Abstract

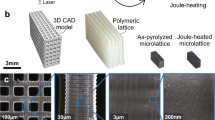

Porous materials with engineered stretching-dominated lattice designs, which offer attractive mechanical properties with ultra-light weight and large surface area for wide-ranging applications, have recently achieved near-ideal linear scaling between stiffness and density. Here, rather than optimizing the microlattice topology, we explore a different approach to strengthen low-density structural materials by designing tube-in-tube beam structures. We develop a process to transform fully dense, three-dimensional printed polymeric beams into graphitic carbon hollow tube-in-tube sandwich morphologies, where, similar to grass stems, the inner and outer tubes are connected through a network of struts. Compression tests and computational modelling show that this change in beam morphology dramatically slows down the decrease in stiffness with decreasing density. In situ pillar compression experiments further demonstrate large deformation recovery after 30–50% compression and high specific damping merit index. Our strutted tube-in-tube design opens up the space and realizes highly desirable high modulus–low density and high modulus–high damping material structures.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its supplementary information files. Source data are provided with this paper.

References

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Bauer, J., Schroer, A., Schwaiger, R. & Kraft, O. Approaching theoretical strength in glassy carbon nanolattices. Nat. Mater. 15, 438–443 (2016).

Biener, J. et al. Advanced carbon aerogels for energy applications. Energy Environ. Sci. 4, 656–667 (2011).

Yang, Z.-Y. et al. Sponge-templated preparation of high surface area graphene with ultrahigh capacitive deionization performance. Adv. Funct. Mater. 24, 3917–3925 (2014).

Oakdale, J. S. et al. Direct laser writing of low-density interdigitated foams for plasma drive shaping. Adv. Funct. Mater. 27, 1702425 (2017).

Frenzel, T., Findeisen, C., Kadic, M., Gumbsch, P. & Wegener, M. Tailored buckling microlattices as reusable light-weight shock absorbers. Adv. Mater. 28, 5865–5870 (2016).

Nishide, H. & Oyaizu, K. Materials science. Toward flexible batteries. Science 319, 737–738 (2008).

Qiu, L., Liu, J. Z., Chang, S. L. Y., Wu, Y. & Li, D. Biomimetic superelastic graphene-based cellular monoliths. Nat. Commun. 3, 1241 (2012).

Gross, J. & Fricke, J. Scaling of elastic properties in highly porous nanostructured aerogels. Nanostruct. Mater. 6, 905–908 (1995).

Pekala, R. W., Alviso, C. T. & Lemay, J. D. Organic aerogels: microstructural dependence of mechanical-properties in compression. J. Non Cryst. Solids 125, 67–75 (1990).

Bock, V., Emmerling, A. & Fricke, J. Influence of monomer and catalyst concentration on RF and carbon aerogel structure. J. Non Cryst. Solids 225, 69–73 (1998).

Worsley, M. A., Kucheyev, S. O., Satcher, J. H., Hamza, A. V. & Baumann, T. F. Mechanically robust and electrically conductive carbon nanotube foams. Appl. Phys. Lett. 94, 073115 (2009).

Barg, S. et al. Mesoscale assembly of chemically modified graphene into complex cellular networks. Nat. Commun. 5, 5328 (2014).

Ni, N. et al. Understanding mechanical response of elastomeric graphene networks. Sci. Rep. 5, 13712 (2015).

Zhang, X. et al. Mechanically strong and highly conductive graphene aerogel and its use as electrodes for electrochemical power sources. J. Mater. Chem. 21, 6494–6497 (2011).

Saane, S. S. R. & Onck, P. R. Atomistic modeling of the stiffness, strength and charge-induced actuation of graphene nanofoams. Extrem. Mech. Lett. 5, 54–61 (2015).

Qin, Z., Jung, G. S., Kang, M. J. & Buehler, M. J. The mechanics and design of a lightweight three-dimensional graphene assembly. Sci. Adv. 3, e1601536 (2017).

Zheng, X. Y. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

García‐Tuñon, E. et al. Printing in three dimensions with graphene. Adv. Mater. 27, 1688–1693 (2015).

Zhu, C. et al. Highly compressible 3D periodic graphene aerogel microlattices. Nat. Commun. 6, 6962 (2015).

Bückmann, T., Thiel, M., Kadic, M., Schittny, R. & Wegener, M. An elasto-mechanical unfeelability cloak made of pentamode metamaterials. Nat. Commun. 5, 4130 (2014).

Frenzel, T., Kadic, M. & Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 358, 1072–1074 (2017).

Tancogne‐Dejean, T., Diamantopoulou, M., Gorji, M. B., Bonatti, C. & Mohr, D. 3D plate‐lattices: an emerging class of low‐density metamaterial exhibiting optimal isotropic stiffness. Adv. Mater. 30, 1803334 (2018).

