Abstract

The existing control chart for monitoring the blood components by attribute is designed using classical statistics. The existing attribute control chart can be applied only when the experimenter is sure about the proportion of defective or all the observations in the sample are determined. In this paper, new attribute control charts for monitoring the blood components under the neutrosophic statistics will be presented. The design of the proposed control chart is given under the neutrosophic statistical interval method. The applications of these control charts demonstrate that the proposed control charts are quite effective, adequate, flexible, and informative for monitoring the blood components under uncertain environment.

Similar content being viewed by others

Introduction

One can ensure the consistency of process output by using statistical process control (SPC) techniques in which the product quality is measured during the manufacturing process. The stability of the process is maintained until the occurrence of causes of process variation. Once the cause affects the process, then the process is come back into an in-control state by detecting and removing such cause. The occurrence of two types of causes namely common cause and assignable cause are involved in process variation. It is important to mention that the common causes cannot be identified whereas unavoidable. The variations due to these causes are also referred to as random causes of variation. But the non-random variation is occurred due to the presence of assignable causes that are definite and specific. In addition, the out-of-control state of the process or process instability is attained by the occurrence of assignable causes. Hence, the detection of causes and the analysis of process variation are achieved by the tool of SPC namely the control chart. The control chart visually represents the process variation over the period of time. There are two types of control charts available in the literature such as attribute control chart and variables control chart and they are respectively applied to monitor the production process where the quality characteristic of the product is non-measurable and measurable. Variables control charts yield more information about the process and involve a minimum sample size since it utilizes quantitative data. In general, variables control charts are designed under the assumption that the parametric form of the distribution of the quality characteristic is known or specified in advance. Many authors have designed and investigated the performance of different variables control charts based on such assumptions. However, some authors proved that the performance of the control charts designed with basic assumption will be unreliable if the pre-specified distribution is invalid. To overcome the drawback, some nonparametric (or distribution-free) control charts have been designed using various methods see, for example1,2,3,4,5,6. In addition7, proposed some other nonparametric control charts, most of them depend on the ordering information on the observed data.

However, the construction of attribute control chart is easier than that of variables chart since the simple calculation is involved in attribute chart construction. Some of the attribute control charts are p-chart, np-chart, u-chart, and c-chart and the applications of these control charts can be found in different situations. A number of studies are available on attribute control chart designing (see for example8,9,10,11,12,13,14,15).

In practice, it is not justifiable to classify an item as defective since it possesses some faults which may not make great effect on the functions of the item, for example, a scratch on the surface of the electronic devices do not affect the function of the device while, it does not mean that the device is “good”. There is some ambiguity in classification of the sample items either defective or non-defective with respect to the specified attribute quality characteristics. But, it is possible to classify the items based on the faults of it and we can also obtain more than two categories (defective or non-defective) of the sample items. Hence, the exact value for proportion defective cannot be obtained and there will be no clear information about proportion defective. Under this situation, one can use the fuzzy concept introduced by16 because the fuzzy concept is applicable where the information is vague, imprecise, and incomplete. Later, the neutrosophic logic was introduced by17 to investigate the indeterminate data. Although neutrosophic logic seems like fuzzy logic, in neutrosophic logic three cases of membership function are considered such as degree of truth-membership T, degree of falsity membership F and degree of indeterminacy membership I. 18proposed neutrosophic statistical methods to interpret and organize the data which are indeterminate and mentioned that neutrosophic statistics is an extension of classical statistics. One can use neutrosophic statistics in any field where the parameters involved are uncertain or indeterminate. The neutrosophic logic is applied for various aspects, for example, 19discussed the application of neutrosophic number linear programming method in production planning. Recently, acceptance sampling plans and control charts are designed under neutrosophic statistics (see, for example, 20,21). 21designed an attribute np control chart and determined the optimal parameters under neutrosophic statistics such that the in-control average run length (ARL) is as close as to the specified ARL values because ARL is considered as one of the most important performance measures in evaluating and comparing the performance of the control charts (see22 for more information).

