Abstract

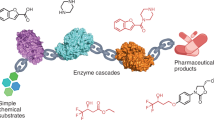

In the past decade, the field of organic synthesis has witnessed tremendous advancements in the areas of photoredox catalysis, electrochemistry, C–H activation, reductive coupling and flow chemistry. While these methods and technologies offer many strategic advantages in streamlining syntheses, their application on the process scale is complicated by several factors. In this Review, we discuss the challenges that arise when these reaction classes and/or flow chemistry technology are taken from a research laboratory operating at the milligram scale to a reactor capable of producing kilograms of product. We discuss how these challenges have been overcome through chemical and engineering solutions. Specifically, this Review will highlight key examples that have led to the production of multi-hundred-gram to kilogram quantities of active pharmaceutical ingredients or their intermediates and will provide insight on the scaling-up process to those developing new technologies and reactions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Campos, K. R. et al. The importance of synthetic chemistry in the pharmaceutical industry. Science 363, eaat0805 (2019).

International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). Quality guidelines. ICH https://www.ich.org/page/quality-guidelines

Akita M. et al. Photocatalysis in Organic Synthesis (Georg Thieme Verlag, 2019).

Prier, C. K., Rankic, D. A. & MacMillan, D. W. C. Visible light photoredox catalysis with transition metal complexes: Applications in organic synthesis. Chem. Rev. 113, 5322–5363 (2013).

Romero, N. A. & Nicewicz, D. A. Organic photoredox catalysis. Chem. Rev. 116, 10075–10166 (2016).

Shaw, M. H., Twilton, J. & MacMillan, D. W. C. Photoredox catalysis in organic chemistry. J. Org. Chem. 81, 6898–6926 (2016).

Beatty, J. W., Douglas, J. J., Cole, K. P. & Stephenson, C. R. J. A scalable and operationally simple radical trifluoromethylation. Nat. Commun. 6, 7919 (2015).

Chu, L. L., Lipshultz, J. M. & MacMillan, D. W. C. Merging photoredox and nickel catalysis: The direct synthesis of ketones by the decarboxylative arylation of α-oxo acids. Angew. Chem. Int. Ed. 54, 7929–7933 (2015).

Cambié, D., Bottecchia, C., Straathof, N. J. W., Hessel, V. & Noël, T. Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment. Chem. Rev. 116, 10276–10341 (2016).

Douglas, J. J., Sevrin, M. J., Cole, K. P. & Stephenson, C. R. J. Preparative scale demonstration and mechanistic investigation of a visible light-mediated radical Smiles rearrangement. Org. Process. Res. Dev. 20, 1148–1155 (2016).

Douglas, J. J., Albright, H., Sevrin, M. J., Cole, K. P. & Stephenson, C. R. J. A visible-light-mediated radical Smiles rearrangement and its application to the synthesis of a difluoro-substituted spirocyclic ORL-1 antagonist. Angew. Chem. Int. Ed. 54, 14898–14902 (2015).

Yayla, H. G. et al. Discovery and mechanistic study of a photocatalytic indoline dehydrogenation for the synthesis of elbasvir. Chem. Sci. 7, 2066–2073 (2016).

Hook, B. D. A. et al. A practical flow reactor for continuous organic photochemistry. J. Org. Chem. 70, 7558–7564 (2005).

Harper, K. C., Moschetta, E. G., Bordawekar, S. V. & Wittenberger, S. J. A laser driven flow chemistry platform for scaling photochemical reactions with visible light. ACS Cent. Sci. 5, 109–115 (2019).

Corcoran, E. B. et al. Aryl amination using ligand-free Ni(II) salts and photoredox catalysis. Science 353, 279–283 (2016).

Corcoran, E. B., McMullen, J. P., Levesque, F., Wismer, M. K. & Naber, J. R. Photon equivalents as a parameter for scaling photoredox reactions in flow: Translation of photocatalytic C–N cross-coupling from lab scale to multikilogram scale. Angew. Chem. Int. Ed. 59, 11964–11968 (2020).