Guell Izard, A., Bauer, J., Crook, C., Turlo, V. & Valdevit, L. Ultrahigh energy absorption multifunctional spinodal nanoarchitectures. Small 15, 1903834 (2019).

Crook, C. et al. Plate-nanolattices at the theoretical limit of stiffness and strength. Nat. Commun. 11, 1579 (2020).

Jacobsen, A. J., Mahoney, S., Carter, W. B. & Nutt, S. Vitreous carbon micro-lattice structures. Carbon 49, 1025–1032 (2011).

Zhang, X., Vyatskikh, A., Gao, H., Greer, J. R. & Li, X. Lightweight, flaw-tolerant, and ultrastrong nanoarchitected carbon. Proc. Natl Acad. Sci. USA 116, 6665–6672 (2019).

Meza, L. R. et al. Resilient 3D hierarchical architected metamaterials. Proc. Natl Acad. Sci. USA 112, 11502–11507 (2015).

Zheng, X. et al. Multiscale metallic metamaterials. Nat. Mater. 15, 1100–1107 (2016).

Oakdale, J. S., Ye, J., Smith, W. L. & Biener, J. Post-print UV curing method for improving the mechanical properties of prototypes derived from two-photon lithography. Opt. Express 24, 27077–27086 (2016).

Xiao, X. et al. Lithographically defined three-dimensional graphene structures. ACS Nano 6, 3573–3579 (2012).

Cebo, T. et al. Chemical vapour deposition of freestanding sub-60 nm graphene gyroids. Appl. Phys. Lett. 111, 253103 (2017).

Garcia, A. E. et al. Scalable synthesis of gyroid-inspired freestanding three-dimensional graphene architectures. Nanoscale Adv. 1, 3870–3882 (2019).

Gray, H. Anatomy of the Human Body Vol. 8 (Lea & Febiger, 1878).

Gibson, L. J., Ashby, M. F. & Harley, B. A. Cellular Materials in Nature and Medicine (Cambridge Univ. Press, 2010).

Karam, G. & Gibson, L. Elastic buckling of cylindrical shells with elastic cores–I. Analysis. Int. J. Solids Struct. 32, 1259–1284 (1995).

Dawson, M. A. & Gibson, L. J. Optimization of cylindrical shells with compliant cores. Int. J. Solids Struct. 44, 1145–1160 (2007).

Allen, H. G. Analysis and Design of Structural Sandwich Panels (Elsevier, 2013).

Sullivan, T. N., Wang, B., Espinosa, H. D. & Meyers, M. A. Extreme lightweight structures: avian feathers and bones. Mater. Today 20, 377–391 (2017).

Xiong, W. et al. Laser‐directed assembly of aligned carbon nanotubes in three dimensions for multifunctional device fabrication. Adv. Mater. 28, 2002–2009 (2016).

Mu, X. et al. Porous polymeric materials by 3D printing of photocurable resin. Mater. Horiz. 4, 442–449 (2017).

do Rosário, J. J., Häntsch, Y., Schneider, G. A. & Lilleodden, E. T. A combined compression and indentation study of mechanical metamaterials based on inverse opal coatings. Acta Mater. 195, 98–108 (2020).

Ashby, M. F. The properties of foams and lattices. Phil. Trans. R. Soc. A 364, 15–30 (2006).

Juodkazis, S., Mizeikis, V., Seet, K. K., Misawaa, H. & Wegst, U. G. K. Mechanical properties and tuning of three-dimensional polymeric photonic crystals. Appl. Phys. Lett. 91, 241904 (2007).

Schaedler, T. A. et al. Ultralight metallic microlattices. Science 334, 962–965 (2011).

Hashin, Z. & Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 11, 127–140 (1963).

Maloney, K. J. et al. Microlattices as architected thin films: analysis of mechanical properties and high strain elastic recovery. APL Mater. 1, 022106 (2013).

Saha, S. K. et al. Scalable submicrometer additive manufacturing. Science 366, 105–109 (2019).

San Juan, J., No, M. L. & Schuh, C. A. Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat. Nanotechnol. 4, 415–419 (2009).

Zhang, X. et al. Three-dimensional high-entropy alloy–polymer composite nanolattices that overcome the strength–recoverability trade-off. Nano Lett. 18, 4247–4256 (2018).

Doolittle, L. R. Algorithms for the rapid simulation of Rutherford backscattering spectra. Nucl. Instrum. Methods B 9, 344–351 (1985).

Chu, W., Mayer, J. & Nicolet, M. Backscattering Spectrometry (Academic Press, 1978).

Lespade, P., Marchand, A., Couzi, M. & Cruege, F. Caracterisation de materiaux carbones par microspectrometrie Raman. Carbon 22, 375–385 (1984).

Vallerot, J.-M., Bourrat, X., Mouchon, A. & Chollon, G. Quantitative structural and textural assessment of laminar pyrocarbons through Raman spectroscopy, electron diffraction and few other techniques. Carbon 44, 1833–1844 (2006).

