Abstract

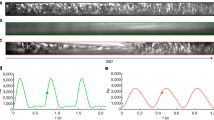

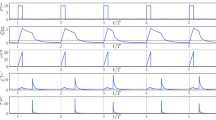

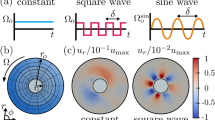

Turbulence is the major cause of friction losses in transport processes and it is responsible for a drastic drag increase in flows over bounding surfaces. While much effort is invested into developing ways to control and reduce turbulence intensities1,2,3, so far no methods exist to altogether eliminate turbulence if velocities are sufficiently large. We demonstrate for pipe flow that appropriate distortions to the velocity profile lead to a complete collapse of turbulence and subsequently friction losses are reduced by as much as 90%. Counterintuitively, the return to laminar motion is accomplished by initially increasing turbulence intensities or by transiently amplifying wall shear. Since neither the Reynolds number nor the shear stresses decrease (the latter often increase), these measures are not indicative of turbulence collapse. Instead, an amplification mechanism4,5 measuring the interaction between eddies and the mean shear is found to set a threshold below which turbulence is suppressed beyond recovery.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lumley, J. & Blossey, P. Control of turbulence. Ann. Rev. Fluid Mech. 30, 311–327 (1998).

Kasagi, N., Suzuki, Y. & Fukagata, K. Microelectromechanical systems-based feedback control of turbulence for skin friction reduction. Ann. Rev. Fluid Mech. 41, 231–251 (2009).

Kim, J. & Bewley, T. R. A linear systems approach to flow control. Ann. Rev. Fluid Mech. 39, 383–417 (2007).

Trefethen, L. N., Trefethen, A. E., Reddy, S. C. & Driscoll, T. A. Hydrodynamic stability without eigenvalues. Science 261, 578–584 (1993).

Brandt, L. The lift-up effect: The linear mechanism behind transition and turbulence in shear flows. Eur. J. Mech. B 47, 80–96 (2014).

Avila, K. et al. The onset of turbulence in pipe flow. Science 333, 192–196 (2011).

Bewley, T. R., Moin, P. & Temam, R. DNS-based predictive control of turbulence: an optimal benchmark for feedback algorithms. J. Fluid Mech. 447, 179–225 (2001).

Högberg, M., Bewley, T. R. & Henningson, D. S. Relaminarization of Reτ = 100 turbulence using gain scheduling and linear state-feedback control. Phys. Fluids 15, 3572–3575 (2003).

Auteri, F., Baron, A., Belan, M., Campanardi, G. & Quadrio, M. Experimental assessment of drag reduction by traveling waves in a turbulent pipe flow. Phys. Fluids 22, 115103 (2010).

Lieu, B., Moarref, R. & Jovanović, M. Controlling the onset of turbulence by streamwise travelling waves. Part 2. Direct numerical simulation. J. Fluid Mech. 663, 100–119 (2010).

Moarref, R. & Jovanović, M. Controlling the onset of turbulence by streamwise travelling waves. Part 1. Receptivity analysis. J. Fluid Mech. 663, 70–99 (2010).

Quadrio, M., Ricco, P. & Viotti, C. Streamwise-traveling waves of spanwise wall velocity for turbulent drag reduction. J. Fluid Mech. 627, 161–178 (2009).

Hof, B., De Lozar, A., Avila, M., Tu, X. Y. & Schneider, T. M. Eliminating turbulence in spatially intermittent flows. Science 327, 1491–1494 (2010).

Rathnasingham, R. & Breuer, K. Active control of turbulent boundary layers. J. Fluid Mech. 495, 209–233 (2003).

Willis, A. P., Hwang, Y. & Cossu, C. Optimally amplified large-scale streaks and drag reduction in turbulent pipe flow. Phys. Rev. E 82, 036321 (2010).

Du, Y. & Karniadakis, G. E. Suppressing wall turbulence by means of a transverse traveling wave. Science 288, 1230–1234 (2000).