Lévesque, F., Di Maso, M. J., Narsimhan, K., Wismer, M. K. & Naber, J. R. Design of a kilogram scale, plug flow photoreactor enabled by high power LEDs. Org. Process. Res. Dev. 24, 2935–2940 (2020).

Politano, F. & Oksdath-Mansilla, G. Light on the horizon: Current research and future perspectives in flow photochemistry. Org. Process. Res. Dev. 22, 1045–1062 (2018).

Grimm, I. et al. Upscaling photoredox cross-coupling reactions in batch using immersion-well reactors. Org. Process. Res. Dev. 24, 1185–1193 (2020).

Ravetz, B. D. et al. Development of a platform for near-infrared photoredox catalysis. ACS Cent. Sci. 6, 2053–2059 (2020).

Beatty, J. W. et al. Photochemical perfluoroalkylation with pyridine N-oxides: Mechanistic insights and performance on a kilogram scale. Chem 1, 456–472 (2016).

Sezen-Edmonds, M. et al. Predicting performance of photochemical transformations for scaling up in different platforms by combining high-throughput experimentation with computational modeling. Org. Process. Res. Dev. 24, 2128–2138 (2020).

Yan, M., Kawamata, Y. & Baran, P. S. Synthetic organic electrochemical methods since 2000: On the verge of a renaissance. Chem. Rev. 117, 13230–13319 (2017).

Baizer, M. M. Electrolytic reductive coupling. J. Electrochem. Soc. 111, 215 (1964).

Leech, M. C., Garcia, A. D., Petti, A., Dobbs, A. P. & Lam, K. Organic electrosynthesis: From academia to industry. React. Chem. Eng. 5, 977–990 (2020).

Horn, E. J. et al. Scalable and sustainable electrochemical allylic C–H oxidation. Nature 533, 77–81 (2016).

Anastas P. T., Warner J. C. Green Chemistry: Theory and Practice (Oxford Univ. Press, 1998).

Gonella J., [(2-Oxo-3-tetrahydrothienylcarbamoyl)-alkylthio] acetic acids, their salts and esters, a process for preparation thereof and the pharmaceutical compositions containing same. US Patent US4411909A (1983).

Hu K., Hu L. The synthetic method of homocysteinic acid thiolactone hydrochloride. China Patent CN109943860A (2019).

Tereshchenko, O. D. et al. Electrochemical scaled-up synthesis of cyclic enecarbamates as starting materials for medicinal chemistry relevant building bocks. Adv. Synth. Catal. 362, 3229–3242 (2020).

Shono, T., Matsumura, Y. & Tsubata, K. Anodic oxidation of N-carbomethoxypyrrolidine: 2-methoxy-N-carbomethoxypyrrolidine. Org. Synth. 63, 206 (1985).

Bärfacker, L. et al. Discovery of BAY 94-8862: A nonsteroidal antagonist of the mineralocorticoid receptor for the treatment of cardiorenal diseases. ChemMedChem 7, 1385–1403 (2012).

Gütz, C., Stenglein, A. & Waldvogel, S. R. Highly modular flow cell for electroorganic synthesis. Org. Process. Res. Dev. 21, 771–778 (2017).

Li, H. et al. Ni-catalyzed electrochemical decarboxylative C–C couplings in batch and continuous flow. Org. Lett. 20, 1338–1341 (2018).

Wilberforce, T. & Olabi, A. G. Design of experiment (DOE) analysis of 5-cell stack fuel cell using three bipolar plate geometry designs. Sustainability. 12, 4488 (2020).

Egbert, J. D. et al. Development and scale-up of continuous electrocatalytic hydrogenation of functionalized nitro arenes, nitriles, and unsaturated aldehydes. Org. Process. Res. Dev. 23, 1803–1812 (2019).