McEvoy, N. et al. Synthesis and analysis of thin conducting pyrolytic carbon films. Carbon 50, 1216–1226 (2012).

Schuepfer, D. B. et al. Assessing the structural properties of graphitic and non-graphitic carbons by Raman spectroscopy. Carbon 161, 359–372 (2020).

Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

Blakslee, O., Proctor, D., Seldin, E., Spence, G. & Weng, T. Elastic constants of compression‐annealed pyrolytic graphite. J. Appl. Phys. 41, 3373–3382 (1970).

ABAQUS/Standard User’s Manual Vol. 1 (Hibbitt, Karlsson & Sorensen, 2001).

Robertson, J. Amorphous carbon. Adv. Phys. 35, 317–374 (1986).

Onck, P. R., Andrews, E. W. & Gibson, L. J. Size effects in ductile cellular solids. Part I: modeling. Int. J. Mech. Sci. 43, 681–699 (2001).

Acknowledgements

We thank J.-B. Forien, M. A. Worsley, C. Zhu and X. Zheng for helpful discussions. The work was performed under the auspices of the US Department of Energy by LLNL under contract no. DE-AC52-07NA27344. The project was supported by the Laboratory Directed Research and Development (LDRD) programme of LLNL (15-ERD-019) (to J.B.). L.L. and P.R.O. would like to acknowledge financial support from the Dutch Polymer Institute (DPI) through project no. 775. Y.M.W. was partially supported by NSF DMR-2104933.

Author information

Authors and Affiliations

Contributions

J.B., J.Y. and P.R.O. conceived and guided the research. J.O. and W.L.S. designed and printed log-pile structures. J.Y. performed Ni electroless plating and carbon conversion. M.M.B. assisted in post processing. J.Y. performed mechanical testing and characterizations. J.L., S.B. and J.Y. conducted in situ pillar compression tests. T.V. and J.D.R. conducted TEM and tomography analysis. M.R.C. ran the TGA analysis. L.B.B.A. carried out ERDA analysis. L.L., P.R.O. and J.v.H. conducted finite element analysis. J.Y., L.L., J.B. and P.R.O. drafted the manuscript. Y.M.W. suggested extra mechanical analysis and manuscript revisions. All authors commented on the drafts.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Materials thanks Xiaoyan Li and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Discussions, Figs. 1–23 and Tables 1–5.

Supplementary Video 1

STEM images of a STinT carbon beam with tilting angles from −71° to 71° with 2° steps.

Supplementary Video 2

TEM images of a STinT carbon beam with tilting angles from −67° to 68° with 3° steps.

Supplementary Video 3

A 3D reconstruction of a STinT carbon beam using TEM tomography.

Supplementary Video 4

In situ SEM compression on a 1:1 aspect ratio FCT STinT carbon pillar with pitch size of 10 μm.

Supplementary Video 5

Zoomed-in in situ SEM compression on a 1:1 aspect ratio SC STinT carbon pillar with pitch size of 10 μm.

Supplementary Video 6

In situ SEM flat-punch indent near edge of a SC STinT carbon plate with pitch size of 5 μm.

Supplementary Video 7

In situ SEM compression up to 10% strain on a 2.5:1 aspect ratio SC STinT carbon pillar with pitch size of 10 μm.

Supplementary Video 8

In situ SEM compression up to 30% strain on a 2.5:1 aspect ratio SC STinT carbon pillar with pitch size of 10 μm.

Supplementary Video 9

In situ SEM compression up to 50% strain on a 2.5:1 aspect ratio SC STinT carbon pillar with pitch size of 10 μm.

Source data

Source Data Fig. 1

Raman spectra of STinT carbons.

Source Data Fig. 2

Modulus versus density plots.

Source Data Fig. 3

Raw data discussing relationships of Ni-layer thickness, STinT carbon density, modulus and mass ratio.

Source Data Fig. 4

Raw data of engineering stress–strain curves.

Source Data Fig. 5

Raw data of damping properties from our STinT carbon and references.

Rights and permissions

About this article

Cite this article

Ye, J., Liu, L., Oakdale, J. et al. Ultra-low-density digitally architected carbon with a strutted tube-in-tube structure. Nat. Mater. 20, 1498–1505 (2021). https://doi.org/10.1038/s41563-021-01125-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01125-w

This article is cited by

-

Accurate additive manufacturing of lightweight and elastic carbons using plastic precursors

Nature Communications (2024)

-

Mechanically resilient, alumina-reinforced carbon nanotube arrays for in-plane shock absorption in micromechanical devices

Microsystems & Nanoengineering (2023)

-

Inverse design of truss lattice materials with superior buckling resistance

npj Computational Materials (2022)

-

Biochar aerogel-based electrocatalyst towards efficient oxygen evolution in acidic media

Biochar (2022)

-

Built from connected nested tubes

Nature Materials (2021)