Abstract

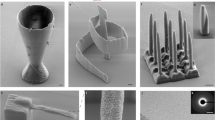

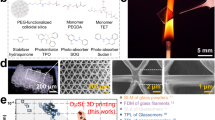

Fabricating inorganic materials with designed three-dimensional nanostructures is an exciting yet challenging area of research and industrial application. Here, we develop an approach to 3D print high-quality nanostructures of silica with sub-200 nm resolution and with the flexible capability of rare-earth element doping. The printed SiO2 can be either amorphous glass or polycrystalline cristobalite controlled by the sintering process. The 3D-printed nanostructures demonstrate attractive optical properties. For instance, the fabricated micro-toroid optical resonators can reach quality factors (Q) of over 104. Moreover, and importantly for optical applications, doping and codoping of rare-earth salts such as Er3+, Tm3+, Yb3+, Eu3+ and Nd3+ can be directly implemented in the printed SiO2 structures, showing strong photoluminescence at the desired wavelengths. This technique shows the potential for building integrated microphotonics with silica via 3D printing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Van Zant, P. Microchip Fabrication (McGraw-Hill Education, 2004).

Fortunato, E., Barquinha, P. & Martins, R. Oxide semiconductor thin-film transistors: a review of recent advances. Adv. Mater. 24, 2945–2986 (2012).

Hsu, T. R. MEMS and Microsystems: Design, Manufacture, and Nanoscale Engineering (John Wiley & Sons, 2008).

Rossi, C. et al. Nanoenergetic materials for MEMS: a review. J. Microelectromech. Syst. 16, 919–931 (2007).

Collot, L., Lefevre-Seguin, V., Brune, M., Raimond, J. M. & Haroche, S. Very high-Q whispering-gallery mode resonances observed on fused silica microspheres. EPL 23, 327–334 (1993).

Okamoto, K. Progress and technical challenge for planar waveguide devices: silica and silicon waveguides. Laser Photonics Rev. 6, 14–23 (2012).

Deal, B. E. & Grove, A. S. General relationship for the thermal oxidation of silicon. J. Appl. Phys. 36, 3770–3778 (1965).

Inoue, K., Michimori, M., Okuyama, M. & Hamakawa, Y. Low temperature growth of SiO2 thin film by double-excitation photo-CVD. Jpn. J. Appl. Phys. 26, 805–811 (1987).

Quirk, M. & Serda, J. Semiconductor Manufacturing Technology (Prentice Hall, 2001).

Gokan, H., Esho, S. & Ohnishi, Y. Dry etch resistance of organic materials. J. Electrochem. Soc. 130, 143–146 (1983).

Van der Heide, P. A. M., Baan Hofman, M. J. & Ronde, H. J. Etching of thin SiO2 layers using wet HF gas. J. Vac. Sci. Technol. A 7, 1719–1723 (1989).

Monk, D. J., Soane, D. S. & Howe, R. T. A review of the chemical reaction mechanism and kinetics for hydrofluoric acid etching of silicon dioxide for surface micromachining applications. Thin Solid Films 232, 1–12 (1993).

Wong, K. V. & Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 208760 (2012).

Mueller, B. Additive manufacturing technologies—rapid prototyping to direct digital manufacturing. Assem. Autom. https://doi.org/10.1108/aa.2012.03332baa.010 (2012).

Camposeo, A., Persano, L., Farsari, M. & Pisignano, D. Additive manufacturing: applications and directions in photonics and optoelectronics. Adv. Opt. Mater. 7, 1800419 (2019).

Chia, H. N. & Wu, B. M. Recent advances in 3D printing of biomaterials. J. Med. Biol. Eng. 9, 4 (2015).

Skylar-Scott, M. A., Gunasekaran, S. & Lewis, J. A. Laser-assisted direct ink writing of planar and 3D metal architectures. Proc. Natl Acad. Sci. USA 113, 6137–6142 (2016).

Hinton, T. J., Hudson, A., Pusch, K., Lee, A. & Feinberg, A. W. 3D printing PDMS elastomer in a hydrophilic support bath via freeform reversible embedding. ACS Biomater. Sci. Eng. 2, 1781–1786 (2016).

Tan, Y. et al. 3D printing facilitated scaffold-free tissue unit fabrication. Biofabrication 6, 024111 (2014).

Kotz, F. et al. Three-dimensional printing of transparent fused silica glass. Nature 544, 337–339 (2017).

Lan, P. X., Lee, J. W., Seol, Y. J. & Cho, D. W. Development of 3D PPF/DEF scaffolds using micro-stereolithography and surface modification. J. Mater. Sci. Mater. Med. 20, 271–279 (2009).

Lopes, A. J., MacDonald, E. & Wicker, R. B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 18, 129–143 (2012).

Xing, J. F., Zheng, M. L. & Duan, X. M. Two-photon polymerization microfabrication of hydrogels: an advanced 3D printing technology for tissue engineering and drug delivery. Chem. Soc. Rev. 44, 5031–5039 (2015).

Tan, D. et al. Reduction in feature size of two-photon polymerization using SCR500. Appl. Phys. Lett. 90, 071106 (2007).