Blood is a necessary liquid of the body and consists of four important components namely, plasma, platelets, and red and white blood cells. The attribute and variable control charts have been widely used in monitoring and improving the blood components. As mentioned by23 that the control charts can affectively monitor the variation and the causes of the variations in the blood components. In particular, to control the count of residual leucocytes and to identify whether the blood components manufacturing process is affected by any assignable causes or not, 23used p-chart, np-chart, u-chart and c-chart. For this purpose, the variable number of samples of platelets, apheresis, leucocyte-depleted in additive solution was taken in sequence order. The monitoring of these blood components is done according to the rules are specified by the American association of blood banks standards24. Hence, the control charts are important tools to check whether the blood components are according to the given specification limits. These provide the immediate signal when the blood components are slightly away from the target or the given specification limits. However, 23discussed the construction of attribute control charts using classical statistics, and the status of the process was determined based on constant control limits. But, in practice, there is a possibility to produce a different number of items during the manufacturing process in each specified period. In this circumstance, the control chart with constant control limits is not applicable to monitor the process. Hence, the control chart having variable control limits will be suitable to handle this problem. That is, the control limits are calculated using variable sample size and such control limits are known as variable-width control limits.

The existing p-chart and u-chart can be applied only when there is no Neutrosophy in sample size or observations. To the best our knowledge, no one has studied the construction of the attribute control charts namely p-chart and u-chart simultaneously under neutrosophic statistics for monitoring the blood components. Therefore, in this study, we attempt to construct above-mentioned control charts under neutrosophic statistics using real data. The estimation of the proportion defective and the calculation of control limits from the data are explained.

Designing of control charts for attribute

As mentioned earlier, attribute control charts are used to monitor the non-measurable quality characteristic (i.e., count data or attribute data) and two types of attribute data are yes/no type data and counting data. In yes/no type data, the sample of items are inspected for the specified quality characteristic and classified as either non-defective or defective if it meets the specification or not. Generally, p-chart is frequently used to monitor this type of data and in p-chart implementation the subgroup sizes need not be the same. Especially, p-chart plots proportion defective (or fraction nonconforming) over time. The following conditions to be satisfied in order to use the p-chart and are as follows. (1) The probability that the product to be defective p should be the same for each sample item. (2) The possibility of an item possessing the characteristic should be independent of the same of other items. (3) The same inspection procedure should be followed for each sample and it must be consistently carried out from sample to sample. In this chart construction, binomial distribution can be used to estimate the distribution of the counts. Sometimes, the classification of an item as defective or non-defective does not make much sense when there is complexity in the item’s nature. Also, an item possessing some characteristics may not greatly affect the functions of the item (for example, bubbles on glass) and such characteristics are considered as defects. A defect occurs when something fails to meet a preset specification for which it cannot be considered as defective. Under this situation, the number of defects on the item is counted and this is called counting type data. In order to monitor these types of data, one can use a u-chart. The number of defects per inspection unit over time is plotted in the u-chart and the area of the possibility that the defect will occur vary in the u-chart.

In all these control charts, there are two control limits involved namely lower control limit (LCL) and upper control limit (UCL). Then the process is considered as in-control if the sample points lie between control limits. Otherwise, the process is declared to be out-of-control. In particular, the control limits are used to decide the state of the manufacturing process. Control charts can be designed under two situations such that the size of the sample is fixed and the same will be variable. In general, the control charts are designed under the assumption that the values involved in such designing are known or specified earlier. One can estimate such required values using the data obtained from the production process when it is not known, in practice. In this study, we discuss the construction of the control chart for the case of estimation of required values with a variable sample size. Therefore, we are able to obtain variable control limits in each chart construction.

Designing of p-chart

In all the proposed control charts construction, the value of LCL is considered to be zero if the estimated value of the same is less than or equal to zero. The traditional procedure of estimating proportion defective (say \(\overline{p}\)) is as follows. From the production process, m number of samples each with different size is taken. The number of defective items contained in each sample is counted and denoted by Di where i = 1, 2, …, m, and the proportion defective \(\overline{p}\) is calculated using the following formula.

Then the LCL and UCL for p-chart are respectively denoted by LCLp and UCLp and determined as follows.

In p-chart construction, the value of \(\overline{p}_{i}\) for each sample plotted against the sample number. Then the process is declared as in-control if the plotted points lie between control limits.

