Abstract

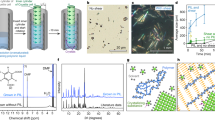

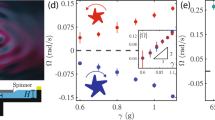

When liquids or solid materials rotate, they impart centrifugal and/or shear forces. This Review surveys rotary devices and systems in which such forces control small-scale flows, self-organization phenomena, materials synthesis or chemical reactivity at molecular and macromolecular levels. Centrifugal forces directed away from the rotation axis enable various separations or lab-on-a-disc systems and can shape interfaces or deposit thin films of functional materials. When these forces act on particles lighter than the rotating fluid, they can provide the basis for colloidal crystallization or trapping; when the direction of rotation changes, they can simulate microgravity conditions and affect motility patterns of living organisms. Shear forces, by contrast, can promote crystallization, couple to molecular-scale assembly and affect its chiral outcomes. Combining centrifugal and shear forces is useful in establishing rotating reactors to accelerate reaction kinetics, modulate chemical reactivity, enable multistep syntheses or support complex extractions. Through these and other examples, we illustrate that rotating reaction vessels can enable new types of chemical experimentation, with outcomes that are not always understood. We argue that rotating systems for studying such processes will become more common given advances in remotely controlled sensors and spectrometers that can monitor the contents of rotating vessels.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lynden-Bell, D. & Pringle, J. E. The evolution of viscous discs and the origin of the nebular variables. Mon. Not. R. Astron. Soc. 168, 603–637 (1974).

Jones, M. & Lambourne, R. in An Introduction to Galaxies and Cosmology 37–41 (Cambridge Univ. Press, 2004).

Berg, H. C. & Anderson, R. A. Bacteria swim by rotating their flagellar filaments. Nature 245, 380–382 (1973).

Dreyfus, R. et al. Microscopic artificial swimmers. Nature 437, 862–865 (2005).

Sharma, A. K. in Advanced Semiconductor Memories: Architectures, Designs, and Applications 549–622 (Wiley-IEEE Press, 2009).

Han, S.-T., Zhou, Y. & Roy, V. A. L. Towards the development of flexible non-volatile memories. Adv. Mater. 25, 5425–5449 (2013).

Noji, H., Yasuda, R., Yoshida, M. & Kinosita, K. Direct observation of the rotation of F-1-ATPase. Nature 386, 299–302 (1997).

Kay, E. R., Leigh, D. A. & Zerbetto, F. Synthetic molecular motors and mechanical machines. Angew. Chem. Int. Ed. 46, 72–191 (2007).

Balzani, V., Credi, A., Raymo, F. M. & Stoddart, J. F. Artificial molecular machines. Angew. Chem. Int. Ed. 39, 3348–3391 (2000).

Eelkema, R. et al. Molecular machines: nanomotor rotates microscale objects. Nature 440, 163 (2006).

Ruangsupapichat, N., Pollard, M. M., Harutyunyan, S. R. & Feringa, B. L. Reversing the direction in a light-driven rotary molecular motor. Nat. Chem. 3, 53–60 (2011).

Faulkner, L. R. & Bard, A. J. in Electrochemical Methods: Fundamentals and Applications 335–360 (Wiley, 2002).

Xing, W., Yin, G. & Zhang, J. Rotating Electrode Methods and Oxygen Reduction Electrocatalysts (Elsevier, 2014).

Grzybowski, B. A., Stone, H. A. & Whitesides, G. M. Dynamic self-assembly of magnetized, millimetre-sized objects rotating at a liquid–air interface. Nature 405, 1033–1036 (2000).

Grzybowski, B. A. & Whitesides, G. M. Dynamic aggregation of chiral spinners. Science 296, 718–721 (2002).

Grzybowski, B. A. & Whitesides, G. M. Directed dynamic self-assembly of objects rotating on two parallel fluid interfaces. J. Chem. Phys. 116, 8571–8577 (2002).

Lenz, P., Joanny, J.-F., Jülicher, F. & Prost, J. Membranes with rotating motors. Phys. Rev. Lett. 91, 108104 (2003).

Goto, Y. & Tanaka, H. Purely hydrodynamic ordering of rotating disks at a finite Reynolds number. Nat. Commun. 6, 5994 (2015).

Yeo, K., Lushi, E. & Vlahovska, P. M. Collective dynamics in a binary mixture of hydrodynamically coupled microrotors. Phys. Rev. Lett. 114, 188301 (2015).

Kokot, G., Snezhko, A. & Aranson, I. S. Emergent coherent states and flow rectification in active magnetic colloidal monolayers. Soft Matter 9, 6757–6760 (2013).

Snezhko, A., Jacob, E., Ben & Aranson, I. S. Pulsating–gliding transition in the dynamics of levitating liquid nitrogen droplets. New J. Phys. 10, 43034 (2008).

Xu, T., Gao, W., Xu, L.-P., Zhang, X. & Wang, S. Fuel-free synthetic micro-/nanomachines. Adv. Mater. 29, 1603250 (2017).

Elgeti, J., Winkler, R. G. & Gompper, G. Physics of microswimmers — single particle motion and collective behavior: a review. Rep. Prog. Phys. 78, 056601 (2015).

Alharbi, T. M. D. et al. Sub-micron moulding topological mass transport regimes in angled vortex fluidic flow. Nanoscale Adv. 3, 3064–3075 (2021).

Strohmeier, O. et al. Centrifugal microfluidic platforms: advanced unit operations and applications. Chem. Soc. Rev. 44, 6187–6229 (2015).

Ducrée, J., Glatzel, T., Brenner, T. & Zengerle, R. in MicroNano Integration 147–153 (Springer, 2004).

Ducrée, J. et al. The centrifugal microfluidic Bio-Disk platform. J. Micromech. Microeng. 17, S103 (2007).

Brenner, T., Glatzel, T., Zengerle, R. & Ducrée, J. Frequency-dependent transversal flow control in centrifugal microfluidics. Lab Chip 5, 146–150 (2005).

Kassegne, S. et al. Coriolis force for facilitating DNA molecular migration and hybridization in compact disk microfluidic platforms. Microsyst. Technol. 21, 719–732 (2015).

Stokes, G. G. On the theories of the internal friction of fluids in motion, and of the equilibrium and motion of elastic solids. Trans. Cambridge Philos. Soc. 8, 287–319 (1845).

Svedberg, T. & Rinde, H. The ultra-centrifuge, a new instrument for the determination of size and distribution of size of particle in amicroscopic colloids. J. Am. Chem. Soc. 46, 2677–2693 (1924).

Van Holde, K. E. & Baldwin, R. L. Rapid attainment of sedimentation equilibrium. J. Phys. Chem. 62, 734–743 (1958).

