids that will be added along the digestion process. As can be seen in Fig. 1, both gastric chamber and reservoir of simulated intestinal fluids are connected to the intestinal chamber by two peristaltic micro-pumps that pump simultaneously, at the same flow rate (1:1 ratio), “chyme” and the simulated intestinal fluids from the gastric chamber and the reservoir, respectively, into the intestinal chamber where intestinal phase is emulated. These devices were fabricated from PMMA sheets using CNC micro-milling (Flexicam Viper 606 with ArtCam software) and laser cutting (Widlaser LS1390 Plus with LaserWorkV6 software). The devices were assembled by bonding several layers using double-sided 3 M tape (467MP; 3 M, Saint Paul, MN, US) applying continuous pressure overnight inside the oven at 65 °C to avoid the formation of bubbles.

As shown in Fig. 1b, the device contains 6 layers: (i) 4 layers (5 mm thickness) that define the height of the digestion chambers and reservoir, (ii) 1 layer (3 mm thickness) that is the bottom layer of chambers and reservoir with grooves to accommodate temperature sensors and heating elements and (iii) 1 bottom layer (5 mm thickness) to incorporate the peristaltic micro-pumps that allow gastric emptying. The bottom PMMA layer contains 2 parallel channels (21.14 mm3 each channel) along with 3 chambers (50.27 mm3 each chamber) that constitute a double synchronous peristaltic pump that connect the reaction chambers and that were fabricated by micromilling using 500-µm (11,000 RPM) and 1.5 mm (6000 RPM) diameter mills (vhf camfactor AG, Lettenstraße 10, 72,119 Ammerbuch, Germany). A rectangular cavity allows to place a PDMS piece bonded to a PDMS membrane fabricated by spin coating PDMS (1:10 w/w) at 1000 rpm for 1 min on top of square glass slide. This PDMS slab contains chambers that match the chambers of the peristaltic pump. Thus, the 6 chambers can be pressurised (using a Fluigents MFCS™-EZ Pressure controller), bending the membrane, displacing the fluid between chambers. The total internal volume of each parallel peristaltic pump is ~ 193 µL. The bottom layer is not bonded but rather screwed to the PMMA layers. This fully seals the PDMS piece between the middle and bottom layers of PMMA and avoids leakage through the holes connecting the digestion chambers, reservoir, and the micro-pump channels. An image of the assembled device with all components integrated can be seen in Fig. 1c. The pump is capable of driving up to 170 µL· min−1 and allows a precise control of the gastric emptying volume with approximately 50 µL per pumping cycle. A depiction of the pumping cycles is provided in Fig. S3.

To ensure a constant mixing of the sample and the simulated digestive fluids, 2 × 5 mm magnetic stirring bars were placed at the bottom of the digestion chambers. The devices were then placed on top of a custom-made magnetic stirrer fabricated out of two pulse width modulation (PWM) controllable motors (recycled from computer cooling fans) placed below the digestion chambers. This provides efficient mixing without causing enzyme degradation by mechanical stress. Mixing is critical for these experiments, not only for enzyme–substrate reactions, but also to prevent localised fluid overheating near the heating elements (which could cause irreversible enzyme denaturation) and ensure fast pH equilibration. A picture of the custom magnetic stirrer and stirring bars can be found in the Electronic Supplementary Information (ESI) (Fig. S3).

Finally, the 3 circular compartments are closed using PDMS lids to avoid evaporation (see Fig. 1c), that were punched with Biopsy punches (Kai-Europe GmbH, Germany) to hold the pH electrodes and tubing for the pH adjustment and the gradual addition of simulated gastric fluids and enzymes. These lids are easy to remove or place back and thus enable easy sampling from the digestion chambers at any time using a standard micropipette.

