Abstract

The present work report for the first time on the production of bacterial cellulose (BC) using natural loofa sponge (Luffa aegyptiaca) as a scaffold for the immobilization of Gluconacetobacter kombuchae. Bacterial cellulose (BC) are recently gained more attention in several fields including biological and biomedical applications due to their outstanding physico-chemical characteristics including high thermal stability, easy biodegradability, good water holding capacity, high tensile strength, and high degree of polymerization. The increase in requirement of alternative method for the enhancement of BC production under economical aspect develops a positive impact in large scale industries. In this study, Luffa aegyptiaca (LA) was introduced in a separate fermentation medium so as to enhance the concentration of BC production by Gluconacetobacter kombuchae. Different process/medium parameters such as initial pH, static/shaking condition, inoculum size, nitrogen source, C/N ratio, supplements (ethanol and acetic acid) were analysed for the production of bacterial cellulose using LA support. The maximum yield of BC was obtained using following condition: culturing condition -shaking; initial pH − 5.5; nitrogen source- yeast extract, C/N ratio – 40 and supplement—ethanol. The characterization of the BC was examined using Fourier Transform Infra-Red spectroscopy and thermo gravimetric analysis. The biofilm formation on the surface of LA was examined by SEM photographs. Thus, implementation of LA as a support in shaking fermentation under suitable medium/process variables enhanced the BC production.

Similar content being viewed by others

Introduction

Bacterial cellulose (BC), one among the carbohydrate polymers, has been increasing applications in the past decades owing to its outstanding characteristics such as hydrophilicity, biocompatibility, crystallinity, tensile strength, moldability, degree of polymerization, biodegradability and thermal stability1,2,3,4,5,6. It is widely used in numerous commercial applications, some of which are: (i) preparation of artificial skin, artificial blood vessel, nano structured biomaterials in tissue engineering, (ii) synthesis of biodegradable materials, wound cleansing material in biomedical field; (iii) manufacturing of low-calorific desserts, fabricated foods and salads in food industry, (iv) as a stability enhancer in paper industry and (v) cosmetics7,8,9. Unlike plant cellulose, BC produced through microbial fermentation has high purity and does not require any energy consuming steps such as hydrolysis and delignification due to the absence of lignin, pectin and hemicellulose10. BC has both amorphous and crystalline structure and the crystallinity degree is significantly influenced by the culturing condition, medium formulation and nature of raw material used11,12.

Although it is structurally similar with plant cellulose (β- 1,4-glucans, (C6H12O6)n), certain bacteria, specifically acetic acid bacteria (AAB) like Agrobacterium, Aerobacterium, Rhizobium, Salmonella, Sarcina, Azetobacter, Achromobacter, Komagataeibacter has the capability of producing Bacterial cellulose (BC) by their metabolic activity13. The preferable carbon sources for the commercial production of BC are glucose, fructose and glycerol 14. The suitable medium formulation is essential for supporting the growth of microorganism and facilitating the production of BC15.

The production of BC has been significantly enhanced by the optimizing medium variables (carbon, nitrogen, potassium, magnesium, phosphorus and sulfur), culturing conditions (pH, temperature, static culture, shaking culture) and submerged/solid state fermentation16,17,18,19,20. The culturing conditions could affect the formation of BC and its morphological structures including mat like structure or pellicle (static) and pellets or granules (shaking). Several researchers demonstrated that the shaking culture condition is more preferable for the production of BC over static culture condition due to the requirement of minimum floor area, mixing and lesser incubation time15,21,22,23. However, it is difficult to achieve more yield of BC using such AABs producing strains under shaking condition. To overcome the difficulties in shaking culture and increase the fermentation efficiency, numerous attempts have been made to improve the production of BC: (i) using genetically modified AAB; (ii) screening of essential medium components; (iii) optimizing culturing conditions/parameters; (iv) modifying the configuration or type of reactors such as cylindrical silicone membrane vessel, rotating disk bioreactor, immobilized cell reactor, hollow fiber reactor and biofilm reactor24,25,26,27,28,29,30. Due to better nutrient transport, high biomass density, high volumetric productivity and also lower capital cost requirement, BC production with immobilized cell cultivation (biofilm on the matrix) are preferable over conventional cultivation31. Biofilm formation takes place during fermentation, where the microorganism gets attached over the surface of the support naturally by microbial immobilization technique32. Several researchers reported the production of ethanol, lactic acid, nisin, succinic acid, bacteriocin, BC and pullulan using biofilm reactors to enhance the productivity31,33,34,35,36,37,38. In the present study, the production of BC was investigated using immobilized Gluconacetobacter kombuchae on Luffa aegyptiaca (LA), as a novel and cost-effective biomass support.

LA is a genus of tropical and sub-tropical plant in the cucumber family of Cucurbitaceae. This plant is generally grown in countries like India, Japan, China and Africa. The chemical composition of LA has protein (4.2%), lipid (1.08%), ash (1.04%), fiber (55.78%) and carbohydrate (37.81%)39. Luffa fiber contains cellulose (60%), hemi-cellulose (30%) and lignin (10%)40. Luffa species have been employed as a potential carrier for microbial/plant cell/animal cell immobilization due to low biodegradability, appropriate ratio of lignin & cellulose, structural stability, large space for cell growth, fixed cells with high cell density, rich composition of lignin, cellulose high mass transfer efficiency in fixed bed, wide range pH stability, exposure to high temperature for repeated sterilization, reusability, texture, shape and high porosity41. It has been successfully used as a carrier/scaffold material for microbial cultivation, plant cell cultivation and biomedical engineering filed42,43,44,45. Luffa species has the following physico-chemical properties in Table 1.

The objective of this work was to examine the implementation of immobilization support, Luffa aegyptiaca for BC production by GluconAcetobacter kombuchae, which was divided in to three specific objectives: (i) comparison of BC production with/without immobilized matrix under shaking/static condition and also to analyze the material property of Luffa aegyptiaca scanning electron microscopy analysis (SEM); (ii) effects of different factors namely initial pH, inoculum size, nitrogen source, C/N ratio, supplement on BC production using suitable condition. (iii) to analyze the thermal & structural properties of produced BC thermogravimetric (TGA) & FTIR analysis respectively. Although, several plastic supports have been employed in biosynthesis of BC in previous studies (Cheng et al. 2009, 2010), this study pioneers at using Luffa aegyptiaca as a novel support for BC synthesis. To goodness of our knowledge, this is the first report that describes the production of bacterial cellulose using LA as a scaffold for the immobilization of Gluconacetobacter kombuchae. The overall schematic representation for the production of BC is described in Fig. 1.

