Abstract

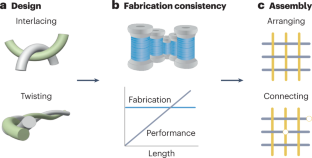

Fibre electronic devices with one-dimensional configurations have attracted increasing interest because they are highly flexible and can be deformed. In particular, they can be woven into breathable and comfortable textiles for wearable applications. Fibre devices with various functionalities, such as energy harvesting and storage, sensing, and display, have thus been extensively explored. However, most fibre devices work individually rather than as systems. This Perspective aims to highlight promising design concepts, assembly strategies and performance improvements for fibre electronic systems. Their real-life applications are then analysed from a multidisciplinary point of view involving materials science, electrical engineering, textile engineering and health monitoring. The remaining challenges are finally summarized to guide future research for both academia and industry.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Xu, X., Xie, S., Zhang, Y. & Peng, H. The rise of fiber electronics. Angew. Chem. Int. Ed. 58, 13643–13653 (2019).

Heo, J. S., Eom, J., Kim, Y. H. & Park, S. K. Recent progress of textile-based wearable electronics: a comprehensive review of materials, devices, and applications. Small 14, 1703034 (2018).

Zeng, W. et al. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Adv. Mater. 26, 5310–5336 (2014).

Fakharuddin, A. et al. Fiber-shaped electronic devices. Adv. Energy Mater. 11, 2101443 (2021).

Liu, R., Wang, Z. L., Fukuda, K. & Someya, T. Flexible self-charging power sources. Nat. Rev. Mater. 7, 870–886 (2022).

Chen, C. et al. Functional fiber materials to smart fiber devices. Chem. Rev. 123, 613–662 (2023).

Chen, G. et al. Electronic textiles for wearable point-of-care systems. Chem. Rev. 122, 3259–3291 (2022).

Libanori, A., Chen, G., Zhao, X., Zhou, Y. & Chen, J. Smart textiles for personalized healthcare. Nat. Electron. 5, 142–156 (2022).

Wang, L. et al. Application challenges in fiber and textile electronics. Adv. Mater. 32, 1901971 (2020).

Ates, H. C. et al. End-to-end design of wearable sensors. Nat. Rev. Mater. 7, 887–907 (2022).

Zheng, Y. Q. et al. Monolithic optical microlithography of high-density elastic circuits. Science 373, 88–94 (2021).

Dong, K. et al. Advances in high-performance autonomous energy and self-powered sensing textiles with novel 3D fabric structures. Adv. Mater. 34, 2109355 (2022).

Wang, Y., Yokota, T. & Someya, T. Electrospun nanofiber-based soft electronics. npg Asia Mater. 13, 22 (2021).

Peng, H. Fiber electronics. Adv. Mater. 32, 1904697 (2020).

Xu, Y. et al. A one-dimensional fluidic nanogenerator with a high power conversion efficiency. Angew. Chem. Int. Ed. 56, 12940–12945 (2017).

Liu, P. et al. Polymer solar cell textiles with interlaced cathode and anode fibers. J. Mater. Chem. A 6, 19947–19953 (2018).

Chen, C. et al. Direct current fabric triboelectric nanogenerator for biomotion energy harvesting. ACS Nano 14, 4585–4594 (2020).

Liao, M., Ye, L., Zhang, Y., Chen, T. & Peng, H. The recent advance in fiber-shaped energy storage devices. Adv. Electron. Mater. 5, 1800456 (2019).

Wang, L. et al. Functionalized helical fibre bundles of carbon nanotubes as electrochemical sensors for long-term in vivo monitoring of multiple disease biomarkers. Nat. Biomed. Eng. 4, 159–171 (2020).

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591, 240–245 (2021).

Choi, H. W. et al. Smart textile lighting/display system with multifunctional fibre devices for large scale smart home and IoT applications. Nat. Commun. 13, 814 (2022).

He, J. et al. Scalable production of high-performing woven lithium-ion fibre batteries. Nature 597, 57–63 (2021).

Seyedin, S. et al. Fibre electronics: towards scaled-up manufacturing of integrated e-textile systems. Nanoscale 13, 12818–12847 (2021).