Peters, B. K. et al. Scalable and safe synthetic organic electroreduction inspired by Li-ion battery chemistry. Science 363, 838–845 (2019).

Joshi, D. K., Sutton, J. W., Carver, S. & Blanchard, J. P. Experiences with commercial production scale operation of dissolving metal reduction using lithium metal and liquid ammonia. Org. Process. Res. Dev. 9, 997–1002 (2005).

Ishifune, M. et al. Electroreduction of aromatics using magnesium electrodes in aprotic solvents containing alcoholic proton donors. Electrochim. Acta 48, 2405–2409 (2003).

Huang, J. K. et al. A highly efficient palladium/copper cocatalytic system for direct arylation of heteroarenes: An unexpected effect of Cu(Xantphos)I. J. Am. Chem. Soc. 132, 3674–3675 (2010).

Caille, S. et al. Molecular complexity as a driver for chemical process innovation in the pharmaceutical industry. J. Org. Chem. 84, 4583–4603 (2019).

Ouellet, S. G. et al. Preparative scale synthesis of the biaryl core of anacetrapib via a ruthenium-catalyzed direct arylation reaction: Unexpected effect of solvent impurity on the arylation reaction. J. Org. Chem. 76, 1436–1439 (2011).

Ackermann, L. & Mulzer, M. Dehydrative direct arylations of arenes with phenols via ruthenium-catalyzed C–H and C–OH bond functionalizations. Org. Lett. 10, 5043–5045 (2008).

Arockiam, P., Poirier, V., Fischmeister, C., Bruneau, C. & Dixneuf, P. H. Diethyl carbonate as a solvent for ruthenium catalyzed C–H bond functionalization. Green Chem. 11, 1871–1875 (2009).

Pozgan, F. & Dixneuf, P. H. Ruthenium(II) acetate catalyst for direct functionalisation of sp2-C–H bonds with aryl chlorides and access to tris-heterocyclic molecules. Adv. Synth. Catal. 351, 1737–1743 (2009).

Bien, J. et al. The first kilogram synthesis of beclabuvir, an HCV NS5B polymerase inhibitor. Org. Process. Res. Dev. 22, 1393–1408 (2018).

Fox, R. J. et al. C–H arylation in the formation of a complex pyrrolopyridine, the commercial synthesis of the potent JAK2 inhibitor, BMS-911543. J. Org. Chem. 84, 4661–4669 (2019).

Wisniewski, S. R. et al. Utilizing native directing groups: Synthesis of a selective IKur inhibitor, BMS-919373, via a regioselective C–H arylation. J. Org. Chem. 84, 4704–4714 (2019).

Wisniewski, S. R. et al. Using native directing groups: Mechanistic understanding of a direct arylation leads to formation of tetracyclic heterocycles via tandem intermolecular, intramolecular C–H activation. J. Org. Chem. 84, 7961–7970 (2019).

Zhang, H. M. et al. Convergent synthesis of PI3K inhibitor GDC-0908 featuring palladium-catalyzed direct C–H arylation toward dihydrobenzothienooxepines. J. Org. Chem. 84, 4796–4802 (2019).

Arrington, K. et al. Convergent synthesis of the NS5B inhibitor GSK8175 enabled by transition metal catalysis. J. Org. Chem. 84, 4680–4694 (2019).

Campeau, L.-C. et al. A robust kilo-scale synthesis of doravirine. Org. Process. Res. Dev. 20, 1476–1481 (2016).

Knappke, C. E. I. et al. Reductive cross-coupling reactions between two electrophiles. Chem. Eur. J. 20, 6828–6842 (2014).

Everson, D. A. & Weix, D. J. Cross-electrophile coupling: Principles of reactivity and selectivity. J. Org. Chem. 79, 4793–4798 (2014).

Gu, J., Wang, X., Xue, W. C. & Gong, H. G. Nickel-catalyzed reductive coupling of alkyl halides with other electrophiles: Concept and mechanistic considerations. Org. Chem. Front. 2, 1411–1421 (2015).