Result and discussion

Identification of initial pH and culturing conditions on BC production

The medium pH is an essential parameter affecting the activity of primary enzymes responsible for BC production, thereby should be optimized in order to achieve maximum concentration of BC. Therefore, the medium pH was varied over the range (4.5–8.5) using HCl or NaOH before sterilization48. Figure 2 explains the effect of intial pH culturing condition on the production of BC using free cell and immobilized cells. The fermentation was carried out using free cells and immobilized cells under shaking and static cultivation for 15 d. Under shaking condition, fermentation medium containing immobilized cells and free cells resulted maximum BC concentration of 15.5 ± 1.65 g/L and 7.4 ± 1.34 g/L respectively (Fig. 2a). In static condition, the maximum BC concentration of 11.3 ± 1.31 g/L and 7.27 ± 1.91 g/L were obtained at pH 5.5 for immobilized cells and free cells respectively (Fig. 2b). From experimental data, it is evident that the production of BC was favored by immobilized cells with shaking. The production of BC in shaking condition was about 1.3 times more than that in static culturing conditions under optimum initial pH. The static culture for BC production has several disadvantages than shaking cultivation due to the lack of essential nutrients in the aerobic region, lowere volumetric productivity and low oxygen level required for microbial growth in the static condition49,50.

A low and high pH resulted in low concentration of BC under shaking and static cultivation using free cells and immobilized cells. This could be attributed to the decrease in the activity of key enzymes responsible for BC production. Previous studies have reported that maximum BC was produced at an initial pH of 5 by Leifsonia sp. CBNU-EW3 (4 g/L) and K. europaeus SGP37 (6.07 ± 0.40 g/L)51,52. Santoso et al., 2020 demonstrated the maximum BC production of 3.906 g/L with optimum pH of 5.4 under static condition using sucrose medium53. Similarly, several researchers have illustrated the maximum BC production at an initial pH of 5 in static condition48,51,52. Rangaswamy et al., 2015 identified the optimum pH of 6 for maximizing BC production (2.1 g/L) by Gluconacetobacter sp. RV28 isolated from rotten fruits. Several authors have reported that BC production was more suitable when the medium pH was ranging from 5 to 654,55. Thus, BC production using immobilized cell on LA support was higher than that in the absence of support. At initial pH 5.5 and shaking condition, the maximum BC production of 15.5 ± 1.65 g/L was achieved using immobilized cell with LA support, which was approximately about two times more than that of the absence of the support.

Culturing condition

Culturing condition (static/shaking) is an essential parameter for the production of BC with various forms. The various forms namely fibrous suspension, pellets, spheres or irregular masses were observed under shaking condition. The produced BC is not restricting the transport of essential nutrients for microbial growth at the air–liquid interface49,56. Tanskul et al. observed the various forms of BC such as granular /tapioca-pearls/few irregular shapes and interconnected reticular pellicles under shaking and static condition respectively57. The different forms of BC synthesis were observed due to the disruptive effect of strong mechanical means (aeration/shaking) on the formation of hydrogen bonds within BC chain58. The photographic images for BC formation on with and without LA support (culture medium 150 ml) are shown in Fig. 3. Figure 3A depicts the formation of BC mat on the top surface of the production medium under static condtion without LA support. This observation was consistent with previous findings (Heieh et al., 2016). Under shaking condition without LA support, viscous and turbid nature of culture was observed as shown in Fig. 3B. This might be due to the uniform elaboration of produced BC throughout the medium. Whereas with LA support, irregular BC aggrgates are formaed on the surface of LA support as shown in Fig. 3C,D under both static and shaking cultivation.

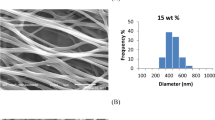

Surface morphology of Luffa ageyptiaca

SEM analysis is used to evaluate the surface morphological changes of Luffa ageyptiaca during the production of BC. The SEM photographs of Luffa ageyptiaca before and after fermentation were illustrated in Fig. 4a–h with different magnification. The SEM micrographs of Luffa ageyptiaca before fermentation show dense, rough, cavities and highly heterogeneous surface with different shape and size as shown in Fig. 4a–d. This kind of surface texture is essential for attachment of cells. During fermentation, Gluconacetobacter kombuchae cells were growing predominantly over the surface of Luffa ageyptiaca with suitable fermentation condition and medium formulation for the production of BC. The rod-shaped cells were clearly visible over the surface of the Luffa ageyptiaca in different magnification (3 kx and 10 kx) as shown in Fig. 4e–h during fermentation. The morphological texture of Luffa ageyptiaca in terms of rough, cavities, pores and highly heterogeneous surface has significantly changed due to the attachment of cells and accumulation of BC over Luffa ageyptiaca during fermentation.

Inoculum size

Microbial polysaccharide production is significantly influenced by inoculum size in batch cultivation59. The larger inoculum size with active seed culture minimizes the length of adaptation (lag period) phase and facilitates the biomass concentration with a short fermentation time leading to higher production of exopolysaccharides60. Figure 5 shows that the effect of inoculum size ranging from 1 to 7% (v/v) on the concentration of BC using immobilized cells with initial pH 5.5 for 15 days incubation. The result illustrated that the concentration of BC raised significantly by increasing the size of inoculum from 1 to 5% v/v and then decreased. The maximum BC concentration of 15.12 ± 1.42 g L−1 was obtained with an inoculum size of 5% (v/v) after 15 days of fermentation than 4%, v/v (14.38 ± 1.94 g L−1). The significant decrease in BC concentration was noted above 5% (v/v) of inoculum size. The possible reason might be that the rapid consumption of feed stock responsible for BC production at larger inoculum size61. And also, the quick utilization of the limiting substrate in the early stage of batch fermentation with larger inoculum size above the optimum, was not suitable for the elaboration of BC in the final stage of fermentation62. In the larger inoculum size containing a greater number of active bacterial cells above the certain level might limit too much composition of oxygen in the production medium. The larger number of microorganisms had been killed due to the insufficient composition of oxygen in the aerobic batch fermentation. However, if the inoculum size goes below a certain level, the number of bacterial cells in fermentation medium responsible for BC elaboration was minimum, and hence the efficiency of fermentation was low62. Therefore, the produced BC might be subjected to the category of product formation directly coupled with energy metabolism and also a growth associated product63. Similarly, the maximum production was achieved under shaking condition using SH medium containing glucose with 5% (v/v) of inoculum size64. Hornung et al., 2006 reported that a significant number of young cells in the aerobic fermentation medium is required for the significant production of BC65. Thus, according to the previous findings, it might be expected from this present study, that 5% (v/v) cell density of Gluconacetobacter kombuchae MTCC (6913) facilitated the maximum BC production in the aerobic medium.