Bancroft, F. C. & Freifelder, D. Molecular weights of coliphages and coliphage DNA: I. Measurement of the molecular weight of bacteriophage T7 by high-speed equilibrium centrifugation. J. Mol. Biol. 54, 537–546 (1970).

Ghirlando, R. The analysis of macromolecular interactions by sedimentation equilibrium. Methods 54, 145–156 (2011).

Schildkraut, C. L., Marmur, J. & Doty, P. Determination of the base composition of deoxyribonucleic acid from its buoyant density in CsCl. J. Mol. Biol. 4, 430–443 (1962).

Durchschlag, H. in Thermodynamic Data for Biochemistry and Biotechnology 45–128 (Springer, 1986).

Ralston, G. Introduction to Analytical Ultracentrifugation Vol. 35, 57–58 (Beckman Instruments, 1993).

Stafford, W. F. III Boundary analysis in sedimentation transport experiments: a procedure for obtaining sedimentation coefficient distributions using the time derivative of the concentration profile. Anal. Biochem. 203, 295–301 (1992).

Correia, J. J., Shire, S., Yphantis, D. A. & Schuster, T. M. Sedimentation equilibrium measurements of the intermediate-size tobacco mosaic virus protein polymers. Biochemistry 24, 3292–3297 (1985).

Teller, D. C. in Methods in Enzymology Vol. 27, 346–441 (Elsevier, 1973).

Vistica, J. et al. Sedimentation equilibrium analysis of protein interactions with global implicit mass conservation constraints and systematic noise decomposition. Anal. Biochem. 326, 234–256 (2004).

Richards, E. G. & Schachman, H. K. Ultracentrifuge studies with Rayleigh interference optics. I. General application. J. Phys. Chem. 63, 1578–1591 (1959).

Prakash, V. & Timasheff, S. N. Mechanism of interaction of vinca alkaloids with tubulin: catharanthine and vindoline. Biochemistry 30, 873–880 (1991).

Akbulut, O. et al. Separation of nanoparticles in aqueous multiphase systems through centrifugation. Nano Lett. 12, 4060–4064 (2012).

Planken, K. L. & Cölfen, H. Analytical ultracentrifugation of colloids. Nanoscale 2, 1849–1869 (2010).

Olander, D. R. The theory of uranium enrichment by the gas centrifuge. Prog. Nucl. Energy 8, 1–33 (1981).

Whitley, S. Review of the gas centrifuge until 1962. Part I: Principles of separation physics. Rev. Mod. Phys. 56, 41–66 (1984).

Ramshaw, C. & Mallinson, R. H. Mass transfer process. US Patent 4283255 (1981).

Lin, C.-C., Liu, W.-T. & Tan, C.-S. Removal of carbon dioxide by absorption in a rotating packed bed. Ind. Eng. Chem. Res. 42, 2381–2386 (2003).

Qian, Z., Li, Z.-H. & Guo, K. Industrial applied and modeling research on selective H2S removal using a rotating packed bed. Ind. Eng. Chem. Res. 51, 8108–8116 (2012).

Ramshaw, C. “Higee” distillation-an example of process intensification. Chem. Eng. Lond. 389, 13–14 (1983).

Fowler, R. Higee-a status report. Chem. Eng. Lond. 456, 35–37 (1989).

Fowler, R., Gerdes, K. F. & Nygaard, H. F. in Offshore Technology Conference OTC-6121-MS (OnePetro, 1989).

Munjal, S., Dudukovc´, M. P. & Ramachandran, P. Mass-transfer in rotating packed beds — I. Development of gas — liquid and liquid — solid mass-transfer correlations. Chem. Eng. Sci. 44, 2245–2256 (1989).

Keyvani, M. & Gardner, N. C. Operating characteristics of rotating beds. Chem. Eng. Prog. 85, 48–52 (1989).

Peel, J., Howarth, C. R. & Ramshaw, C. Process intensification: Higee seawater deaeration. Chem. Eng. Res. Des. 76, 585–593 (1998).

Chang, C.-C. et al. Combined photolysis and catalytic ozonation of dimethyl phthalate in a high-gravity rotating packed bed. J. Hazard. Mater. 161, 287–293 (2009).

Garcia, G. E. C., van der Schaaf, J. & Kiss, A. A. A review on process intensification in HiGee distillation. J. Chem. Technol. Biotechnol. 92, 1136–1156 (2017).

Kiss, A. A. & Jobson, M. Taking reactive distillation to the next level of process intensification. Chem. Eng. Trans. 69, 553–558 (2018).

Gudena, K., Rangaiah, G. P. & Lakshminarayanan, S. Modeling and analysis of solid catalyzed reactive HiGee stripping. Chem. Eng. Sci. 80, 242–252 (2012).

Yu, C.-H., Huang, C.-H. & Tan, C.-S. A review of CO2 capture by absorption and adsorption. Aerosol Air Qual. Res. 12, 745–769 (2012).

Oko, E., Wang, M. & Joel, A. S. Current status and future development of solvent-based carbon capture. Int. J. Coal Sci. Technol. 4, 5–14 (2017).

Chen, J.-F., Wang, Y.-H., Guo, F., Wang, X.-M. & Zheng, C. Synthesis of nanoparticles with novel technology: high-gravity reactive precipitation. Ind. Eng. Chem. Res. 39, 948–954 (2000).

Brown, J. et al. A hand-powered, portable, low-cost centrifuge for diagnosing anemia in low-resource settings. Am. J. Trop. Med. Hyg. 85, 327–332 (2011).

Wong, A. P., Gupta, M., Shevkoplyas, S. S. & Whitesides, G. M. Egg beater as centrifuge: isolating human blood plasma from whole blood in resource-poor settings. Lab Chip 8, 2032–2037 (2008).

Bhamla, M. S. et al. Hand-powered ultralow-cost paper centrifuge. Nat. Biomed. Eng. 1, 0009 (2017).

Gorkin, R. et al. Centrifugal microfluidics for biomedical applications. Lab Chip 10, 1758–1773 (2010).

Madou, M. et al. Lab on a CD. Annu. Rev. Biomed. Eng. 8, 601–628 (2006).

Siegrist, J. et al. Validation of a centrifugal microfluidic sample lysis and homogenization platform for nucleic acid extraction with clinical samples. Lab Chip 10, 363–371 (2010).

Cho, Y.-K. et al. One-step pathogen specific DNA extraction from whole blood on a centrifugal microfluidic device. Lab Chip 7, 565–573 (2007).

Schembri, C. T., Burd, T. L., Kopf-Sill, A. R., Shea, L. R. & Braynin, B. Centrifugation and capillarity integrated into a multiple analyte whole blood analyser. J. Anal. Methods Chem. 17, 99–104 (1995).

