Abstract

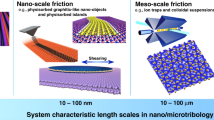

Frictional sliding between patterned surfaces is of fundamental and practical importance in the haptic engineering of soft materials. In emerging applications such as remote surgery and soft robotics, thin fluid films between solid surfaces lead to a multiphysics coupling between solid deformation and fluid dissipation. Here, we report a scaling law that governs the peak friction values of elastohydrodynamic lubrication on patterned surfaces. These peaks, absent in smooth tribopairs, arise due to a separation of length scales in the lubricant flow. The framework is generated by varying the geometry, elasticity and fluid properties of soft tribopairs and measuring the lubricated friction with a triborheometer. The model correctly predicts the elastohydrodynamic lubrication friction of a bioinspired robotic fingertip and human fingers. Its broad applicability can inform the future design of robotic hands or grippers in realistic conditions, and open up new ways of encoding friction into haptic signals.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. All other data that support the results in this study are available from the corresponding author on reasonable request.

Code availability

The MATLAB codes for solving Supplementary equation (S10) are available at https://doi.org/10.6084/m9.figshare.14233238.

References

Wong, T. S. et al. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 477, 443–447 (2011).

Bau, O., Poupyrev, I., Israr, A. & Harrison, C. TeslaTouch: electrovibration for touch surfaces. In: Proc. 23rd Annual ACM Symposium on User Interface Software and Technology 283–292 (Association for Computing Machinery, 2010).

Levesque, V. et al. Enhancing physicality in touch interaction with programmable friction. In: Proc. SIGCHI Conference on Human Factors in Computing Systems 2481–2490 (Association for Computing Machinery, 2011).

Basdogan, C., Giraud, F., Levesque, V. & Choi, S. A review of surface haptics: enabling tactile effects on touch surfaces. IEEE Trans. Haptics 13, 450–470 (2020).

Adams, M. J. et al. Finger pad friction and its role in grip and touch. J. R. Soc. Interface 10, 20120467 (2013).

Saintyves, B., Jules, T., Salez, T. & Mahadevan, L. Self-sustained lift and low friction via soft lubrication. Proc. Natl Acad. Sci. USA 113, 5847–5849 (2016).

Wang, Y. M., Dhong, C. & Frechette, J. Out-of-contact elastohydrodynamic deformation due to lubrication forces. Phys. Rev. Lett. 115, 248302 (2015).

Dzidek, B., Bochereau, S., Johnson, S. A., Hayward, V. & Adams, M. J. Why pens have rubbery grips. Proc. Natl Acad. Sci. USA 114, 10864–10869 (2017).

Delmas, P., Hao, J. & Rodat-Despoix, L. Molecular mechanisms of mechanotransduction in mammalian sensory neurons. Nat. Rev. Neurosci. 12, 139–153 (2011).

Smith, A. M., Chapman, C. E., Deslandes, M., Langlais, J.-S. & Thibodeau, M.-P. Role of friction and tangential force variation in the subjective scaling of tactile roughness. Exp. Brain Res. 144, 211–223 (2002).

Robles-De-La-Torre, G. & Hayward, V. Force can overcome object geometry in the perception of shape through active touch. Nature 412, 445–448 (2001).

Janko, M., Wiertlewski, M. & Visell, Y. Contact geometry and mechanics predict friction forces during tactile surface exploration. Sci. Rep. 8, 4868 (2018).

Ayyildiz, M., Scaraggi, M., Sirin, O., Basdogan, C. & Persson, B. N. J. Contact mechanics between the human finger and a touchscreen under electroadhesion. Proc. Natl Acad. Sci. USA 115, 12668–12673 (2018).

Gueorguiev, D., Bochereau, S., Mouraux, A., Hayward, V. & Thonnard, J.-L. Touch uses frictional cues to discriminate flat materials. Sci. Rep. 6, 25553 (2016).

Weber, A. I. et al. Spatial and temporal codes mediate the tactile perception of natural textures. Proc. Natl Acad. Sci. USA 110, 17107–17112 (2013).

Flanagan, J. R., Burstedt, M. K. & Johansson, R. S. Control of fingertip forces in multidigit manipulation. J. Neurophysiol. 81, 1706–1717 (1999).

Abraira, V. E. & Ginty, D. D. The sensory neurons of touch. Neuron 79, 618–639 (2013).

Kandaswamy, D., Murthy, M., Alexander, M. & Krothapalli, S. B. Handling objects with very wet skin reduce variability during precision grip task. Neurosci. Lett. 703, 177–183 (2019).