Min, T., Kang, S. M., Speyer, J. L. & Kim, J. Sustained sub-laminar drag in a fully developed channel flow. J. Fluid Mech. 558, 309–318 (2006).

Park, J. & Choi, H. Effects of uniform blowing or suction from a spanwise slot on a turbulent boundary layer flow. Phys. Fluids 11, 3095–3105 (1999).

Sumitani, Y. & Kasagi, N. Direct numerical simulation of turbulent transport with uniform wall injection and suction. AIAA J. 33, 1220–1228 (1995).

Fukagata, K., Iwamoto, K. & Kasagi, N. Contribution of Reynolds stress distribution to the skin friction in wall-bounded flows. Phys. Fluids 14, 73–76 (2002).

Fransson, J. H. M. & Alfredsson, P. H. On the disturbance growth in an asymptotic suction boundary layer. J. Fluid Mech. 482, 51–90 (2003).

Matisse, P. & Gorman, M. Neutrally buoyant anisotropic particles for flow visualization. Phys. Fluids 27, 759–760 (1984).

Willis, A. P. The Openpipeflow Navier–Stokes solver. SoftwareX 6, 124–127 (2017).

Avila, M., Willis, A. P. & Hof, B. On the transient nature of localized pipe flow turbulence. J. Fluid Mech. 646, 127–136 (2010).

Barkley, D. et al. The rise of fully turbulent flow. Nature 526, 550–553 (2015).

Willis, A. & Kerswell, R. Turbulent dynamics of pipe flow captured in a reduced model: puff relaminarization and localized ‘edge’ states. J. Fluid Mech. 619, 213–233 (2009).

Jimenez, J. & Pinelli, A. The autonomous cycle of near-wall turbulence. J. Fluid Mech. 389, 335–359 (1999).

Acknowledgements

We acknowledge the European Research Council under the European Union’s Seventh Framework Programme (FP/2007-2013)/ERC Grant Agreement 306589, the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (grant agreement no. 737549) and the Deutsche Forschungsgemeinschaft (Project No. FOR 1182) for financial support. We thank our technician P. Maier for providing highly valuable ideas and greatly supporting us in all technical aspects. We thank M. Schaner for technical drawings, construction and design. We thank M. Schwegel for a Matlab code to post-process experimental data.

Author information

Authors and Affiliations

Contributions

J.K. and B.H. designed the experiments. J.K. and D.S. carried out the experiments and post-processed the data. M.R. carried out the rotor experiments. J.K., D.S. and B.H. analysed the experimental results. J.K. and B.H. supervised the experimental work. B.S. and N.B.B. performed the computer simulations of the Navier–Stokes equations. B.S., M.A. and N.B.B. analysed the numerical results. M.A., A.P.W. and B.H. supervised the computer simulations. D.S., A.P.W., M.A. and B.S. performed the theoretical analysis. J.K., B.S., D.S., M.A. and B.H. wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Destabilizing turbulence in pipe flow.

Videos

Supplementary Movie

Relaminarization by vigorously stirring a turbulent pipe flow with four rotors.

Supplementary Movie

Relaminarization by impulsive movement of a pipe segment.

Rights and permissions

About this article

Cite this article

Kühnen, J., Song, B., Scarselli, D. et al. Destabilizing turbulence in pipe flow. Nature Phys 14, 386–390 (2018). https://doi.org/10.1038/s41567-017-0018-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41567-017-0018-3

This article is cited by

-

Magnetic fluid film enables almost complete drag reduction across laminar and turbulent flow regimes

Communications Physics (2024)

-

Application of a hydrophobic coating to a pressurized pipe and its effect on energy losses and fluid flow profile

Scientific Reports (2024)

-

Turbulence suppression by cardiac-cycle-inspired driving of pipe flow

Nature (2023)

-

Saving energy in turbulent flows with unsteady pumping

Scientific Reports (2023)

-

Interfacial friction at action: Interactions, regulation, and applications

Friction (2023)