Zhao, X. et al. Soft fibers with magnetoelasticity for wearable electronics. Nat. Commun. 12, 6755 (2021).

AMERI Research. Smart textiles market to 2024: key product categories (active, passive, ultra smart), application (sensing, thermo-electricity, energy harvesting, luminescence & aesthetics), end-use, regional segmentation, competitive dynamics, M&A insights, pricing analysis (OPP, IPP, RAP) and segment forecast. AMERI Research https://www.ameriresearch.com/product/smart-textiles-market/ (2017).

Sun, H., Zhang, Y., Zhang, J., Sun, X. & Peng, H. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2, 17023 (2017).

Khudiyev, T. et al. Thermally drawn rechargeable battery fiber enables pervasive power. Mater. Today 52, 80–89 (2022).

Liao, M. et al. Industrial scale production of fibre batteries by a solution-extrusion method. Nat. Nanotechnol. 17, 372–377 (2022).

Zhang, Y., Wang, H., Lu, H., Li, S. & Zhang, Y. Electronic fibers and textiles: recent progress and perspective. iScience 24, 102716 (2021).

Agcayazi, T., Chatterjee, K., Bozkurt, A. & Ghosh, T. K. Flexible interconnects for electronic textiles. Adv. Mater. Technol. 3, 1700277 (2018).

Castano, L. M. & Flatau, A. B. Smart fabric sensors and e-textile technologies: a review. Smart Mater. Struct. 23, 053001 (2014).

Loke, G. et al. Digital electronics in fibres enable fabric-based machine-learning inference. Nat. Commun. 12, 3317 (2021).

Rein, M. et al. Diode fibres for fabric-based optical communications. Nature 560, 214–218 (2018).

Zhang, Z. et al. A one-dimensional soft and color-programmable light-emitting device. J. Mater. Chem. C 6, 1328–1333 (2018).

Zhang, Z. et al. Textile display for electronic and brain-interfaced communications. Adv. Mater. 30, 1800323 (2018).

Zhang, Z. et al. A colour-tunable, weavable fibre-shaped polymer light-emitting electrochemical cell. Nat. Photon. 9, 233–238 (2015).

Ye, L. et al. Stabilizing lithium into cross-stacked nanotube sheets with an ultra-high specific capacity for lithium oxygen batteries. Angew. Chem. Int. Ed. 58, 2437–2442 (2019).

Chen, J. Y. et al. Electrospun poly(3-hexylthiophene) nanofibers with highly extended and oriented chains through secondary electric field for high-performance field-effect transistors. Adv. Electron. Mater. 1, 1400028 (2015).

Yang, Q. et al. In situ formation of Co9S8 quantum dots in MOF-derived ternary metal layered double hydroxide nanoarrays for high-performance hybrid supercapacitors. Adv. Energy Mater. 10, 1903193 (2020).

Fu, X., Xu, L., Li, J., Sun, X. & Peng, H. Flexible solar cells based on carbon nanomaterials. Carbon 139, 1063–1073 (2018).

Hu, Y. et al. Photo-to-electricity generation of aligned carbon nanotubes in water. J. Mater. Chem. A 7, 1996–2001 (2019).

Gao, Z. et al. Flexible self-powered textile formed by bridging photoactive and electrochemically active fiber electrodes. J. Mater. Chem. A 7, 14447–14454 (2019).

Nakanishi, Y. et al. Concentrated-polymer-brush-modified silica nanoparticles self-assembled in ionic liquid containing iodide/tTriiodide (I–/I3–)-redox system as quasi-solid electrolytes for dye-sensitized solar cells. ACS Appl. Nano Mater. 4, 6620–6628 (2021).

Liu, Y. et al. Electron-affinity-triggered variations on the optical and electrical properties of dye molecules enabling highly efficient dye-sensitized solar cells. Angew. Chem. Int. Ed. 57, 14125–14128 (2018).

Xie, X., Criddle, C. & Cui, Y. Design and fabrication of bioelectrodes for microbial bioelectrochemical systems. Energy Environ. Sci. 8, 3418–3441 (2015).

Pereira, A. R., de Souza, J. C. P., Iost, R. M., Sales, F. C. P. F. & Crespilho, F. N. Application of carbon fibers to flexible enzyme electrodes. J. Electroanal. Chem. 780, 396–406 (2016).