Stuart, H., Wang, S., Khatib, O. & Cutkosky, M. R. The Ocean One hands: an adaptive design for robust marine manipulation. Int. J. Rob. Res. 36, 150–166 (2017).

Jones, L. Haptics (MIT Press, 2018).

Khojasteh, B., Janko, M. & Visell, Y. Complexity, rate, and scale in sliding friction dynamics between a finger and textured surface. Sci. Rep. 8, 13710 (2018).

Greene, G. W. et al. Adaptive mechanically controlled lubrication mechanism found in articular joints. Proc. Natl Acad. Sci. USA 108, 5255–5259 (2011).

Urueña, J. M. et al. Normal load scaling of friction in gemini hydrogels. Biotribology 13, 30–35 (2018).

Moyle, N. et al. Enhancement of elastohydrodynamic friction by elastic hysteresis in a periodic structure. Soft Matter 16, 1627–1635 (2020).

Peng, Y., Serfass, C. M., Hill, C. N. & Hsiao, L. C. Bending of soft micropatterns in elastohydrodynamic lubrication tribology. Exp. Mech. https://doi.org/10.1007/s11340-021-00715-8 (2021).

Varenberg, M. & Gorb, S. N. Hexagonal surface micropattern for dry and wet friction. Adv. Mater. 21, 483–486 (2009).

Grubin, A. Investigation of the Contact Machine Components Ch. 2 (Central Scientific Research Institute for Technology and Mechanical Engineering, 1949).

Greenwood, J. An extension of the Grubin theory of elastohydrodynamic lubrication. J. Phys. D 5, 2195 (1972).

Hamrock, B. J. & Dowson, D. Elastohydrodynamic lubrication of elliptical contacts for materials of low elastic modulus I—fully flooded conjunction. J. Lubr. Technol. 100, 236–245 (1978).

Gropper, D., Wang, L. & Harvey, T. J. Hydrodynamic lubrication of textured surfaces: a review of modeling techniques and key findings. Tribol. Int. 94, 509–529 (2016).

Schilling, J., Sengupta, K., Goennenwein, S., Bausch, A. R. & Sackmann, E. Absolute interfacial distance measurements by dual-wavelength reflection interference contrast microscopy. Phys. Rev. E 69, 021901 (2004).

Davies, H. S. et al. Elastohydrodynamic lift at a soft wall. Phys. Rev. Lett. 120, 2–7 (2018).

Luo, J., Wen, S. & Huang, P. Thin film lubrication. Part I. Study on the transition between EHL and thin film lubrication using a relative optical interference intensity technique. Wear 194, 107–115 (1996).

Born, M. & Wolf, E. Principles of Optics: Electromagnetic Theory of Propagation, Interference and Diffraction of Light (Elsevier, 2013).

Fowell, M., Myant, C., Spikes, H. & Kadiric, A. A study of lubricant film thickness in compliant contacts of elastomeric seal materials using a laser induced fluorescence technique. Tribol. Int. 80, 76–89 (2014).

Myant, C., Reddyhoff, T. & Spikes, H. Laser-induced fluorescence for film thickness mapping in pure sliding lubricated, compliant, contacts. Tribol. Int. 43, 1960–1969 (2010).

Lugt, P. M. & Morales-Espejel, G. E. A review of elasto-hydrodynamic lubrication theory. Tribol. Trans. 54, 470–496 (2011).

Scaraggi, M. Lubrication of textured surfaces: a general theory for flow and shear stress factors. Phys. Rev. E 86, 026314 (2012).

Banquy, X., Burdyńska, J., Lee, D. W., Matyjaszewski, K. & Israelachvili, J. Bioinspired bottle-brush polymer exhibits low friction and Amontons-like behavior. J. Am. Chem. Soc. 136, 6199–6202 (2014).

Davies, G. A. & Stokes, J. R. On the gap error in parallel plate rheometry that arises from the presence of air when zeroing the gap. J. Rheol. 49, 919–922 (2005).

Scaraggi, M., Carbone, G. & Dini, D. Experimental evidence of micro-EHL lubrication in rough soft contacts. Tribol. Lett. 43, 169–174 (2011).

Bonnevie, E. D. et al. Sub-critical impact inhibits the lubricating mechanisms of articular cartilage. J. Biomech. 53, 64–70 (2017).

Deen, W. M. Analysis of Transport Phenomena 2nd edn (Oxford Univ. Press, 2011).

Stachowiak, G. & Batchelor, A. W. Engineering Tribology (Butterworth-Heinemann, 2013).

