Abstract

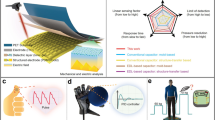

Artificial pressure sensors often use soft materials to achieve skin-like softness, but the viscoelastic creep of soft materials and the ion leakage, specifically for ionic conductors, cause signal drift and inaccurate measurement. Here we report drift-free iontronic sensing by designing and copolymerizing a leakage-free and creep-free polyelectrolyte elastomer containing two types of segments: charged segments having fixed cations to prevent ion leakage and neutral slippery segments with a high crosslink density for low creep. We show that an iontronic sensor using the polyelectrolyte elastomer barely drifts under an ultrahigh static pressure of 500 kPa (close to its Young’s modulus), exhibits a drift rate two to three orders of magnitude lower than that of the sensors adopting conventional ionic conductors and enables steady and accurate control for robotic manipulation. Such drift-free iontronic sensing represents a step towards highly accurate sensing in robotics and beyond.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available at https://doi.org/10.6084/m9.figshare.25266307.

References

Luh, J., Fisher, W. & Paul, R. Joint torque control by a direct feedback for industrial robots. IEEE Trans. Autom. Control 28, 153–161 (1983).

Cheng, G. et al. A comprehensive realization of robot skin: sensors, sensing, control, and applications. Proc. IEEE 107, 2034–2051 (2019).

Dahiya, R. E-Skin: from humanoids to humans (point of view). Proc. IEEE 107, 247–252 (2019).

Cho, A., Kim, J., Lee, S. & Kee, C. Wind estimation and airspeed calibration using a UAV with a single-antenna GPS receiver and pitot tube. IEEE Trans. Aerosp. Electron. Syst. 47, 109–117 (2011).

Xu, Z. et al. Digital mapping of surface turbulence status and aerodynamic stall on wings of a flying aircraft. Nat. Commun. 14, 2792 (2023).

Yang, S. et al. A survey of intelligent tires for tire-road interaction recognition toward autonomous vehicles. IEEE Trans. Intell. Veh. 7, 520–532 (2022).

Liu, Y. et al. Electronic skin as wireless human–machine interfaces for robotic VR. Sci. Adv. 8, eabl6700 (2022).

Zhu, M. L. et al. Haptic-feedback smart glove as a creative human–machine interface (HMI) for virtual/augmented reality applications. Sci. Adv. 6, eaaz8693 (2020).

Sun, Z., Zhu, M., Shan, X. & Lee, C. Augmented tactile-perception and haptic-feedback rings as human–machine interfaces aiming for immersive interactions. Nat. Commun. 13, 5224 (2022).

Chortos, A., Liu, J. & Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 15, 937–950 (2016).

Kang, S.-K. et al. Bioresorbable silicon electronic sensors for the brain. Nature 530, 71–76 (2016).

Wang, L. et al. A review of wearable sensor systems to monitor plantar loading in the assessment of diabetic foot ulcers. IEEE Trans. Biomed. Eng. 67, 1989–2004 (2020).

Su, Q. et al. A stretchable and strain-unperturbed pressure sensor for motion interference-free tactile monitoring on skins. Sci. Adv. 7, eabi4563 (2021).

Lee, S. et al. Nanomesh pressure sensor for monitoring finger manipulation without sensory interference. Science 370, 966–970 (2020).

Boutry, C. M. et al. A stretchable and biodegradable strain and pressure sensor for orthopaedic application. Nat. Electron. 1, 314–321 (2018).

Yang, C. & Suo, Z. Hydrogel ionotronics. Nat. Rev. Mater. 3, 125–142 (2018).

Chang, Y. et al. First decade of interfacial iontronic sensing: from droplet sensors to artificial skins. Adv. Mater. 33, 2003464 (2021).

Lee, H. R., Kim, C. C. & Sun, J. Y. Stretchable ionics—a promising candidate for upcoming wearable devices. Adv. Mater. 30, 1704403 (2018).

Yuan, Y. et al. Microstructured polyelectrolyte elastomer-based ionotronic sensors with high sensitivities and excellent stability for artificial skins. Adv. Mater. https://doi.org/10.1002/adma.202310429 (2023).

Sun, T. L. et al. Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat. Mater. 12, 932–937 (2013).

Leocmach, M., Perge, C., Divoux, T. & Manneville, S. Creep and fracture of a protein gel under stress. Phys. Rev. Lett. 113, 038303 (2014).

Rubinstein, M. & Colby, R. H. Polymer Physics (Oxford Univ., 2003).

Biot, M. A. General theory of three‐dimensional consolidation. J. Appl. Phys. 12, 155–164 (1941).

Zhu, J. & Liu, Q. The osmocapillary effect on a rough gel surface. J. Mech. Phys. Solids 170, 105124 (2023).

Karobi, S. N. et al. Creep behavior and delayed fracture of tough polyampholyte hydrogels by tensile test. Macromolecules 49, 5630–5636 (2016).

Zhou, Y. et al. The stiffness-threshold conflict in polymer networks and a resolution. J. Appl. Mech. 87, 031002 (2020).

Choi, J.-H., Xie, W., Gu, Y., Frisbie, C. D. & Lodge, T. P. Single ion conducting, polymerized ionic liquid triblock copolymer films: high capacitance electrolyte gates for n-type transistors. ACS Appl. Mater. Interfaces 7, 7294–7302 (2015).