Screening of nitrogen source

Nitrogen source is essential for supporting the growth of cells. The presence of Nitrogen in the production medium might not be coupled with the biosynthesis of BC 15,66 in an industrial scale process. In order to keep the composition of nitrogen content in the production medium at desired level, various nitrogen sources namely ammonium sulphate, peptone, sodium nitrite, tryptone were considered and substituted with yeast extract (3 g/L) on the basis of equivalent nitrogen content. The comparison of N-sources for the production of BC was evaluated using immobilised cells at initial pH 5.5 under shaking condition for 15 days as shown in Fig. 6. Peptone and Tryptone in the medium resulted the BC concentration of 8.4 ± 1.27 g/L and 8.67 ± 1.98 g/L respectively. Ammonium sulphate and sodium nitrite showed lower BC concentration of 3.95 ± 0.3 and 2.67 ± 0.42 g/L respectively. It was noted that there was no significant difference in the concentration of BC between the control medium and ammonium sulphate or sodium nitrate in the production medium. Maximum BC concentration of 15.9 ± 1.4 g/L was obtained using yeast extract in the production medium among other N-sources used with equal composition of nitrogen content. The production of BC using yeast extract was approximately 2 folds higher than peptone or tryptone in the production medium. The reason might be that yeast extract has a rich source of nutrients including carbon, amino acids and vitamin B complex essential for for stimulating the cellular growth as well as the synthesis of product67,68. Similar to the findings, Embuscado et al., 1994 reported that inorganic N-sources such as sodium nitrate as well as ammonium sulphate resulted in relatively low production of BC during fermentation69.

Effect of carbon to nitrogen ratio

The production of microbial polysaccharides is highly influenced by primary medium factor, C/N ratio, weight of carbon per weight of nitrogen). This factor could facilitate the metabolic processes resulting in polysaccharide elaboration from protein synthesis during fermentation70,71. As illustrated in Fig. 7, the effect of C/N ratio on the production of BC was investigated by adjusting the composition of carbon content, while keeping the same concentration of nitrogen in the production medium. When the C/N ratio was increased, BC concentration significantly increased till a C/N ratio of 40 and then decreased. A maximum BC concentration of 17.6 ± 1.52 g/L was achieved with C/N ratio of 40. It was noticed that relatively a very low concentration of BC (1.8 ± 0.42 g/L) was obtained in the absence of sucrose indicating the carbon limiting nature of polysaccharide. When the C/N ratio was increased as high as above 40, the production of BC drastically decreased due to the high concentration of limiting substrate (carbon source) leading to substrate inhibition. At high substrate concentration, fructose produced by the hydrolysis of sucrose might be acting as an osmotic stressor. In such situation, the presence of fermentable sugars in the production medium could not diffuse across the cellular membrane leading to trigger defense mechanisms against osmotic stress72. This effect was described by Seesuriyachan et al. for other xopolysaccharides73. The previous literature illustrated that high carbon to nitrogen ratio would provide relatively low yield of exopolysaccharide as well as cell density74.

Effect of supplement on BC production

The previous literature demonstrated that the secondary substrates or supplements (organic acids or ethanol) are essential to facilitate the production of BC21,75,76,77. Thus, in the present study, ethanol and acetic acid was used as supplement carbon source for BC production and their effect on BC production was investigated to identify the suitable secondary substrate (Fig. 8a). It was noted that production of BC (20.37 ± 2.81 g/L) was relatively higher using ethanol as a supplement in the production medium than acetic acid (18.16 ± 1.65 g/L). It was seen that the difference in the concentration of BC obtained between acetic acid and control was not significant. Even though, consumption of ethanol and acetic acid in the medium might suddenly provide energy source in the biosynthetic path way of TCA cycle due to the liberation of ATP, thus, facilitating the fermentation process for BC production78; the presence of acetic acid in the medium eventually decreased the pH leading to low concentration of BC. This might be due to the fact that the suitable pH range is 5–6 for the production of BC54. Ethanol in the production medium could be acting as a facilitator for the production of BC. Ethanol can produce the reduced form of NADH, which lowers the redox potential. Low redox potential is essential for the optimal production of BC79. Thus, ethanol was selected as a secondary substrate for the enhancement of BC production in the currentt study.

Figure 8b described the effect of ethanol concentration on the concentration of BC using immobilized cell biofilm reactor. To investigate its effect, different concentrations of ethanol (0–3%, v/v) were introduced in to the production medium. The concentration of BC was significantly increased to maximum level at 1.5%, v/v of ethanol concentration and then decreased. As shown in Fig. 8b, the supplement, ethanol with concentration at 1.5%, v/v significantly improved the BC production 23.97 ± 2.68 g/L as compared to control (17.59 ± 1.32 g/L) shown in Fig. 8a. It was noted that the production of BC slightly improved by 32% due to the addition of ethanol. And also, ethanol in the production medium has the ability of eliminating the non-cellulose producing strains during the shaking cultivation15. It is also noted that high concentrations of ethanol (above 1.5%, v/v) in the cuture medium caused reduction in BC concentration owing to the inhibitory effect on cell growth77.

In Table 2 the volumetric productivity of BC obtained using LA has been compared with the previous reported. The productivity obtained with LA was better or comparable than the previous reports. The improved producitivty is probably due to the following the reasons: (i) cultivation of high density of biomass on the surface of LA support; (ii) enough space for the cultivation of biomass; (iii) mess like structure for the better attachment of cells; (iv) re-usability of support (iv) facilitate the better micro-environmental condition for the continuous transport of essential nutrientsvolumetric productivity of BC31. Thus, LA appears to be a promising support for facilitating BC production.