Moragas, T., Correa, A. & Martin, R. Metal-catalyzed reductive coupling reactions of organic halides with carbonyl-type compounds. Chem. Eur. J. 20, 8242–8258 (2014).

Richmond, E. & Moran, J. Recent advances in nickel catalysis enabled by stoichiometric metallic reducing agents. Synthesis. 50, 499–513 (2018).

Weix, D. J. Methods and mechanisms for cross-electrophile coupling of Csp2 halides with alkyl electrophiles. Acc. Chem. Res. 48, 1767–1775 (2015).

Goldfogel M. J., Huang, L., Weix, D. J. in Nickel Catalysis in Organic Synthesis (ed. Ogoshi, S.) 183-222 (Wiley-VCH, 2020).

Biswas, S. et al. Nickel-catalyzed cross-electrophile reductive couplings of neopentyl bromides with aryl bromides. J. Org. Chem. 85, 8214–8220 (2020).

Hughes, J. M. E. & Fier, P. S. Desulfonylative arylation of redox-active alkyl sulfones with aryl bromides. Org. Lett. 21, 5650–5654 (2019).

Mennie, K. M., Vara, B. A. & Levi, S. M. Reductive sp3–sp2 coupling reactions enable late-stage modification of pharmaceuticals. Org. Lett. 22, 556–559 (2020).

Kim, S., Goldfogel, M. J., Gilbert, M. M. & Weix, D. J. Nickel-catalyzed cross-electrophile coupling of aryl chlorides with primary alkyl chlorides. J. Am. Chem. Soc. 142, 9902–9907 (2020).

Hansen, E. C. et al. New ligands for nickel catalysis from diverse pharmaceutical heterocycle libraries. Nat. Chem. 8, 1126–1130 (2016).

Liao, J. et al. Deaminative reductive cross-electrophile couplings of alkylpyridinium salts and aryl bromides. Org. Lett. 21, 2941–2946 (2019).

Nimmagadda, K. et al. Development and execution of an Ni(II)-catalyzed reductive cross-coupling of substituted 2-chloropyridine and ethyl 3-chloropropanoate. Org. Process. Res. Dev. 24, 1141–1148 (2020).

Grenville, R. K., Mak, A. T. C. & Brown, D. A. R. Suspension of solid particles in vessels agitated by axial flow impellers. Chem. Eng. Res. Des. 100, 282–291 (2015).

Zwietering, T. N. Suspending of solid particles in liquid by agitators. Chem. Eng. Sci. 8, 244–253 (1958).

Watanabe, E., Chen, Y. D., May, O. & Ley, S. V. A practical method for continuous production of sp3-rich compounds from (hetero)aryl halides and redox-active esters. Chem. Eur. J. 26, 186–191 (2020).

Perkins, R. J., Hughes, A. J., Weix, D. J. & Hansen, E. C. Metal-reductant-free electrochemical nickel-catalyzed couplings of aryl and alkyl bromides in acetonitrile. Org. Process. Res. Dev. 23, 1746–1751 (2019).

Kumar, G. S. et al. Nickel-catalyzed chain-walking cross-electrophile coupling of alkyl and aryl halides and olefin hydroarylation enabled by electrochemical reduction. Angew. Chem. Int. Ed. 59, 6513–6519 (2020).

Broggi, J., Terme, T. & Vanelle, P. Organic electron donors as powerful single-electron reducing agents in organic synthesis. Angew. Chem. Int. Ed. 53, 384–413 (2014).

Suzuki, N., Hofstra, J. L., Poremba, K. E. & Reisman, S. E. Nickel-catalyzed enantioselective cross-coupling of N-hydroxyphthalimide esters with vinyl bromides. Org. Lett. 19, 2150–2153 (2017).