Khudiyev, T. et al. 100 m long thermally drawn supercapacitor fibers with applications to 3D printing and textiles. Adv. Mater. 32, 2004971 (2020).

Hong, S. et al. Carbon nanotube fibers with high specific electrical conductivity: synergistic effect of heteroatom doping and densification. Carbon 184, 207–213 (2021).

Zhang, X., Lu, W., Zhou, G. & Li, Q. Understanding the mechanical and conductive properties of carbon nanotube fibers for smart electronics. Adv. Mater. 32, 1902028 (2020).

Shen, B., Zhai, W. & Zheng, W. Ultrathin flexible graphene film: an excellent thermal conducting material with efficient EMI shielding. Adv. Funct. Mater. 24, 4542–4548 (2014).

Fang, B., Chang, D., Xu, Z. & Gao, C. A review on graphene fibers: expectations, advances, and prospects. Adv. Mater. 32, 1902664 (2020).

Zhang, R. et al. Growth of half-meter long carbon nanotubes based on Schulz–Flory distribution. ACS Nano 7, 6156–6161 (2013).

Zhang, R., Zhang, Y. & Wei, F. Controlled synthesis of ultralong carbon nanotubes with perfect structures and extraordinary properties. Acc. Chem. Res. 50, 179–189 (2017).

Ren, J., Sun, X., Chen, P., Wang, Y. & Peng, H. Research progress of fiber-shaped electrochemical energy storage devices. Chin. Sci. Bull. 65, 3150–3159 (2020).

Lim, H.-R. et al. Advanced soft materials, sensor integrations, and applications of wearable flexible hybrid electronics in healthcare, energy, and environment. Adv. Mater. 32, 1901924 (2020).

Jain, R. et al. Nanostructuring versus microstructuring in battery electrodes. Nat. Rev. Mater. 7, 736–746 (2022).

Liu, X. H. et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6, 1522–1531 (2012).

Yan, W. et al. Single fibre enables acoustic fabrics via nanometre-scale vibrations. Nature 603, 616–623 (2022).

Zeng, S. et al. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling. Science 373, 692–696 (2021).

Wang, Y. et al. 3D-printed all-fiber Li-ion battery toward wearable energy storage. Adv. Funct. Mater. 27, 1703140 (2017).

Fu, K. et al. Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Adv. Mater. 28, 2587–2594 (2016).

Li, Y. et al. 3D-printed, all-in-one evaporator for high-efficiency solar steam generation under 1 sun illumination. Adv. Mater. 29, 1700981 (2017).

Kaufman, J. J. et al. Structured spheres generated by an in-fibre fluid instability. Nature 487, 463–467 (2012).

Kanik, M. et al. Strain-programmable fiber-based artificial muscle. Science 365, 145–150 (2019).

Shen, Y. et al. Thermally drawn multifunctional fibers: toward the next generation of information technology. InfoMat 4, e12318 (2022).

Fuller, B. J. Cryoprotectants: the essential antifreezes to protect life in the frozen state. Cryoletters 25, 375–388 (2004).

de Ryck, A. & Quéré, D. Fluid coating from a polymer solution. Langmuir 14, 1911–1914 (1998).

Mirri, F. et al. Lightweight, flexible, high-performance carbon nanotube cables made by scalable flow coating. ACS Appl. Mater. Interf. 8, 4903–4910 (2016).

Haefner, S. et al. Influence of slip on the Plateau–Rayleigh instability on a fibre. Nat. Commun. 6, 7409 (2015).

Wang, P. et al. Bioinspired anti-Plateau–Rayleigh-instability on dual parallel fibers. Adv. Mater. 32, 2003453 (2020).

Richardson, J. J., Björnmalm, M. & Caruso, F. Technology-driven layer-by-layer assembly of nanofilms. Science 348, aaa2491 (2015).

Xu, S. et al. Preparation and controlled coating of hydroxyl-modified silver nanoparticles on silk fibers through intermolecular interaction-induced self-assembly. Mater. Des. 95, 107–118 (2016).

Tan, Y. J. et al. A transparent, self-healing and high-κ dielectric for low-field-emission stretchable optoelectronics. Nat. Mater. 19, 182–188 (2020).