Taylor, J. Introduction to Error Analysis: The Study of Uncertainties in Physical Measurements (University Science Books, 1996).

Kalra, A., Lowe, A. & Al-Jumaily, A. Mechanical behaviour of skin: a review. J. Mater. Sci. Eng. 5, 1000254 (2016).

Bongaerts, J. H. H., Fourtouni, K. & Stokes, J. R. Soft-tribology: lubrication in a compliant PDMS–PDMS contact. Tribol. Int. 40, 1531–1542 (2007).

Seror, J., Zhu, L. Y., Goldberg, R., Day, A. J. & Klein, J. Supramolecular synergy in the boundary lubrication of synovial joints. Nat. Commun. 6, 6497 (2015).

Hsiao, L. C. & Pradeep, S. Experimental synthesis and characterization of rough particles for colloidal and granular rheology. Curr. Opin. Colloid Interface Sci. 43, 94–112 (2019).

Pradal, C. & Stokes, J. R. Oral tribology: bridging the gap between physical measurements and sensory experience. Curr. Opin. Food Sci. 9, 34–41 (2016).

Jerolmack, D. J. & Daniels, K. E. Viewing Earth’s surface as a soft-matter landscape. Nat. Rev. Phys. 1, 716–730 (2019).

Johnston, I. D., McCluskey, D. K., Tan, C. K. L. & Tracey, M. C. Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J. Micromech. Microeng. 24, 035017 (2014).

Xia, Y. N. et al. Replica molding using polymeric materials: a practical step toward nanomanufacturing. Adv. Mater. 9, 147–149 (1997).

Xia, Y. N. et al. Complex optical surfaces formed by replica molding against elastomeric masters. Science 273, 347–349 (1996).

Fiorini, G. S., Jeffries, G. D. M., Lim, D. S. W., Kuyper, C. L. & Chiu, D. T. Fabrication of thermoset polyester microfluidic devices and embossing masters using rapid prototyped polydimethylsiloxane molds. Lab Chip 3, 158–163 (2003).

Wang, L. & Dandy, D. S. High-throughput inertial focusing of micrometer- and sub-micrometer-sized particles separation. Adv. Sci. 4, 1700153 (2017).

Pinto-Iguanero, B., Olivares-Pérez, A. & Fuentes-Tapia, I. Holographic material film composed by Norland Noa 65® adhesive. Opt. Mater. 20, 225–232 (2002).

Acknowledgements

The authors thank R. Ewoldt, J. F. Brady, R. G. Larson, J. Frechette and A. Dunn for discussions. Y.P., C.M.S., C.N.H. and L.C.H. were supported in part by the National Science Foundation (NSF) through award no. CBET-2042635 and the AAAS Marion Milligan Mason Award. K.G. was funded by the Eugene V. Cota-Robles Fellowship from the University of California, Los Angeles. Y.V. was supported by the NSF through award no. 1751348.

Author information

Authors and Affiliations

Contributions

Y.P. and L.C.H. designed the study and validated the theory. Y.P., C.M.S. and C.N.H. produced the micropatterned substrates. Y.P., A.K., Y.S. and Y.V. conducted the human finger experiments. Y.P., K.G. and V.J.S. conducted the robotic finger experiments. All authors reviewed the data and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–12 and Tables 1–4.

Supplementary Video 1

Demonstration of sliding experiments between a robotic finger and soft patterned substrates.

Supplementary Video 2

Demonstration of sliding experiments between a human finger and soft patterned substrates.

Source data

Source Data Fig. 1

Raw data for Fig. 1i.

Source Data Fig. 2

Raw data for Fig. 2b.

Source Data Fig. 3

Raw data for Fig. 3.

Source Data Fig. 4

Raw data for Fig. 4.

Rights and permissions

About this article

Cite this article

Peng, Y., Serfass, C.M., Kawazoe, A. et al. Elastohydrodynamic friction of robotic and human fingers on soft micropatterned substrates. Nat. Mater. 20, 1707–1711 (2021). https://doi.org/10.1038/s41563-021-00990-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-00990-9

This article is cited by

-

Creasing in microscale, soft static friction

Nature Communications (2023)

-

Active mechanical haptics with high-fidelity perceptions for immersive virtual reality

Nature Machine Intelligence (2023)

-

Development of microbeads from unmodified biomass with tunable size and competitive mechanical properties

Cellulose (2023)

-

Friction control of elastic materials on glass by means of textured surfaces

Scientific Reports (2022)

-

Statistical mechanics of rate-independent stick-slip on a corrugated surface composed of parabolic wells

Continuum Mechanics and Thermodynamics (2022)