Temperature control

Digital temperature sensors 2 × 2 mm (MAX30205 Human Body Temperature Sensor, Maxim IntegratedTM, San José, California, USA) were integrated at the bottom of the gastric and intestinal chambers (Fig. 1c). The sensors have high accuracy (± 0.1 °C) in the human body temperature range and have a small footprint. The temperature readings are used to modulate the power delivered to the heating elements, more precisely insulated Nichrome (NiCr) wires having high resistivity, via a proportional integral derivative (PID) control loop to maintain temperature constant at 37 °C. The PID control algorithm was used following the standard method. The error in the temperature was set as the difference from the current temperature and the set point. The proportional term was calculated proportionally to this error. The integral term was calculated considering the change in temperature achieved during this last step. The derivative term was calculated taking into account the time evolution of the temperature, i.e. the change in the error in temperature over time. The constants used to calculate and equilibrate these terms were calibrated experimentally for a fast and precise response while avoiding overshooting in temperature to avoid enzyme degradation.

pH sensing and control

For pH sensing, potentiometric Iridium oxide (IrOx) sensors were used. The electrodes were fabricated following the anodic deposition approach reported by Yamanaka et al.26, which yields hydrated IrOx films with high (super-Nernstian) pH sensitivity27. The metal oxide sensors have number of attractive characteristics for integration into microsystems, such as their simple construction and ease of miniaturization, high mechanical and chemical stability and low cross-sensitivity to various salts28. In our system the sensors were fabricated by electrochemical deposition onto a titanium wire substrate. IrOx sensors are also biocompatible and have even been shown in vivo applications29.

As reference electrode a simple single-junction Ag/AgCl reference electrodes encapsulated with 3 M KCl solutions in micropipette tips were fabricated using an approach adapted from Barlag et al.30. In our system, the Ca2+-Alginate gel on the reference electrodes acts as the salt bridge that enables a connection between the reference electrode and the samples. A detailed protocol for the electrode fabrication is provided in ESI.

The electric potential difference between the pH electrodes is registered by an electronic circuit based on the ESP32 microcontroller. The real-time pH readings are used to control the pumping of 1 M HCl or 1 M NaOH from two inexpensive, custom-made programmable syringe pumps, to adjust the pH to the values set for each phase of digestion. The custom-made syringe pumps were adapted from previous work by Martin Fischlechner (Projects | DropletKitchen—https://dropletkitchen.github.io/).

A Printed Circuit Board (PCB) was designed to interface the syringe pumps, temperature sensors, heating elements and mixer motors with an Arduino Uno microcontroller and other extra electronic components required for the automation. A conceptual schematic of the system can be found in ESI (Fig. S4).

In-vitro digestion

Detailed information on material references and suppliers can be found in ESI. A commercial casein labelled with a red fluorescent dye BODIPY TR-X (EnzChek™ Protease Substrate, 589/617 nm)31 and lipase substrate labelled with a green fluorescent dye BODIPY-C12 (EnzChek™ Lipase Substrate, 482/515 nm)32 were used to measure the digestion rate and study the enzyme kinetics during in-vitro digestions. These reporter molecules are quenched by proximity, but become fluorescent after exposure to digestive enzymes.

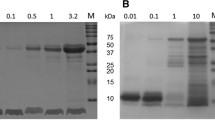

The simulated digestive fluids were prepared following the INFOGEST protocol (see ESI—Table S1 for detailed recipes) and stored at − 20 °C before use. Enzyme activity of pepsin and pancreatin was determined according to the procedure described by Brodkorb et al.10. Samples of 100 µL in the static digestions and 20 µL in the semi-dynamic digestions were collected throughout the gastric and intestinal phases and enzymes were inactivated by adding Pefabloc® (5 mM final concentration in the digesta) to inhibit protease activity and Orlistat® (1 mM final concentration) to inhibit lipase activity. The digestion rate was quantified by measuring the fluorescence of the test molecules using a BioTeK® Synergy H1 microplate reader (Winnoski, VT, USA).

INFOGEST static protocol

In vitro static digestions were carried out in a thermomixer (Eppendorf™, Hamburg, Germany) or inside a single compartment of the digestion-chip. Briefly, 1 mL sample (protease and lipase substrate) was mixed 1:1 with simulated salivary fluid (SSF) and incubated for 2 min at 37 °C. Following this, the simulated gastric fluid (SGF) and pepsin (final concentration 2.000 U/mL), were mixed 1:1 with the bolus, the pH adjusted to 3.0 (using 1 M HCl) and allowed to digest for 2 h. Then, the simulated intestinal fluid (SIF) containing bile salts (10 mM) and pancreatin (final concentration of trypsin 100 U/mL) were added to the end-point of the gastric phase (chyme), the pH was increased to 7.0 (using 1 M NaOH) and the chyme was incubated for further 2 h.