Characterization of bacterial cellulose

Thermal stability and FTIR spectra

The thermal stability of microbial polysaccharide was examined by TGA curve for the determination of thermal transitions, melting point and decomposition point85,86. Thermo-gravimetric analysis (TGA) for produced BC by immobilized Gluconacetobacter kombuchae using sucrose medium is shown in Fig. 9a. The degree of crystallinity/amorphous, stability of functional groups and molecular mass of the microbial polysaccharide could greatly influence the thermal degradation14,85. Majorly three thermal degradation regions were observed in TG curve as shown in the Fig. 9a. A small variation (approximately 4%) in weight loss (89–228 °C) followed by around 68% of dynamic weight loss (228–370 °C) obtained in the second stage of thermal degradation. It might be due to the rapid thermal transformation of back bone structure of polysaccharide by breaking down the linkages of C–C, C–O. Above 370 °C , the final stage of thermal degradation accomplished by thermal decomposition of repeating monomer units followed by char formation87. The decomposition temperature of the produced BC using biofilm fermentation was found to be 270 °C.

FTIR spectrum for produced BC using biofilm fermentation is shown in Fig. 9b. The intensity of the transmittance peak around 1400 cm−1 has also been well associated with the degree of crystallinity, i.e., “crystallinity band”88,89. Due to the low intensity peak observed around 1400 cm−1 indicating the presence of crystallinity of BC, the absorption band at 879 cm−1 has been assigned to –C–O–C stretching at (1→4) glycosidic linkage indicating “amorphous” absorption band90. Based on the presence of characteristic band , it is noticed that the produced BC has both amorphous and crystalline nature11,91. The peaks at 1651, 1425, 1368 indicates H–O–H bending of absorbed water, CH2 scissoring, and CH bending92,93. Other features of polysaccharide were also found from the spectra. The characteristic bands of cellulose (type I) was confirmed due to the presence of stretching vibration of hydroxyl groups (–OH) at 3281.3 cm−1, the stretching vibration of (–CH–) at 2917.6 cm−1. The presence of absorption peak around 2800 cm−1, 1032 cm−1 and 1600 cm−1 were due to the symmetric stretching vibration of methyl (–CH3), stretching vibrations of the pyranose ring and stretching of -O-C-O functional group respectively94. The peak appeared at 1032, 896 and 554 cm−1 showed –C–O–H– bond of carbohydrates (or) –C–O–C– vibrational stretching in the pyranose ring, antisymmetric out of phase ring stretching of β-glucosidic linkage between glucose units and carbohydrate peak respectively93,95,96. The obtained results were compared with existing reports97,98,99,100.

Materials

Chemical reagents and medium components

The medium componets namely sucrose, yeast extract, beef extract, agar, tryptone and peptone and chemical reagents namely ammonium sulfate, sodium nitrate, magnesium sulphate, potassium sulphate, sodium hydroxide, acetic acid and ethanol were obtained from from Himedia, India with a purity standard more than 95%. The microbial strain, Gluconacetobacter kombuchae MTCC6913 was procured from the Microbial Type Culture Collection (MTCC) & Gene Bank, Chandigarh, India.

Methods

The schematic representation of materials and method for the production of BC using LA support was depicted in Fig. 10.

Microorganism and culture condion

The microorganism was cultured using nutrient agar medium containing the following composition (in g/L): yeast extract – 1.5, beef extract − 1.5; and agar − 15. The growth medium was prepared using nutrient broth, sterilized and cooled. Two loops of inoculum from nutrient agar culture were aseptically transferred into the nutrient broth (seed culture medium) and the culture was maintained in an orbital shaker at 30 °C and 150 rpm for one day. This seed culture was sub-cultured once in two weeks.

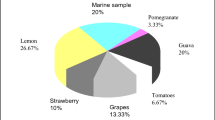

Collection of the support material Luffa aegyptiaca and batch fermentation

Luffa aegyptiaca (LA) is a vegetative support material with mesh like structure. In the Loofah or sponge gourd (Luffa aegyptiaca), interior fibers made up of mesh like structure was used as a support for the attachment of cells and facilitate the biofilm formation during fermentation. LA was collected from local villages, Thanjavur, India. After removing the seeds, LA was thoroughly washed with distilled water to remove dirt and other impurities, dried in sun-light and then cut in to small pieces. The support was kept in 250 mL Erlenmeyer flask, in which the production medium (150 ml) was added in the following composition101 in g/L: sucrose − 25, yeast extract − 3, magnesium sulphate − 5, potassium sulphate—3 and pH 7.0 (before sterilization). The production medium with support material was sterilized at 121 °C for 20 min. After cooling, 5% v/v of inoculum (1.71 ± 0.07 × 107 CFU/mL and OD at 600 nm = 0.53) was introduced into the production medium. During fermentation, the cells as well as the pellicle were attached over the surface of support for facilitating the production of BC.

Recovery of BC

After fermentation, BC was recovered according to the method prescribed by Cheng et al. 2009 with some modifications37. The medium was subjected to autoclaving at 121 °C to inactivate the cellular protein. The BC formed on the LA was carefully scraped using a knife and along with the fermentation broth, centrifuged at 8000 rpm for 20 min. The precipitated BC with cells was treated with 0.1 N NaOH for 30 min at 90 °C, for the removal of cells and other medium constituents. The sample was then washed with distilled water till the pH of wash water became neutral. It was oven-dried at 70 °C for 12 h to remove the moisture content in the BC pellet and then weighed. The concentration of BC was expressed in dry basis (gram of dry BC per liter of sample taken for analysis). All the experiments were investigated in triplicates and the data was represented by mean ± SD.

Factors affecting the production of BC

The effect of initial pH (4.5–8.5) on the concentration of BC was studied in four ways according to the cell type and culturing condition: (i) shaking culture with immobilized cells on LA; (ii) shaking culture with suspended cells; (iii) static culture with immobilized cells on LA; (iv) static culture with suspended cells. Culturing condition, initial pH and the cell types that produced maximum BC were selected and used in further studies. The different factors namely inoculum size (1–14%, v/v), nitrogen source (ammonium sulfate, yeast extract, sodium nitrate, tryptone and peptone), carbon to nitrogen (C/N) ratio (0–80), supplement source (acetic acid and ethanol) and composition of supplement (0.5–3%, v/v) on concentration of BC were investigated in batch fermentation.