Designing of u-chart

This type of control chart (i.e., u-chart) is also known as a control chart for defects (or nonconformities) and these charts are used to monitor the average number of defects per unit \(\overline{u}\). The average number of defects per unit is obtained as \(\overline{u} = {{\sum\nolimits_{i = 1}^{m} {u_{i} } } \mathord{\left/ {\vphantom {{\sum\nolimits_{i = 1}^{m} {u_{i} } } {\sum\nolimits_{i = 1}^{m} {n_{i} } }}} \right. \kern-\nulldelimiterspace} {\sum\nolimits_{i = 1}^{m} {n_{i} } }}\) where \(u_{i} = {{x_{i} } \mathord{\left/ {\vphantom {{x_{i} } {n_{i} }}} \right. \kern-\nulldelimiterspace} {n_{i} }}\) and xi, ni are number of defects in the ith sample with size ni, respectively. Then the control limits are denoted by LCLu and UCLu and are obtained as

Designing the methodology of control charts for an attribute using neutrosophic statistics

p-chart

Obviously, in most of the conventional attribute control charts, there is a pair of control limits involved in designing but the same chart designed under neutrosophic statistics consists of two pairs of control limits, that is, one pair of the lower control limits corresponding to lower value involved in neutrosophic and the other pair of upper control limits corresponding to upper value involved in neutrosophic statistics. 25introduced the exponentially weighted moving average (EWMA) chart and used the Laplace transformation to study run length under interaction using the classical statistics. Therefore, the formulas for finding the control limits for an attribute p-chart under neutrosophic statistics are given as follows.

where \(\overline{p}_{l} = {{\sum\nolimits_{i = 1}^{m} {D_{li} } } \mathord{\left/ {\vphantom {{\sum\nolimits_{i = 1}^{m} {D_{li} } } {\sum\nolimits_{i = 1}^{m} {n_{li} } }}} \right. \kern-\nulldelimiterspace} {\sum\nolimits_{i = 1}^{m} {n_{li} } }}\) and \(\overline{p}_{u} = {{\sum\nolimits_{i = 1}^{m} {D_{ui} } } \mathord{\left/ {\vphantom {{\sum\nolimits_{i = 1}^{m} {D_{ui} } } {\sum\nolimits_{i = 1}^{m} {n_{ui} } }}} \right. \kern-\nulldelimiterspace} {\sum\nolimits_{i = 1}^{m} {n_{ui} } }}\), Dli and Dui denote the number of defective items in the ith sample with sample sizes nl and nu, respectively. Sometimes, when we determine the control limits, the average value of n (i.e., \(\overline{n}\)) is used instead of nl and nu.

u-chart

Following equations are used to determine the control limits for u-chart under neutrosophic statistics.

where \(\overline{u}_{l} = {{\sum\nolimits_{i = 1}^{m} {u_{li} } } \mathord{\left/ {\vphantom {{\sum\nolimits_{i = 1}^{m} {u_{li} } } {\sum\nolimits_{i = 1}^{m} {n_{li} } }}} \right. \kern-\nulldelimiterspace} {\sum\nolimits_{i = 1}^{m} {n_{li} } }}\), \(\overline{u}_{u} = {{\sum\nolimits_{i = 1}^{m} {u_{ui} } } \mathord{\left/ {\vphantom {{\sum\nolimits_{i = 1}^{m} {u_{ui} } } {\sum\nolimits_{i = 1}^{m} {n_{ui} } }}} \right. \kern-\nulldelimiterspace} {\sum\nolimits_{i = 1}^{m} {n_{ui} } }}\), \(u_{li} = {{x_{li} } \mathord{\left/ {\vphantom {{x_{li} } {n_{l} }}} \right. \kern-\nulldelimiterspace} {n_{l} }}\) and \(u_{ui} = {{x_{ui} } \mathord{\left/ {\vphantom {{x_{ui} } {n_{u} }}} \right. \kern-\nulldelimiterspace} {n_{u} }}\). xli and xui denote the number of defects contained in the ith sample with sample sizes nl and nu, respectively. In this study, we discuss the designing of p-chart and u-chart under neutrosophic statistics using real-time data.