Semi-dynamic protocol

The digestion-chip aims to faithfully emulate the in-vivo conditions by incorporating some dynamic features, in the gastric phase, such as gradual acidification, addition of enzymes and simulated gastric fluid, and performing different gastric emptying, as shown in Fig. 2. The semi-dynamic protocol followed here was adapted from Mulet-Cabero et al.18 and is represented in Fig. 6. Glucose (100 mg mL−1) was added to the enzyme substrate to increase the overall caloric content of the sample as the total incubation time in the gastric phase is calculated as a function of the caloric content of the sample, according to the spreadsheet provided by Mulet-Cabero et al., leading to 80 min of total gastric incubation time. Briefly, 100 mg·mL−1 glucose was added to 500 µL of substrate (protease or lipase substrates) and mixed 1:1 with SSF and then incubated for 2 min at 37 °C, in the gastric chamber. The gastric phase initiates with just 10% of the total amount of gastric secretions to be added owing to the fasting levels. Thus, 10% of simulated gastric fluids (100 µL of SGF + pepsin) was added to the oral phase in the gastric chamber and the remaining 90% (900 µL of SGF + pepsin) was gradually added using a New Era NE-2000 syringe pump (New Era Pump Systems, Inc., NY, USA) at a constant flow rate of 11.25 µL·min−1, achieving a 1:1 volume ratio with respect to the oral phase at the end of the gastric phase (80 min). The pH was gradually acidified from ≈ 7 to ≈ 2 at the end. This was achieved by a constant communication between the pumping of HCl (1 M) using a custom-made syringe pump and the readings from the pH sensors. The gradual addition of HCl contributes to an increasing enzyme activity over the gastric phase.

During the incubation time in the gastric phase, sequential emptying into the intestinal chamber were performed. The number of gastric emptying is defined by the user, and in this case 4 were done, every 20 min. The gastric emptying was performed through sequential pressurisations of the chambers from the peristaltic micro-pump using the pressure controller. Chyme from the gastric chamber is mixed 1:1 with simulated intestinal fluids (SIF + bile salts + pancreatin). Here, 250 µL of chyme was mixed with 250 µL of simulated intestinal fluids after each emptying and incubated in the intestinal chamber for 2 h. Following each emptying the pH was adjusted to 7.0 adding NaOH (1 M).

Results and discussion

Temperature and pH control

Before the experiments, the two pairs of pH electrodes (sensing & reference) were calibrated using four calibration points by sequentially immersing the probes in standard pH reference solutions, with pH = 1.7, 4.0, 7.0 and 9.2.

In Electronic Supplementary Information (ESI), Fig. S1a shows the response of the potential difference to the calibration solutions, showing a fast response and stabilisation (under 60 s) of the sensors. The calibration plots are displayed in Fig. S1b, showing a good linear response. Slope values typically ranged between − 65 mV/pH and − 70 mV/pH. The performance of these probes was then further validated by comparing the pH measurements to a commercial pH-meter (Mettler Toledo®) in SGF solutions with different pH values ranging from 2.0 to 7.0. Maximum discrepancies were found with around ± 0.2 pH points for the more acidic pH values (2.0–3.0) and were minimal in the range of pH 3.0–7.0 (under ± 0.1 pH points). Furthermore, the probes long-term stability was validated in SGF (pH 3.0), showing a ± 10 mV variation over a period exceeding 10 h. The stability of the electrode pair and of each electrode independently against a commercial probe can be found in ESI (Fig. S2).

Figure 3 shows an example of the temperature and pH monitoring and control in a (a) static digestion using only one digestion chamber—and thus with a single pH probe and a temperature sensor—and (b) semi-dynamic digestion using both incubation chambers and two pairs of sensors. Figure 3a shows the temperature (in red) in the chambers, which is set at 37 °C and maintained constant throughout the entire experiment. The spikes around 150 min are due to the addition of the intestinal components (SIF + Pancreatin + Bile salts) to the digestion chamber. The pH (in blue) is first adjusted from a value around 6.5–3.0 for the gastric phase of digestion. Then, the pH is increased back to 7.0 for the intestinal phase of digestion. In this example, the pH reached a value higher than the set value of 7.0 due to an excessive addition of 1 M NaOH. This was mitigated by the subsequent addition of 1 M HCl, showing the versatility and reliability of the platform. Figure 3b.1 shows the pH data from a semi-dynamic digestion. The pH in the gastric chamber is gradually reduced throughout the digestion, whereas the pH in the intestinal chamber is maintained at a constant pH value, around 7.5. Here, NaOH was used to adjust the pH, as recommended in the INFOGEST protocol. The use of NaOH instead of sodium bicarbonate (NaHCO3) mitigates gas formation throughout the in-vitro digestion. Figure 3b.2 shows the temperature readings from the same experiment.