Characterization of BC

With the help of Scanning Electron Microscope (VEGA3 XM, TESCAN USA, Inc.,), the surface morphology of LA and cells attached over LA (biofilm formation) were examined. The functional groups and thermal properties (TGA curve) of produced BC were examined by FTIR spectroscopy (PerkinElmer Spectrum Version 10.03.09) and thermogravimetric analysis (SDT Q600 V20.9 Build 20).

For FTIR analysis, the sample preparation was done by KBr pellet method. The sample spectrum was scanned from a range of 4000 cm−1 to 400 cm−1. In Thermo-gravimetric analysis, the sample was subjected to heating from 30 to 500 °C at a rate of 10 °C per min, under the atmosphere of nitrogen with a flow rate of 100 mL per min. The percentage lost by weight of the sample was evaluated as a function of temperature. Prior to thermal analysis, the sample to be analyzed was dried sufficiently enough in hot air oven to remove the moisture in the sample.

Conclusion

The influence of LA support on the production of BC under static and shaking condition was examined. The heterogeneous surface morphology of LA interms of roughness, cavities and spiral structure facilitating the better attachment of cells improved BC production under shaking condition. The various morphological forms of BC was observed with/without LA support under static and shaking condtion. Based on the maximum yield of BC, shaking condition with LA support for cell attachment was considered for further studies. The suitable medium factors/process conditions for the microbial synthesis of BC were found to be: initial pH-5.5, inoculum size – 5% (v/v), nitrogen source – yeast extract, C/N ratio – 40; supplement – ethanol (1.5% v/v). Thermal and structural characterization of produced BC was investigated using TGA and FTIR analysis. Thermal decomposition of produced BC was found to be 270 °C. Based on the easy availability, cost effective and surface morphology of LA for the better attachment of cells yielding the maximum yield of BC, Luffa ageyptiaca could be a promising scaffold for bioprocess applications.

References

Lin, D., Lopez-sanchez, P., Li, R. & Li, Z. Production of bacterial cellulose by Gluconacetobacter hansenii CGMCC 3917 using only waste beer yeast as nutrient source. Bioresour. Technol. 151, 113–119 (2014).

Mohite, B. V. & Patil, S. V. A novel biomaterial: bacterial cellulose and its new era applications. Biotechnol. Appl. Biochem. 61, 101–110 (2014).

Andrade, F. K. et al. Studies on the biocompatibility of bacterial cellulose. J. Bioact. Compat. Polym. 28, 97–112 (2013).

Dayal, M. S. & Catchmark, J. M. Mechanical and structural property analysis of bacterial cellulose composites. Carbohydr. Polym. 144, 447–453 (2016).

Lee, K. Y. et al. High performance cellulose nanocomposites: comparing the reinforcing ability of bacterial cellulose and nanofibrillated cellulose. ACS Appl. Mater. Interfaces 4, 4078–4086 (2012).

Lee, K. Y., Buldum, G., Mantalaris, A. & Bismarck, A. More than meets the eye in bacterial cellulose: biosynthesis, bioprocessing, and applications in advanced fiber composites. Macromol. Biosci. 14, 10–32 (2014).

Jozala, A. F. et al. Bacterial nanocellulose production and application: a 10-year overview. Appl. Microbiol. Biotechnol. 100, 2063–2072 (2016).

Cacicedo, M. L. et al. Progress in bacterial cellulose matrices for biotechnological applications. Bioresour. Technol. 213, 172–180 (2016).

Ullah, H., Wahid, F., Santos, H. A. & Khan, T. Advances in biomedical and pharmaceutical applications of functional bacterial cellulose-based nanocomposites. Carbohydr. Polym. 150, 330–352 (2016).

Brown, A. J. Brown on acetic ferment. J. Chem. Soc. Trans. 49, 432–439 (1886).

Esa, F., Tasirin, S. M. & Rahman, N. A. Overview of bacterial cellulose production and application. Agric. Agric. Sci. Procedia 2, 113–119 (2014).

Lynd, L. R., Weimer, P. J., van Zyl, W. H. & Pretorius, I. S. Microbial cellulose utilization: fundamentals and biotechnology. Microbiol. Mol. Biol. Rev. 66, 739–739 (2002).

Lin, S. P. et al. Biosynthesis, production and applications of bacterial cellulose. Cellulose 20, 2191–2219 (2013).

Mohammadkazemi, F., Azin, M. & Ashori, A. Production of bacterial cellulose using different carbon sources and culture media. Carbohydr. Polym. 117, 518–523 (2015).

Chawla, P. R., Bajaj, I. B., Survase, S. A. & Singhal, R. S. Microbial cellulose: Fermentative production and applications. Food Technol. Biotechnol. 47, 107–124 (2009).

Jung, J. Y., Park, Y. H. & Park, J. K. Effect of medium composition on the bacterial cellulose production by Gluconacetobacter hansenii PJK. Korean J. Biotechnol. Bioeng. 18, 94–99 (2003).

Nguyen, V. T., Flanagan, B., Gidley, M. J. & Dykes, G. A. Characterization of cellulose production by a Gluconacetobacter xylinus strain from Kombucha. Curr. Microbiol. 57, 449–453 (2008).

Bae, S. & Shoda, M. Bacterial cellulose production by fed-batch fermentation in molasses medium. Biotechnol. Prog. 20, 1366–1371 (2004).

Son, C., Chung, S., Lee, J. & Kim, S. Isolation and cultivation characteristics of Acetobacter xylinum KJ-1 producing bacterial cellulose in shaking cultures. J. Microbiol. Biotechnol. 12, 722–728 (2002).

Jun, J. Y., Park, J. K. & Chang, H. N. Bacterial cellulose production by Gluconacetobacter hansenii in an agitated culture without living non-cellulose producing cells. Enzyme Microb. Technol. 37, 347–354 (2005).

Park, J. K., Jung, J. Y. & Park, Y. H. Cellulose production by Gluconacetobacter hansenii in a medium containing ethanol. Biotechnol. Lett. 25, 2055–2059 (2003).

Son, H. et al. Increased production of bacterial cellulose by Acetobacter sp. V6 in synthetic media under shaking culture conditions. Bioresour. Technol. 86, 215–219 (2003).

Sani, A. & Dahman, Y. Improvements in the production of bacterial synthesized biocellulose nanofibres using different culture methods. J. Chem. Technol. Biotechnol. 85, 151–164 (2010).