David, C., Emily, L. B., Nilay, H., Mycah, R. U. & Susan, L. Z. A widely applicable dual-catalytic system for cross-electrophile coupling. ACS Catal. 10, 12642–12656 (2020).

Baumann, M., Moody, T. S., Smyth, M. & Wharry, S. A perspective on continuous flow chemistry in the pharmaceutical industry. Org. Process. Res. Dev. 24, 1802–1813 (2020).

Teoh, S. K., Rathi, C. & Sharratt, P. Practical assessment methodology for converting fine chemicals processes from batch to continuous. Org. Process. Res. Dev. 20, 414–431 (2016).

Cole, K. P. et al. Kilogram-scale prexasertib monolactate monohydrate synthesis under continuous-flow CGMP conditions. Science 356, 1144–1150 (2017).

Brewer, A. C. et al. Development and scale-up of a continuous aerobic oxidative Chan–Lam coupling. Org. Process. Res. Dev. 23, 1484–1498 (2019).

Broom, T. et al. The synthesis of bromomethyltrifluoroborates through continuous flow chemistry. Org. Process. Res. Dev. 18, 1354–1359 (2014).

Laue, S., Haverkamp, V. & Mleczko, L. Experience with scale-up of low-temperature organometallic reactions in continuous flow. Org. Process. Res. Dev. 20, 480–486 (2016).

Wong, S. W. et al. Operation strategy development for Grignard reaction in a continuous stirred tank reactor. Org. Process. Res. Dev. 20, 540–550 (2016).

Thaisrivongs, D. A., Naber, J. R. & McMullen, J. P. Using flow to outpace fast proton transfer in an organometallic reaction for the manufacture of verubecestat (MK-8931). Org. Process. Res. Dev. 20, 1997–2004 (2016).

Thaisrivongs, D. A., Naber, J. R., Rogus, N. J. & Spencer, G. Development of an organometallic flow chemistry reaction at pilot-plant scale for the manufacture of verubecestat. Org. Process. Res. Dev. 22, 403–408 (2018).

Susanne, F. et al. Match-making reactors to chemistry: A continuous manufacturing enabled sequence to a key benzoxazole pharmaceutical intermediate. Org. Process. Res. Dev. 21, 1779–1793 (2017).

Stueckler, C. et al. Development of a continuous flow process for a Matteson reaction: From lab scale to full-scale production of a pharmaceutical intermediate. Org. Process. Res. Dev. 23, 1069–1077 (2019).

Li, P. et al. Continuous flow conditions for high temperature formation of a benzodioxan pharmaceutical intermediate: rapid scaleup for early phase material delivery. Org. Process. Res. Dev. 24, 1938–1947 (2020).

Levterov, V. V. et al. Photochemical in-flow synthesis of 2,4-methanopyrrolidines: Pyrrolidine analogues with improved water solubility and reduced lipophilicity. J. Org. Chem. 83, 14350–14361 (2018).

Williams, J. D. et al. Finding the perfect match: A combined computational and experimental study toward efficient and scalable photosensitized [2 + 2] cycloadditions in flow. Org. Process. Res. Dev. 23, 78–87 (2019).

Beaver, M. G. et al. Development and execution of a production-scale continuous [2 + 2] photocycloaddition. Org. Process. Res. Dev. 24, 2139–2146 (2020).

McMullen, J. P. et al. Development and scale-up of a continuous reaction for production of an active pharmaceutical ingredient intermediate. Org. Process. Res. Dev. 22, 1208–1213 (2018).

Noël T., Su Y., Hessel V. in Organometallic Flow Chemistry (ed. Noël T.) 1-41 (Springer, 2016).

Di Maso, M. J. et al. Development of a green and sustainable manufacturing process for gefapixant citrate (MK-7264). Part 5: completion of the API free base via a direct chlorosulfonylation process. Org. Process. Res. Dev. 24, 2491–2497 (2020).