(a) Example of real-time temperature and pH control during a static digestion experiment in a single incubation chamber. The temperature (red) of the digestive fluids is maintained constant at 37 °C while the pH (blue) is first adjusted to 3.0 in the gastric phase and then increased to 7.0 in the intestinal phase. (b.1) Example of pH data from a semi-dynamic digestion showing gradual acidification of the gastric phase (in red) while the intestinal phase (in blue) is kept at a constant pH of 7.0–7.5. (b.2) Temperature data corresponding to the gastric and intestinal incubation chambers. The spikes observed in the intestinal phase correspond to each gastric emptying where the SIF is introduced at room temperature and mixed with the gastric phase (at 37 °C).

Static in-vitro digestion

To validate static in-vitro digestions using the digestion-chip, we replicated the INFOGEST protocol in our device and compared the results with the standard bench-top approach. Figure 4 shows the extension of digestion of the two test molecules in terms of the normalised fluorescence intensity measured and as a function of time. The fluorescence intensity measured at each wavelength is proportional to the extension of hydrolysis of the respective substrate. Figure 4a shows the digestion of the protease substrate, which expectedly increased rapidly within the first minutes of the gastric phase and then reached a plateau indicating that the substrate was fully converted by pepsin. Here, there was a constant enzyme activity of pepsin at a pH of 3.0, which is considered the optimal pH of maximum activity. There was though a further increase when the intestinal components (SIF + pancreatin) were added to the chyme, which plateaued after 60 min of digestion. Interestingly, pancreatin contributed more than pepsin (in the gastric phase) for protein digestion owing to the presence of different enzymes, which include trypsin, among others. These enzymes can further break down the reporter molecules in different locations contributing to a higher hydrolysis degree and, thus higher fluorescence intensity. Pancreatin has an optimal activity between pH 6.0–8.0. The digestion on-chip replicates the time-dependence obtained during the standard bench-top protocol. Control experiments without enzymes were performed to verify whether there was a fluorescence increase during both gastric and intestinal phases (ESI—Fig. S5).

Comparison of the static in-vitro digestion in the digestion-chip (N = 3) and the standard bench-top protocol (N = 4), both following the INFOGEST protocol. The data is presented as normalised fluorescence intensity, which is proportional to the concentration of hydrolysed protease or lipase substrates. (a) Protease substrate digestion (λex = 589 nm; λem = 617 nm). (b) Lipase substrate digestion (λex = 482 nm; λem = 515 nm).

Figure 4b shows the digestion of the lipase substrate in equivalent experiments. This substrate is not digested during the gastric phase, due to the absence of lipase enzymes, as shown by the nearly null values measured during the whole duration of the gastric phase. However, when the lipase substrate enters the intestinal phase of digestion, there is a rapid increase due to the high amount of substrate available and the action of lipases present in pancreatin. Here, the digestion was slightly faster for the digestion-chip and then reaches a plateau following the trends observed in the standard bench-top protocol.

The results summarised in Fig. 4 demonstrate the capabilities of this experimental setup to replicate digestive conditions, with an automated control of the experimental conditions while using low volumes of sample and reagents. Our device circumvents the need to do preliminary tests to assess the volumes of acid and base needed to adjust pH and provides its constant monitoring, together with temperature, thus avoiding adjustment errors. In addition, these results enabled to discard possible enzyme degradation due to mechanical strain or localised excessive heating near the heating elements.

Semi-dynamic in-vitro digestion

Nevertheless, as previously discussed, static digestion protocols fail to replicate the complexity of human digestion. An advantage of the digestion-chip is that it allows a very simple integration of key dynamic digestion features, while maintaining a small footprint and using low sample and reagent volumes. To validate the capacity of the device to integrate dynamic features in the gastric phase, we performed experiments including gradual acidification, gradual addition of enzymes and gastric emptying. The results from the on-chip semi-dynamic in-vitro digestions are summarised in Fig. 5, where the experimental data is normalised to the highest measured fluorescence value and the concentration of digestion products is assumed to be proportional to the fluorescence intensity.