Luo, Y. S. & Liu, S. I. A voltage multiplier with adaptive threshold voltage compensation. IEEE J. Solid-State Circuits 52, 2208–2214 (2017).

Li, D. et al. Scalable and hierarchically designed polymer film as a selective thermal emitter for high-performance all-day radiative cooling. Nat. Nanotechnol. 16, 153–158 (2021).

Liu, M. et al. A review: electrospun nanofiber materials for lithium–sulfur batteries. Adv. Funct. Mater. 29, 1905467 (2019).

de Mulatier, S., Nasreldin, M., Delattre, R., Ramuz, M. & Djenizian, T. Electronic circuits integration in textiles for data processing in wearable technologies. Adv. Mater. Technol. 3, 1700320 (2018).

Shi, J. et al. Smart textile-integrated microelectronic systems for wearable applications. Adv. Mater. 32, 1901958 (2020).

Canales, A. et al. Multifunctional fibers for simultaneous optical, electrical and chemical interrogation of neural circuits in vivo. Nat. Biotechnol. 33, 277–284 (2015).

Ibanez Labiano, I. et al. Screen printing carbon nanotubes textiles antennas for smart wearables. Sensors 21, 4934 (2021).

Ding, C. et al. Durability study of thermal transfer printed textile electrodes for wearable electronic applications. ACS Appl. Mater. Interf. 14, 29144–29155 (2022).

Hong, H., Hu, J. & Yan, X. UV curable conductive ink for the fabrication of textile-based conductive circuits and wearable UHF RFID tags. ACS Appl. Mater. Interf. 11, 27318–27326 (2019).

Xiao, Y. et al. Fabrication of silver electrical circuits on textile substrates by reactive inkjet printing. IEEE Sens. J. 22, 11056–11064 (2022).

Sungyong, S., Kim, B., Son, Y. K., Ji Eun, K. & Il-Yeon, C. A flexible textile wristwatch using transfer printed textile circuit technique. In 2012 IEEE Int. Conf. on Consumer Electronics (ICCE) 21–22 (IEEE, 2012).

Yoon, J. et al. Robust and stretchable indium gallium zinc oxide-based electronic textiles formed by cilia-assisted transfer printing. Nat. Commun. 7, 11477 (2016).

Komolafe, A. et al. Integrating flexible filament circuits for e-textile applications. Adv. Mater. Technol. 4, 1900176 (2019).

Li, Q. & Tao, X. M. Three-dimensionally deformable, highly stretchable, permeable, durable and washable fabric circuit boards. Proc. R. Soc. A 470, 20140472 (2014).

Lin, R. et al. Digitally-embroidered liquid metal electronic textiles for wearable wireless systems. Nat. Commun. 13, 2190 (2022).

Linz, T. et al. Embroidered interconnections and encapsulation for electronics in textiles for wearable electronics applications. Adv. Sci. Technol. 60, 85–94 (2009).

Dhawan, A., Seyam, A. M., Ghosh, T. K. & Muth, J. F. Woven fabric-based electrical circuits: Part I. Evaluating interconnect methods. Text. Res. J. 74, 913–919 (2004).

Molla, M. T. I. et al. Surface-mount manufacturing for e-textile circuits. In Proc. 2017 ACM Int. Symp. on Wearable Computers, 18–25 (ACM, 2017).

Post, E. R., Orth, M., Russo, P. R. & Gershenfeld, N. E-broidery: design and fabrication of textile-based computing. IBM Syst. J. 39, 840–860 (2000).

Zysset, C., Kinkeldei, T. W., Munzenrieder, N., Cherenack, K. & Troster, G. Integration method for electronics in woven textiles. IEEE Trans. Compon. Packaging Manuf. Technol. 2, 1107–1117 (2012).

Wu, H. Y. et al. Seamlessly-integrated textile electric circuit enabled by self-connecting interwoven points. Chin. J. Polym. Sci. 40, 1323–1330 (2022).

Dils, C. et al. Interconnecting embroidered hybrid conductive yarns by ultrasonic plastic welding for e-textiles. Text. Res. J. 92, 4501–4520 (2022).

Park, S. et al. Adaptive and multifunctional hydrogel hybrid probes for long-term sensing and modulation of neural activity. Nat. Commun. 12, 3435 (2021).