Lai, S. et al. Design of a compact disk-like microfluidic platform for enzyme-linked immunosorbent assay. Anal. Chem. 76, 1832–1837 (2004).

Lee, B. S. et al. A fully automated immunoassay from whole blood on a disc. Lab Chip 9, 1548–1555 (2009).

Zhao, M. et al. High-speed interferometric detection of label-free immunoassays on the biological compact disc. Clin. Chem. 52, 2135–2140 (2006).

Sackmann, E. K., Fulton, A. L. & Beebe, D. J. The present and future role of microfluidics in biomedical research. Nature 507, 181–189 (2014).

Walker, G. M. & Beebe, D. J. A passive pumping method for microfluidic devices. Lab Chip 2, 131–134 (2002).

Hwang, H., Kim, S. H., Kim, T. H., Park, J. K. & Cho, Y. K. Paper on a disc: balancing the capillary-driven flow with a centrifugal force. Lab Chip 11, 3404–3406 (2011).

Kainz, D. M., Früh, S. M., Hutzenlaub, T., Zengerle, R. & Paust, N. Flow control for lateral flow strips with centrifugal microfluidics. Lab Chip 19, 2718–2727 (2019).

Thiha, A. & Ibrahim, F. A colorimetric enzyme-linked immunosorbent assay (ELISA) detection platform for a point-of-care dengue detection system on a lab-on-compact-disc. Sensors 15, 11431–11441 (2015).

Sayad, A. A. et al. A microfluidic lab-on-a-disc integrated loop mediated isothermal amplification for foodborne pathogen detection. Sens. Actuators B Chem. 227, 600–609 (2016).

Nwankire, C. E. et al. Label-free impedance detection of cancer cells from whole blood on an integrated centrifugal microfluidic platform. Biosens. Bioelectron. 68, 382–389 (2015).

Morais, S., Tamarit-López, J., Carrascosa, J., Puchades, R. & Maquieira, Á. Analytical prospect of compact disk technology in immunosensing. Anal. Bioanal. Chem. 391, 2837–2844 (2008).

Kinahan, D. J., Kearney, S. M., Dimov, N., Glynn, M. T. & Ducrée, J. Event-triggered logical flow control for comprehensive process integration of multi-step assays on centrifugal microfluidic platforms. Lab Chip 14, 2249–2258 (2014).

Miyazaki, C. M. et al. Label-free, spatially multiplexed SPR detection of immunoassays on a highly integrated centrifugal Lab-on-a-Disc platform. Biosens. Bioelectron. 119, 86–93 (2018).

Kinahan, D. J. et al. Paper imbibition for timing of multi-step liquid handling protocols on event-triggered centrifugal microfluidic lab-on-a-disc platforms. RSC Adv. 5, 1818–1826 (2015).

Kinahan, D. J. et al. Xurography actuated valving for centrifugal flow control. Lab Chip 16, 3454–3459 (2016).

Kinahan, D. et al. Baking powder actuated centrifugo-pneumatic valving for automation of multi-step bioassays. Micromachines 7, 175 (2016).

McArdle, H. et al. “TORNADO” — Theranostic one-step RNA detector; microfluidic disc for the direct detection of microRNA-134 in plasma and cerebrospinal fluid. Sci. Rep. 7, 1750 (2017).

Nwankire, C. et al. Fluidic automation of nitrate and nitrite bioassays in whole blood by dissolvable-film based centrifugo-pneumatic actuation. Sensors 13, 11336–11349 (2013).

Hess, J. F. et al. Review on pneumatic operations in centrifugal microfluidics. Lab Chip 19, 3745–3770 (2019).

Schwemmer, F. et al. LabDisk for SAXS: a centrifugal microfluidic sample preparation platform for small-angle X-ray scattering. Lab Chip 16, 1161–1170 (2016).

Woo, H.-K. et al. Exodisc for rapid, size-selective, and efficient isolation and analysis of nanoscale extracellular vesicles from biological samples. ACS Nano 11, 1360–1370 (2017).

Klatt, J.-N. et al. Miniaturization, parallelization, and automation of endotoxin detection by centrifugal microfluidics. Anal. Chem. 93, 8508–8516 (2021).

Rissin, D. M. et al. Single-molecule enzyme-linked immunosorbent assay detects serum proteins at subfemtomolar concentrations. Nat. Biotechnol. 28, 595–599 (2010).

Rissin, D. M. et al. Simultaneous detection of single molecules and singulated ensembles of molecules enables immunoassays with broad dynamic range. Anal. Chem. 83, 2279–2285 (2011).

Wilson, D. H. et al. The Simoa HD-1 analyzer: a novel fully automated digital immunoassay analyzer with single-molecule sensitivity and multiplexing. J. Lab. Autom. 21, 533–547 (2016).

Prado, E. et al. Non-targeted sportomics analyses by mass spectrometry to understand exercise-induced metabolic stress in soccer players. Int. J. Mass. Spectrom. 418, 1–5 (2017).

Land, K. J., Boeras, D. I., Chen, X. S., Ramsay, A. R. & Peeling, R. W. REASSURED diagnostics to inform disease control strategies, strengthen health systems and improve patient outcomes. Nat. Microbiol. 4, 46–54 (2019).

Miyazaki, C. M., Carthy, E. & Kinahan, D. J. Biosensing on the centrifugal microfluidic lab-on-a-disc platform. Processes 8, 1360 (2020).

Zhang, L. et al. Hand-powered centrifugal microfluidic platform inspired by the spinning top for sample-to-answer diagnostics of nucleic acids. Lab Chip 18, 610–619 (2018).

Michael, I. et al. A fidget spinner for the point-of-care diagnosis of urinary tract infection. Nat. Biomed. Eng. 4, 591–600 (2020).

Ebhota, W. S., Karun, A. S. & Inambao, F. L. Centrifugal casting technique baseline knowledge, applications, and processing parameters: overview. Int. J. Mater. Res. 107, 960–969 (2016).

Pradeep, A. D. & Rameshkumar, T. Review on centrifugal casting of functionally graded materials. Mater. Today Proc. 45, 729–734 (2021).

Watanabe, Y., Inaguma, Y., Sato, H. & Miura-Fujiwara, E. A novel fabrication method for functionally graded materials under centrifugal force: the centrifugal mixed-powder method. Materials 2, 2510–2525 (2009).

Saleh, B. et al. Review on the influence of different reinforcements on the microstructure and wear behavior of functionally graded aluminum matrix composites by centrifugal casting. Met. Mater. Int. 26, 933–960 (2020).

Zygmuntowicz, J. et al. Investigation on fabrication and property of graded composites obtained via centrifugal casting in the magnetic field. Compos. B Eng. 173, 106999 (2019).