Devine, P. N. et al. Extending the application of biocatalysis to meet the challenges of drug development. Nat. Rev. Chem. 2, 409–421 (2018).

Huffman, M. A. et al. Design of an in vitro biocatalytic cascade for the manufacture of islatravir. Science 366, 1255–1259 (2019).

Acknowledgements

We thank F. Levesque, K. Xiao, J. Hughes, D. Schultz and D. Lehnherr for their help in reviewing this manuscript.

Author information

Authors and Affiliations

Contributions

K.L., P.S.F. and K.M.M. contributed to the literature search for the article. K.L. contributed to the writing of the article and the preparation of figures. P.S.F. and K.M.M. contributed to the editing of the manuscript, coordinated the project and supervised the writing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information

Nature Reviews Chemistry thanks A. Peneau and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Glossary

- Process mass intensity

-

(PMI). The ratio between the mass of raw material input and the mass of desired output.

- Continuous stirred-tank reactor

-

(CSTR). A reactor run at steady state with a continuous flow of reactants and products. With continuous stirring, reaction conditions do not change over time.

- Plug flow reactors

-

(PFRs). Tubular reactors run with a constant flow of reactants and products, without stirring and with materials travelling linearly as a plug of fluid.

- Immersion well

-

(IW). A fixed-volume batch reactor with an inner jacketed well to house a light source. The reaction mixture is irradiated from within the reactor set-up.

- Undivided cell

-

An electrochemical cell where the anode and the cathode are housed in the same chamber.

- Process greenness score

-

(PGS). A calculation used by industrial companies to evaluate the potential environmental impact of chemical manufacturing processes. A higher score indicates a greener reaction.

- Redox flow batteries

-

Electrochemical cells that generate chemical energy by pumping separated anolyte and catholyte solutions across an ion-selective membrane placed in between two electrodes.

- Turbulent flow

-

A type of fluid flow characterized by chaotic changes in the direction and magnitude of flow as a result of changes in pressure and flow velocity.

- Divided cells

-

Electrochemical cells where the anode and the cathode are housed in different chambers, separated by an ion-permeable membrane or salt bridge.

- Overcharge protectant

-

A redox shuttle reagent that consumes excess current generated by the system.

- Just suspended speed

-

The impeller speed where no solids remain stationary for more than 2 s. A value used in process scale-up to predict the ideal agitation rate.

- Assay yield

-

(AY). The ratio of reaction selectivity towards the desired product (%) to conversion of the starting material (%).

- Scaled up

-

In flow chemistry, increasing the size of a flow reactor while maintaining the same reactor design.

- Scaled out

-

In flow chemistry, increasing the reaction time of a flow process while maintaining the same reactor size and design.

- Numbered up

-

In flow chemistry, increasing the number of flow reactors of the same size and design to create a system of parallel reactors.

- Good manufacturing practices

-

Regulations implemented by the US Food and Drug Administration that require manufacturers to ensure their products are safe, pure and effective.

- Reynolds number

-

The ratio of density, flow speed and the characteristic length of the system to the dynamic viscosity of the fluid. Used to predict flow patterns.

- Transitional flow

-

A mixture of turbulent flow towards the centre of the pipe and laminar flow, where fluid particles follow smooth paths in layers, on the edges.

Rights and permissions

About this article

Cite this article

Lovato, K., Fier, P.S. & Maloney, K.M. The application of modern reactions in large-scale synthesis. Nat Rev Chem 5, 546–563 (2021). https://doi.org/10.1038/s41570-021-00288-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41570-021-00288-z

This article is cited by

-

Red light-driven electron sacrificial agents-free photoreduction of inert aryl halides via triplet-triplet annihilation

Nature Communications (2023)

-

Poly(heptazine imide) ligand exchange enables remarkable low catalyst loadings in heterogeneous metallaphotocatalysis

Nature Communications (2023)

-

Exploring metallic and plastic 3D printed photochemical reactors for customizing chemical synthesis

Scientific Reports (2022)