Watanabe, K. Stuctural features of bacterial cellulose vary depending on the culture conditions. In Proceedings of’94 Cellulose R & D, 1st Annual Meeting of the Cellulose ociety of Japan 45–50 (1994).

Yoshino, T., Asakura, T. & Toda, K. Cellulose production by Acetobacter pasteurianus on silicone membrane. J. Ferment. Bioeng. 81, 32–36 (1996).

Serafica, G., Mormino, R. & Bungay, H. Inclusion of solid particles in bacterial cellulose. Appl. Microbiol. Biotechnol. 58, 756–760 (2002).

Hornung, M., Ludwig, M. & Schmauder, H. P. Optimizing the production of bacterial cellulose in surface culture: a novel aerosol bioreactor working on a fed batch principle (part 3). Eng. Life Sci. 7, 35–41 (2007).

Ishikawa, A., Matsuoka, M., Tsuchida, T. & Yoshinaga, F. Increase in cellulose production by sulfaguanidine-resistant mutants derived from Acetobacter xylinum subsp. sucrofermentans. Biosci. Biotechnol. Biochem. 59, 2259–2262 (1995).

Toyosaki, H. et al. Screening of bacterial cellulose-producing Acetobacter strains suitable for agitated culture. Biosci. Biotechnol. Biochem. 59, 1498–1502 (1995).

Santoso, S. P. et al. Eco-friendly cellulose–bentonite porous composite hydrogels for adsorptive removal of azo dye and soilless culture. Cellulose 26, 3339–3358 (2019).

Cotton, J. C., Pometto, A. L. & Gvozdenovic-Jeremic, J. Continuous lactic acid fermentation using a plastic composite support biofilm reactor. Appl. Microbiol. Biotechnol. 57, 626–630 (2001).

Characklis, W. G. & Wilderer, P. A. Structure and function of biofilms. In Dahlem Workshop on Structure and Function of Biofilms (1988: Berlin, Germany) (Wiley, 1989).

Demirci, A., Pometto, A. L. & Ho, K. L. G. Ethanol production by Saccharomyces cerevisiae in biofilm reactors. J. Ind. Microbiol. Biotechnol. 19, 299–304 (1997).

Urbance, S. E., Pometto, A. L., DiSpirito, A. A. & Demirci, A. Medium evaluation and plastic composite support ingredient selection for biofilm formation and succinic acid production by Actinobacillus succinogenes. Food Biotechnol. 17, 53–65 (2003).

Velázquez, A. C., Pometto, A. L., Ho, K. L. G. & Demirci, A. Evaluation of plastic-composite supports in repeated fed-batch biofilm lactic acid fermentation by Lactobacillus casei. Appl. Microbiol. Biotechnol. 55, 434–441 (2001).

Pongtharangkul, T. & Demirci, A. Evaluation of culture medium for nisin production in a repeated-batch biofilm reactor. Biotechnol. Prog. 22, 217–224 (2006).

Cheng, K. C., Catchmark, J. M. & Demirci, A. Enhanced production of bacterial cellulose by using a biofilm reactor and its material property analysis. J. Biol. Eng. 3, 1–10 (2009).

Cheng, K. C., Demirci, A. & Catchmark, J. M. Enhanced pullulan production in a biofilm reactor by using response surface methodology. J. Ind. Microbiol. Biotechnol. 37, 587–594 (2010).

Oladoja, N. A., Aboluwoye, C. O. & Akinkugbe, A. O. Evaluation of loofah as a sorbent in the decolorization of basic dye contaminated aqueous system. Ind. Eng. Chem. Res. 48, 2786–2794 (2009).

Mazali, I. O. & Alves, O. L. Morphosynthesis: high fidelity inorganic replica of the fibrous network of loofa sponge (Luffa cylindrica). An. Acad. Bras. Cienc. 77, 25–31 (2005).

Ogbonna, J. C., Liu, Y.-C., Liu, Y.-K. & Tanaka, H. Loofa (Luffa cylindrica) sponge as a carrier for microbial cell immobilization. J. Ferment. Bioeng. 78, 437–442 (1994).

Slokoska, L. S. & Angelova, M. B. Immobilization of polymethylgalacturonase producing Aspergillus niger on Luffa sponge material. Zeitschrift fur Naturforsch. Sect. C J. Biosci. 53, 968–972 (1998).

Ogbonna, J. C., Mashima, H. & Tanaka, H. Scale up of fuel ethanol production from sugar beet juice using loofa sponge immobilized bioreactor. Bioresour. Technol. 76, 1–8 (2001).

Liu, Y.-K., Seki, M. & Furusaki, S. Plant cell immobilization in loofa sponge using two-way bubble circular system. J. Chem. Eng. Japan 32, 8–14 (1999).

Demirkıran, N. D., Havıtçıoğlu, H., Ziylan, A., Cankurt, Ü. & Hüsemoğlu, B. Novel multilayer meniscal scaffold provides biomechanical and histological results comparable to polyurethane scaffolds: an 8 week rabbit study. Acta Orthop. Traumatol. Turc. 53, 120–128 (2019).

Chen, J. P. & Lin, C. T. Dynamic seeding and perfusion culture of hepatocytes with galactosylated vegetable sponge in packed-bed bioreactor. J. Biosci. Bioeng. 102, 41–45 (2006).

Chen, Y. et al. In-depth analysis of the structure and properties of two varieties of natural luffa sponge fibers. Materials (Basel) 10, 479 (2017).

Gopu, G. & Govindan, S. Production of bacterial cellulose from Komagataeibacter saccharivorans strain BC1 isolated from rotten green grapes. Prep. Biochem. Biotechnol. 48, 842–852 (2018).

Hsieh, J. T., Wang, M. J., Lai, J. T. & Liu, H. S. A novel static cultivation of bacterial cellulose production by intermittent feeding strategy. J. Taiwan Inst. Chem. Eng. 63, 46–51 (2016).

Andriani, D., Apriyana, A. Y. & Karina, M. The optimization of bacterial cellulose production and its applications: a review. Cellulose 27, 6747–6766 (2020).

Dubey, S. et al. From rotten grapes to industrial exploitation: Komagataeibacter europaeus SGP37, a micro-factory for macroscale production of bacterial nanocellulose. Int. J. Biol. Macromol. 96, 52–60 (2017).

Velmurugan, P. et al. Production and characterization of bacterial cellulose by Leifsonia sp. CBNU-EW3 isolated from the earthworm, Eisenia fetida. Biotechnol. Bioprocess Eng. 20, 410–416 (2015).