Zhong, J. et al. Efficient and scalable synthesis of highly aligned and compact two-dimensional nanosheet films with record performances. Nat. Commun. 9, 3484 (2018).

Kim, J. Y. et al. Single-step fabrication of quantum funnels via centrifugal colloidal casting of nanoparticle films. Nat. Commun. 6, 7772 (2015).

Mujiyono, M., Suharto, S., Mukhammad, A. F. H., Nurhadiyanto, D. & Sumowidagdo, A. L. Manufacture of nickel collimator for BNCT: smelting of nickel using electrical arc furnace and centrifugal casting preparation. Indones. J. Phys. Nucl. Appl. 3, 21–28 (2018).

Richards, R. G., MacHunter, D. M., Gates, P. J. & Palmer, M. K. Gravity separation of ultra-fine (−0.1 mm) minerals using spiral separators. Miner. Eng. 13, 65–77 (2000).

Pardee, F. Separator for ore, coal, &c. US Patent 629595 (1899).

Stokes, Y. M. Computing flow in a spiral particle separator. Computing 10, 14 (2001).

Matthews, B. W., Fletcher, C. A. J. & Partridge, A. C. Computational simulation of fluid and dilute particulate flows on spiral concentrators. Appl. Math. Model. 22, 965–979 (1998).

Vonnegut, B. Rotating bubble method for the determination of surface and interfacial tensions. Rev. Sci. Instrum. 13, 6–9 (1942).

Princen, H. M., Zia, I. Y. Z. & Mason, S. G. Measurement of interfacial tension from the shape of a rotating drop. J. Colloid Interface Sci. 23, 99–107 (1967).

Grzybowski, B. A., Fitzner, K., Paczesny, J. & Granick, S. From dynamic self-assembly to networked chemical systems. Chem. Soc. Rev. 46, 5647–5678 (2017).

Lee, T., Gizynski, K. & Grzybowski, B. A. Non-equilibrium self-assembly of monocomponent and multicomponent tubular structures in rotating fluids. Adv. Mater. 29, 1704274 (2017).

Winkelmann, J., Mughal, A., Williams, D. B., Weaire, D. & Hutzler, S. Theory of rotational columnar structures of soft spheres. Phys. Rev. E 99, 020602 (2019).

Winkelmann, J., Mughal, A., Weaire, D. & Hutzler, S. Equilibrium configurations of hard spheres in a cylindrical harmonic potential. EPL 127, 44002 (2019).

Adler, I., Barabe, D. & Jean, R. V. A history of the study of phyllotaxis. Ann. Bot. 80, 231–244 (1997).

Erickson, R. O. Tubular packing of spheres in biological fine structure. Science 181, 705–716 (1973).

Hutzler, S., Weaire, D., Elias, F. & Janiaud, E. Juggling with bubbles in cylindrical ferrofluid foams. Philos. Mag. Lett. 82, 297–301 (2002).

Yan, J., Bloom, M., Bae, S. C., Luijten, E. & Granick, S. Linking synchronization to self-assembly using magnetic Janus colloids. Nature 491, 578–581 (2012).

Zhou, Y. et al. Biomimetic hierarchical assembly of helical supraparticles from chiral nanoparticles. ACS Nano 10, 3248–3256 (2016).

Lee, T., Sobolev, Y. I., Cybulski, O. & Grzybowski, B. A. Dynamic assembly of small parts in vortex–vortex traps established within a rotating fluid. Adv. Mater. 31, 1902298 (2019).

Timonen, J. V. I. & Grzybowski, B. A. Tweezing of magnetic and non-magnetic objects with magnetic fields. Adv. Mater. 29, 1603516 (2017).

Gibson, B. K. Liquid mirror telescopes-history. J. R. Astron. Soc. Can. 85, 158–171 (1991).

Skey, H. Art. XI — An astronomical telescope on a new construction. Trans. Proc. N. Z. Inst. 5, 119 (1872).

Wood, R. W. The mercury paraboloid as a reflecting telescope. Astrophys. J. 29, 164–176 (1909).

Borra, E. F., Content, R., Drinkwater, M. J. & Szapiel, S. A diffraction-limited f/2 1.5 meter diameter liquid mirror. Astrophys. J. 346, L41–L44 (1989).

Hickson, P. et al. The Large Zenith Telescope: a 6 m liquid-mirror telescope. Publ. Astron. Soc. Pac. 119, 444 (2007).

Gibson, B. K. & Hickson, P. in Evolution of the Universe of Galaxies: Edwin Hubble Centennial Symposium 265 (Astronomical Society of the Pacific, 1990).

Kim, D. W. et al. in Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II Vol. 9912, 99120P (SPIE, 2016).

Emslie, A. G., Bonner, F. T. & Peck, L. G. Flow of a viscous liquid on a rotating disk. J. Appl. Phys. 29, 858–862 (1958).

Wilson, S. K., Hunt, R. & Duffy, B. R. The rate of spreading in spin coating. J. Fluid Mech. 413, 65–88 (2000).

Xia, Y. & Whitesides, G. M. Soft lithography. Angew. Chem. Int. Ed. 37, 550–575 (1998).

Grigorescu, A. E. & Hagen, C. W. Resists for sub-20-nm electron beam lithography with a focus on HSQ: state of the art. Nanotechnology 20, 292001 (2009).

Ahn, N. et al. Highly reproducible perovskite solar cells with average efficiency of 18.3% and best efficiency of 19.7% fabricated via Lewis base adduct of lead(II) iodide. J. Am. Chem. Soc. 137, 8696–8699 (2015).

Kan, B. et al. A series of simple oligomer-like small molecules based on oligothiophenes for solution-processed solar cells with high efficiency. J. Am. Chem. Soc. 137, 3886–3893 (2015).

Chiang, C.-H., Nazeeruddin, M. K., Grätzel, M. & Wu, C.-G. The synergistic effect of H2O and DMF towards stable and 20% efficiency inverted perovskite solar cells. Energy Environ. Sci. 10, 808–817 (2017).

Guan, W., Zhou, W., Lu, J. & Lu, C. Luminescent films for chemo- and biosensing. Chem. Soc. Rev. 44, 6981–7009 (2015).

Lee, W., Zhang, X. & Briber, R. M. A simple method for creating nanoporous block-copolymer thin films. Polymer 51, 2376–2382 (2010).

Jiang, P., Prasad, T., McFarland, M. J. & Colvin, V. L. Two-dimensional nonclose-packed colloidal crystals formed by spincoating. Appl. Phys. Lett. 89, 011908 (2006).

He, H. et al. Uniform doping of graphene close to the Dirac point by polymer-assisted assembly of molecular dopants. Nat. Commun. 9, 3956 (2018).