Figure 5a shows the digestion of the protease and lipase substrates during the gastric phase. As expected, there is a more gradual increase in the protein digestion when compared to the static conditions (Fig. 5a) given the linear dependence with time for the first 20 min of the semi-dynamic digestion. This is due to the gradual acidification of the gastric phase (see Fig. 3b.1) and the gradual addition of pepsin. The product concentration then stabilises and starts to decrease owing to a completed hydrolisation of the substrate from the gastric enzymes (pepsin) and the dilution from the incoming gastric fluids. Concurrently, lipid digestion was not significant since lipases are not included in the gastric phase. This is reflected by the very low fluorescence intensity shown in Fig. 5a.

For intestinal digestion, 4 gastric emptying were performed at time-points 20, 40, 60 and 80 min. Additionally, an extra emptying was done at time-point 0 (without gastric incubation time) to analyse the kinetics of the intestinal enzymes in isolation. Figure 5b shows that there was a rapid increase in the extension of digestion of both substrates, similar to the static experiments. The digestion of the protease substrate occurs fast following the first emptying to then slowly decrease until it stabilises close to the end of the incubation. The lipase substrate digestion follows the same trend as the protease substrate, given that enzyme concentration and pH are kept constant throughout the experiment.

To further validate the results from the on-chip semi-dynamic digestions, we fitted the protease digestion data (which shows clearer and richer dynamics) to a first order kinetics reaction model:

where \(k\) is the reaction rate constant. The model data is equally normalised to the highest digestion products concentration. We use a simple first order kinetics model, which is limited to a specific reaction. In this case, we have a complex substrate with different cleavage points. Thus, we can only define effective values for the rate constant \(k\), since mechanistically it does not correspond to a specific hydrolysis reaction but to a sum of all different cleaving reactions. More details about the differential equations to modelling the enzyme kinetics can be found in ESI (Section “6”). Figure 6a shows the experimental results of the gastric phase together with the best model fitting (for \(k=0.0043 {s}^{-1}{(U/\mu L)}^{-1}\)). The model reproduces accurately the dependence observed in the gastric phase, with a sharp initial increase in product concentration followed by a slow decrease due to sample dilution once the completed hydrolysis by pepsin. A diagrammatic depiction of the evolution of [S], [E] and the total reaction volume is also included.

Results of the first-order kinetics model fitted to the experimental protease substrate digestion results in the digestion-chip. Best fitting of the model (red) for the digestion rate constant \(k\) to the experimental data from the semi-dynamic digestions (black). (a) Gastric phase, (b) intestinal phase.

The intestinal phase is much more complex (Fig. 6b). Pancreatin is a mixture of enzymes, and intestinal digestion occurs on top of a partially digested substrate from the different gastric emptying, which are sequentially added to the same reaction chamber. Nevertheless, the model can predict well the first half of the intestinal phase (with \(k=0.046 {s}^{-1}{(U/\mu L)}^{-1}\)), showing a sharp increase at the start of the reaction after the first emptying. This is followed by a moderate decrease at t = 20 min, attributed to the dilution caused by the second gastric emptying. Another sharp increase follows, which is justified by the continuation of the digestion.

The model predicts a sequential increase on the total digestion products concentration resulting from the cleavage of protease substrate by intestinal enzymes, which is restarted after each gastric emptying. To observe a better match with the experimental results, it would be necessary to increase the time resolution of the experiments. Finally, the model does not reproduce the decrease in product concentration to the same extent observed experimentally during the second half of the intestinal phase.

We hypothesise that this discrepancy could be due to enzyme degradation, possibly caused by auto-proteolytic activity, and enzyme product inhibition, which have been described in the literature33,34,35,36,37,38 but were not considered in our model. These would effectively reduce enzyme activity over time and therefore the total product content cannot account for the dilution caused by the increase in volume after each gastric emptying. In fact, the last gastric emptying occurs at t = 80 min, after which the intestinal product concentration remains constant until the end of the digestion, showing that there is no degradation of the product. In our devices all gastric emptying volumes are combined into the same intestinal phase and thus, the intestinal phase kinetics should be taken as an end-point measurement. Adding to our digestion-chip the capacity to incubate intestinal phase reactions independently is one of our current research goals.

