Abstract

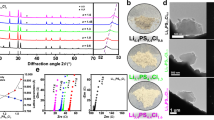

Designing a stable solid–electrolyte interphase on a Li anode is imperative to developing reliable Li metal batteries. Herein, we report a suspension electrolyte design that modifies the Li+ solvation environment in liquid electrolytes and creates inorganic-rich solid–electrolyte interphases on Li. Li2O nanoparticles suspended in liquid electrolytes were investigated as a proof of concept. Through theoretical and empirical analyses of Li2O suspension electrolytes, the roles played by Li2O in the liquid electrolyte and solid–electrolyte interphases of the Li anode are elucidated. Also, the suspension electrolyte design is applied in conventional and state-of-the-art high-performance electrolytes to demonstrate its applicability. Based on electrochemical analyses, improved Coulombic efficiency (up to ~99.7%), reduced Li nucleation overpotential, stabilized Li interphases and prolonged cycle life of anode-free cells (~70 cycles at 80% of initial capacity) were achieved with the suspension electrolytes. We expect this design principle and our findings to be expanded into developing electrolytes and solid–electrolyte interphases for Li metal batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that all the data and relevant information are available within the article and Supplementary Information. Additional data are available from the corresponding author upon reasonable request.

Code availability

The MD and DFT simulation codes are available at https://github.com/prudnick94/LiSolvation_Li2OSuspension and https://github.com/exenGT/Li2O, respectively.

References

Xiao, J. et al. Understanding and applying Coulombic efficiency in lithium metal batteries. Nat. Energy 5, 561–568 (2020).

Zheng, J. et al. Regulating electrodeposition morphology of lithium: towards commercially relevant secondary Li metal batteries. Chem. Soc. Rev. 49, 2701–2750 (2020).

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Wu, H., Jia, H., Wang, C., Zhang, J. G. & Xu, W. Recent progress in understanding solid electrolyte interphase on lithium metal anodes. Advanced Energy Materials 11, 2003092 (2021).

Zachman, M. J., Tu, Z., Choudhury, S., Archer, L. A. & Kourkoutis, L. F. Cryo-STEM mapping of solid–liquid interfaces and dendrites in lithium-metal batteries. Nature 560, 345–349 (2018).

Li, Y. et al. Correlating structure and function of battery interphases at atomic resolution using cryoelectron microscopy. Joule 2, 2167–2177 (2018).

Li, Y. et al. Atomic structure of sensitive battery materials and interfaces revealed by cryo–electron microscopy. Science 358, 506–510 (2017).

Shadike, Z. et al. Identification of LiH and nanocrystalline LiF in the solid–electrolyte interphase of lithium metal anodes. Nat. Nanotechnol. https://doi.org/10.1038/s41565-020-00845-5 (2021).

Boyle, D. T. et al. Corrosion of lithium metal anodes during calendar ageing and its microscopic origins. Nat. Energy https://doi.org/10.1038/s41560-021-00787-9 (2021).

Xu, K. Electrolytes and interphases in Li-ion batteries and beyond. Chem. Rev. 114, 11503–11618 (2014).

Cao, X. et al. Monolithic solid–electrolyte interphases formed in fluorinated orthoformate-based electrolytes minimize Li depletion and pulverization. Nat. Energy 4, 796–805 (2019).

Fan, X. et al. Non-flammable electrolyte enables Li-metal batteries with aggressive cathode chemistries. Nat. Nanotechnol. 13, 715–722 (2018).

Zhang, X. Q. et al. Regulating anions in the solvation sheath of lithium ions for stable lithium metal batteries. ACS Energy Lett. 4, 411–416 (2019).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Yuan, S. et al. Salt-rich solid electrolyte interphase for safer high-energy-density Li metal batteries with limited Li excess. Chem. Commun. 56, 8257–8260 (2020).

Yamada, Y., Wang, J., Ko, S., Watanabe, E. & Yamada, A. Advances and issues in developing salt-concentrated battery electrolytes. Nat. Energy 4, 269–280 (2019).

Fan, X. et al. Highly fluorinated interphases enable high-voltage Li-metal batteries. Chem 4, 174–185 (2018).

Qian, J. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Suo, L. et al. “Water-in-salt” electrolyte enables high-voltage aqueous lithium-ion chemistries. Science 350, 938–943 (2015).