Pradhan, B., Kohlmeyer, R. R. & Chen, J. Fabrication of in-plane aligned carbon nanotube–polymer composite thin films. Carbon 48, 217–222 (2010).

Bourzac, K. Carbon nanotube computers face a make-or-break moment. Chem. Eng. News 97, 22–25 (2019).

Shulaker, M. M. et al. Carbon nanotube computer. Nature 501, 526–530 (2013).

Chen, X., Smith, N. M., Iyer, K. S. & Raston, C. L. Controlling nanomaterial synthesis, chemical reactions and self assembly in dynamic thin films. Chem. Soc. Rev. 43, 1387–1399 (2014).

Boodhoo, K. V. K. & Jachuck, R. J. Process intensification: spinning disk reactor for styrene polymerization. Appl. Therm. Eng. 20, 1127–1146 (2000).

Pask, S. D., Nuyken, O. & Cai, Z. The spinning disk reactor: an example of a process intensification technology for polymers and particles. Polym. Chem. 3, 2698–2707 (2012).

Jacobsen, N. C. & Hinrichsen, O. Micromixing efficiency of a spinning disk reactor. Ind. Eng. Chem. Res. 51, 11643–11652 (2012).

Lodha, H., Jachuck, R., & Suppiah Singaram, S. Intensified biodiesel production using a rotating tube reactor. Energy Fuels 26, 7037–7040 (2012).

Jachuck, R. J. J. & Ramshaw, C. Process intensification: heat transfer characteristics of tailored rotating surfaces. Heat Recover. Syst. CHP 14, 475–491 (1994).

Stankiewicz, A. I. & Moulijn, J. A. Process intensification: transforming chemical engineering. Chem. Eng. Prog. 96, 22–34 (2000).

Ochando-Pulido, J. M., Stoller, M., Di Palma, L., Martínez-Férez, A. & Vilardi, G. in Nanophotocatalysis and Environmental Applications (eds Inamuddin, G. S., Kumar, A., Lichtfouse, E. & Asiri, A. M.) 303–333 (Springer, 2019).

Visscher, F., van der Schaaf, J., Nijhuis, T. A. & Schouten, J. C. Rotating reactors — A review. Chem. Eng. Res. Des. 91, 1923–1940 (2013).

Oxley, P., Brechtelsbauer, C., Ricard, F., Lewis, N. & Ramshaw, C. Evaluation of spinning disk reactor technology for the manufacture of pharmaceuticals. Ind. Eng. Chem. Res. 39, 2175–2182 (2000).

Feng, X., Patterson, D. A., Balaban, M., Fauconnier, G. & Emanuelsson, E. A. C. The spinning cloth disc reactor for immobilized enzymes: a new process intensification technology for enzymatic reactions. Chem. Eng. J. 221, 407–417 (2013).

Britton, J., Stubbs, K. A., Weiss, G. A. & Raston, C. L. Vortex fluidic chemical transformations. Chem. Eur. J. 23, 13270–1327 (2017).

Yasmin, L., Chen, X., Stubbs, K. A. & Raston, C. L. Optimising a vortex fluidic device for controlling chemical reactivity and selectivity. Sci. Rep. 3, 2282 (2013).

Luo, X., Smith, P., Raston, C. L. & Zhang, W. Vortex fluidic device-intensified aqueous two phase extraction of C-phycocyanin from Spirulina maxima. ACS Sustain. Chem. Eng. 4, 3905–3911 (2016).

Luo, X., Su, P., Zhang, W. & Raston, C. L. Microfluidic devices in fabricating nano or micromaterials for biomedical applications. Adv. Mater. Technol. 4, 1900488 (2019).

Britton, J., Castle, J. W., Weiss, G. A. & Raston, C. L. Harnessing thin-film continuous-flow assembly lines. Chem. Eur. J. 22, 10773–10776 (2016).

Britton, J., Chalker, J. M. & Raston, C. L. Rapid vortex fluidics: continuous flow synthesis of amides and local anesthetic lidocaine. Chem. Eur. J. 21, 10660–10665 (2015).

Britton, J., Dalziel, S. B. & Raston, C. L. The synthesis of di-carboxylate esters using continuous flow vortex fluidics. Green Chem. 18, 2193–2200 (2016).

Yasmin, L., Stubbs, K. A. & Raston, C. L. Vortex fluidic promoted Diels–Alder reactions in an aqueous medium. Tetrahedron Lett. 55, 2246–2248 (2014).

Ho, L. A., Raston, C. L. & Stubbs, K. A. Angled vortex fluidic mediated multicomponent photocatalytic and transition metal-catalyzed reactions. Chem. Eur. J. 24, 8869–8874 (2018).

Gandy, M. N., Raston, C. L. & Stubbs, K. A. Photoredox catalysis under shear using thin film vortex microfluidics. Chem. Commun. 51, 11041–11044 (2015).

Oksdath-Mansilla, G., Kucera, R. L., Chalker, J. M. & Raston, C. L. Azide–alkyne cycloadditions in a vortex fluidic device: enhanced “on water” effects and catalysis in flow. Chem. Commun. 57, 659–662 (2021).

Yasmin, L., Eggers, P. K., Skelton, B. W., Stubbs, K. A. & Raston, C. L. Thin film microfluidic synthesis of fluorescent highly substituted pyridines. Green Chem. 16, 3450–3453 (2014).

Yasmin, L., Coyle, T. & Raston, C. L. Stereospecific synthesis of resorcin[4]arenes and pyrogallol[4]arenes in dynamic thin films. Chem. Commun. 49, 10932–10934 (2013).

Martin, A. D., Boulos, R. A., Hubble, L. J., Hartlieb, K. J. & Raston, C. L. Multifunctional water-soluble molecular capsules based on p-phosphonic acid calix[5]arene. Chem. Commun. 47, 7353–7355 (2011).

Chen, X., Dobson, J. F. & Raston, C. L. Vortex fluidic exfoliation of graphite and boron nitride. Chem. Commun. 48, 3703–3705 (2012).

Vimalanathan, K., Chen, X. & Raston, C. L. Shear induced fabrication of intertwined single walled carbon nanotube rings. Chem. Commun. 50, 11295–11298 (2001).

Goh, Y. A. et al. Shear flow assisted decoration of carbon nano-onions with platinum nanoparticles. Chem. Commun. 49, 5171–5173 (2013).

Luo, X. et al. Laser irradiated vortex fluidic mediated synthesis of luminescent carbon nanodots under continuous flow. React. Chem. Eng. 3, 164–170 (2018).

Alharbi, T. M. D., Vimalanathan, K., Lawrance, W. D. & Raston, C. L. Controlled slicing of single walled carbon nanotubes under continuous flow. Carbon 140, 428–432 (2018).