Luo, Y. et al. Learning human–environment interactions using conformal tactile textiles. Nat. Electron. 4, 193–201 (2021).

Park, Y. G., Lee, S. & Park, J. U. Recent progress in wireless sensors for wearable electronics. Sensors 19, 4353 (2019).

Tian, X. et al. Wireless body sensor networks based on metamaterial textiles. Nat. Electron. 2, 243–251 (2019).

Stanley, J., Hunt, J. A., Kunovski, P. & Wei, Y. A review of connectors and joining technologies for electronic textiles. Eng. Rep. 4, e12491 (2022).

Chen, M. et al. Imperceptible, designable, and scalable braided electronic cord. Nat. Commun. 13, 7097 (2022).

Hwang, S. et al. Integration of multiple electronic components on a microfibre towards an emerging electronic textile platform. Nat. Commun. 13, 3173 (2022).

Pattinson, S. W. et al. Additive manufacturing of biomechanically tailored meshes for compliant wearable and implantable devices. Adv. Funct. Mater. 29, 1901815 (2019).

Loke, G. et al. Structured multimaterial filaments for 3D printing of optoelectronics. Nat. Commun. 10, 4010 (2019).

Vu, C. H. T. & Won, K. Leaching-resistant carrageenan-based colorimetric oxygen indicator films for intelligent food packaging. J. Agric. Food Chem. 62, 7263–7267 (2014).

Idros, N. & Chu, D. Triple-indicator-based multidimensional colorimetric sensing platform for heavy metal ion detections. ACS Sens. 3, 1756–1764 (2018).

Xiong, J., Chen, J. & Lee, P. S. Functional fibers and fabrics for soft robotics, wearables, and human–robot interface. Adv. Mater. 33, 2002640 (2021).

Jinno, H. et al. Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat. Energy 2, 780–785 (2017).

Kwon, C. et al. Self-bondable and stretchable conductive composite fibers with spatially controlled percolated Ag nanoparticle networks: novel integration strategy for wearable electronics. Adv. Funct. Mater. 30, 2005447 (2020).

Ma, R., Lee, J., Choi, D., Moon, H. & Baik, S. Knitted fabrics made from highly conductive stretchable fibers. Nano Lett. 14, 1944–1951 (2014).

Ryu, S. et al. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 9, 5929–5936 (2015).

Huang, J. et al. Stretchable and heat-resistant protein-based electronic skin for human thermoregulation. Adv. Funct. Mater. 30, 1910547 (2020).

Torres Alonso, E. et al. Graphene electronic fibres with touch-sensing and light-emitting functionalities for smart textiles. npj Flex. Electron. 2, 25 (2018).

Yang, Z. et al. Conductive and elastic 3D helical fibers for use in washable and wearable electronics. Adv. Mater. 32, 1907495 (2020).

Chen, S. et al. Transparent and waterproof ionic liquid-based fibers for highly durable multifunctional sensors and strain-insensitive stretchable conductors. ACS Appl. Mater. Interf. 10, 4305–4314 (2018).

Meng, W., Nie, M., Liu, Z. & Zhou, J. Buckled fiber conductors with resistance stability under strain. Adv. Fiber Mater. 3, 149–159 (2021).

Lee, J. et al. Intrinsically strain-insensitive, hyperelastic temperature-sensing fiber with compressed micro-wrinkles for integrated textronics. Adv. Mater. Technol. 5, 2000073 (2020).

Lee, W. et al. Universal assembly of liquid metal particles in polymers enables elastic printed circuit board. Science 378, 637–641 (2022).

Cao, J. et al. Ultra-robust stretchable electrode for e-skin: in situ assembly using a nanofiber scaffold and liquid metal to mimic water-to-net interaction. InfoMat 4, e12302 (2022).

Lv, Z. et al. Autonomous chemistry enabling environment-adaptive electrochemical energy storage devices. CCS Chem. 5, 11–29 (2023).

Deng, J. et al. A shape-memory supercapacitor fiber. Angew. Chem. Int. Ed. 54, 15419–15423 (2015).

Rao, J. et al. All-fiber-based quasi-solid-state lithium-ion battery towards wearable electronic devices with outstanding flexibility and self-healing ability. Nano Energy 51, 425–433 (2018).