Kim, H. J., Chen, B., Suo, Z. & Hayward, R. C. Ionoelastomer junctions between polymer networks of fixed anions and cations. Science 367, 773–776 (2020).

Fan, F. et al. Effect of molecular weight on the ion transport mechanism in polymerized ionic liquids. Macromolecules 49, 4557–4570 (2016).

Yang, R. et al. Iontronic pressure sensor with high sensitivity over ultra-broad linear range enabled by laser-induced gradient micro-pyramids. Nat. Commun. 14, 2907 (2023).

Bai, N. et al. Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity. Nat. Commun. 11, 209 (2020).

Zhang, Y. et al. Highly stable flexible pressure sensors with a quasi-homogeneous composition and interlinked interfaces. Nat. Commun. 13, 1317 (2022).

Mannsfeld, S. C. B. et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 9, 859–864 (2010).

Yiming, B. et al. A mechanically robust and versatile liquid‐free ionic conductive elastomer. Adv. Mater. 33, 2006111 (2021).

Nie, B., Li, R., Cao, J., Brandt, J. D. & Pan, T. Flexible transparent iontronic film for interfacial capacitive pressure sensing. Adv. Mater. 27, 6055–6062 (2015).

Cui, X. et al. Flexible and breathable all-nanofiber iontronic pressure sensors with ultraviolet shielding and antibacterial performances for wearable electronics. Nano Energy 95, 107022 (2022).

Yu, X. et al. Ultra-tough waterborne polyurethane-based graft-copolymerized piezoresistive composite designed for rehabilitation training monitoring pressure sensors. Small 19, 2303095 (2023).

Bai, N. et al. Graded interlocks for iontronic pressure sensors with high sensitivity and high linearity over a broad range. ACS Nano. 16, 4338–4347 (2022).

Li, P. et al. Skin-inspired large area iontronic pressure sensor with ultra-broad range and high sensitivity. Nano Energy 101, 107571 (2022).

Shi, J. et al. Embedment of sensing elements for robust, highly sensitive, and cross-talk–free iontronic skins for robotics applications. Sci. Adv. 9, eadf8831 (2023).

Terabe, H. et al. in Proc. International Solid State Sensors and Actuators Conference (Transducers’ 97) Vol. 2 1481–1484 (IEEE, 1997).

Lu, P. et al. Iontronic pressure sensor with high sensitivity and linear response over a wide pressure range based on soft micropillared electrodes. Sci. Bull. 66, 1091–1100 (2021).

Chen, X. et al. Channel-crack-designed suspended sensing membrane as a fully flexible vibration sensor with high sensitivity and dynamic range. ACS Appl. Mater. Interfaces 13, 34637–34647 (2021).

Ha, K.-H. et al. Highly sensitive capacitive pressure sensors over a wide pressure range enabled by the hybrid responses of a highly porous nanocomposite. Adv. Mater. 33, 2103320 (2021).

Docherty, K. M. & Kulpa, C. F. Jr Toxicity and antimicrobial activity of imidazolium and pyridinium ionic liquids. Green. Chem. 7, 185–189 (2005).

Rivlin, R. & Thomas, A. G. Rupture of rubber. I. Characteristic energy for tearing. J. Polym. Sci. 10, 291–318 (1953).

Acknowledgements

The work is supported by National Key Research and Development Program of China (grants 2023YFB3812500), the National Natural Science Foundation of China (nos. T2225017, 12302212 and 52073138), the Science, Technology, and Innovation Commission of Shenzhen Municipality (ZDSYS20210623092005017), the Science Technology and Innovation Committee of Shenzhen Municipality (no. JCYJ20220530114810024), the Shenzhen Sci-Tech Fund (no. YTDPT20181011104007) and the Guangdong Provincial Key Laboratory Program (no. 2021B1212040001). The authors acknowledge the assistance of SUSTech Core Research Facilities.

Author information

Authors and Affiliations

Contributions

C.Y. and C.F.G. conceived the idea and designed the research. Y.H. designed, synthesized and characterized the polyelectrolyte elastomer. Y.C. designed, fabricated and characterized the drift-free iontronic sensor. Y.H. designed and performed the closed-loop robotic manipulation. C.Y. and C.F.G. drafted the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Huanyu Cheng and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1 and 2, Figs. 1–35, Tables 1–4 and descriptions of Movies 1–7.

Supplementary Video 1

Clamping of a steel block of the gripper with a PEE-based sensor.

Supplementary Video 2

Clamping of a steel block of the gripper with an ionogel-based sensor.

Supplementary Video 3

Clamping of a cherry tomato of the gripper with a PEE-based sensor.

Supplementary Video 4

Clamping of a cherry tomato of the gripper with an ionogel-based sensor.

Supplementary Video 5

Clamping of a cherry tomato of the gripper with a hydrogel-based sensor.

Supplementary Video 6

Effect of β on creep behaviour.

Supplementary Video 7

Creep behaviours under a high/low pressure/modulus ratio.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, Y., Cheng, Y., Yang, C. et al. Creep-free polyelectrolyte elastomer for drift-free iontronic sensing. Nat. Mater. (2024). https://doi.org/10.1038/s41563-024-01848-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41563-024-01848-6