Alharbi, T. M. D., Vimalanathan, K., Alsulami, I. K. & Raston, C. L. Vertically aligned laser sliced MWCNTs. Nanoscale 11, 21394–21403 (2019).

Al-Antaki, A. H. M. et al. Continuous flow copper laser ablation synthesis of copper(I and II) oxide nanoparticles in water. ACS Omega 4, 13577–13584 (2019).

Mohammed Al-Antaki, A. H. et al. Continuous flow synthesis of phosphate binding h-BN@magnetite hybrid material. RSC Adv. 8, 40829–40835 (2018).

Yuan, T. Z. et al. Shear-stress-mediated refolding of proteins from aggregates and inclusion bodies. ChemBioChem 16, 393–396 (2015).

Britton, J., Meneghini, L. M., Raston, C. L. & Weiss, G. A. Accelerating enzymatic catalysis using vortex fluidics. Angew. Chem. Int. Ed. 55, 11387–11391 (2016).

Luo, X. et al. Vortex fluidic-mediated fabrication of fast gelated silica hydrogels with embedded laccase nanoflowers for real-time biosensing under flow. ACS Appl. Mater. Interfaces 12, 51999–52007 (2020).

Luo, X. et al. Vortex fluidic mediated synthesis of macroporous bovine serum albumin-based microspheres. ACS Appl. Mater. Interfaces 10, 27224–27232 (2018).

Luo, X. et al. High-shear-imparted tunable fluorescence in polyethylenimines. ChemPhotoChem 2, 343–348 (2018).

He, S., Joseph, N., Luo, X. & Raston, C. Continuous flow thin film microfluidic mediated nano-encapsulation of fish oil. LWT 103, 88–93 (2019).

He, S., Joseph, N., Luo, X. & Raston, C. L. Vortex fluidic mediated food processing. PLoS ONE 14, e0216816 (2019).

Andrade, M. A. & Martins, L. M. D. R. S. New trends in C–C cross-coupling reactions: the use of unconventional conditions. Molecules 25, 5506 (2020).

Taylor, G. I. Stability of a viscous liquid contained between two rotating cylinders. Philos. Trans. R. Soc. Lond. Ser. A 223, 289–343 (1923).

Gleick, J. Chaos: Making a New Science 119–155 (Penguin Books, 2008).

Grossmann, S., Lohse, D. & Sun, C. High–Reynolds number Taylor-Couette turbulence. Annu. Rev. Fluid Mech. 48, 53–80 (2016).

Andereck, C. D., Liu, S. S. & Swinney, H. L. Flow regimes in a circular Couette system with independently rotating cylinders. J. Fluid Mech. 164, 155–183 (1986).

Coles, D. Transition in circular Couette flow. J. Fluid Mech. 21, 385–425 (1965).

Wetzel, T. et al. Numerical model of turbulent CZ melt flow in the presence of AC and CUSP magnetic fields and its verification in a laboratory facility. J. Cryst. Growth 230, 81–91 (2001).

Jeong, H., Lee, Y., Ji, M., Lee, G. & Chung, H. The optimum solidification and crucible rotation in silicon Czochralski crystal growth. J. Mech. Sci. Technol. 24, 407–414 (2010).

Schwabe, D. G. Spiral crystal growth in the Czochralski process — revisited, with new interpretations. Cryst. Res. Technol. 55, 1900073 (2020).

Mokshin, A. V. & Barrat, J. L. Shear-induced crystallization of an amorphous system. Phys. Rev. E 77, 021505 (2008).

Zaccone, A., Wu, H., Gentili, D. & Morbidelli, M. Theory of activated-rate processes under shear with application to shear-induced aggregation of colloids. Phys. Rev. E 80, 051404 (2009).

Richard, D. & Speck, T. The role of shear in crystallization kinetics: From suppression to enhancement. Sci. Rep. 5, 14610 (2015).

Mura, F. & Zaccone, A. Effects of shear flow on phase nucleation and crystallization. Phys. Rev. E 93, 042803 (2016).

Holmqvist, P., Lettinga, M. P., Buitenhuis, J. & Dhont, J. K. G. Crystallization kinetics of colloidal spheres under stationary shear flow. Langmuir 21, 10976–10982 (2005).

Blaak, R., Auer, S., Frenkel, D. & Löwen, H. Crystal nucleation of colloidal suspensions under shear. Phys. Rev. Lett. 93, 068303 (2004).

Cerdà, J. J., Sintes, T., Holm, C., Sorensen, C. M. & Chakrabarti, A. Shear effects on crystal nucleation in colloidal suspensions. Phys. Rev. E 78, 031403 (2008).

Yu, L. W., Derks, D., Van Blaaderen, A. & Imhof, A. Melting and crystallization of colloidal hard-sphere suspensions under shear. Proc. Natl Acad. Sci. USA 106, 10564–10569 (2009).

Rwei, S. P., Manas-Zloczower, I. & Feke, D. L. Observation of carbon black agglomerate dispersion in simple shear flows. Polym. Eng. Sci. 30, 701–706 (1990).

Vassileva, N. D., Van Den Ende, D., Mugele, F. & Mellema, J. Fragmentation and erosion of two-dimensional aggregates in shear flow. Langmuir 23, 2352–2361 (2007).

Zaccone, A., Wu, H., Lattuada, M. & Morbidelli, M. Charged molecular films on Brownian particles: Structure, interactions, and relation to stability. J. Phys. Chem. B 112, 6793–6802 (2008).

Soos, M. et al. Effect of shear rate on aggregate size and morphology investigated under turbulent conditions in stirred tank. J. Colloid Interface Sci. 319, 577–589 (2008).

Zaccone, A. et al. Breakup of dense colloidal aggregates under hydrodynamic stresses. Phys. Rev. E 79, 061401 (2009).

Conchúir, B. Ó. & Zaccone, A. Mechanism of flow-induced biomolecular and colloidal aggregate breakup. Phys. Rev. E 87, 032310 (2013).

Forsyth, C. et al. Influence of controlled fluid shear on nucleation rates in glycine aqueous solutions. Cryst. Growth Des. 15, 94–102 (2015).

Sun, J., Sobolev, Y. I., Zhang, W., Zhuang, Q. & Grzybowski, B. A. Enhancing crystal growth using polyelectrolyte solutions and shear flow. Nature 579, 73–79 (2020).

Onuki, A. Phase transitions of fluids in shear flow. J. Phys. Condens. Matter 9, 6119–6157 (1997).

Yucel, T., Cebe, P. & Kaplan, D. L. Vortex-induced injectable silk fibroin hydrogels. Biophys. J. 97, 2044–2050 (2009).