Ren, X. et al. Enabling high-voltage lithium-metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Chen, S. et al. High-voltage lithium-metal batteries enabled by localized high-concentration electrolytes. Adv. Mater. 30, 1706102 (2018).

Chen, S. et al. High-efficiency lithium metal batteries with fire-retardant electrolytes. Joule 2, 1548–1558 (2018).

Amanchukwu, C. V., Kong, X., Qin, J., Cui, Y. & Bao, Z. Nonpolar alkanes modify lithium-ion solvation for improved lithium deposition and stripping. Advanced Energy Materials 9, 1902116 (2019).

Tasaki, K. et al. Solubility of lithium salts formed on the lithium-ion battery negative electrode surface in organic solvents. J. Electrochem. Soc. 156, A1019 (2009).

Huang, W., Wang, H., Boyle, D. T., Li, Y. & Cui, Y. Resolving nanoscopic and mesoscopic heterogeneity of fluorinated species in battery solid-electrolyte interphases by cryogenic electron microscopy. ACS Energy Lett. 5, 1128–1135 (2020).

Liu, Y. et al. Solubility-mediated sustained release enabling nitrate additive in carbonate electrolytes for stable lithium metal anode. Nat. Commun. 9, 3656 (2018).

Wang, J. et al. Improving cyclability of Li metal batteries at elevated temperatures and its origin revealed by cryo-electron microscopy. Nat. Energy 4, 664–670 (2019).

Lowe, J. S. & Siegel, D. J. Modeling the interface between lithium metal and its native oxide. ACS Appl. Mater. Interfaces 12, 46015–46026 (2020).

Guo, R. & Gallant, B. M. Li2O solid electrolyte interphase: probing transport properties at the chemical potential of lithium. Chem. Mater. https://doi.org/10.1021/acs.chemmater.0c00333 (2020).

Tan, L. et al. In-situ tailored 3D Li2O@Cu nanowires array enabling stable lithium metal anode with ultra-high coulombic efficiency. J. Power Sources 463, 228178 (2020).

Shen, C. et al. Li2O-reinforced solid electrolyte interphase on three-dimensional sponges for dendrite-free lithium deposition. Front. Chem. 6, 517 (2018).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J. G. Accurate determination of Coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2017).

Kim, M. S. et al. Langmuir–Blodgett artificial solid-electrolyte interphases for practical lithium metal batteries. Nat. Energy 3, 889–898 (2018).

Pei, A., Zheng, G., Shi, F., Li, Y. & Cui, Y. Nanoscale nucleation and growth of electrodeposited lithium metal. Nano Lett. 17, 1132–1139 (2017).

Fister, T. T. et al. Electronic structure of lithium battery interphase compounds: comparison between inelastic X-ray scattering measurements and theory. J. Chem. Phys. 135, 224513 (2011).

Ozhabes, Y., Gunceler, D. & Arias, T. A. Stability and surface diffusion at lithium-electrolyte interphases with connections to dendrite suppression. Preprint at arXiv https://arxiv.org/abs/1504.05799 (2015).

Lu, Y., Tu, Z. & Archer, L. A. Stable lithium electrodeposition in liquid and nanoporous solid electrolytes. Nat. Mater. 13, 961–969 (2014).

Kim, S. C. et al. Potentiometric measurement to probe solvation energy and its correlation to lithium battery cyclability. J. Am. Chem. Soc. 143, 10301–10308 (2021).

Amanchukwu, C. V. et al. A new class of ionically conducting fluorinated ether electrolytes with high electrochemical stability. J. Am. Chem. Soc. 142, 7393–7403 (2020).

Kamphaus, E. P. et al. Role of inorganic surface layer on solid electrolyte interphase evolution at Li-metal anodes. ACS Appl. Mater. Interfaces 11, 31467–31476 (2019).

Xie, J. et al. Atomic layer deposition of stable LiAlF4 lithium ion conductive interfacial layer for stable cathode cycling. ACS Nano 11, 7019–7027 (2017).

Kim, M. S. et al. Enabling reversible redox reactions in electrochemical cells using protected LiAl intermetallics as lithium metal anodes. Sci. Adv. https://doi.org/10.1126/sciadv.aax5587 (2019).

Kim, M. S. et al. Langmuir–Blodgett artificial solid-electrolyte interphases for practical lithium metal batteries. Nat. Energy https://doi.org/10.1038/s41560-018-0237-6 (2018).