Santoso, S. P. et al. Enhanced production of bacterial cellulose by Komactobacter intermedius using statistical modeling. Cellulose 27, 2497–2509 (2020).

Lima, H. L. S. et al. Bacterial cellulose production by Komagataeibacter hansenii ATCC 23769 using sisal juice—an agroindustry waste. Braz. J. Chem. Eng. 34, 671–680 (2017).

Zakaria, J. & Nazeri, M. Optimization of bacterial cellulose production from pineapple waste: effect of temperature, pH and concentration. In 5th Engineering Conference, ‘Engineering Towards Change - Empowering Green Solutions’ 10–12 (2012).

Krystynowicz, A. et al. Factors affecting the yield and properties of bacterial cellulose. J. Ind. Microbiol. Biotechnol. 29, 189–195 (2002).

Tanskul, S., Amornthatree, K. & Jaturonlak, N. A new cellulose-producing bacterium, Rhodococcus sp. MI 2: screening and optimization of culture conditions. Carbohydr. Polym. 92, 421–428 (2013).

Bootten, T. J., Harris, P. J., Melton, L. D. & Newman, R. H. WAXS and 13C NMR study of Gluconoacetobacter xylinus cellulose in composites with tamarind xyloglucan. Carbohydr. Res. 343, 221–229 (2008).

Choudhury, A. R., Sharma, N. & Prasad, G. S. Deoiledjatropha seed cake is a useful nutrient for pullulan production. Microb. Cell Fact. 11, 3–11 (2012).

Wang, X. et al. Modeling for gellan gum production by Sphingomonas paucimobilis ATCC 31461 in a simplified medium. Microbiology 72, 3367–3374 (2006).

Hamieh, A., Olama, Z. & Holail, H. Microbial production of polyhydroxybutyrate, a biodegradable plastic using agro-industrial waste. Glob. Adv. Res. J. Microbiol. 2, 54–64 (2013).

Cheng, Z., Yang, R., Liu, X., Liu, X. & Chen, H. Green synthesis of bacterial cellulose via acetic acid pre-hydrolysis liquor of agricultural corn stalk used as carbon source. Bioresour. Technol. 234, 8–14 (2017).

Lazaridou, A., Roukas, T., Biliaderis, C. G. & Vaikousi, H. Characterization of pullulan produced from beet molasses by Aureobasidium pullulans in a stirred tank reactor under varying agitation. Enzyme Microb. Technol. 31, 122–132 (2002).

Tanskul, S., Amornthatree, K. & Jaturonlak, N. A new cellulose-producing bacterium, Rhodococcus sp. MI 2: screening and optimization of culture conditions. Carbohydr. Polym. 92, 421–428 (2013).

Hornung, M., Ludwig, M., Gerrard, A. M. & Schmauder, H. P. Optimizing the production of bacterial cellulose in surface culture: Evaluation of substrate mass transfer influences on the bioreaction (Part 1). Eng. Life Sci. 6, 537–545 (2006).

Matsuoka, M., Tsuchida, T., Matsushita, K., Adachi, O. & Yoshinaga, F. A synthetic medium for bacterial cellulose production by Acetobacter xylinum subsp sucrofermentans. Biosci. Biotechnol. Biochem. 60, 575–579 (1996).

Santos, S. M., Carbajo, J. M. & Villar, J. C. The effect of carbon and nitrogen sources on bacterial cellulose production and properties from Gluconacetobacter sucrofermentans CECT 7291 focused on its use in degraded paper restoration. BioResources 8, 3630–3645 (2013).

Singh, R., Mathur, A., Goswami, N. & Mathur, G. Effect of carbon sources on physicochemical properties of bacterial cellulose produced from Gluconacetobacter xylinus MTCC 7795. e-Polymers 16, 331–336 (2016).

Embuscado, M. E., Marks, J. S. & BeMiller, J. N. Bacterial cellulose. I. Factors affecting the production of cellulose by Acetobacter xylinum. Food Hydrocoll. 8, 407–418 (1994).

Thomas, W. H., Seibert, D. L. R., Alden, M., Neori, A. & Eldridge, P. Yields, Photosynthetic Efficiencies, and Proximate Chemical Composition of Dense Cultures of Marine Microalgae. A Subcontract Report. Scripps Institution of Oceanography, San Diego, CA (USA) (1983). https://doi.org/10.1016/0144-4565(84)90022-2.

Thomas, W. H., Seibert, D. L. R., Alden, M., Neori, A. & Eldridge, P. Yields, photosynthetic efficiencies and proximate composition of dense marine microalgal cultures. II. Dunaliella primolecta and Tetraselmis suecica experiments. Biomass 5, 211–225 (1984).

Seesuriyachan, P. et al. Optimization of exopolysaccharide overproduction by Lactobacillus confusus in solid state fermentation under high salinity stress. Biosci. Biotechnol. Biochem. 76, 912–917 (2012).

Ogino, H. et al. Complete genome sequence of NBRC 3288, a unique cellulose-nonproducing strain of Gluconacetobacter xylinus isolated from vinegar. J. Bacteriol. 193, 6997–6998 (2011).

Chen, W., Zhao, Z., Chen, S. F. & Li, Y. Q. Optimization for the production of exopolysaccharide from Fomes fomentarius in submerged culture and its antitumor effect in vitro. Bioresour. Technol. 99, 3187–3194 (2008).

Jahan, F., Kumar, V., Rawat, G. & Saxena, R. K. Production of microbial cellulose by a bacterium isolated from fruit. Appl. Biochem. Biotechnol. 167, 1157–1171 (2012).

Kim, S. Y., Kim, J. N., Wee, Y. J., Park, D. H. & Ryu, H. W. Production of bacterial cellulose by Gluconacetobacter sp. RKY5 isolated from persimmon vinegar. Appl. Biochem. Biotechnol. 131, 705–715 (2006).

Naritomi, T., Kouda, T., Yano, H. & Yoshinaga, F. Effect of lactate on bacterial cellulose production from fructose in continuous culture. J. Ferment. Bioeng. 85, 89–95 (1998).

Lu, Z. et al. Effects of alcohols on bacterial cellulose production by Acetobacter xylinum 186. World J. Microbiol. Biotechnol. 27, 2281–2285 (2011).