Babenko, V., Piejko, M., Wójcik, S., Mak, P. & Dzwolak, W. Vortex-induced amyloid superstructures of insulin and its component A and B chains. Langmuir 29, 5271–5278 (2013).

Kondepudi, D. K., Kaufman, R. J. & Singh, N. Chiral symmetry breaking in sodium chlorate crystallizaton. Science 250, 975–976 (1990).

McBride, J. M. & Carter, R. L. Spontaneous resolution by stirred crystallization. Angew. Chem. Int. Ed. 30, 293–295 (1991).

Viedma, C. Chiral symmetry breaking during crystallization: complete chiral purity induced by nonlinear autocatalysis and recycling. Phys. Rev. Lett. 94, 65504 (2005).

Bodák, B., Maggioni, G. M. & Mazzotti, M. Population-based mathematical model of solid-state deracemization via temperature cycles. Cryst. Growth Des. 18, 7122–7131 (2018).

Ribó, J. M., Crusats, J., Sagués, F., Claret, J. & Rubires, R. Chiral sign induction by vortices during the formation of mesophases in stirred solutions. Science 292, 2063–2066 (2001).

Escudero, C., Crusats, J., Diez-Pérez, I., El-Hachemi, Z. & Ribó, J. M. Folding and hydrodynamic forces in J-aggregates of 5-phenyl-10,15,20-tris(4-sulfophenyl)porphyrin. Angew. Chem. Int. Ed. 45, 8032–8035 (2006).

Tsuda, A. et al. Spectroscopic visualization of vortex flows using dye-containing nanofibers. Angew. Chem. Int. Ed. 46, 8198–8202 (2007).

Wolffs, M. et al. Macroscopic origin of circular dichroism effects by alignment of self-assembled fibers in solution. Angew. Chem. Int. Ed. 46, 8203–8205 (2007).

Okano, K. & Yamashita, T. Formation of chiral environments by a mechanical induced vortex flow. ChemPhysChem 13, 2263–2271 (2012).

Arteaga, O. et al. Reversible and irreversible emergence of chiroptical signals in J-aggregates of achiral 4-sulfonatophenyl substituted porphyrins: intrinsic chirality vs. chiral ordering in the solution. Chem. Commun. 52, 10874–10877 (2016).

Kehoe, D. K., McCarthy, J., Gough, J. J., Bradley, A. L. & Gun’ko, Y. K. Macroscopic vortex-induced optical activity in silver nanowires. J. Phys. Chem. C 123, 15307–15313 (2019).

Li, Y. et al. Enantiomorphic microvortex-enabled supramolecular sensing of racemic amino acids by using achiral building blocks. Angew. Chem. Int. Ed. 59, 3486–3490 (2020).

Kuroha, M. et al. Chiral supramolecular nanoarchitectures from macroscopic mechanical rotations: effects on enantioselective aggregation behavior of phthalocyanines. Angew. Chem. Int. Ed. 58, 18454–18459 (2019).

Huang, J.-C. et al. Circularly polarized luminescence of achiral metal–organic colloids and guest molecules in a vortex field. Chem. Eur. J. 27, 6760–6766 (2021).

Sun, J. et al. Control over the emerging chirality in supramolecular gels and solutions by chiral microvortices in milliseconds. Nat. Commun. 9, 2599 (2018).

Okano, K., Taguchi, M., Fujiki, M. & Yamashita, T. Circularly polarized luminescence of rhodamine B in a supramolecular chiral medium formed by a vortex flow. Angew. Chem. Int. Ed. 50, 12474–12477 (2011).

Hermans, T. M., Bishop, K. J. M., Stewart, P. S., Davis, S. H. & Grzybowski, B. A. Vortex flows impart chirality-specific lift forces. Nat. Commun. 6, 5640 (2015).

Hermans, T. M., Sato, A. & Marichez, V. Method for chiral resolution and device therefor. WO Patent 2,016,020,532 (2017).

Cybulski, O. et al. Concentric liquid reactors for chemical synthesis and separation. Nature 586, 57–63 (2020).

Jänecke, E. Über Entmischungserscheinungen anorganischer Salze in wässrigen ammoniakalischen Lösungen. Z. Elektrochem. Angew. Phys. Chem. 33, 518–526 (1927).

Pattle, R. E. Systems of mutually immiscible liquid layers. Nature 165, 203–204 (1950).

Hildebrand, J. H. Seven liquid phases in equilibrium. J. Phys. Colloid Chem. 53, 944–947 (1949).

Eckelmann, J. & Lu, U. Mixing liquids-mission impossible? A colorful demonstration on immiscible systems. J. Chem. Educ. 90, 224–227 (2013).

Kitson, P. J. et al. Digitization of multistep organic synthesis in reactionware for on-demand pharmaceuticals. Science 359, 314–319 (2018).

Hartman, R. L., McMullen, J. P. & Jensen, K. F. Deciding whether to go with the flow: evaluating the merits of flow reactors for synthesis. Angew. Chem. Int. Ed. 50, 7502–7519 (2011).

Pastre, J. C., Browne, D. L. & Ley, S. V. Flow chemistry syntheses of natural products. Chem. Soc. Rev. 42, 8849–8869 (2013).

Itoh, H., Thien, M. P., Hatton, T. A. & Wang, D. I. C. A liquid emulsion membrane process for the separation of amino acids. Biotechnol. Bioeng. 35, 853–860 (1990).

Ahmad, A. L., Kusumastuti, A., Derek, C. J. C. & Ooi, B. S. Emulsion liquid membrane for heavy metal removal: An overview on emulsion stabilization and destabilization. Chem. Eng. J. 171, 870–882 (2011).

Kumar, A., Thakur, A. & Panesar, P. S. A review on emulsion liquid membrane (ELM) for the treatment of various industrial effluent streams. Rev. Environ. Sci. Biotechnol. 18, 153–182 (2019).

Schöller, C., Chaudhuri, J. B. & Pyle, D. L. Emulsion liquid membrane extraction of lactic acid from aqueous solutions and fermentation broth. Biotechnol. Bioeng. 42, 50–58 (1993).

Kumar, A., Thakur, A. & Panesar, P. S. Lactic acid and its separation and purification techniques: A review. Rev. Environ. Sci. Biotechnol. 18, 823–853 (2019).

Herranz, R. et al. Ground-based facilities for simulation of microgravity: organism-specific recommendations for their use, and recommended terminology. Astrobiology 13, 1–17 (2012).

Wuest, S. L., Richard, S., Kopp, S., Grimm, D. & Egli, M. Simulated microgravity: Critical review on the use of random positioning machines for mammalian cell culture. Biomed. Res. Int. 2015, 971474 (2015).

Braddock, M. From target identification to drug development in space: using the microgravity assist. Curr. Drug Discov. Technol. 17, 45–56 (2019).