Conclusions

This work describes a novel in-vitro digestion platform, a digestion-chip, where digestion occurs inside miniaturised and automated incubation chambers with integrated sensors. The combination of an integrated peristaltic micro-pump and custom-made small-footprint syringe pumps, which are low-cost and programmable, allows sample and reagents to be automatically manipulated in the system. The continuous sensing of pH and temperature enables full automated control via feedback-loops driving the heating elements and the pumping of acid or base. The fabrication process is simple and affordable, and the device design facilitates sampling during the digestion experiments.

The experimental results demonstrate that the digestion-chip can reliably perform static in-vitro digestions, replicating the gold-standard INFOGEST protocol while bringing several advantages, such as the automated adjustment of pH and temperature in each digestion phase. Additionally, the digestion-chip allows the integration of crucial dynamics of human digestion, providing more physiologically relevant outcomes through its use in semi-dynamic digestion simulations, and showing the capability to adapt to different protocols depending on the study requirements.

Furthermore, the reduced dimensions and low complexity of the setup, the small amounts of sample and reagents required and its user-friendly operation, make this approach particularly attractive for studying new drugs, bioactive compounds and nano-formulations. The production of such compounds is typically expensive during the early stages of development and requires extensive in-vivo testing to study their fate along the gastrointestinal tract39.

The choice of a correct in-vitro digestion model for each specific case-study is critical for an adequate assessment of the food digestibility and bioaccessibility and to guarantee the validity and applicability of the experimental outcomes. Our system allows for low-cost, facile and reliable assessment of bioaccessibility and digestion dynamics. We believe that this is a prototype of a future family of versatile and miniaturised digestion simulation tools that can easily adapt diverse protocols, particularly useful for in-vitro digestion of new and expensive nanomaterials. Finally, coupling with gut-on-chip40,41 or multi-organ-chip models will enable replicating the complete gastrointestinal tract and analyse compound cytotoxicity, intestinal permeability and potentially first-pass metabolism, providing comprehensive studies of bioaccessibility and bioavailability in a single platform.

Data availability

The data generated during the current study is available from the corresponding authors on reasonable request.

Abbreviations

- GIT:

-

Gastrointestinal tract

- PMMA:

-

Polymethylmethacrylate

- TIM:

-

TNO gastrointestinal model

- SHIME:

-

Simulator of the human intestinal microbial ecosystem

- INRA:

-

National Institute for Agricultural Research

- CNC:

-

Computer numerical control

- PDMS:

-

Polydimethylsiloxane

- PWM:

-

Pulse width modulation

- NiCr:

-

Nichrome

- PID:

-

Proportional integral derivative

- IrOx:

-

Iridium oxide

- PCB:

-

Printed circuit board

- SSF:

-

Simulated salivary fluid

- SGF:

-

Simulated gastric fluid

- SIF:

-

Simulated intestinal fluid

References

Silva, P. M. et al. Recent advances in oral delivery systems of resveratrol: Foreseeing their use in functional foods. Food Funct. 14, 10286–10313 (2023).

Bohn, T. et al. Correlation between in vitro and in vivo data on food digestion. What can we predict with static in vitro digestion models?. Crit. Rev. Food Sci. Nutr. 58, 2239–2261 (2018).

Ketnawa, S., Suwannachot, J. & Ogawa, Y. In vitro gastrointestinal digestion of crisphead lettuce: Changes in bioactive compounds and antioxidant potential. Food Chem. 311, 125885 (2020).

Antunes, F. et al. Models to predict intestinal absorption of therapeutic peptides and proteins. Curr. Drug Metab. 14, 4–20 (2013).

Li, C. et al. Current in vitro digestion systems for understanding food digestion in human upper gastrointestinal tract. Trends Food Sci. Technol. 96, 114–126 (2020).

Mackie, A., Mulet-Cabero, A.-I. & Torcello-Gómez, A. Simulating human digestion: Developing our knowledge to create healthier and more sustainable foods. Food Funct. 11, 9397–9431 (2020).

Hollebeeck, S. et al. Development of a standardised human in vitro digestion protocol based on macronutrient digestion using response surface methodology. Food Chem. 138, 1936–1944 (2013).