Heo, M.-S. & Son, H.-J. Development of an optimized, simple chemically defined medium for bacterial cellulose production by Acetobacter sp. A9 in shaking cultures. Biotechnol. Appl. Biochem. 36, 41 (2002).

Tyagi, N. & Suresh, S. Production of cellulose from sugarcane molasses using Gluconacetobacter intermedius SNT-1: optimization & characterization. J. Clean. Prod. 112, 71–80 (2016).

Costa, A. F. S., Almeida, F. C. G., Vinhas, G. M. & Sarubbo, L. A. Production of bacterial cellulose by Gluconacetobacter hansenii using corn steep liquor as nutrient sources. Front. Microbiol. 8, 1–12 (2017).

Revin, V., Liyaskina, E., Nazarkina, M., Bogatyreva, A. & Shchankin, M. Cost-effective production of bacterial cellulose using acidic food industry by-products. Braz. J. Microbiol. 49, 151–159 (2018).

Stepanov, N. & Efremenko, E. “Deceived” concentrated immobilized cells as biocatalyst for intensive bacterial cellulose production from various sources. Catalysts 8, 33 (2018).

Cheng, K. C., Catchmark, J. M. & Demirci, A. Enhanced production of bacterial cellulose by using a biofilm reactor and its material property analysis. J. Biol. Eng. 3, 12 (2009).

Auta, R., Adamus, G., Kwiecien, M., Radecka, I. & Hooley, P. Production and characterization of bacterial cellulose before and after enzymatic hydrolysis. Afr. J. Biotechnol. 16, 470–482 (2017).

Hamidi, M., Kennedy, J. F., Khodaiyan, F., Mousavi, Z. & Hosseini, S. S. Production optimization, characterization and gene expression of pullulan from a new strain of Aureobasidium pullulans. Int. J. Biol. Macromol. 138, 725–735 (2019).

Vazquez, A., Foresti, M. L., Cerrutti, P. & Galvagno, M. Bacterial cellulose from simple and low cost production media by Gluconacetobacter xylinus. J. Polym. Environ. 21, 545–554 (2013).

Bertocchi, C., Delneri, D., Signore, S., Weng, Z. & Bruschi, C. V. Characterization of microbial cellulose from a high-producing mutagenized Acetobacter pasteurianus strain. Biochim. Biophys. Acta Gen. Subj. 1336, 211–217 (1997).

Ciolacu, D., Ciolacu, F. & Popa, V. I. Amorphous cellulose—structure and characterization. Cellul. Chem. Technol. 45, 13 (2011).

Goh, W. N. et al. Microstructure and physical properties of microbial cellulose produced during fermentation of black tea broth (kombucha)/ II.. Int. Food Res. J. 19, 153–158 (2012).

Lynd, L. R., Weimer, P. J., Van Zyl, W. H. & Isak, S. Microbial cellulose utilization : fundamentals and biotechnology microbial cellulose utilization : fundamentals and biotechnology. Microbiol. Mol. Biol. Rev. 66, 506–577 (2002).

Huang, C. et al. Using wastewater after lipid fermentation as substrate for bacterial cellulose production by Gluconacetobacter xylinus. Carbohydr. Polym. 136, 198–202 (2016).

Fan, X. et al. Production of nano bacterial cellulose from beverage industrial waste of citrus peel and pomace using Komagataeibacter xylinus. Carbohydr. Polym. 151, 1068–1072 (2016).

Huang, C. et al. Evaluating the possibility of using acetone-butanol-ethanol (ABE) fermentation wastewater for bacterial cellulose production by Gluconacetobacter xylinus. Lett. Appl. Microbiol. 60, 491–496 (2015).

Sun, D., Yang, J. & Wang, X. Bacterial cellulose/TiO2 hybrid nanofibers prepared by the surface hydrolysis method with molecular precision. Nanoscale 2, 287–292 (2010).

Dayal, M. S. et al. Effect of media components on cell growth and bacterial cellulose production from Acetobacter aceti MTCC 2623. Carbohydr. Polym. 94, 12–16 (2013).

Hong, L. et al. Hydroxyapatite/bacterial cellulose composites synthesized via a biomimetic route. Mater. Lett. 60, 1710–1713 (2006).

Hassan, E., Abdelhady, H., Abd l-Salam, S. & Abdullah, S. The characterization of bacterial cellulose produced by Acetobacter xylinum and Komgataeibacter saccharovorans under optimized fermentation conditions. Br. Microbiol. Res. J. 9, 1–13 (2015).

Chen, H. H., Chen, L. C., Huang, H. C. & Lin, S. B. In situ modification of bacterial cellulose nanostructure by adding CMC during the growth of Gluconacetobacter xylinus. Cellulose 18, 1573–1583 (2011).

Mohd Amin, M. C. I., Ahmad, N., Halib, N. & Ahmad, I. Synthesis and characterization of thermo- and pH-responsive bacterial cellulose/acrylic acid hydrogels for drug delivery. Carbohydr. Polym. 88, 465–473 (2012).

Tsouko, E. et al. Bacterial cellulose production from industrial waste and by-product streams. Int. J. Mol. Sci. 16, 14832–14849 (2015).

Acknowledgements

All authors are thankful to the Management SASTRA Deemed to be University, Thanjavur, Tamil Nadu, India for providing the necessary facilities.

Author information

Authors and Affiliations

Contributions

S.S.A.R., V.T., S.V.G., S.K., P.P.: Experimental investigation; V.P., writing, analysis and conceptualization; S.K.: writing, analysis, conceptualization and project supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rahman, S.S.A., Vaishnavi, T., Vidyasri, G.S. et al. Production of bacterial cellulose using Gluconacetobacter kombuchae immobilized on Luffa aegyptiaca support. Sci Rep 11, 2912 (2021). https://doi.org/10.1038/s41598-021-82596-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-82596-4

This article is cited by

-

Harnessing Symbiotic Association of Lactic Acid Bacteria and Cellulose-Synthesizing Bacteria for Enhanced Biological Activity

Iranian Journal of Science (2024)

-

Eco-friendly Production of Bacterial Cellulose with Komagataeibacter intermedius Strain by Using Jasminum sambac and Camellia sinensis Plants

Journal of Polymers and the Environment (2024)

-

Simultaneous use of two-step fermentation and in-situ addition of chitosan oligosaccharide improving bacterial cellulose pellicle in the synthesis and various behaviors

Cellulose (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.