Application of control charts for an attribute using neutrosophic statistics

A manufacturing company of producing a lot of blood components and the manufacturer wants to inspect the residual leucocyte count per sampling of platelets, apheresis, leucocyte-depleted in additive solution. The company is uncertain about the sample size to be used for inspection purpose. The sample size is selected in interval rather than the exact ample size. The values of the lower sample size and upper sample size are shown in Tables 1 and 2. From these tables, it is clear that the existing p-chart and u-chart under classical statistics cannot be applied for the monitoring of blood components. For this purpose, the attribute control charts based on neutrosophic statistics is recommended to inspect the residual leucocyte count in each of the lots, and also there are 30 lots. In this inspection, we consider the performance of the p-chart and u-chart.

p-chart with a variable sample size

The residual leucocyte count data for 30 lots with a variable sample size are provided in Table 1. From this data, we can determine the control limits for p-chart under neutrosophic statistics. For this data, \(\overline{p}_{l}\) and \(\overline{p}_{u}\) are calculated as follows.

We consider the variable sample sizes to calculate the control limits therefore, the control limits for p-chart under neutrosophic statistics are calculated as follows.

Using the control limits formulae, we can calculate the control limits for the lower and upper value of the data under neutrosophic statistics and reported in Table 1.

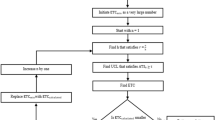

The performance of the proposed p-chart for residual leucocytes count data is shown in Fig. 1. From this figure, it is understood that the process is under control since the proportion defective for each sample lies between control limits. In addition, from Fig. 1, it is clear that several points are near UCLl and UCLu and that several points lie in the indeterminate interval which needs industrial engineers’ attention.

u-chart with a variable sample size

Table 2 presents the residual leucocyte count data for 30 lots with a variable sample size along with calculated control limits. For the calculation of control limits for u-chart under neutrosophic statistics, \(\overline{u}_{l}\) and \(\overline{u}_{u}\) are calculated as follows.

The control limits for u-chart under neutrosophic statistics are calculated using the following formulae. We can obtain variable control limits since variable sample sizes are used in the calculation.

Figure 2 shows the performance of the proposed u-chart for residual leucocytes count data and the process is declared as out-of-control because the defects per unit of 5th sample lie beyond the control limits. In addition, from Fig. 2 that the several points lie in an indeterminate interval which needs industrial engineers’ attention.

Concluding remarks

In this paper, new attribute control charts for monitoring the blood components under the neutrosophic statistics was presented. The design of the proposed control chart was given under the neutrosophic statistical interval method. The proposed control chart can be applied when there is uncertainty in the observations or in the sample size. The application of the proposed chart was given using the blood component data. From the analysis, it can be concluded that the proposed chart is flexible in monitoring the blood components. The proposed chart gives the results in indeterminate intervals which are required in uncertainty. The hematologists can apply the proposed control chart for monitoring the blood-related diseases. The proposed control chart can be applied in medical sciences for monitoring various diseases. The proposed control chart using the other sampling schemes can be considered as future research.

Data availability

The data is given in the paper. The data is taken from https://www.sciencedirect.com/science/article/pii/S1473050218301277.

Change history

04 July 2022

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1038/s41598-022-15749-8

References

Amin, R. W., Reynolds, M. R. Jr. & Saad, B. Nonparametric quality control charts based on the sign statistic. Commun. Stat. Theory Methods 24, 1597–1623 (1995).

Albers, W. & Kallenberg, W. C. Empirical non-parametric control charts: Estimation effects and corrections. J. Appl. Stat. 31, 345–360 (2004).

Bakir, S. T. A distribution-free Shewhart quality control chart based on signed-ranks. Qual. Eng. 16, 613–623 (2004).

Chakraborti, S. & Eryilmaz, S. A nonparametric Shewhart-type signed-rank control chart based on runs. Commun. Stat. Simul. Comput. 36, 335–356 (2007).

Qiu, P. Distribution-free multivariate process control based on log-linear modeling. IIE Trans. 40, 664–677 (2008).