Yang, P. et al. Thermal self-protection of zinc-ion batteries enabled by smart hygroscopic hydrogel electrolytes. Adv. Energy Mater. 10, 2002898 (2020).

Degenstein, L. M., McQueen, R. H. & Krogman, N. T. ‘What goes where?’ Characterizing Edmonton’s municipal clothing waste stream and consumer clothing disposal. J. Clean. Prod. 296, 126516 (2021).

Zamani, B., Sandin, G. & Peters, G. M. Life cycle assessment of clothing libraries: can collaborative consumption reduce the environmental impact of fast fashion? J. Clean. Prod. 162, 1368–1375 (2017).

Dulal, M. et al. Toward sustainable wearable electronic textiles. ACS Nano 16, 19755–19788 (2022).

Yousef, S. et al. Sustainable green technology for recovery of cotton fibers and polyester from textile waste. J. Clean. Prod. 254, 120078 (2020).

Satyanarayana, K. G., Arizaga, G. G. C. & Wypych, F. Biodegradable composites based on lignocellulosic fibers — an overview. Prog. Polym. Sci. 34, 982–1021 (2009).

Daria, M., Krzysztof, L. & Jakub, M. Characteristics of biodegradable textiles used in environmental engineering: a comprehensive review. J. Clean. Prod. 268, 122129 (2020).

Tempro Tec. Stainless steel sewing thread. Tempro Tec https://www.temprotec.com/textiles-for-insulation-covers/stainless-steel-accessories-and-threads/ (2015).

SWICOFIL. Metal-plated chemical yarns. SWICOFIL https://www.swicofil.com/commerce/products/2swicosilver/619/introduction (2019).

DexMat. Galvorn CNT yarn. DexMat https://store.dexmat.com/ (2023).

Google. Jacquard by Google weaves new digital experiences into the things you love, wear, and use every day. Google https://atap.google.com/jacquard/ (2021).

Clim8. Garments that can monitor the body and environment temperature and regulate the skin temperature based on the sensing modules and electrical heating of conductive fibres. Clim8 https://myclim8.com/products/ (2021).

Embro. Technical embroidery according to your specifications. Embro https://embro-tech.com/en/ (2021).

Gong, W. et al. Continuous and scalable manufacture of amphibious energy yarns and textiles. Nat. Commun. 10, 868 (2019).

Luo, Y. et al. Technology roadmap for flexible sensors. ACS Nano 17, 5211–5295 (2023).

Lee, H. & Roh, J. S. Wearable electromagnetic energy-harvesting textiles based on human walking. Text. Res. J. 89, 2532–2541 (2019).

Xiang, S., Zhang, N. & Fan, X. From fiber to fabric: progress towards photovoltaic energy textile. Adv. Fiber Mater. 3, 76–106 (2021).

Wang, M. et al. Fusing stretchable sensing technology with machine learning for human–machine interfaces. Adv. Funct. Mater. 31, 2008807 (2021).

Wang, M. et al. Gesture recognition using a bioinspired learning architecture that integrates visual data with somatosensory data from stretchable sensors. Nat. Electron. 3, 563–570 (2020).

Acknowledgements

H.P. acknowledges funding support from the Ministry of Science and Technology of China (2022YFA1200023) and the Science and Technology Commission of Shanghai Municipality (21511104900, 20JC1414902). K.Z. acknowledges funding support from the National Natural Science Foundation of China (22105045).

Author information

Authors and Affiliations

Contributions

K.Z., X.S. and C.T. contributed equally to this work. All authors contributed to the writing and editing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Materials thanks Xiaodong Chen, Wei Gao and Xiaoming Tao for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeng, K., Shi, X., Tang, C. et al. Design, fabrication and assembly considerations for electronic systems made of fibre devices. Nat Rev Mater 8, 552–561 (2023). https://doi.org/10.1038/s41578-023-00573-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41578-023-00573-x

This article is cited by

-

Vertical-Aligned and Ordered-Active Architecture of Heterostructured Fibers for High Electrochemical Capacitance

Advanced Fiber Materials (2024)

-

Calcium–Oxygen Fiber Batteries for Next-Generation Wearables

Advanced Fiber Materials (2024)