Lucas-González, R. et al. In vitro digestion models suitable for foods: Opportunities for new fields of application and challenges. Food Res. Int. 107, 423–436 (2018).

Alegría, A., Garcia-Llatas, G. & Cilla, A. Gastrointestinal Digestion Models, General Introduction. In The Impact of Food Bioactives on Health: in vitro and ex vivo models (eds. Verhoeckx, K., Cotter, P., López-Expósito, I., Kleiveland, C., Lea, T., Mackie, A., Requena, T., Swiatecka, D., Wichers, H.) 3–93 (Springer, 2015).

Williams, H. D. et al. Toward the establishment of standardized in vitro tests for lipid-based formulations, part 3: Understanding supersaturation versus precipitation potential during the in vitro digestion of type I, II, IIIA, IIIB and IV lipid-based formulations. Pharm. Res. 30, 3059–3076 (2013).

Brodkorb, A. et al. INFOGEST static in vitro simulation of gastrointestinal food digestion. Nat. Protoc. 14, 991–1014 (2019).

Williams, H. D. et al. Toward the establishment of standardized in vitro tests for lipid-based formulations, part 1: Method parameterization and comparison of in vitro digestion profiles across a range of representative formulations. J. Pharm. Sci. 101, 3360–3380 (2012).

Minekus, M. et al. A standardised static in vitro digestion method suitable for food—an international consensus. Food Funct. 5, 1113–1124 (2014).

Xavier, M. et al. Safety and fate of nanomaterials in food: The role of in vitro tests. Trends Food Sci. Technol. 109, 593–607 (2021).

Colombo, R. et al. Advances in static in vitro digestion models after the COST action Infogest consensus protocol. Food Funct. 12, 7619–7636 (2021).

Dupont, D. & Mackie, A. R. Static and dynamic in vitro digestion models to study protein stability in the gastrointestinal tract. Drug Discov. Today Dis. Models 17–18, 23–27 (2015).

Dupont, D. et al. Can dynamic in vitro digestion systems mimic the physiological reality?. Crit. Rev. Food Sci. Nutr. 59, 1546–1562 (2019).

Mulet-Cabero, A.-I. et al. A standardised semi-dynamic in vitro digestion method suitable for food—an international consensus. Food Funct. 11, 1702–1720 (2020).

Verwei, M. et al. Evaluation of two dynamic in vitro models simulating fasted and fed state conditions in the upper gastrointestinal tract (TIM-1 and tiny-TIM) for investigating the bioaccessibility of pharmaceutical compounds from oral dosage forms. Int. J. Pharm. 498, 178–186 (2016).

Minekus, M. et al. A multicompartmental dynamic computer-controlled model simulating the stomach and small intestine. Altern. Lab. Anim. 23, 197–209 (1995).

Molly, K., Vande Woestyne, M. & Verstraete, W. Development of a 5-step multi-chamber reactor as a simulation of the human intestinal microbial ecosystem. Appl. Microbiol. Biotechnol. 39, 254–258 (1993).

Cueva, C. et al. Gastrointestinal digestion of food-use silver nanoparticles in the dynamic SIMulator of the GastroIntestinal tract (simgi®). Impact on human gut microbiota. Food Chem. Toxicol. 132, 110657 (2019).

Ménard, O., Picque, D. & Dupont, D. The DIDGI® system. In The Impact of Food Bioactives on Health 73–81 (Springer, 2015). https://doi.org/10.1007/978-3-319-16104-4_8

Egger, L. et al. Digestion of milk proteins: Comparing static and dynamic in vitro digestion systems with in vivo data. Food Res. Int. 118, 32–39 (2019).

Lefebvre, D. E. et al. Utility of models of the gastrointestinal tract for assessment of the digestion and absorption of engineered nanomaterials released from food matrices. Nanotoxicology 9, 523–542 (2015).

Yamanaka, K. Anodically electrodeposited iridium oxide films (AEIROF) from alkaline solutions for electrochromic display devices. Jpn. J. Appl. Phys. 28, 632 (1989).

Mingels, R. H. G. et al. Iridium and Ruthenium oxide miniature pH sensors: Long-term performance. Sens. Actuators B Chem. 297, 126779 (2019).