Chatterjee, S. & Qiu, P. Distribution-free cumulative sum control charts using bootstrap-based control limits. Ann. Appl. Stat. 3, 349–369 (2009).

Qiu, P. & Li, Z. On nonparametric statistical process control of univariate processes. Technometrics 53, 390–405 (2011).

Duclos, A. & Voirin, N. The p-control chart: A tool for care improvement. Int. J. Qual. Health Care 22, 402–407 (2010).

Aebtarm, S. & Bouguila, N. An empirical evaluation of attribute control charts for monitoring defects. Expert Syst. Appl. 38, 7869–7880 (2011).

Haridy, S., Wu, Z., Lee, K. M. & Rahim, M. A. An attribute chart for monitoring the process mean and variance. Int. J. Prod. Res. 52, 3366–3380 (2014).

Yang, S. F. & Arnold, B. C. Monitoring process variance using an ARL-unbiased EWMA-p control chart. Qual. Reliabil. Eng. Int. 32, 1227–1235 (2016).

Zhu, H., Zhang, C. & Deng, Y. Optimisation design of attribute control charts for multi-station manufacturing system subjected to quality shifts. Int. J. Prod. Res. 54, 1804–1821 (2016).

Arif, O.-H., Aslam, M. & Jun, C.-H. EWMA NP control chart for the Weibull distribution. J. Test. Eval. 45, 1022–1028 (2017).

Quinino, R. C., Bessegato, L. F. & Cruz, F. R. An attribute inspection control chart for process mean monitoring. Int. J. Adv. Manuf. Technol. 90, 2991–2999 (2017).

Aslam, M., Azam, M., Kim, K.-J. & Jun, C.-H. Designing of an attribute control chart for two-stage process. Meas. Control 51, 285–292 (2018).

Zadeh, L. A. Fuzzy sets. Inf. Control 8, 338–353 (1965).

Smarandache, F. Neutrosophic logic-generalization of the intuitionistic fuzzy logic. arXiv:math/0303009 (2003).

Smarandache, F. Introduction to Neutrosophic Statistics, Sitech and Education Publisher, Craiova 123 (Romania-Educational Publisher, Columbus, 2014).

Ye, J. Neutrosophic number linear programming method and its application under neutrosophic number environments. Soft. Comput. 22, 4639–4646 (2018).

Aslam, M. & Raza, M. A. Design of new sampling plans for multiple manufacturing lines under uncertainty. Int. J. Fuzzy Syst. 21, 978–992 (2019).

Aslam, M., Bantan, R. A. & Khan, N. Design of a new attribute control chart under neutrosophic statistics. Int. J. Fuzzy Syst. 21, 433–440 (2019).

Li, Z., Zou, C., Gong, Z. & Wang, Z. The computation of average run length and average time to signal: An overview. J. Stat. Comput. Simul. 84, 1779–1802 (2014).

Pereira, P., Seghatchian, J., Caldeira, B., Xavier, S. & de Sousa, G. Statistical control of the production of blood components by control charts of attribute to improve quality characteristics and to comply with current specifications. Transfus. Apheres. Sci. 57, 285–290 (2018).

Standards, A. A. o. B. B. C. o. Standards for Blood Banks and Transfusion Services. (The Committee, 1974).

Li, Z., Wang, Z. & Wu, Z. Necessary and sufficient conditions for non-interaction of a pair of one-sided EWMA schemes with reflecting boundaries. Stat. Probab. Lett. 79, 368–374 (2009).

Acknowledgements

The authors are deeply thankful to the reviewers and the editor for their valuable suggestions to improve the quality of the paper.

Funding

The author (P. Jeyadurga) would like to thank the Kalasalingam Academy of Research and Education for providing financial support through Post-doctoral fellowship.

Author information

Authors and Affiliations

Contributions

N.K., M.A., P.J., S.B. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1038/s41598-022-15749-8

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khan, N., Aslam, M., Jeyadurga, P. et al. RETRACTED ARTICLE: Monitoring of production of blood components by attribute control chart under indeterminacy. Sci Rep 11, 922 (2021). https://doi.org/10.1038/s41598-020-79851-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-79851-5

This article is cited by

-

Monitoring non-parametric profiles using adaptive EWMA control chart

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.