Amselem, S. Remote controlled autonomous microgravity lab platforms for drug research in space. Pharm. Res. 36, 183 (2019).

Wilson, J. W. et al. Media ion composition controls regulatory and virulence response of Salmonella in spaceflight. PLoS ONE 3, e3923 (2008).

Kopp, S. et al. Identifications of novel mechanisms in breast cancer cells involving duct-like multicellular spheroid formation after exposure to the Random Positioning Machine. Sci. Rep. 6, 26887 (2016).

Schwarz, R. P., Goodwin, T. J. & Wolf, D. A. Cell culture for three-dimensional modeling in rotating-wall vessels: an application of simulated microgravity. J. Tissue Cult. Methods 14, 51–57 (1992).

Hoson, T., Kamisaka, S., Masuda, Y., Yamashita, M. & Buchen, B. Evaluation of the three-dimensional clinostat as a simulator of weightlessness. Planta 203, S187–S197 (1997).

Borst, A. G. & Van Loon, J. J. W. A. Technology and developments for the random positioning machine, RPM. Microgravity Sci. Technol. 21, 287–292 (2009).

Benavides Damm, T., Walther, I., Wüest, S. L., Sekler, J. & Egli, M. Cell cultivation under different gravitational loads using a novel random positioning incubator. Biotechnol. Bioeng. 111, 1180–1190 (2014).

Moorman, S. J., Burress, C., Cordova, R. & Slater, J. Stimulus dependence of the development of the zebrafish (Danio rerio) vestibular system. J. Neurobiol. 38, 247–258 (1999).

Liu, Y., Li, X., Anken, R. H., Wang, G. & Hilbig, R. Effects of wall vessel rotation on the growth of larval zebrafish inner ear otoliths. Microgravity Sci. Technol. 23, 13–18 (2010).

Brungs, S., Hauslage, J., Hilbig, R., Hemmersbach, R. & Anken, R. Effects of simulated weightlessness on fish otolith growth: clinostat versus rotating-wall vessel. Adv. Space Res. 48, 792–798 (2011).

Meier, S. W., Lueptow, R. M. & Ottino, J. M. A dynamical systems approach to mixing and segregation of granular materials in tumblers. Adv. Phys. 56, 757–827 (2007).

Brucks, A., Arndt, T., Ottino, J. M. & Lueptow, R. M. Behavior of flowing granular materials under variable g. Phys. Rev. E 75, 032301 (2007).

Mellmann, J. The transverse motion of solids in rotating cylinders — forms of motion and transition behavior. Powder Technol. 118, 251–270 (2001).

Umbanhowar, P. B., Lueptow, R. M. & Ottino, J. M. Modeling segregation in granular flows. Annu. Rev. Chem. Biomol. Eng. 10, 129–153 (2019).

Moog, R. S., Ediger, M. D., Boxer, S. G. & Fayer, M. D. Viscosity dependence of the rotational reorientation of rhodamine B in mono- and polyalcohols. Picosecond transient grating experiments. J. Phys. Chem. 86, 4694–4700 (1982).

Srivastava, A. & Doraiswamy, S. Rotational diffusion of rose bengal. J. Chem. Phys. 103, 6197–6205 (1995).

Dorsey, G. F. Fiber optic rotary joints — a review. IEEE Trans. Compon. Hybrids Manuf. Technol. 5, 37–41 (1982).

Shapar, V. Principles of compensation of optical rays’ rotation and multi-channel optical rotary connectors. Appl. Opt. 57, 8023 (2018).

Höfflin, J., Torres Delgado, S. M., Suárez Sandoval, F., Korvink, J. G. & Mager, D. Electrifying the disk: a modular rotating platform for wireless power and data transmission for lab on a disk application. Lab Chip 15, 2584–2587 (2015).

Martinez-Duarte, R., Gorkin, R. A., Abi-Samra, K. & Madou, M. J. The integration of 3D carbon-electrode dielectrophoresis on a CD-like centrifugal microfluidic platform. Lab Chip 10, 1030–1043 (2010).

Loo, J. F. C. et al. Sample-to-answer on molecular diagnosis of bacterial infection using integrated lab-on-a-disc. Biosens. Bioelectron. 93, 212–219 (2017).

Torres Delgado, S. M. et al. Wirelessly powered and remotely controlled valve-array for highly multiplexed analytical assay automation on a centrifugal microfluidic platform. Biosens. Bioelectron. 109, 214–223 (2018).

Torres Delgado, S. M., Korvink, J. G. & Mager, D. The eLoaD platform endows centrifugal microfluidics with on-disc power and communication. Biosens. Bioelectron. 117, 464–473 (2018).

Torres Delgado, S. M. et al. Fully automated chemiluminescence detection using an electrified-Lab-on-a-Disc (eLoaD) platform. Lab Chip 16, 4002–4011 (2016).

Zhu, D., Liu, B. & Wei, G. Two-dimensional material-based colorimetric biosensors: a review. Biosensors 11, 259 (2021).

Kaur, B., Kaur, N. & Kumar, S. Colorimetric metal ion sensors — A comprehensive review of the years 2011–2016. Coord. Chem. Rev. 358, 13–69 (2018).

Wu, D. et al. Fluorescent chemosensors: the past, present and future. Chem. Soc. Rev. 46, 7105–7123 (2017).

Shamsipur, M., Barati, A. & Nematifar, Z. Fluorescent pH nanosensors: design strategies and applications. J. Photochem. Photobiol. C Photochem. Rev. 39, 76–141 (2019).

Wolfbeis, O. S. Luminescent sensing and imaging of oxygen: fierce competition to the Clark electrode. BioEssays 37, 921–928 (2015).

Acknowledgements

This work was supported by the Institute for Basic Science, Republic of Korea (IBS-R020-D1) and by the National Science Center, Poland (grant Maestro, no. 2018/30/A/ST5/00529).

Author information

Authors and Affiliations

Contributions

All authors participated in the writing, editing and discussion of the content of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors hold patents related to material synthesis in rotary devices: South Korea Patent Application 10-2019-0008413 (B.A.G. and Y.I.S.), Patent WO2020/153739 (O.C., B.M.-K., Y.I.S. and B.A.G.).

Additional information

Peer review information

Nature Reviews Materials thanks Colin Raston, Nils Paust and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Grzybowski, B.A., Sobolev, Y.I., Cybulski, O. et al. Materials, assemblies and reaction systems under rotation. Nat Rev Mater 7, 338–354 (2022). https://doi.org/10.1038/s41578-021-00404-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41578-021-00404-x

This article is cited by

-

Large-scale assembly of isotropic nanofiber aerogels based on columnar-equiaxed crystal transition

Nature Communications (2023)