Juodkazis, S., Mizeikis, V., Seet, K. K., Miwa, M. & Misawa, H. Two-photon lithography of nanorods in SU-8 photoresist. Nanotechnology 16, 846–849 (2005).

Ovsianikov, A. et al. Ultra-low shrinkage hybrid photosensitive material for two-photon polymerization microfabrication. ACS Nano 2, 2257–2262 (2008).

Brigo, L. et al. 3D nanofabrication of SiOC ceramic structures. Adv. Sci. 5, 1800937 (2018).

Schmidt, J. et al. Multiscale ceramic components from preceramic polymers by hybridization of vat polymerization-based technologies. Addit. Manuf. 30, 100913 (2019).

Chandrappan, J. et al. Doping silica beyond limits with laser plasma for active photonic materials. Opt. Mater. Express 5, 2849–2861 (2015).

El-Ganainy, R., Khajavikhan, M., Christodoulides, D. N. & Ozdemir, S. K. The dawn of non-Hermitian optics. Commun. Phys. 2, 37 (2019).

Zhong, T. et al. Nanophotonic rare-earth quantum memory with optically controlled retrieval. Science 357, 1392–1395 (2017).

Mohanty, S. R. A relationship between heat conductivity and viscosity of liquids. Nature 168, 42 (1951).

Lin, B. & Zhou, S. Poly (ethylene glycol)-grafted silica nanoparticles for highly hydrophilic acrylic-based polyurethane coatings. Prog. Org. Coat. 106, 145–154 (2017).

Kotz, F. et al. Two-photon polymerization of nanocomposites for the fabrication of transparent fused silica glass microstructures. Adv. Mater. 33, 2006341 (2021).

Farsari, M. & Chichkov, B. N. Two-photon fabrication. Nat. Photon. 3, 450–452 (2009).

Hossein-Zadeh, M. & Vahala, K. J. Free ultra-high-Q microtoroid: a tool for designing photonic devices. Opt. Express 15, 166–175 (2007).

Liu, Z. P. et al. Direct laser writing of whispering gallery microcavities by two-photon polymerization. Appl. Phys. Lett. 97, 211105 (2010).

Moore, D. G., Barbera, L., Masania, K. & Studart, A. R. Three-dimensional printing of multicomponent glasses using phase-separating resins. Nat. Mater. 19, 212–217 (2020).

Nguyen, D. T. et al. 3D-printed transparent glass. Adv. Mater. 29, 1701181 (2017).

Grossmann, T. et al. Direct laser writing for active and passive high-Q polymer microdisks on silicon. Opt. Express 19, 11451–11456 (2011).

Gan, Z., Cao, Y., Evans, R. A. & Gu, M. Three-dimensional deep sub-diffraction optical beam lithography with 9 nm feature size. Nat. Commun. 4, 2061 (2013).

Richman, E. K., Kang, C. B., Brezesinski, T. & Tolbert, S. H. Ordered mesoporous silicon through magnesium reduction of polymer templated silica thin films. Nano Lett. 8, 3075–3079 (2008).

Acknowledgements

X.W., B.Z., W.W., H.G., Q.F., C.N. and J.L. gratefully acknowledge the financial support by the Welch Foundation grant C-1716. J.B. gratefully acknowledges the financial support by the Welch Foundation grant E-1728. This work was conducted in part using resources of the Shared Equipment Authority at Rice University. We thank J. Li at the Shared Equipment Authority of Rice University for help with the SAXS experiments. We also thank X-M. Lin at Argonne National Laboratory for help with Fourier transform infrared spectroscopy experiments.

Author information

Authors and Affiliations

Contributions

X.W., J.L. and P.M.A. designed the experiment; X.W. and B.Z. performed the nanocomposite ink preparation and 2PP printing; X.W., B.Z., W.W., H.G., G.G., Y.Z., Q.F., C.N. and X.Z. contributed to sample characterization; F.Y. and J.T.R. helped with the optical resonator test; and S.Y. and J.B. helped with the photoluminescence measurements.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Materials thanks Paolo Colombo, Kunal Masania and Bastian Rapp for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–6 and Discussion.

Source data

Source Data Fig. 3

Source data for curves in Fig. 3.

Rights and permissions

About this article

Cite this article

Wen, X., Zhang, B., Wang, W. et al. 3D-printed silica with nanoscale resolution. Nat. Mater. 20, 1506–1511 (2021). https://doi.org/10.1038/s41563-021-01111-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01111-2

This article is cited by

-

One-photon three-dimensional printed fused silica glass with sub-micron features

Nature Communications (2024)

-

3D microprinting of inorganic porous materials by chemical linking-induced solidification of nanocrystals

Nature Communications (2023)

-

Site-directed placement of three-dimensional DNA origami

Nature Nanotechnology (2023)

-

Three-dimensional printing of silica glass with sub-micrometer resolution

Nature Communications (2023)

-

The effects of PEG molecular weight on fused silica glass sintering by using nano silicon oxide powder

Journal of Sol-Gel Science and Technology (2023)