Manjakkal, L., Szwagierczak, D. & Dahiya, R. Metal oxides based electrochemical pH sensors: Current progress and future perspectives. Prog. Mater. Sci. 109, 100635 (2020).

Marzouk, S. A. M. et al. Electrodeposited iridium oxide pH electrode for measurement of extracellular myocardial acidosis during acute ischemia. Anal. Chem. 70, 5054–5061 (1998).

Barlag, R. et al. A student-made silver–silver chloride reference electrode for the general chemistry laboratory: ∼ 10 min preparation. J. Chem. Educ. 91, 766–768 (2014).

de Haan, P. et al. Digestion-on-a-chip: A continuous-flow modular microsystem recreating enzymatic digestion in the gastrointestinal tract. Lab. Chip 19, 1599–1609 (2019).

Basu, D., Manjur, J. & Jin, W. Determination of lipoprotein lipase activity using a novel fluorescent lipase assay. J. Lipid Res. 52, 826–832 (2011).

Calleri, E. et al. Development of a bioreactor based on trypsin immobilized on monolithic support for the on-line digestion and identification of proteins. J. Chromatogr. A 1045, 99–109 (2004).

Cingöz, A., Hugon-Chapuis, F. & Pichon, V. Evaluation of various immobilized enzymatic microreactors coupled on-line with liquid chromatography and mass spectrometry detection for quantitative analysis of cytochrome c. J. Chromatogr. A 1209, 95–103 (2008).

Gauthier, S. F. et al. Assessment of protein digestibility by in vitro enzymatic hydrolysis with simultaneous dialysis. J. Nutr. 112, 1718–1725 (1982).

Butts, C. A., Monro, J. A. & Moughan, P. J. In vitro determination of dietary protein and amino acid digestibility for humans. Br. J. Nutr. 108, S282–S287 (2012).

Thresher, W. C., Swaisgood, H. E. & Catignani, G. L. Digestibilities of the protein in various foods as determinedin vitro by an immobilized digestive enzyme assay (IDEA). Plant. Foods Hum. Nutr. 39, 59–65 (1989).

Johansson, D. G. A. et al. Protein autoproteolysis: conformational strain linked to the rate of peptide cleavage by the pH dependence of the N → O acyl shift reaction. J. Am. Chem. Soc. 131, 9475–9477 (2009).

Huang, X. et al. Encapsulation of resveratrol in zein/pectin core-shell nanoparticles: Stability, bioaccessibility, and antioxidant capacity after simulated gastrointestinal digestion. Food Hydrocoll. 93, 261–269 (2019).

Déat, E. et al. Combining the dynamic TNO-gastrointestinal tract system with a Caco-2 cell culture model: Application to the assessment of lycopene and α-tocopherol bioavailability from a whole food. J. Agric. Food Chem. 57, 11314–11320 (2009).

Yi, J. et al. Effects of lipids on in vitro release and cellular uptake of β-carotene in nanoemulsion-based delivery systems. J. Agric. Food Chem. 63, 10831–10837 (2015).

Acknowledgements

This work was funded by the SbDtoolBox—Nanotechnology-based tools and tests for Safer-by-Design nanomaterials, with the reference NORTE-01-0145-FEDER-000047, funded by Norte 2020, North-Regional Operational Programme under the PORTUGAL 2020 Partnership Agreement, through the European Regional Development Fund (ERDF) and by the European Union’s Horizon 2020 research and innovation programme through the project GASTRIC, under the Marie Sklodowska-Curie Grant Agreement No. 101003440.

Author information

Authors and Affiliations

Contributions

VC: investigation, methodology, data analysis, writing – original draft preparation, and writing – review and editing. PR: investigation, methodology, data analysis, writing – original draft preparation, and writing – review and editing. TD: investigation, methodology, data analysis. AA: investigation, methodology, data analysis, writing – original draft preparation, and writing – review and editing. AV: investigation, methodology, data analysis. LP: writing – review and editing, funding acquisition, project administration. MX: conceptualisation, data analysis, supervision, writing – review and editing, funding acquisition, project administration. CG: conceptualisation, data analysis, supervision, writing – review and editing, funding acquisition, project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Calero, V., Rodrigues, P.M., Dias, T. et al. A miniaturised semi-dynamic in-vitro model of human digestion. Sci Rep 14, 11923 (2024). https://doi.org/10.1038/s41598-024-54612-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-54612-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.