Abraham, M. J. et al. Gromacs: high performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 1–2, 19–25 (2015).

Jorgensen, W. L., Maxwell, D. S. & Tirado-Rives, J. Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J. Am. Chem. Soc. 118, 11225–11236 (1996).

Dodda, L. S., De Vaca, I. C., Tirado-Rives, J. & Jorgensen, W. L. LigParGen web server: an automatic OPLS-AA parameter generator for organic ligands. Nucleic Acids Res. 45, W331–W336 (2017).

Doherty, B., Zhong, X., Gathiaka, S., Li, B. & Acevedo, O. Revisiting OPLS force field parameters for ionic liquid simulations. J. Chem. Theory Comput. 13, 6131–6135 (2017).

Benitez, L. & Seminario, J. M. Ion diffusivity through the solid electrolyte interphase in lithium-ion batteries. J. Electrochem. Soc. 164, E3159–E3170 (2017).

Radin, M. D., Rodriguez, J. F., Tian, F. & Siegel, D. J. Lithium peroxide surfaces are metallic, while lithium oxide surfaces are not. J. Am. Chem. Soc. 134, 1093–1103 (2012).

Humphrey, W., Dalke, A. & Schulten, K. VMD: Visual Molecular Dynamics. J. Mol. Graph. 14, 33–38 (1996).

Allouche, A. Gabedit—a graphical user interface for computational chemistry softwares. J. Comput. Chem. 32, 174–182 (2011).

Mortensen, J. J., Hansen, L. B. & Jacobsen, K. W. Real-space grid implementation of the projector augmented wave method. Phys. Rev. B 71, 035109 (2005).

Enkovaara, J. et al. Electronic structure calculations with GPAW: a real-space implementation of the projector augmented-wave method. J. Phys. Condens. Matter 22, 253202 (2010).

Hjorth Larsen, A. et al. The atomic simulation environment—a Python library for working with atoms. J. Phys. Condens. Matter 29, 273002 (2017).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Acknowledgements

We acknowledge support from the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy under the Battery Materials Research Program and Battery 500 Consortium. Z.Z. acknowledges the support from the Stanford Interdisciplinary Graduate Fellowship. S.T.O. acknowledges support from the Knight Hennessy scholarship for graduate studies at Stanford University.

Author information

Authors and Affiliations

Contributions

M.S.K. and Y. Cui conceived the idea and conceptualized the work. M.S.K. performed the experiments and analysed the data with guidance from Y. Cui. M.S.K., Z.Z. and Y. Cui wrote the manuscript. Z.Z. performed cryo-STEM and SEM experiments and analyses. P.E.R. performed MD simulations and analysed the data. J.W. conducted DFT calculations. Z.Y. synthesized FDMB electrolyte and helped to take impedance measurements. S.T.O. performed XPS analysis. Y. Chen performed 7Li NMR analysis. S.C.K. measured the cell potential and relative Li+ solvation energy of the electrolytes. W.Z. helped take SEM images. Z.Y., H.W., S.C.K., D.T.B., X.K., Z.H. and W.H. provided technical help and helpful discussions. S.F.B. and L.-W.W. reviewed the manuscript. Y. Cui, Z.B. and J.Q. supervised the overall study. All the authors discussed the manuscript and provided comments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Jiguang Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–37, Figure Captions 1 and 2, Tables 1–5, Notes 1–21 and references.

Rights and permissions

About this article

Cite this article

Kim, M.S., Zhang, Z., Rudnicki, P.E. et al. Suspension electrolyte with modified Li+ solvation environment for lithium metal batteries. Nat. Mater. 21, 445–454 (2022). https://doi.org/10.1038/s41563-021-01172-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01172-3

This article is cited by

-

High lithium oxide prevalence in the lithium solid–electrolyte interphase for high Coulombic efficiency

Nature Energy (2024)

-

Low-temperature anode-free potassium metal batteries

Nature Communications (2023)

-

Growing single-crystalline seeds on lithiophobic substrates to enable fast-charging lithium-metal batteries

Nature Energy (2023)

-

Origin of dendrite-free lithium deposition in concentrated electrolytes

Nature Communications (2023)

-

High-entropy electrolytes for practical lithium metal batteries

Nature Energy (2023)